- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

Ever wanted to start your own 3D printing business? Or just want to sell sick 3D prints online? Well, for mass manufacturing 3D printed parts, you’ll need a print farm!

Ever wanted to start your own 3D printing business? Or just want to sell sick 3D prints online? Well, for mass manufacturing 3D printed parts, you’ll need a print farm!

Just like a real farm has tons of animals, print farms are made up of many 3D printers to pump out as many models as possible. While print farms can be pretty large investments, costing anywhere from $5,000 to over $100,000, they can yield significant returns depending on how you wield their manufacturing power.

Etsy shops, online on-demand printing services, and contract small-scale manufacturing are just a few ways you can profit from a print farm.

But for a good print farm, you’ll need machines that don’t just print high-quality models but are also extremely reliable. In the sections below, I’ve reviewed what I believe to be the best 3D printers to include in your print farm.

I’ve also gone over everything I’ve learned from building and operating my own print farm.

Enjoy!

Build volume: 220 x 220 x 250 mm

Build volume: 250 x 210 x 200 mm

Table of Contents

- Product Reviews:

- Best 3D Printers for Print Farm At A Glance

- 1. Creality Ender 3 (Pro/V2) (Best Choice)

- 2. Prusa i3 MK3S+ (Premium Choice)

- 3. Elegoo Neptune 2S (Best Value)

- 4. Creality CR-10 (Best for Advanced Users)

- 5. Prusa Mini+ (Easy to Use)

- What Is A Print Farm?

- What It Takes To Start A Print Farm?

- Considerations for Print Farm Printers

- Conclusion

Product Reviews:

Let’s get into the best 3D printers for a print farm. In each of the sections below, we’ll go over a different printer, discussing its features, pros, cons, and more.

Best 3D Printers for Print Farm At A Glance

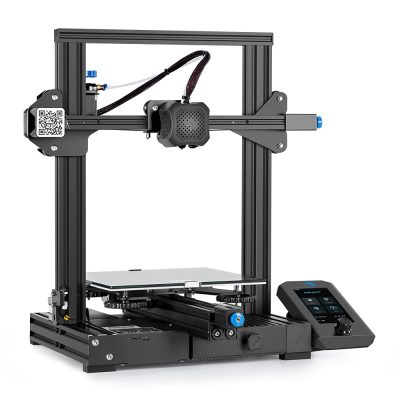

1. Creality Ender 3 (Pro/V2) (Best Choice)

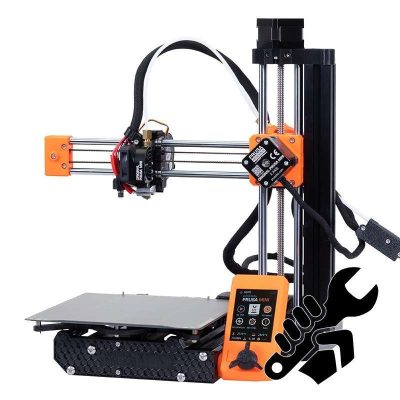

2. Prusa i3 MK3S+ (Premium Choice)

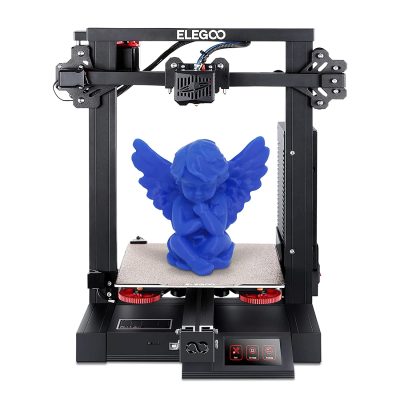

3. Elegoo Neptune 2S (Best Value)

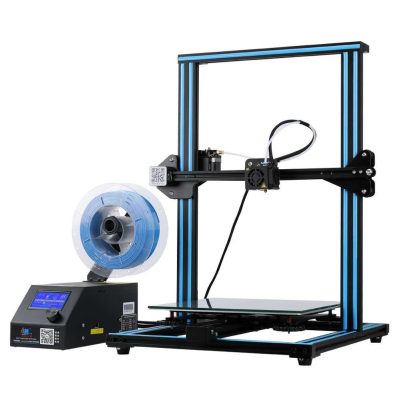

4. Creality CR-10 (Best for Advanced Users)

5. Prusa Mini+ (Easy to Use)

3D Printer Type: FDM | Materials: PLA, ABS, TPU & PETG | Build Volume: 220 x 220 x 250 mm

Our first printer to discuss is the Creality Ender 3, which comes in three four versions: the Original, Pro, V2, and the new S1. All four are great options for a print farm and are a great bang for your buck.

The Original Ender 3 costs under $200 and can put out prints that look better than ones made on a $1,000 printer. And the other versions of the Ender 3 (the Pro, V2, and S1) cost just a bit more but can print even better models. Note: the S1 can print with flexible filament with its direct drive extruder so if you’re looking to print phone cases, this is Ender to get

But the best part about the Ender 3 (Pro/V2) is its mod-ability. While the Ender 3 (Pro/V2) is decently dependable, you can make it even more reliable by adding some of the many available upgrades to the machine. For the Ender 3s in my print farm, I’ve added rubber feet, an E3D nozzle (more long-lasting), and a metal extruder, which has improved their consistency drastically.

Overall, the Ender 3, whether you get the Original, Pro, or V2, is my personal favorite choice for a machine on a print farm. It’s pretty reliable right out of the box, especially the V2, but once you add in the upgrades, it gets a whole lot better. And its low price makes it fit into any print farm budget!

Pros

- Good bang for your buck

- Comes in a few versions, each with different features

- Many optional upgrades exist

Cons

- Not super reliable in pure stock form (especially for the Original and Pro)

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon filled & Woodfill | Build Volume: 250 x 210 x 210 mm

If you’re looking for the best print quality for an FDM 3D printer, you can’t beat the Prusa i3 MK3S+. Developed by the expert team at Prusa Research, the i3 MK3S+ has every detail of a 3D printer right.

With a great build plate, automatic bed leveling sensor, touchscreen interface, high-temperature hot end, and so much more, it’s the perfect machine for a print farm. Just be prepared to spend a little on the higher side because each one of these bad boys goes for just under $1,000 a pop.

And if you look at the thousands of reviews for the printer, the one thing that basically all users can agree on is that the MK3S+ is super reliable. For the two years I’ve had the printer, I don’t think I can recall more than a few failed prints. And it only takes a simple search on Prusa’s large forum and Q/A section to figure out the issue and solve it!

The Prusa i3 MK3S+ isn’t as upgradeable as the Ender 3, but it really doesn’t need to be, considering how many features are already on the machine. As for the build volume, it’s just the right size, boasting a 210 x 210 x 250 mm build volume that will fit basically any regular print job.

While you can’t print ABS on the MK3S+ because it lacks an enclosure, it has a direct drive extruder and a high-temperature hot end. These features mean basically every other filament material, including flexibles, can be printed on the MK3S+.

It’s also worth noting that power loss recovery is a feature on the MK3S+!

As long as the budget isn’t an issue with you, I’d say the MK3S+ is the most premium choice to include in your print farm. It prints super high-quality models (decently fast, too) and almost never fails.

Pros

- Very high-quality prints

- Direct-drive extruder

- Decently large build volume

- Extremely reliable; almost never fails

- Prints fast

- Sturdy frame design

Cons

- Expensive

3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU | Build Volume: 220 x 220 x 250 mm

Elegoo is a popular 3D printer company, mainly known for its excellent resin (SLA) printers. However, their Neptune 2S is definitely a notable FDM printer that’s worthy of consideration for your print farm.

At first glance, the Neptune 2S looks a lot like the Creality Ender 3. But, unlike the Original and Pro versions of the Ender 3, the Neptune is decked-out with features that make the detail in prints exceptional.

For example, though there isn’t an automatic bed leveling sensor, the Neptune 2S comes with strong leveling springs. These will keep the bed level longer than usual, so you don’t have to redo the manual leveling process as frequently.

Additionally, the printer comes with a 32-bit motherboard that’s fast and powerful enough to handle the latest firmware releases with the most features. The touchscreen, full-color LCD interface also helps as it makes using the printer very easy.

But my favorite part about the Neptune 2S is its stock metal extruder. The metal construction makes the extruder super accurate and reliable, and I’ve yet to have an extrusion issue with my Neptune printer.

I also love the magnetic metal build plate that makes it easy to remove parts. All you have to do is take the bed off the printer, bend it, and your prints pop right off.

The downsides of the printer, however, are that you can’t print flexibles due to the Bowden-drive extruder configuration. Additionally, a fair amount of users, including myself, have found that layer shifting is common, so you’ll have to tighten the axis belts every so often.

But if you’re okay with that issue and want a solid FDM printer that won’t have extrusion issues, definitely add the Neptune 2S to your cart!

Pros

- Very reliable

- Sturdy build

- Flexible magnetic build plate for easy print removal

- Stock strong bed leveling springs

- Metal extruder

Cons

- Manual bed leveling is required

- No belt tensioners

3D Printer Type: FDM | Materials: PLA, TPU & ABS | Build Volume: 300 x 300 x 400 mm

Creality really nailed it with the Ender 3, but the CR-10 is another great option. Its strong suit is its size. The Original Creality CR-10 offers a build volume of 300 x 300 x 400 mm, which is extremely large considering the sub-$300 price point of the machine.

This much space on a print farm-ready machine will allow you to mass-produce large 3D models. I love using my Original CR-10 to print large models, like a Batman mask or shoe rack. But the extra space is also convenient if you’re just printing smaller models because you can’t print more at once.

And, if you want to go even bigger, you can opt to get the CR-10 S5 which gives you an extra 200 mm on the X and Y axes.

As for the other features on the Original CR-10, it’s pretty limited. The machine rocks an older 8-bit Creality motherboard with no automatic bed leveling or filament runout sensor. However, don’t let the simplicity of the machine fool you, as it’s still very reliable.

As long as the bed is level and the nozzle is unclogged, you’ll likely run into very few issues. And the quality of the prints from the Original CR-10 is still decent and good enough for most print farm jobs.

If you want the most print space per dollar, the CR-10 is my recommendation. While it lacks the features of the newer 3D printers, it’s one hell of a reliable and consistent machine. Plus, if you really want those extra bells and whistles, like auto-leveling or a runout sensor, you can choose one of the later versions of the CR-10, like the CR-10 Smart Pro.

Pros

- Other variations exist with more features

- Inexpensive; a good bang for your buck

- Large build space

Cons

- Somewhat outdated features

- Manual bed leveling

- Bowden-drive extruder (can’t print flexibles)

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, Polycarbonate, CPE, PVA/BVOH, PVB, HIPS, Polypropylene, Flex, nGen, Nylon & Woodfill | Build Volume: 180 x 180 x 180 mm

Lastly, the Prusa Mini+ is another printer from Prusa Research and is like a younger brother to the Prusa i3 MK3S+. The Mini+ is meant to be a more value-efficient printer for farms than the MK3S+. That’s because, with two Mini+ printers, you can print more parts than with one MK3S+, and the cost is about the same.

The Prusa Mini+ is a lot like the MK3S+, with exceptional build quality and thousands of happy users who reiterate the machine’s reliability. But, there are a few differences.

For one, the Mini+ is Bowden-drive, so printing flexibles won’t be as easy as on the direct drive MK3S+. Additionally, as indicated by the name, the build volume on the Mini+ is a little smaller, at 180 x 180 x 180 mm. While smaller than you might want for a print farm machine, it’s still enough space to print more than a few prints at once or midsized parts.

The print quality on the Mini+ is also something worth mentioning. If I had to print a miniature model on an FDM printer, the Mini+ would have to be my go-to. The E3D hot end lays out the filament so smoothly that the resulting models look just spectacular.

While the printer is decently pricey for its size, I promise the quality won’t let you down. So if you like the quality and reliability of Prusa printers but want a more cost-efficient machine than the MK3S+, the Prusa Mini+ is your guy.

Pros

- Spectacular print quality

- High-quality E3D hot end

- Automatic bed leveling sensor

- PEI Spring Steel build plate

Cons

- Bowden drive extruder (can’t print flexibles)

- Smaller build plate

What Is A Print Farm?

A print farm is a large collection of 3D printers that work to produce parts efficiently and consistently. There’s no official number of 3D printers that you must have to call your set up a “print farm”, but I’d say above 10 is the minimum.

Every print farm varies depending on the machines included, the filament/resin used, the environment around the printers, the software used, etc. But they all are or should be pretty reliable, being able to push out 3D prints day-in and day-out.

What It Takes To Start A Print Farm?

It probably comes as no surprise that it takes a lot to start a print farm. In the mini-sections below, I’ve briefly reviewed the main components of any print farm, including the hardware and other things you need to make your print farm worth it (or profitable):

3D Printers

Obviously, for a print farm, you need 3D printers. How many you get is up to you, but definitely above 10 so that you can still operate your business if a few machines break down.

As for the actual machines, we’ll go over the best printers for a print farm in the later sections, but the Ender 3 V2, Prusa Mini+, and CR-10 are my three favorites because they’re all good bang for your buck.

Materials

Just like a gun needs ammunition, 3D printers need filament or resin, depending on the type of printer, to actually print models. For FDM 3D printers (e.g. Ender 3), you’ll need a lot of filament.

I recommend buying the filament in bulk to save money, and you should also look for jumbo spools that are larger than 1 kg. This will save you time because you won’t have to replace the filament spool as often if each spool is bigger.

You also need to offer a diverse range of filament materials. Having the top 3 filament materials – PLA, ABS, and PETG – is 100% necessary, but it’s also a smart move to offer some exotic materials too, like Nylon, Carbon Fiber composite, and polycarbonate, as this will attract more customers.

Lastly, don’t forget to get some different colors of filament too! Nobody wants all-red 3D prints, even if that’s the cheapest color. Trust me when I say that offering some extra colors will go a long way in growing your customer base!

Target Market

And, on this note of customer base, you need a target market when proposing your 3D print farm. While on-demand 3D print services can still be profitable with your own print farm, you need to focus on one specific audience.

For example, instead of making your service for all people who want 3D printed parts, focus it on people looking for cosplay items. Making your 3D print farm business more niche will narrow the audience as a whole but attract more actual customers (and you’ll be an expert for your audience).

Storage

Surprisingly, storage is also a pretty major component of any print farm.

On top of the space required by the printers themselves, take into account the space required for all the tools and extra materials (filament spools) too. And because filament can degrade in quality when exposed to moisture, dust, and other substances, you might want to make a special storage area for filament spools. Filament dry boxes and heated containers are perfect for this!

I also strongly recommend reserving one area of your print farm for a small workshop. This way you can repair printers on your farm and have the printer back up and running in no time.

Spare Parts

Whether you like it or not, your 3D printers will break. No matter the quality of the 3D printers on your farm, something will eventually break when they’re pumping out prints for days on end. That’s why it’s essential to have some spare parts lying around.

Now you don’t need to keep spares of every single part on your 3D printers, but having some extras on the parts that break the most, like the nozzle, is smart. For my print farm of Ender 3s, I have a box of extra nozzles, hot ends, and extruder gears just in case some break.

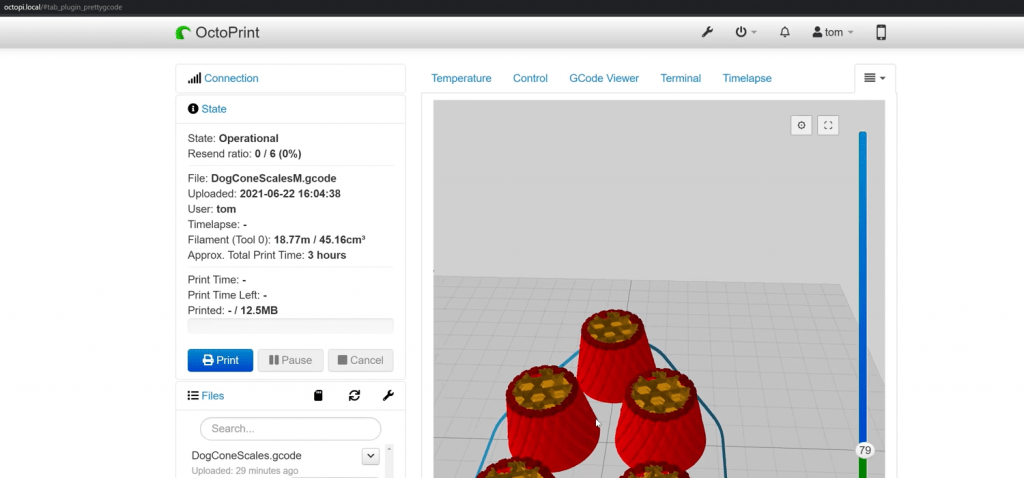

3D Print Farm Software

Lastly, automation is the key to an efficient and consistent 3D print farm. Ideally, you won’t have to be in your print farm all day to make sure everything is running smoothly. A 3D print farm software helps with this by automating your printers.

There are a handful of different software options, including OctoPrint, Buildbee, 3DPrinterOS, Slant3D, and Authentise. Each software works differently, but they all require some form of computer (e.g. Raspberry Pi board) attachment for the printers. The computer hosts a server that you can remotely access and use to control your printers, set up a print queue, and more.

My personal favorite software is OctoPrint, though, because I love the control it gives me. While it doesn’t natively support control over multiple printers, you can use an app container (e.g. Docker) or just have an OctoPrint server for each printer. For a more cohesive experience, 3DPrinterOS is a great option, though it does cost money.

Check out our article on how to set up OctoPrint on your 3D printer here.

Considerations for Print Farm Printers

When looking for a 3D printer to fill your print farm with, there are a few aspects of the machine to keep in mind.

Reliability

The single most important aspect of a machine for your print farm is its reliability. You want a 3D printer that can consistently print models without failure.

While there’s no one way to rate a printer’s reliability, the better the machine’s build quality, the more reliable it is. That’s why the more expensive machines are typically more reliable, but this isn’t always the case, as we’ll talk about later.

The best way you can rate the reliability of a 3D printer is by checking the reviews of the machine. Reddit is also an amazing source!

Print Quality

No matter how reliable your print farm is, if the prints suck, no one will want 3D prints from your business. That’s why the quality of prints is also extremely important for the machines in your print farm.

Like with reliability, there isn’t really a good way to rate the quality of prints by a specific machine. You can get an idea of how nicely the prints will turn out based on the build plate material, hot end type, and motion system. But, just like with reliability, checking the reviews helps the most.

Material Compatibility

The material compatibility of the 3D printer regulates which filament (or resin) materials you can print on the machine and which you can’t. Most printers can handle PLA and PETG.

However, if you want to print ABS, you’ll need a printer with an enclosure and a high-temperature bed (minimum 100 °C). And for printing flexible materials like TPU and TPE, you’ll want a printer with a direct drive extruder.

And for the more industrial materials, like Nylon and PC, you’ll want a high-temperature hot end.

Build Volume

Build volume is also extremely important because the more space you have, the more items you can print at once. A typical volume you want for a print farm printer is 200 x 200 x 200 mm or higher. But this isn’t a hard requirement, and you can use a printer with a smaller volume if the machine makes up for it in other areas.

Price

Of course, price is probably the first aspect of a printer you look at. And it’s very important!

You shouldn’t overpay for a printer that doesn’t put out its worth. As you want ten or more printers in your farm, picking out a machine that will make your budget work is important, so don’t break the bank for only a few high-quality printers!

Automatic Bed Leveling

Automatic bed leveling is an increasingly popular feature on 3D printers that makes the whole printing experience much easier. All you have to do is click a button, and your printer will level itself rather than having to manually rotate the bed knobs to get a level bed.

You should keep an eye out for printers with an automatic bed leveling sensor, but it’s not totally necessary, so don’t rule out machines just because they don’t have ABL.

Check out our article on the best auto-leveling 3D printers here.

Power Loss Recovery

The last consideration for a print farm machine is a small but vital one: power loss recovery. If the power goes out on your print farm, you wouldn’t want all of the ongoing print jobs to be wasted. Power loss recovery is a feature in the firmware of your printer’s motherboard that will ensure your 3D printer resumes any ongoing prin jobs once the power is back.

Conclusion

Though it’s no small investment (with money, time, and effort), building a 3D print farm can help you start your own 3D printing business or fill your manufacturing needs. But if you build one, do it right! Make sure you’ve got a 3D printer that won’t disappoint you even after hundreds of high-quality prints.

If you’re deciding which machine to fill your print farm with, my first suggestion would have to go to the Ender 3 V2. It’s a bit more expensive than the Original or Pro versions of the Ender 3 but its extra features, like belt tensioners and a glass build plate, allow for exceptional quality prints. And the machine has a very low failure rate.

But if the print quality is your #1 concern, you definitely need to check out both the Prusa i3 MK3S+ and Mini+. These printers cost a bit extra, but with the premium price comes premium features, like automatic bed leveling, a smooth motion system, and a powerful, never-failing metal extruder.