- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Big parts, big machines, big power. Welcome to industrial 3D printing.

Big parts, big machines, big power. Welcome to industrial 3D printing.

Industrial 3D printers are becoming standard equipment at all manufacturing operations. From huge automotive manufacturers to small one-person workshops, they churn out durable and detailed parts at unmatched speed.

But you can’t hop on the industrial 3D printing train blindly. These are costly machines, and buying the wrong printer is a mistake your business can’t afford.

Read on and learn which of the best industrial 3D printers in 2024 have what you need.

Table of Contents

- Top 10 Industrial 3D Printers In 2024

- 1. Raise3D Pro2 Plus (Best Choice)

- 2. Intamsys Funmat HT Enhanced (Best Value)

- 3. Mosaic Element HT (Premium Choice)

- 4. Creality CR-M4 (Best Budget Option)

- 5. Raise3D E2 (Highest Productivity)

- 6. Sinterit Lisa (SLS Printing)

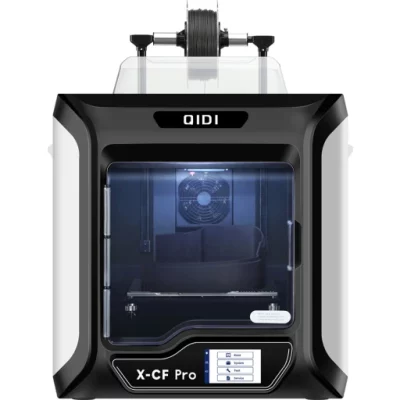

- 7. Qidi Tech X-CF Pro (Best Usability)

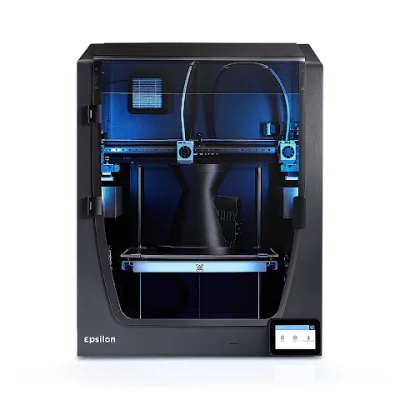

- 8. BCN3D Epsilon W50 (Best Large-Format)

- 9. Roboze Plus PRO (Most Versatile)

- 10. Markforged Metal X (Metal Printing)

- Industrial 3D Printing: What Does It Mean?

- The New Industrial Revolution

Top 10 Industrial 3D Printers In 2024

1. Raise3D Pro2 Plus (Best Choice)

2. Intamsys Funmat HT Enhanced (Best Value)

3. Mosaic Element HT (Premium Choice)

4. Creality CR-M4 (Best Budget Option)

5. Raise3D E2 (Highest Productivity)

6. Sinterit Lisa (SLS Printing)

7. Qidi Tech X-CD Pro

8. BCN3D Epsilon W50 (Best Large-Format)

9. Roboze Plus PRO (Most Versatile)

10. Markforged Metal X (Metal Printing)

3D Printer Type: FDM | Materials: Thermoplastic filaments, reinforced filaments | Build Volume: 305 × 305 × 605 mm (single extruder); 280 × 305 × 605 mm (dual extruder) | Layer Resolution: 10 microns | Max Print Speed: 150 mm/s

Are you looking for the first industrial 3D printer for your business? Or do you want to add to the machine collection of an existing operation? Whichever way you answered, it doesn’t matter — you need a Raise3D Pro2 Plus.

This machine ticks all the boxes of a full-fledged industrial 3D printer, except for the sky-high price tag.

The Pro2 Plus has a dual extruder that lets you print two materials at once. Additionally, the printer can handle even carbon fiber, glass, and wood-filled filaments. The possibilities of different combinations are endless.

The HEPA-filtered enclosure keeps fumes out of your nose and bed and nozzle temperatures steady for reliably high-quality prints.

Did I hear you ask: “How high-quality?”

The printer can achieve a minimum layer resolution of 10 microns. That’s basically unheard of for an FDM printer. No matter how fine your details, they’ll come out clear and sharp.

Oh, and that price. At a very affordable price, the Pro2 Plus delivers the performance you’d see on machines that cost three times as much.

But nothing is perfect. The print platform is finicky to level and the (admittedly big and bright) touchscreen has some reliability issues. Also, why can’t a printer this big fit a 3kg filament spool?

I’m nitpicking, though. Raise3D Pro2 Plus is simply the best industrial 3D printer you can get at this price.

Pros

- Reliably high print quality

- Incredible layer resolution

- Filtered enclosure

- Supports reinforced materials

- Low price

Cons

- Difficult to calibrate

- Small but annoying technical issues

3D Printer Type: FDM | Materials: Thermoplastic filaments, reinforced filaments | Build Volume: 260 x 260 x 260 mm | Layer Resolution: 50 microns | Max Print Speed: 300 mm/s

You have to love the name of this 3D printer — Funmat sounds like a carnival ride. But the real fun part for additive manufacturers is the fact that Intamsys Funmat HT Enhanced provides excellent value with its very low price point.

But does that mean the Funmat is less capable?

Not at all. With an extruder reaching a searing 450°C (842°F), the Funmat can print with an incredible range of engineering-grade materials, including nylon, PEEK, and reinforced filaments. Whatever material you need to give your business a boost, Funmat delivers.

The printer keeps up the heat with the enclosed high-temperature print bed. The steady high temperatures practically eliminate warping and curling. You’ll get reliable print quality out of this machine.

But let’s get to the best part — the price.

You wouldn’t believe how affordable Funmat’s performance is- Funmat costs only about $6,000 ($1000 less than a year ago). The sturdy construction and automated features are not something you’d expect from a machine this affordable.

The low price starts to show in the detail accuracy. It’s good for an FDM printer but can’t compete with Raise3D, which is about the same price. Funmat’s print volume is also quite small.

But at this price, you can forgive those slights. Intamsys Funmat HT Enhanced provides more bang for your buck than any other industrial 3D printer.

Pros

- Affordable

- Wide material range

- High-temperature extruder and bed

- Automation and features

Cons

- Low detail

- Small print volume

3D Printer Type: FDM | Materials: Thermoplastic filaments | Build Volume: 355 x 355 x 355 mm | Layer Resolution: 20 microns | Max Print Speed: 100 mm/s

Demanding customers require the best parts. If only the best is good enough for your clients — and you — Mosaic Element HT is your workhorse.

First, let’s address that “HT” part of the printer’s name. It stands for “high temperature” and it’s not empty marketing speech. This FDM printer’s extruder reaches a searing 500°C.

The ridiculous temperature means that it can process industrial-grade advanced thermoplastics. PEEK, PEKK, Ultem 9085, and many other high-end filaments work extremely well with this machine.

And that’s a good thing because Mosaic Element HT can incorporate eight materials into one part.

It’s all thanks to Mosaic’s material pods. They feed filament into the extruder with a separate motor and require no splicing.

Together with the printer’s CoreXY mechanism, it can achieve awesome detail and part quality. The 20-micron layer resolution doesn’t quite match Raise3D Pro2 Plus, but the difference is so small it basically doesn’t matter.

The print quality and multi-material support make Element HT fit any role. Whether your business does prototyping, product design, or produces small batches of functional industrial components, this printer will work for you.

As a final industrial-oriented cherry on top, Element HT connects seamlessly to Mosaic’s Array industrial automation suite. This machine means business in both performance and usability.

It is expensive, though. Element HT costs a lot and you’ll be tied to Mosaic’ (pretty pricey) filaments due to the special material handling system.

If you’re serious about the 3D printing business, Mosaic Element HT will be an invaluable business partner.

Pros

- 500°C hot end

- Prints eight materials in single part

- Accurate and reliable

- Material support

- Simple usability

Cons

- High cost

- Slower than you’d expect

3D Printer Type: FDM | Materials: Thermoplastic filaments, reinforced filaments | Build Volume: 450 x 450 x 470 mm | Layer Resolution: 50 microns | Max Print Speed: 120 mm/s

Creality markets its CR-M4 as a “quasi-industrial” 3D printer. What does that mean?

I speak printer, so let me translate for you. It means industrial-level performance at a price that won’t break the bank.

CR-M4 punches above its price tag in many ways. Its print volume, for instance, rivals much more expensive machines — beating the Mosaic Element HT, among others.

Although it looks like a consumer-level printer, the machine is solidly built. The rigid Z-axis does exactly what it promises, providing predictable performance.

The print quality isn’t mindblowing, but it’s good. More importantly, it’s reliable. CR-M4 produces steadily produces good-looking prints to keep your business productive.

It also has automatic and effective bed leveling to further boost your productivity. And it meshes with additional printers through Creality Cloud.

Ever wanted to set up a print farm in 15 minutes?

The hot end reaches 300°C and the print bed heats to 100°C, giving you a lot of choices in materials. That said, this brings me to my biggest grumble about the CR-M4.

The printer doesn’t ship with an enclosure. I wouldn’t try printing something like nylon (unless you really want warped prints).

In addition, the nozzle that ships with the printer is brass. Creality’s list of supported materials includes carbon fiber-reinforced PLA, but that will likely quickly wear the nozzle out.

But I can’t really fault the printer for these shortcomings at this price. Creality CR-M4 is an excellent budget-friendly printer — especially for print farms.

Pros

- Affordable

- Reliable performance

- Good print quality

- Easy connectivity

- Large print volume

Cons

- No enclosure

- Default brass nozzle

- Loud

3D Printer Type: FDM | Materials: Thermoplastic filaments, reinforced filaments | Build Volume: 330mm x 240mm x 240mm (single extruder); 295mm x 240mm x 240mm (dual extruder) | Layer Resolution: 20 microns | Max Print Speed: 150 mm/s

You know that good old workhorse that just keeps plowing the fields, rain or shine? If your business was a farm, Raise3D E2 would be that workhorse.

Business owners looking to boost their productivity shouldn’t miss out on this printer.

But how does the E2 achieve that high productivity?

The first (and perhaps most important thing) is that it uses independent dual extruder (IDEX) technology. This printer has two print heads that can move independently. That opens a world of opportunities for businesses.

Want to add two materials in one print? You can. Want to print mirrored parts to make, say, cases? You can. Want to print two identical pieces at once for small-scale batch production? You can!

Not only that, the print quality is very good. The E2 loses to its Pro2 Plus brother so little that you can’t tell the difference.

Second, the E2 is packed with features that increase its reliability. The automatic bed leveling is advanced and works nearly flawlessly (although it’s easy to misplace the print bed when putting it back in).

The user interface is clear and simple, so you won’t have to spend hours troubleshooting. You’re also ready to print practically out of the box.

My biggest gripe about the E2 is the disappointing build volume. The machine is massive, so you’d expect a big print chamber.

As long as you’re not after big prints, Raise3D E2 will take your productivity to new heights.

Pros

- IDEX printing

- Great print quality

- Sturdy and reliable

- Easy to set up and use

Cons

- Small build volume

- Huge and heavy

- Build plate is easy to misplace

3D Printer Type: SLS | Materials: Nylon PA12, TPU powders | Build Volume: 150 x 200 x 150 mm |Layer Resolution: 75 microns | Max Print Speed: 3 mm/s

You don’t have to worry about ending up like Tommy Wiseau — this Lisa won’t tear you apart. Instead, Sinterit Lisa is an incredibly compact selective laser sintering (SLS) 3D printer that’ll put together high-quality parts.

Industrial SLS printers are usually huge. But Lisa doesn’t care about your preconceptions and does whatever she wants.

For an industrial-grade SLS printer, Lisa is positively petite with a weight of just 90 pounds (41kg) and a height of 660 mm. She’ll bring SLS power to any office or workshop.

Lisa can create accurate prints, on par with machines five times her size. Since she’s an SLS printer, you don’t have to worry about creating support. The nylon or TPU powder in Lisa’s print chamber supports the parts and saves you trouble.

And as a cherry on top of it all, Lisa won’t break your budget (in terms of SLS printers).

Of course, Lisa’s print volume is as small as she is. She also doesn’t know what to do with powders other than Nylon and TPU. Finally, Lisa can be temperamental, so be prepared to spend time with print preparation.

She’s worth the effort, though. Sinterit Lisa brings quality SLS parts to even the smallest 3D printing business.

Pros

- Affordable

- Extremely compact SLS printer

- Good part quality

- Complex and sturdy parts

Cons

- Small print volume

- Limited materials

- Lengthy print preparation

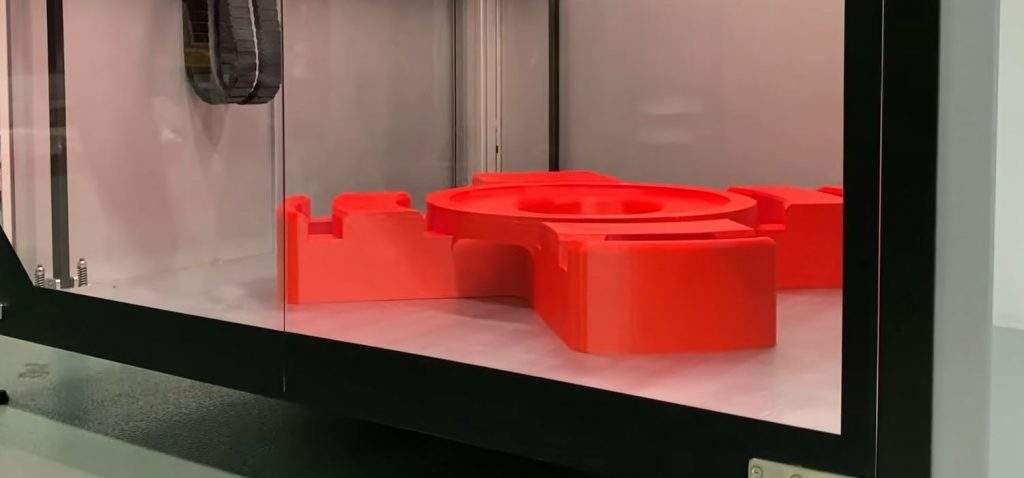

3D Printer Type: FDM | Materials: Thermoplastic filaments, reinforced filaments | Build Volume: 300 x 250 x 300 mm |Layer Resolution: 50 microns | Max Print Speed: 120 mm/s

The original Qidi Tech X-CF Pro was already a pretty good machine. But then it got updated in 2022 and I was surprised they made it a lot better.

If you’d like to simply print advanced materials without worrying about your 3D printer, Qidi Tech X-CF Pro lets you do just that.

The X-CF Pro is so simple to use from the beginning to the end. The assembly and setup are quick and easy, partially thanks to the detailed instructional videos you get.

Operating the printer is straightforward with the large, clear, and intuitive touchscreen. You’ll probably have to level the bed manually for the first time but after that, you can rely on the excellent BL Touch auto-leveling system.

And then we have the print quality.

The X-CF Pro makes great prints. Its detail level isn’t quite on par with Raise3D or Mosaic, but it’s perfectly sufficient.

The machine is reliable as well. A filament run-out sensor and print resume functionality keep mishaps from ruining your prints. The filament spool holders are top-notch and preserve even sensitive materials like nylon.

Speaking of materials, the printer fully supports third-party filaments. With the 300°C hot end, you can print with almost anything you want.

I guess I should mention a downside… Well, the X-CF Pro is kind of slow. The build volume could also stand to be larger, considering the machine’s size.

Look, do you want a printer that just works? If yes, Qidi Tech X-CF Pro has you covered.

Pros

- Simple to set up and use

- Reliable printing

- Good detail quality

- Solidly built

- Third-party filament support

Cons

- Slow-ish

- Mediocre build volume

- Big machine

3D Printer Type: FDM | Materials: Thermoplastic filaments | Build Volume: 420 x 300 x 400 |Layer Resolution: 50 microns | Max Print Speed: N/A

“I want large-format, industrial-quality parts, but the machines are so expensive.” Does this sound like you? Then, my friend, you must meet BCN3D Epsilon W50.

This FDM printer makes large-scale 3D printing cheap(ish) and easy.

Costing less than $10,000, Epsilon W50 has a big print volume. Its HEPA-filtered enclosure keeps the temperature steady, so you can reliably fill that huge heated build chamber.

And you have a lot of options on how you want to fill it.

Like Raise3D E2, Epsilon W50 has two independent extruders. You can easily mix two materials in one print, but that’s not all.

The Mirror Mode lets you print two mirrored halves of one part — electronics cases, anybody? Meanwhile, the Duplication Mode moves each extruder independently, creating two identical parts. What a way to boost productivity.

You can get to printing quickly, too, since the machine is ready to go straight out of the box. Installation and setup take only about 20 minutes.

The closed print chamber can run a bit too hot, though, which might cause quality issues with materials like PLA. Bed leveling is also weirdly time-consuming, considering how automated the printer is otherwise.

In short, BCN3D Epsilon W50 is a reliable large-format 3D printer that won’t break the bank.

Pros

- Affordable for what it is

- Large build volume

- IDEX independent print heads

- Supports third-party filaments

Cons

- Can overheat some filaments

- Fiddly bed calibration

3D Printer Type: FDM | Materials: Thermoplastics, reinforced filaments | Build Volume: 300 x 250 x 220 mm |Layer Resolution: 15 microns | Max Print Speed: N/A

Roboze Plus PRO is a relative newcomer on the market, having launched in July 2022. But it was and still is a welcome sight — it can print with advanced high-performance materials.

Plus PRO is compatible with such exotic filaments as PEKK, carbon fiber-reinforced materials, flexible TPU filament, PEEK, and the list goes on. The extensive material support lets you print parts for practically any purpose — from rapid prototyping to replacing metals in mechanical applications.

If you need one printer for multiple uses, this is a good contender.

The machine gives you accurate and reliable results to boot. Roboze’s unique beltless design moves the print head fast with very high accuracy. The 15-micron resolution doesn’t quite beat Raise3D Pro2 Plus, but it’s still very good for an FDM printer.

Getting those reliable results isn’t a headache, either. Plus PRO integrates with Roboze’s own Prometheus slicer, which makes using it a cinch.

Unfortunately, the print chamber is embarrassingly small compared to the size of the printer. This behemoth weighs 660 pounds (300 kg) and is likely taller than you. You may also run into some software bugs since this is a newly released machine.

As long as you don’t need huge parts, Roboze Plus PRO brings to the table fantastic versatility with its material range.

Pros

- Accurate and reliable printing

- Great detail level

- Large and versatile material library

Cons

- Small print chamber

- Heavy and huge machine

3D Printer Type: Metal FDM | Materials: Steel, copper, Inconel filaments | Build Volume: 300 x 220 x 180 mm |Layer Resolution: 50 microns | Max Print Speed: N/A

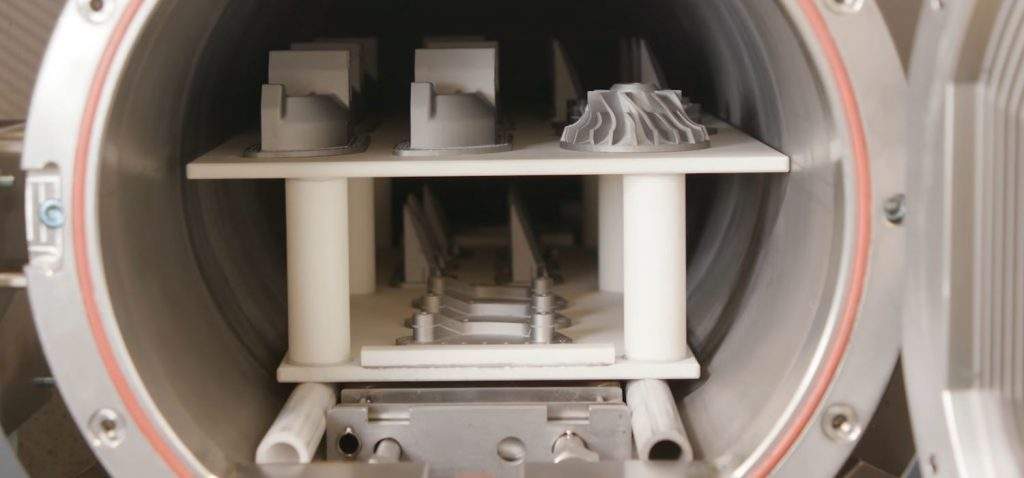

Markforged Metal X brings heavy metal thunder to additive manufacturing technology. This 3D printer makes printing directly with metal filaments accessible to more companies than ever before.

How has Markforged achieved such a feat?

Metal X works similarly to any FDM printer. The powder metal rods are encased in a plastic binder. The binder is removed during the printing process, leaving only various grades of steel, copper, or Inconel alloy in its wake.

As a result, you can print sturdy, corrosion-resistant, and complex metal parts, like engine components. With a minimum layer height of 50 microns, Metal X is also as accurate as some of the listed plastic FDM printers, like Intamsys Funmat HT Enhanced.

Printing directly with metal isn’t as easy as with plastic, though. The raw metal prints require extensive post-processing.

You have to wash the parts to remove the binder and sinter them in a blazing furnace. Metal X is not a beginner’s printer — not that it even tries to be.

Oh, and the machine is very expensive. It carries a hefty price tag of nearly $100,000.

But that’s still cheap for an industrial metal printer. Markforged Metal X lets you embrace your inner Conan the Barbarian and solve the riddle of steel.

Pros

- Prints with metal

- Good detail accuracy

- Affordable (for a metal printer)

Cons

- Still expensive

- Parts need heavy post-processing

- Shrinkage during washing and sintering

Industrial 3D Printing: What Does It Mean?

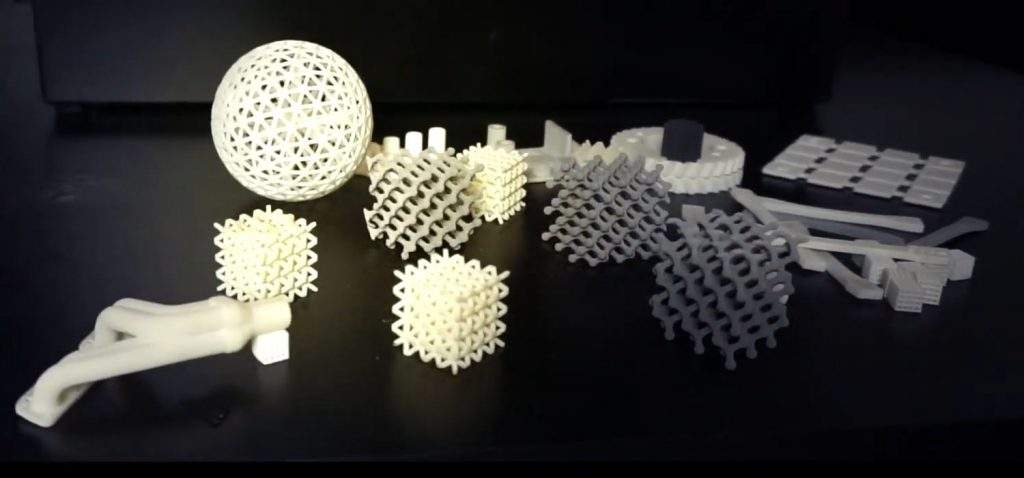

3D printing is becoming increasingly popular among hobbyists, but it’s making an even bigger impact in industrial applications. From consumer goods to aerospace, it seems every manufacturer is scrambling to employ 3D printing technology.

It’s easy to see why. Industrial 3D printers allow you to make parts in-house, practically eliminating lead times. They can produce parts of comparable (or better) strength and quality to traditional manufacturing — while reducing material consumption and costs.

But even manufacturing experts might wonder what an “industrial 3D printer” actually is. Let’s unpack that title and see what it means.

What Is an Industrial 3D Printer?

Technically, you could use any 3D printer in an industrial setting. But just sitting in a professional workshop or factory doesn’t make it an industrial printer.

The key to defining an industrial 3D printer is the manufacturer’s design intent.

Industrial 3D printers are designed and built from the beginning to offer high part quality and productivity to business-oriented users — even at the expense of ease of use or affordability. This sets them apart from consumer and prosumer printers, which often prioritize accessibility and lower price.

That’s not to say industrial printers can’t be affordable (we listed several that are). But they’re still designed to offer industrial-level rapid prototyping and part manufacturing experience.

What Makes a Printer ‘Industrial?’

So, whether or not a printer is industrial depends on the manufacturer’s design philosophy. But how does that philosophy translate to practice?

You can generally determine a printer’s industrial capability by looking at four factors — build volume, extruder temperature, heated build chamber, and automation. It’s not a rule set in stone, but these details can reveal whether or not you’re looking at an industrial 3D printer.

Large Enough Build Volume

Industrial manufacturing depends on production volume. Of course, small-batch manufacturing is a thing (and that’s where 3D printing shines) but you’ll still want to maximize your productivity.

Industrial 3D printers generally have larger print chambers than consumer-level ones, giving them the ability to print larger components or multiple parts at once.

High Extruder Temperature

Many engineering-grade materials have very high melting temperatures, upward of 325°C (617°F). To print with such materials as reinforced filaments, nylon, or PEEK, industrial 3D printers need high-temperature extruders.

Heated Build Chamber

Any business depends on steady product quality. A heated print bed and chamber that reaches at least 80°C (176°F) prevents warping and gives you a predictable part quality.

Automation

You can’t afford to keep manually feeding data to your printer and re-calibrating it after every print job. Industrial 3D printers are highly automated to keep them in constant operation without slowing your business down.

How to Choose the Right Industrial 3D Printer for You

Picking an industrial 3D printer can seem daunting — especially if you’re buying your first one.

How can you be sure you get the features you need?

The choice isn’t as difficult as you may think. Consider these factors when browsing the listed printers and you should have a clear idea of what you need.

Size

Consider both the print volume and the size of the machine when choosing the printer. Larger build volumes quickly rack up 3D printer prices, so don’t overpay if you only need small components. An industrial 3D printer can also be a huge machine — make sure you have the space for it.

3D Printing Technology

Not every 3D printer is equal. Some produce more durable parts (EOS P500, Markforged Metal X) while others emphasize detail accuracy (Raise3D Pro2 Plus, Stratasys F370). Research the different technologies and pick one that serves your needs.

Materials

Do you need flexible parts? Or perhaps you need extreme corrosion resistance? Different materials shine in different applications, so make sure your printer prints the one you need.

Ease of Use

It’s best to pick a 3D printer that anyone can use, but that’s not always possible with complex industrial machines. Hiring a professional 3D printer operator can add to your costs. It may just be something you have to do, but it’s good to be aware of this potential expense beforehand.

Resolution

Does the detail accuracy and precision matter to you? Consider whether you need intricate details or smooth surfaces. If not, you may be able to save some money by choosing a less accurate 3D printer.

Software

Every 3D printer needs computer software for operation. Check what slicers and other software your printer supports, how complicated they are to use, and whether there are cheap (or even free) alternatives.

Customer Service

Your 3D printer will break eventually — there’s no way around it. Make sure the manufacturer offers good customer service and prompt maintenance to keep your business running.

The New Industrial Revolution

Whichever field you’re active in, an industrial 3D printer can boost your productivity and open new business opportunities. You now know what to look for when choosing your new 3D printer. To make the choice even easier, here are some of our recommendations.

- My top choice for an industrial 3D printer is Raise3D Pro2 Plus.

- If your business is on a budget, Intamsys Funmat HT Enhanced or Creality CR-M4 will serve you well.

- Those looking for maximum productivity will love Raise3D E2 and BCN3D Epsilon W50.

- For demanding users, Mosaic Element HT is a great choice.

But you know your manufacturing needs best. With this guide, you can find the printer that revolutionizes your manufacturing business.