- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Do you want to 3D print parts that are incredibly tough and have stunning detail?

Do you want to 3D print parts that are incredibly tough and have stunning detail?

Then you need a nylon 3D printer.

Nylon is one of the best and most versatile 3D printing filaments. It’s just as easy to print as PLA or ABS but gives superior print quality and strength that you just can’t get with other filaments.

But you need to use the right 3D printer with nylon filaments. Nylon has a high melting temperature (above 250°C) so using an underpowered printer can clog or break the machine.

Nylon can also suck up moisture from the air, so your printer needs the right kind of storage compartment. Otherwise, you’ll end up with ruined filament.

Here are the best nylon 3D printers in 2022 — just pick one that fits your needs.

Best Nylon 3D Printers At A Glance

1. Matterhackers Pulse XE (High Performance)

2. Qidi Tech X-Plus (Best Choice)

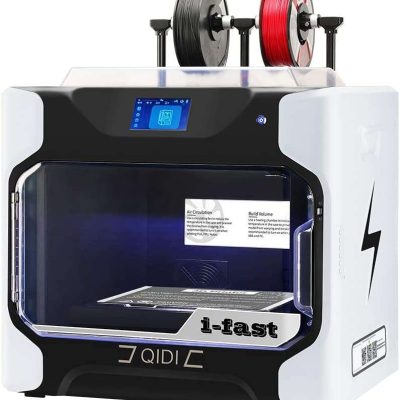

3. Qidi Tech i-Fast (Premium Choice)

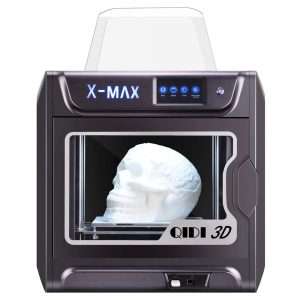

4. Qidi Tech X-Max (Best Value)

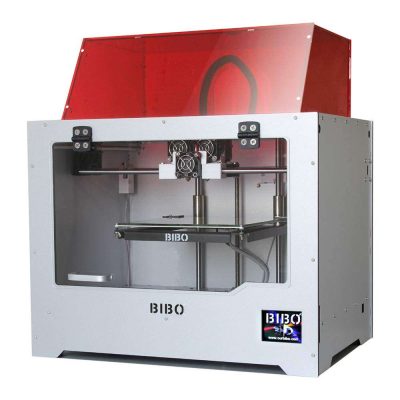

5. Bibo 2 Touch (Most Reliable)

6. Dremel 3D45-01 (Highest Quality of Prints)

3D Printer Type: FDM | Materials: NylonX, TPU, ABS, PETG & PLA | Build Volume: 250 x 220 x 215 mm

The Pulse XE from MatterHackers is built like a tank. It has been designed from the get-go to print nylon and other abrasive materials. And the best part of it is that the high versatility and performance are ready to go straight out of the box.

The hot end can reach up to 300°C to easily melt nylon material. The included hardened steel nozzle extrudes nylon without issue and can even handle filaments reinforced with carbon or glass fiber. No matter what high-performance filament you choose to print with, this machine has your back — but that’s not all.

An optional Olsson Ruby nozzle has an actual gemstone at its tip that gives it incredible abrasion resistance. Together, the premium parts combine into a machine that will save you a lot of money in maintenance.

The Pulse XE is a lateral-bed printer that moves the heated print bed from side to side during printing. This design gives it an average print speed, since going too fast could cause print shifting.

As a unique quirk, the Pulse XE is designed to work primarily with MatterHackers’ MatterControl software. You can operate it independently, but the dedicated controller unlocks features like automatic bed leveling. That also means that you’ll want a computer to control it.

All in all, the Pulse XE performs fantastically and doesn’t need much maintenance. It’s ideal for anyone looking to get reliably high-quality prints.

Pros

- High performance out of the box

- Premium build quality

- Low maintenance

- Wide material range

Cons

- Mediocre print speed

- Needs a computer for maximum performance

3D Printer Type: FDM | Materials: PLA, TPU, ABS, PETG, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 270 x 200 x 200 mm

Do you want it all in one package? The Qidi Tech X-Plus has you covered, no matter what you want to print.

The X-Plus comes with not one but two swappable extruders. Extruder A is for general materials, like PLA and ABS, while Extruder B has a maximum temperature of 300°C. You can realize projects with practically any filament, including nylon and carbon fibers.

Another unique double feature is the removable, flexible metal printing plate. It’s double-sided, with each side compatible with one of the swappable extruders. Just be careful which side you use or you might have issues with bed adhesion.

You can mount the filament in two different ways. For general materials, the outside top-loader offers smooth filament feeding. The internal holder, on the other hand, will ensure dry filament with nylon printing.

As its name implies, the X-Plus delivers a well-sized print chamber. It’s also fast, so you won’t have to wait long to fill the heated printing bed.

The print chamber is enclosed and has an air filtration system to keep fumes out of your nose. That also means it’s quiet enough you can keep the printer in your room.

Who thought you’d be able to fall asleep with a 3D printer running?

If there’s a downside, it’s in user support. The documentation has some shoddy English and online resources can be hit or miss.

The Qidi Large Size X-Plus is a fantastic machine at less than $1,000. That’s why we’re ranking it as the overall best 3D printer for nylon.

Pros

- Prints practically any filament

- Excellent value for money

- Easy to use

- Large print volume

- Friendly and fast customer service

Cons

- Poorly translated documentation

- Inconsistent print bed adhesion

3D Printer Type: FDM | Materials: PLA, TPU, ABS, PETG, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 360 x 250 x 320 mm

The Qidi Tech i-Fast is a nylon 3D printer for those who want the best — no matter the price. Its collection of high-end features is enough for any hobbyist and even light manufacturing operations.

The first thing to know about the i-Fast is that it’s big. It has the largest print volume out of any machine in this guide.

And if you thought big parts would be slow to print, think again. With a max print speed of 150 mm/s, the i-Fast lets you dream big and makes you can turn your dream into reality.

To support those big prints, the i-Fast’s heated chamber has a maximum print bed temperature of 60°C which improves adhesion. You can easily make the roughest and toughest parts without issue.

But you haven’t heard the best yet.

The i-Fast can even print with metal. Yes, you read that right.

You’ll have to do a sintering step in post-processing, but the i-Fast’s automatic dual extruder can handle stainless steel filaments. Ever wanted to print spare parts for small machines? You just might be able to.

Naturally, the big productivity also makes the i-Fast a big machine. It won’t fit in just in any nook or cranny. Qidi’s documentation can also be of questionable quality, but luckily the 5-inch color touchscreen is intuitive.

The Qidi Tech i-Fast is a premium 3D printer for premium parts. If you want heavy metal, that’s what you’ll get.

Pros

- Big print volume

- Wide materials options (including metal filament)

- Comes with an automatic dual extruder

- Wi-Fi connectivity

- Qidi’s quality customer service

Cons

- Expensive

- Needs lots of space

- Poorly translated documentation

3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 300 x 250 x 300 mm

At around $1,000, the Qidi Tech X-Max gives you a lot of bang for your buck. Considering its price point, the X-Max is one of the best nylon 3D printers you can get.

How has Qidi done it?

To begin with, X-Max has a large print chamber for how much you pay for it. It has enough space for you to print out big single parts or a whole collection of small parts — your choice. You’ll be hard-pressed to find a printer with this much volume for this price.

But the good things don’t end there. X-Max has advanced features you’d usually see in professional printers, like Wi-Fi connectivity, a five-inch color touchscreen, a lit chamber, and a bendable double-sided printing bed.

And you get it all at a reasonable budget. That leaves you with enough money to buy advanced filament materials, like nylon and carbon fiber.

The printer is pretty bulky, so you’ll have to find enough space for it. At the same time, though, it has an enclosed chamber that keeps fumes and noise levels low. Put the printer in any corner and you won’t even notice it’s there.

But at this price, X-Max has had to cut some corners. It doesn’t have a filament run-out sensor, so keep a close eye on the filament while doing big prints. The surface finish is also pretty rough, and we’d replace the included nozzle with a higher-grade one for nylon printing.

But that’s nitpicking. At its price, the Qidi Tech X-Max delivers an amazing value proposition that’s hard to beat.

Pros

- Advanced features at a reasonable price

- Large print volume

- Supports lots of materials

- Easy to use

Cons

- Rough surface quality

- Documentation is poorly translated

- No filament sensor

3D Printer Type: FDM | Materials: PLA, ABS, HIPS, TPU, PETG, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 214 x 186 x 160 mm

Some things you can count on — the sun comes up in the morning, birds go tweet, and the BIBO 2 Touch prints. It’s just that reliable.

BIBO has enclosed the printer in a 6mm-thick aluminum frame that’s sturdy enough to survive a meteor impact. It’s not the prettiest design, but the BIBO 2 Touch reminds us of your granddad’s old car — kind of ugly, but also basically indestructible. Yet the printer is more than just its frame.

The BIBO 2 Touch has dual extruders that let you print with two different filaments (supported by dual filament holders), print two copies of the same part at once, or print with two different colors. If you can imagine it, you can print it.

You might expect an affordable dual extruder printer to break easily, but that’s not the case. Take care of it and the BIBO will keep going for years. With all the money you save on maintenance, you can buy the laser engraver add-on for marking soft materials like wood or cardboard.

As a downside, the small touchscreen is fairly buggy. You can expect more or less frequent glitches, but luckily BIBO offers good customer service to resolve those issues.

If you want to buy a nylon 3D printer that will keep you in action for years, get the BIBO 2 Touch.

Pros

- Extremely sturdy construction

- Dual extrusion

- Wide material range

- Great customer service

- Laser engraver add-on

Cons

- Small and buggy touchscreen

- No automatic bed leveling

- Outdated design

3D Printer Type: SLA | Materials: PLA, ECO ABS, PETG & Nylon | Build Volume: 254 x 152 x 170 mm

In case you didn’t know, filament printers don’t use lasers. We felt the need to point that out because the Dremel DigiLab 3D45-01 produces laser-accurate part detail.

On paper, the 3D45-01 doesn’t have any lower layer thickness than the other listed printers. But the stats tell only a half-truth. It’s the smart sensors and additional features on the printer that make it shine.

Dremel’s filaments come with RFID chips that the 3D45-01 can read to automatically adjust printing settings for optimal printing quality. The machine levels the heated bed and controls enclosure temperature on its own to ensure maximum print quality. Thanks to Dremel’s printing technology, getting that great quality is also very easy.

Wi-fi connectivity lets you operate the printer completely remotely. If you want to check on your print, you can do that thanks to the built-in camera. Place the admittedly bulky printer in your basement and start your prints from the bed.

Getting that amazing print quality and convenience doesn’t come cheap, though. Not only is the printer itself pricey but you’ll have to use Dremel’s own expensive printing materials for the automated controls to work. The 3D45-01 is prone to clogging and third-party materials won’t make the issue any better.

This is the 3D printer for people who want the highest possible detail quality, whatever the price.

Pros

- High detail and accuracy

- Automated printer control

- Remote operation

- Easy to use

Cons

- Doesn’t support third-party filament

- Clogs easily

- Bulky printer with a mediocre print volume

Printing with Nylon Filament

Now that we’ve looked at the printers, let’s explore nylon itself. Knowing more about the material can help you pick a 3D printer that best suits your needs.

Nylon, also called polyamide, is a synthetic polymer that’s used everywhere from space shuttles to pantyhose. It’s easy to print, but still offers high part strength and excellent detail quality.

But there are also a few considerations you need to keep in mind.

Nylon melts at temperatures above 250°C (482°F). Not all 3D printer extruders can reach these temperatures, so choose your machine wisely. Additionally, nylon filaments are harsh on the print nozzle and require a durable, all-metal nozzle. Otherwise, you’ll be replacing this part on a weekly basis.

You can print with nylon using many different 3D printing technologies. Selective laser sintering (SLS) is popular in high-level industrial use, but these machines are big and expensive. For home printing, though, there are many excellent fused deposition modeling (FDM) printers, as you’ve learned.

What Designs is Nylon Filament Best For?

Nylon’s molecular structure is built from extremely long chains of molecules consisting of endlessly repeating, short sections of atoms. This structure makes nylon composites flexible and strong but detailed enough that they can have very thin walls. There aren’t many materials that can deliver this level of detail and durability.

Nylon also has a low friction coefficient, making it good for moving parts. It’s a fantastic option for printing parts like:

- Hinges and joints

- Casings for electronics

- Snap-fit parts

- Tool handles

- Load-bearing parts

For more practical examples, you can use nylon print screwdrivers, gears, nuts and bolts, skateboard wheels, or flex ties. If it needs to last long in a mechanical application, print it with nylon.

Which Printer Settings to Use with Nylon?

Nylon is rather demanding to print. It needs high temperatures to melt and is prone to warping unless you use a properly heated bed.

Start experimenting with these nylon print settings and tweak them based on the results you get:

- Extruder hot end temperature: 250°C-300°C

- Printing plate temperature: 75°C-100°C

- Printing speed: 20-80 mm/s (you may be able to go higher depending on your filament and printer)

- Printer chamber: Enclosed

Additionally, nylon filament is very hygroscopic and it absorbs moisture from the air. Wet filament makes prints weak by lowering layer adhesion and can cause poor surface quality.

Always store nylon filament in an air-tight container and dry it before printing. You can dry nylon filament by placing it in a 70°C home oven for 6-8 hours.

Is Nylon Filament Toxic?

In itself, nylon filament isn’t dangerous and it’s safe to handle without gloves. But once the printing process starts melting the filament, nylon gives off toxic fumes and compounds.

You can mitigate this problem with the right safety precautions.

Always use an enclosed print chamber in a well-ventilated area when printing with nylon. Try to choose a printer with good HEPA filters to keep the fumes out of ambient air. If you can attach a ventilation system to your printer, even better.

When working with nylon, you should wear a respirator that protects you from fine particulate matter and volatile organic compounds. It’s also best to not be in the same room as a running nylon printer.

Tips for Printing Nylon Filament

To get the best results out of your nylon printer, follow these useful tips:

- Always use an enclosed printer in a well-ventilated room.

- Dry your filament before printing.

- Use a heated printing plate to reduce warping.

- Use stainless steel or other all-metal nozzles.

- Don’t set the print speed too high to ensure layer adhesion.

Advantages of Using Nylon Filament

- Strong and flexible parts

- Can print moving parts

- Excellent detail and surface quality

- You can color printed parts

- Good heat, chemical, and UV resistance

Disadvantages of Using Nylon Filament

- Filament absorbs moisture and needs drying before printing

- Prone to warping

- Nylon filament is difficult to store

- Nylon is more expensive than other filaments

- Printing with nylon releases toxic fumes

Recommended Nylon Filament Brands

Successful nylon printing can be as much about using the right material as it is about using the right printer. Not all filaments are equal and some of them are more suitable for certain parts or 3D printers than others.

Here are our recommendations for the best nylon filaments.

Overture

Overture markets its 1.75 mm nylon filament under the moniker Easy Nylon, which should tell you the name of the game. The filament uses Overture’s (vaguely described) Zer0 Warp technology, which does reduce warping, especially if you use PVP glue on the print platform.

Made out of a mix of Nylon 6 and Nylon 6.6, Overture’s filament is strong and durable. It also has a good tolerance of +/- 0.05mm, so you shouldn’t see much clogging.

You’ll absolutely need an all-metal hot end, but thanks to the low cost of this filament, you can afford that!

Polymaker

Polymaker offers a lot of options, including Nylon 6 filaments reinforced with carbon and glass fibers, Nylon 12 Carbon Fiber, and composite material CoPa. As a standout feature, Polymaker says the filaments don’t need an enclosure and a heated printing platform of only 50°C. You’ll probably still want to use an enclosure because of the nylon fumes.

These filaments are serious business and can make extremely durable engineering-grade parts. They don’t deal well with overhangs, though, and parts need annealing in an 80°C oven for six hours after printing. But if you want to put in a bit of extra effort for extra strength, this is your material.

Taulman3D

If you need ridiculous strength, here’s what you want. Taulman3D’s Alloy 910 nylon composite is a premium material. It sees regular use in cars and airplanes worldwide — enough said about its credentials.

With this nylon 3D filament, you can print fully industrial-level parts at home, since it prints at temperatures between 250-270°C. It can be a bit tricky to dry and work with, but you won’t get parts this strong with many other materials. Of course, the high performance also comes at a fairly high price point.

But Which Printer Is the Right One For Me?

You now know a lot about nylon 3D printers and their materials. But if you’re still unsure about which one to pick, here are our top three recommendations.

If you’re buying your first-ever 3D printer, buy the Matterhackers Pulse XE. If part quality is all that matters to you, go for Dremel 3D45-01. And if you just want it all, get the Qidi Tech X-Plus.

But any of the printers on this guide will get you printing strong, detailed, and durable parts. That’s what nylon is all about.