- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

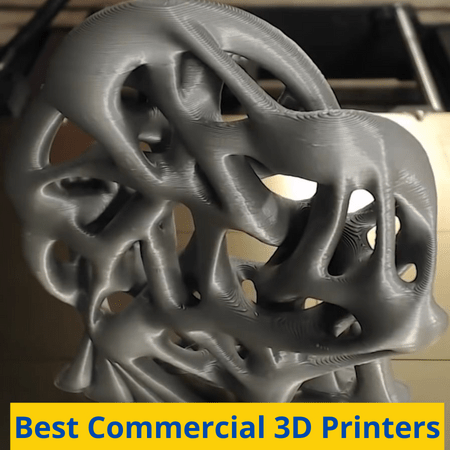

Are you dreaming of making industrial-quality parts at your SME? Well, stop dreaming and start printing!

Are you dreaming of making industrial-quality parts at your SME? Well, stop dreaming and start printing!

Commercial 3D printers let even a tiny garage operation make parts NASA would send to space. A professional 3D printer is a business partner you can’t afford to not have.

But we also know that with an SME budget, you can’t afford to pick the wrong 3D printer, either. You have to choose the right machine for the right application to avoid wasting its potential. But how do you do that?

Read on and meet the best commercial 3D printers in 2023.

Table of Contents

- Best Commercial 3D Printers At A Glance

- 1. Raise3D Pro2 Plus (Best Overall)

- 2. MakerBot Method X (Best Value)

- 3. Nexa3D XiP (Premium Choice)

- 4. Ultimaker S7 (Easy to Use)

- 5. Prusa i3 MK3S+ (Best for High-Quality Prints)

- 6. Dremel DigiLab 3D45-EDU (Best for School Use)

- 7. Zortrax M300 Dual (Best for Detailed Prints)

- 8. BCN3D Epsilon W50 (Best for Beginners)

- 9. Phrozen Sonic Mega 8K (Best for Decorative Parts)

- 10. FlashForge Guider 3 Plus (Best Large-Format)

- Industrial Quality at Small Business Budgets

- Conclusion

Best Commercial 3D Printers At A Glance

1. Raise3D Pro2 Plus (Best Overall)

2. MakerBot Method X (Best Value)

3. Nexa3D XiP (Premium Choice)

4. Ultimaker S5 (Easiest to Use)

5. Prusa i3 MK3S+ (Best for High Quality Prints)

6. Dremel 3D45-EDU (Best for School Use)

7. Zortrax M300 Dual (Best for Detailed Prints)

8. BCN3D Epsilon W50 (Best for Beginners)

9. Phrozen Sonic Mega 8K

10. FlashForge Guider 3 Plus

3D Printer Type: FDM | Materials: PLA, ABS, HIPS, PC (Polycarbonate), TPU, Nylon, TPE, PETG, Metal Infused PLA, Woodfilled PLA & Carbon Fiber Reinforced Materials | Build Volume: 305 × 305 × 605 mm

Freddy Mercury probably would’ve liked Raise3D Pro2 Plus. If you want it all and you want it now, this is your machine.

This award winner simply does everything you could need.

As a particular highlight, the dual extruder of the Pro2 Plus can print with two materials at once. You can mix any two options from its staggering material range into one part in the machine’s well-sized build chamber. This is one printer that really makes you create any part you want.

And you have a lot of options. With a maximum extruder temperature of 300°C (572°F), Pro2 Plus works with anything from basic ABS to advanced carbon fiber-reinforced nylons and more.

Oh, and that print quality. This is one of the most accurate FDM printers I’ve seen.

Pro2 Plus isn’t the most beginner-friendly 3D printer since it doesn’t have automatic bed leveling. But if you know what you’re doing, Raise3D Pro2 Plus is the best commercial 3D printer available right now.

Pros

- High accuracy and part quality

- Supports third-party filaments

- Low price

- Dual extruder

- Large print volume

Cons

- Difficult calibration

- Some technical issues

- No steel nozzle included as default

3D Printer Type: FDM | Materials: PLA, Tough PLA, PETG, PETG-ESD, Nylon, PC-ABS, ABS, ASA & PVA | Build Volume: 190 x 190 x 196 mm

It just keeps going and going and going… And that’s precisely where the amazing value of MakerBot Method X lies

Now, Method X is not the cheapest model on this list, and I wouldn’t say it’s good value for home users. But we’re talking about serious business. That’s where Method X delivers a lot of bang for your buck.

This printer has been designed from the beginning to make printing as easy as possible. It has plenty of automated features, like bed leveling, thermal regulation, and a temperature -controlled filament drawer, that contribute to consistent and predictable part quality.

When you’re doing business, every minute you spend on troubleshooting means lost money. That’s not even a consideration with Method X. Focus on printing product instead of playing engineer.

The printer also produces high-quality parts, both in terms of surface detail and strength. You can make engineering-grade prints for demanding customers.

That said, Method X isn’t a flashy printer. It has a small build chamber and you need to buy separate extruders to make full use of the admittedly wide material range.

But that’s Method X for you. It doesn’t boast, it doesn’t grumble — it just prints. In business, that kind of reliability carries immense value.

Pros

- Extremely reliable

- Great value for businesses

- Simple to use

- Wide material range

Cons

- Needs add-ons for reinforced materials

- Default slicer could be better

3D Printer Type: LSPc | Materials: Nexa3D, Henkel, BASF, and Keystone resins | Build Volume: 195mm x 115mm x 210mm

There was a time when resin prints were brittle and fragile. Those days are gone. Nexa3D XiP is a resin printer that produces premium-quality parts in looks, durability, and strength.

How is a resin printer able to achieve all that?

Part of the secret lies in Nexa3D proprietary Lubricant Sublayer Photo-curing (LSPc) technology. It’s basically a derivative of SLA that boost the XiP’s print speed to blisteringly fast 18cm/h. Despite the speed, the parts come out with excellent detail.

The second part of the puzzle is XiP’s support for third-party materials. Nexa3D boasts that the printer can use any available resin — and it’s not empty marketing talk.

The machine supports flexible, strong, biocompatible, and high-detail resins alike. The XiP can make anything from architectural models to engine components.

Whatever you want to print, you can print it — and fast.

The XiP is also very easy to use. Its simply interface makes it simple to use its advanced features. As a special highlight, I want to mention the stacking mode, which (with careful support design) enables small-scale batch production.

So, who is this printer for? It’s for engineers, artists, dentists, doctors — anyone who needs high-detail premium-grade prints.

Pros

- Fast printing

- High detail quality

- Open material platform

- Reliable and consistent

- Enables small-batch production

Cons

- Costly

- No resin-level monitoring

- Occasionally glitchy slicer

3D Printer Type: FDM | Materials: Tough PLA, TPU 95A, ABS, Nylon, TPU | Build Volume: 330 x 240 x 300 mm

Ultimaker S5 was a very easy 3D printer to use. The new S7 — which dropped just at the beginning of 2023 — continues its predecessor’s legacy of straightforward and simple usability.

The S7 comes pre-built and calibrated, so you can put it to work as soon as you unpack it. A new inductive build plate sensor completely eliminates manual leveling. Just plug the printer in, give it five minutes to set itself up, and get to business.

Like the S5, the S7 integrates seamlessly with Ultimaker’s own Cura software. It has pre-defined profiles for more than 280 materials, so you can use it to print any part you can dream of. Even metal filament printing is possible, thanks to the swappable print cores.

The print quality is great. The flexible heated print bed, together with dual extruders, produces reliable, consistent results, even with multi-material printing.

As a nice touch, the S7 has a new air filtration unit. You can say goodbye to smells and particles wafting about your workshop.

Although the S7 makes printing even easier than its predecessor, I’d hesitate to call it a must-upgrade machine. The print volume and accuracy haven’t changed, so you won’t get much of a performance boost for the printer’s high price.

If you want simple usability at a lower price, I’d say you can safely go for the S5. But those looking for the latest and greatest in user-friendliness can’t do better than the S7.

Pros

- Simple setup and operation

- Good print quality

- Material options

- Modular print cores

Cons

- Expensive

- Slow printing

- Not that big of an upgrade

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon filled & Woodfill | Build Volume: 250 x 210 x 210 mm

Don’t judge a book by its cover or a 3D printer by its price. At only $1,000, Prusa i3 MK3S+ punches way above its weight. It produces high-quality prints you wouldn’t expect from such an affordable machine.

Sure, the minimum layer thickness isn’t as impressive as with Raise3D Pro2 Plus or Fusion3 EDGE. But layer resolution isn’t the end-all-be-all of part quality.

The i3 MK3S+ features predefined printing profiles for Prusa filaments. Just pick the right profile — you’ll get reliably successful prints with almost zero effort. You can quickly alter the default profiles to match third-party filaments as well.

And you can print with almost any filament you want.

The i3 MK3S+ has a high-quality extruder that can reach 300°C. Carbon fiber, nylon or other engineering filaments are within your reach. And they print as effortlessly as anything.

You’ll want to get an enclosure to prevent warping with advanced filaments, though. The Prusa also can’t make huge parts, but what it does make is of consistently high quality.

Pros

- Reliably great part quality

- Affordable

- Big, helpful online community

- Simple to use

Cons

- No enclosure

- Small print volume

- Laggy software

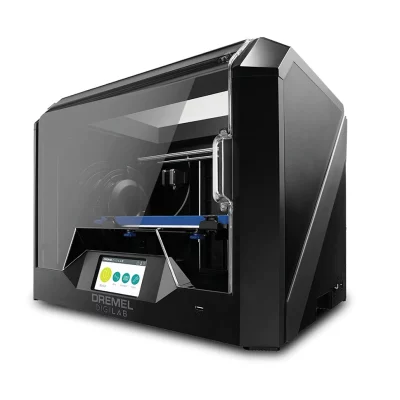

3D Printer Type: FDM | Materials: PLA, ECO ABS, PETG & Nylon | Build Volume: 254 x 152 x 170 mm

To get good at something, you should start young. Dremel DigiLab 3D45-EDU is a perfect 3D printer for teaching future additive manufacturing experts. Just look at the awards it’s received.

But what makes it so great for schools?

DigiLab 3D45 has a perfect balance of affordability, performance, and ease of use. You can set up and calibrate the printer in 15 minutes. Then you’re ready to start showing students how 3D printing works.

While the Dremel isn’t the most accurate machine, it’s still a professional 3D printer. It produces detailed prints of good quality.

As the students learn, the 3D45 lets them adjust the settings more accurately. The 3D45-EDU package even comes with 30 lesson plans from the 3rd to 12th grades.

The build chamber isn’t huge, but it’s more than enough for school use. Also, Dremel claims 3D45 can handle nylon, but the 280°C extruder temperature seems a bit low for that.

Nonetheless, Dremel DigiLab 3D45-EDU is a great package for getting students excited about 3D printing.

Learn more in our guide of the best 3D printers for schools.

(NOTE: Dremel no longer manufactures 3D printers and has licensed its brand to 3PI. The machines are the same, but it’s good to know who to talk to if you need technical support.)

Pros

- Included lesson plans

- Easy setup and operation

- Good part quality

Cons

- Small print volume

- Slow speed

- Limited materials

3D Printer Type: LPD Plus | Materials: Most Z-Materials, PLA, Tough PLA, ABS, ASA, PETG, CPE, Nylon, TPU, TPE & PVA | Build Volume: 265 x 265 x 300 mm

Zortrax M300 Dual will surprise you. It creates highly detailed prints — despite the on-paper rough and inaccurate 150-micron layer height.

How on earth does this 3D printer do it?

The M300 Dual’s secret lies in the Layer Plastic Deposition (LDP) technology. It’s essentially Zortrax’s own spin of fused filament fabrication (FFF/FDM). Tailor-made for this system, LDP makes use of M300’s accurate leveling and calibration sensors to deliver very high-quality prints.

Another part of the puzzle is Zortrax’s proprietary filaments. The 3D printer has a complete Zortrax ecosystem, so it knows precisely how to handle the materials to deliver fine details beyond its specs.

The dual extruder also prints with two nozzles, one distributing Zortrax’s water-soluble support material. This is a really handy invention since you can just wash the supports away after printing.

Of course, that means you need to buy Zortrax’s filaments. You can use third-party materials, but you may not get as fine detail.

Zortrax M300 Dual will bring more detail than you’d expect to all small businesses.

Pros

- Excellent detail and part quality

- Water-soluble supports

Cons

- Practically locked to Zortrax filaments

- Mediocre volume

3D Printer Type: FFF | Materials: PLA, PVA, PETG, TPU, ABS, PP & PA | Build Volume: 420 x 300 x 400 mm

An entry-level 3D printer often sacrifices production power for simple usability. It’s a good thing, then, that BCN3D Epsilon W50 isn’t an entry-level 3D printer. It’s a professional machine that’s easy enough for beginners to use.

The printer’s quick to set up and calibrate. The most laborious part is print bed calibration — it’s not hard, just time-consuming. Even if it’s your first 3D printer, you’ll get Epsilon W50 ready to go in about 20 minutes.

And it still brings serious power to your workshop.

Epsilon W50 uses an independent dual extruder system. It can print two materials at once, print mirrored component halves, or two identical parts at once. Combined with the big print volume, you’ll enjoy industrial-level productivity.

One thing deterring beginners might be Epsilon W50’s admittedly high price point. But think of this high-end 3D printer like a good pair of boots — it costs more upfront but it will keep printing reliably for years.

In a nutshell, BCN3D Epsilon W50 is a beginner-friendly machine with veteran-level performance.

Pros

- Easy and reliable printing

- Independent dual extruder system

- Large print volume

Cons

- Expensive

- Default hot end doesn’t support reinforced filaments

- Long bed calibration process

3D Printer Type: LCD | Materials: Photopolymer resins | Build Volume: 330 x 185 x 400 mm

Beauty is in the eye of the beholder — unless you print something with Phrozen Sonic Mega 8K. Then your prints will be gorgeous on a universally objective basis.

This machine is a dream come true for any business making decorative parts or statues.

Sonic Mega 8K is, as its name implies, a resin 3D printer armed with an 8K resolution screen. The high-resolution screen makes the printer capable of accurately reproducing even the tiniest details. It squarely beats the Nexa3D in print quality.

Prints made with Sonic Mega 8K are so highly detailed that you’ve likely never seen anything like them.

High-detail printers generally don’t print very big, but Phrozen has eliminated size as a consideration. Sonic Mega 8K has a huge print chamber. You can make your prints massive and beautiful.

However, the big build volume is a double-edged sword. You have to plan your prints very carefully or they will fail simply because they get too heavy to stick to the print plate. Gravity, you are a harsh mistress.

Printing huge objects also makes post-processing a real hassle. Although the printer supports third-party resins, I wouldn’t necessarily recommend it for printing functional parts.

For decorative parts, though, this machine can’t be beaten. Phrozen Sonic Mega 8K is a must-have for any business making statues, miniatures, or decorations.

Pros

- Stunning print quality

- Affordable

- Large build volume

Cons

- Very slow

- Suffers from size

3D Printer Type: FDM | Materials: ABS, PLA, PC, PA, HIPS, ASA, PETG, PA-CF, PLA-CF, PETG-CF, PETG-GF | Build Volume: 350 x 350 x 600 mm

Size matters in additive manufacturing. Flashforge Guider 3 Plus makes it possible for small businesses to produce big prints.

The Guider 3 Plus print chamber has roughly the same huge size as the Raise 3D Pro2 Plus’. It loses in height by a few millimeters but is wider and deeper.

Yet, the Guider 3 Plus races ahead in speed. As a CoreXY-based 3D printer, it’s capable of reaching high print speeds without sacrificing accuracy. You can produce large and detailed parts fast, which can really cut your lead times and boost profitability.

But you don’t have to print big parts. The large chamber and fast printing make this printer ideal for small-scale batch production.

FlashForge clearly understands business, because the company has loaded the Guider 3 Plus with excellent industrial-oriented management features. The automated bed leveling is fast and reliable, a quick-release switch makes swapping the nozzle simple, and the printer has remote monitoring and print resume functionality.

On top of that, the printer supports plenty of materials from consumer filaments to reinforced engineering thermoplastics.

Essentially, FlashForge Guider 3 Plus turns your workshop into a real factory.

The machine is a bit costly, but I think the price point is justified (some might even argue it’s a steal). This printer will be an excellent business partner for anyone making large or small-batch prints.

Pros

- Large print volume

- Accurate detail

- Fast printing

- Industrial-grade management features

Cons

- Pricey

Industrial Quality at Small Business Budgets

Commercial 3D printers are great equalizers. They’re quickly changing the SME landscape by narrowing the gap between small and large businesses.

The best professional 3D printers make printing plastics easy, fast, and affordable. You can produce components with detail quality comparable to injection molding and strength that can surpass metal.

But not just every 3D printer deserves the title of a “commercial 3D printer.” What is it that makes a 3D printer professional?

What Is a Commercial 3D Printer?

Commercial 3D printers — also called prosumer or professional 3D printers — sit in the space between consumer 3D printers and full-blown industrial 3D printing behemoths.

In general, a commercial 3D printer costs less than $10,000. They have features that only the most advanced hobbyists might need but which are valuable for professional applications.

At the same time, they’re not meant for large-scale mass production like industrial printers. In short, they’re a low-cost method for SMEs to make use of industrial-grade materials.

What Can Commercial 3D Printers Make?

Commercial 3D printers generally support a wide variety of different materials, which allows them to make almost anything.

Of course, the supported materials vary between machines, but in general, a good commercial 3D printer can produce anything from consumer goods to high-performance machinery components.

You also don’t have to make products for sale with a commercial 3D printer. For example, if you run a garage or engineering business, a high-grade 3D printer can allow you to produce your own spare parts for your tools.

Many SMEs use commercial 3D printers to make products such as:

- Design models and prototypes

- Props and clothing

- Decorations and statues

- Miniatures

- Jigs and fixtures

- Dental molds

- Medical appliances

- Jewelry

- Packaging

- Electronics casings

What to Look for in a Commercial 3D Printer

Are you about to buy the first printer for your business? You might feel a bit lost among all the options for professional 3D printers — and I sympathize.

When browsing through our list of machines, keep an eye on these details to find the right machine for you.

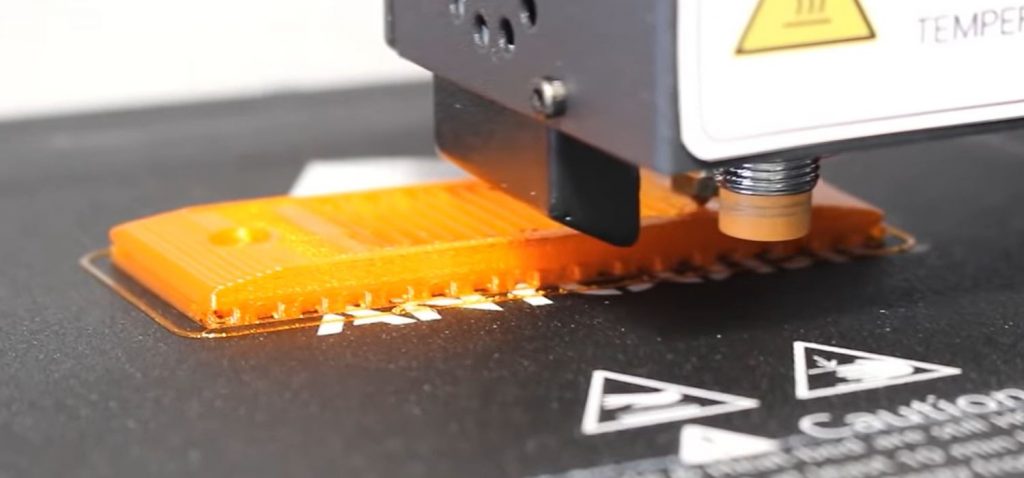

3D Printing Technology

Different types of 3D printers excel at different tasks. If you need strong parts that don’t necessarily look amazing, FDM technology can create components tougher than metal. But if intricate detail is your key to success, SLA resin printers will blow you away with their detail quality.

Printing Performance

Pay attention to the maximum nozzle temperature (with FDM printers) and print speed. The higher the maximum temperature, the more materials you can print with. And, of course, the faster you can print, the higher your productivity.

Material Range

Good professional 3D printers will support a wide variety of materials, from flexible ones to reinforced engineering plastics. But wider material compatibility can add to the price. If you know you only need one or two materials, don’t sink money into a machine that can do it all

Build Volume

Commercial applications often require you to create large prints. Make sure your printer can build big enough parts — otherwise, it’s just a waste of money.

Printer Features

High-end 3D printers often come with advanced features, like a heated print bed and chamber, a built-in camera, and more. These aren’t just expensive toys. You want them to ensure consistently high part quality.

Uses of Commercial 3D Printers

Professional 3D printers are versatile machines that can benefit many different types of SMEs. If you create a product, you can probably reduce costs, shorten lead times, and streamline workflows with a 3D printer. Here are just some of their leading commercial uses.

Part Design & Prototyping

3D printing enables a higher degree of design freedom when compared to traditional manufacturing. Combined with materials that can create true-to-life surface textures and detail, you have a powerful prototyping technology in your hands.

The best professional 3D printers produce accurate prototypes in a matter of hours — featuring shapes that are impossible for conventional production methods. You can save time and money by creating your prototypes in-house.

Small-Scale Manufacturing

Commercial 3D printers support end-use ready materials, such as nylon or PEEK, and produce durable parts with smooth surfaces. You can print ready-to-sell components for cars, drones, or functional tools.

Alternatively, you can print spare parts for machinery you use for different jobs. Save money and keep your machines running, how about that?

Medical Applications

SLA resin printers — like Phrozen Sonic Mega 8K I mentioned — can create accurate medical appliances from durable, biocompatible materials. These printers are quickly becoming standard fixtures in every dentist’s office, for example. Read our review of the best dental 3D printers here.

But even filament printers have their medical uses. They let doctors produce all kinds of useful tools, like hooks, trays, or medical models.

Architecture

Every major building began its life as a blueprint and a model. In the past decade or so, a professional 3D printer has become an architect’s best friend.

Building models by hand can take weeks and cost a fortune. Now, imagine designing a building in 3D modeling software and printing it overnight for a meeting in the morning.

Conclusion

Commercial 3D printers have done to SMEs what industrial printers did to large-scale businesses. They’ve made manufacturing faster, cheaper, and more accessible. A professional 3D printer will be a welcome addition to your business.

If you’re still wondering what the best commercial 3D printers for you are, here are our suggestions:

- The one commercial 3D printer to rule them all is Raise3D Pro2 Plus.

- For the most detailed parts, choose Phrozen Sonic Mega 8K or Zortrax M300 Dual

- Ultimaker S7 and Makerbot Method X let you produce durable end-use parts.

- For batch production, Nexa3D XiP and FlashForge Guider 3 Plus are good choices.

- To train future 3D printing professionals, Dremel DigiLab 3D45-EDU is unbeatable.