- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Have you been searching for a great titanium 3D printer but aren’t sure which one to go for? Look no further. After conducting intense tests, we’ve found some amazing options out there — and we’ve put them all together in this single guide.

Have you been searching for a great titanium 3D printer but aren’t sure which one to go for? Look no further. After conducting intense tests, we’ve found some amazing options out there — and we’ve put them all together in this single guide.

There are a whole lot of metal 3D printing technologies out there (SLM, SLS, RPD, EBM… the list could go on!), as well as different laser setups and build volumes.

But don’t get intimidated by all the different types and technologies. Whether you’re a doctor looking to print back braces, or you want to print models for car parts, or just print some cool titanium stuff, you’re gonna find the perfect titanium 3D printer that suits your needs right here.

Let’s get right into it!

Table of Contents

Best Titanium 3D Printers At A Glance

1. EOS M 290 (Premium Choice)

2. Renishaw RenAM 500Q (Best Choice)

3. Trumpf TruPrint 2000 (Best Value)

4. SLM Solutions SLM 500 (Best for Large Automotive Applications)

5. VELO3D Sapphire (Best Flexible Titanium 3D Printer)

3D Printer Type: DMLS | Materials: EOS Titanium, EOS Copper Cu, EOS CobaltChrome, EOS Nickel Alloy, EOS Stainless Steel, EOS Aluminum & EOS CaseHardeningSteel 20MnCr5 | Build Volume: 250 x 250 x 325 mm

First off we have the EOS M 290, a DMLS (Direct Metal Laser Sintering) 3D printer made by EOS. And honestly guys, this EOS is a pretty cool printer. It EOSN’T the best, but it is pretty good. Okay. I’ll stop now.

The defining characteristic of this printer is its fast and accurate printing which yields a pretty sharp layer resolution of 100 microns. It uses a super high quality 400 watt laser that captures precise details at high speed. The 290 is PERFECT for creating a strong, lightweight build with complex designs, which is why it’s especially useful in the aerospace and automotive industries.

It comes with support for a huge variety of materials from aluminum to high-grade steel and of course, titanium.

Unfortunately for those out there who like to experiment with a variety of materials from different manufacturers, the EOS M 290 comes with a closed material system — there’s no room for any mix-and-match.

But when you consider who this printer is targeted for — as well as the variety of EOS’ own powders — it’s not too big a deal. However, if you’re used to working with certain powder brands and aren’t inclined to give them up, this may not be the printer for you.

The EOS M 290 has a build volume of 250 x 250 x 325 mm, which is pretty sizable. Not the biggest printer out there, but good enough for most titanium 3D printing applications.

Pros

- Fast and accurate

- 100 micron resolution

- EOS offers a large variety of powders

Cons

- REALLY pricey

- Closed material system

3D Printer Type: Power Bed Fusion | Materials: Aluminum & Titanium Alloys | Build Volume: 250 x 250 x 350 mm

The RenAM 500Q is, in a word, FAST.

…Actually, allow us to add two more words. It’s also clean and efficient. So if you need super fast production of titanium parts, and speedy output is your highest priority, this is a great printer for you.

With a slightly bigger build volume than the EOS M 290 at 250 x 250 x 350 mm, the RenAM 500Q comes with four 500 Watt lasers. Yep, that’s right, FOUR whole lasers. Yay world domination!

And each of these lasers can access and cover the entire powder bed at once — resulting in increased speed and productivity. In fact, it prints at a speed of a whopping 150 cubic centimeters per hour.

As for the clean part, the RenAM 500Q consumes low amounts of argon (which saves a whole lot of money and…argon), AND it is also armed with the SafeChange filter system which automatically switches to a clean filter whenever necessary.

It’s also efficient because it uses automated powder and waste handling systems — and what’s more is that it can be converted into a powder sieving and recirculation system once you’re done printing. Pretty neat.

Pros

- 4 lasers for increased speed and productivity

- SafeChange filter system

- Convenient and efficient powder systems

Cons

- Expensive

3D Printer Type: Laser Metal Fusion | Materials: Stainless Steel, Tool Steels, Aluminum, Nickel-Based, Cobalt-Chrome, Titanium Alloys | Build Volume: 200 x 200 x 200 mm

*Bugs Bunny voice* What’s up, Doc? We got just the printer for you! *carrot crunch sound*

If you’re a doctor, dentist, or orthodontist looking for a great titanium 3D printer for medical implants, this is the one to get. The Trumpf TruPrint 2000 is a metal 3D printer specifically tailored to medical applications.

The TruPrint 2000 comes with two 300 W lasers for faster output. It’s also equipped with a 55 micron focus diameter. This allows prints to have smooth surfaces and better print quality than with bigger focus diameters.

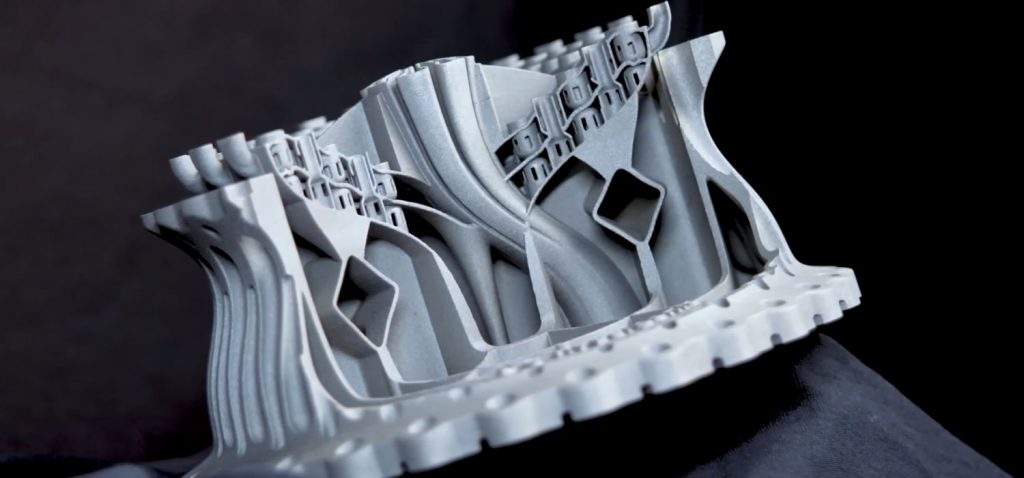

It has a relatively smaller build volume of 200 x 200 x 200 mm which is ample space for most medical applications but wouldn’t be really suited to aerospace and the like. It can print complex geometries that are quite literally impossible to manufacture traditionally.

This printer doesn’t require many add-ons, so it ends up being relatively affordable compared to some other metal 3D printers.

As an example, the TruPrint 2000 can print spinal fusion cages, with the 55 micron laser aiding massively in creating those intricate structures.

This printer is also capable of producing nineteen implants in 24 hours. If you need a metal 3D printer to print high-quality medical devices at an amazing speed, this is it.

Pros

- More affordable than other metal 3D printers

- Fast output

- Tailored to medical applications

Cons

- Smaller build volume than other printers on this list

3D Printer Type: Selective Laser Melting | Materials: Stainless Steel 316L, Titanium Ti64, Aluminum AlSi10Mg, Titanium (Ti6Al4V) | Build Volume: 500 x 280 x 365 mm

Time to bring out the big guns!

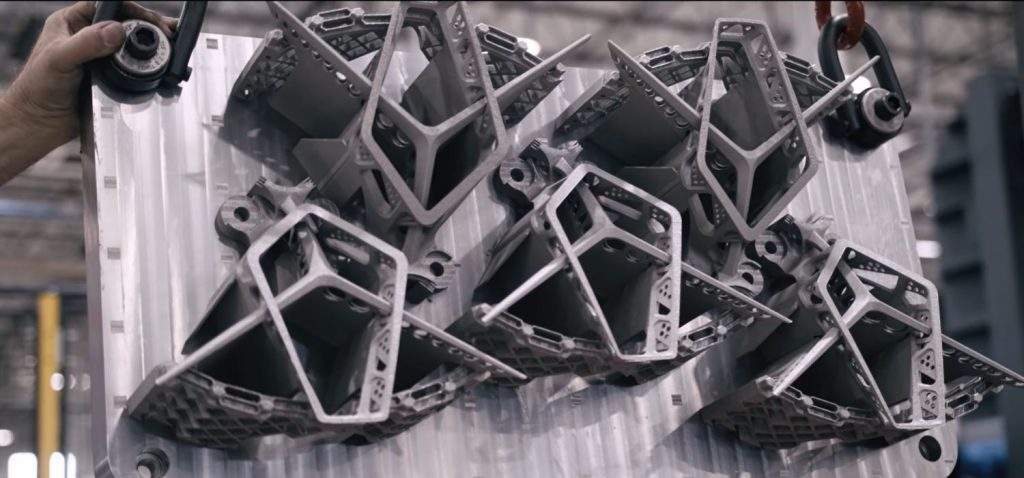

With a build volume of a whopping 500 x 280 x 365 mm, the SLM 500 doesn’t play. It comes in two options: first, the Twin model which comes with two 400 Watt lasers or two 700W lasers.

Or you can opt for the Quad model with four 400 W lasers or four 700 W lasers.

The SLM 500 is best for large automotive and aerospace applications that require a larger build volume, as well as faster print speed.

It’s got a build speed of up to 171 cubic centimeters per hour. Pretty darn fast. In fact, we would venture to say that the SLM 500 is kind of like a 3D printer Bugatti.

SPEAKING OF WHICH, Bugatti, the company, actually went ahead and used this 3D printer to print brake calipers for the Bugatti Chiron. One brake caliper took just about 45 hours of printing and can withstand forces of 125 kg per mm2. WOW.

The SLM 500 comes with a laser power monitoring system that, like its name says, monitors laser power and warns you about any areas with laser power deviation.

At 2400 kg, this machine is a heavyweight — so if you need to build big stuff, this is the one for you.

Pros

- Perfect for aerospace or automotive industry applications

- Lots of space to print

Cons

- Expensive

3D Printer Type: Laser Power Bed Fusion | Materials: Titanium, Nickel, Steel, Copper & Aluminum | Build Volume: 315mm Ø x 400mm Z

Want to venture into the world of infinite geometries — printing crazy stuff like overhangs and holes with no supports?

“It’s not real,” the naysayers might tell you. But oh boy, is it real.

The Velo3D Sapphire is a metal 3D printer that allows for support-free metal 3D printing with its unique design. So if you want a flexible titanium 3D printer that you can create super complex designs with (without the need for support), this is your printer.

This printer comes in two models — the Sapphire and the Sapphire 1MZ. The Sapphire has a build volume of 315 x 400 mm while the Sapphire 1MZ comes at a HUMONGOUS build volume of 315 x 1000 mm for taller builds.

It uses a process called solid printing to eliminate supports, enabling you to print overhangs down to just ZERO degrees, low angles, as well as holes and inner tubes from 100 mm to 500 mm. And not a single support.

Also, thanks to the lack of support, there’s no need to post-process these parts — which can save you a lot of time and money.

This printer is also really, REALLY fast, with the ability to run up to 8 times faster than a single laser machine.

Pros

- Support free printing for complex designs

- One of the biggest build volumes among SLM printers today

- Super fast

Cons

- Expensive

What is Titanium 3D Printing?

Titanium 3D printing refers to the process of 3D printing titanium to produce metal parts. Amazing!

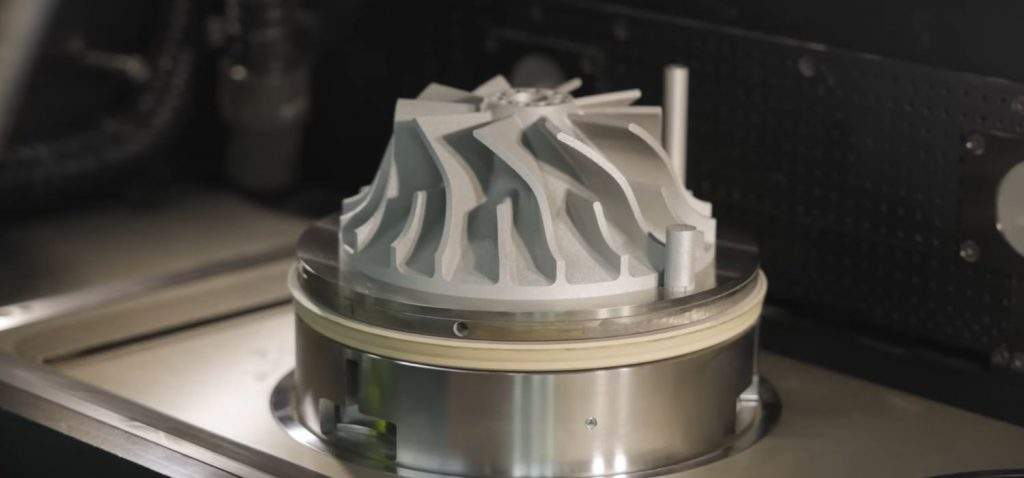

Seriously though — the way it works is that titanium is converted into a metal powder, and that powder is used in metal 3D printers to print titanium parts — most often through the use of a laser to produce your design layer by layer.

Titanium is super common — in fact, if not the most common — metal used in 3D printing because it’s as strong as steel and nearly half as heavy. This mechanical property lends itself well to a whole bunch of different applications, from aerospace to dentistry.

A note for 3D printing titanium: Whenever you print a metal, your build plate has to be the same material as the material you are printing. So if you want to print titanium stuff, make sure you always get a titanium build plate along with your printer.

What Can You 3D Print with Titanium?

So anything you can traditionally make out of metal, you can 3D print with titanium. Actually, scratch that — you can print models and designs of high complexity that are IMPOSSIBLE to build with traditional CNC manufacturing.

Mostly, people print parts for cars as well as medical and dental implants with titanium 3D printers. Since titanium is a biocompatible material, it is safe and approved for usage in patients. However, always make sure to buy metal powders from reputable vendors only.

If you’re specifically looking for a 3D printer for dentistry read our article here.

What Titaniums Use in 3D Printing?

Titanium is used mostly in aerospace, healthcare, as well as automotive industry, and even electronics. It’s strong and lightweight, and this makes it useful in so many different applications.

Heck, there’s even a whole song about it! (Thank you, Sia and David Guetta, for publicizing this glorious metal.)

Advantages of 3D Printing Titanium

Price

First of all, making stuff out of titanium using traditional manufacturing methods can be pretty expensive. But with 3D printers, the cost per part is greatly reduced. And there’s no need to source parts from other places.

Efficiency and Low Waste

There’s a lot of material waste in traditional metal manufacturing and even high energy consumption.

3D printing, however, enables more efficient and relatively more eco-friendly manufacturing (don’t get us wrong — 3D printing has its environmental downsides too, but not nearly as much as traditional manufacturing). By using only what is necessary to make a print, titanium 3D printing cuts down on a lot of material waste and consequently, cost.

Freedom of Design

With traditional metal manufacturing, you don’t get much room for cool designs.

3D printing turns that on its head and enables you to make complex designs — and it becomes just a walk in the park.

Disadvantages of 3D Printing Titanium

Post-processing

With 3D printing metals, you’re most probably going to be removing support structures after printing — as well as sanding and other post-processing stuff. So that’s kind of a bummer.

Price

Weird how this is both a pro and a con, but let us explain.

3D printing equipment, though saving costs in the long run, is initially pretty expensive.

Strength

Don’t get us wrong — while 3D printed parts can be pretty strong, sometimes they aren’t as strong as traditionally manufactured parts. This varies from printer to printer and depends on each use case, but a lot of industries are using 3D printed parts just fine.

However, for some applications, the technology just isn’t ready to replace traditional manufacturing just yet. We hope to see it happen in the coming future though!

What 3D Printer Technology Supports Titanium?

Direct Energy Deposition (DED)

Directed Energy Deposition (DED) is an additive manufacturing (3D printing) method which uses lasers and energy beams to melt a material deposited by a nozzle.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is an additive manufacturing process in which a powdered metal is melted by a high-energy beam of electrons.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a metal additive manufacturing process that melts powder with lasers. Read our guide to learn more about SLM 3D printers.

Laser Powder Bed Fusion (LPBF)

Laser Powder Bed Fusion is a generic name for SLM 3D printing.

Selective Laser Sintering (SLS)

SLS (Selective Laser Sintering) uses (again) a laser to fuse metals together through sintering — which doesn’t make the metals reach their melting point. Sintering uses lasers to make a powder turn solid without melting it.

Binder Jetting

Binder jetting is yet another additive manufacturing process where a printhead puts liquid binding agent onto a powder bed. This is one of the fastest 3D printing processes out there.

So Which Is the Best Titanium 3D Printer?

If your top priority is speed, consider the Renishaw RenAM 500Q or the Velo3D Sapphire printers. The Velo3D Sapphire series is also great for complex designs and printing without support if that’s something you’re interested in.

If you’re looking for a great titanium 3D printer for medical, dental, or orthodontic devices, the Trumpf Truprint 2000 is your best bet.

If you want a printer specifically for automotive or aerospace applications, go for the EOS M 290 or the SLM Solutions SLM 500.