PLA and ABS are the king and queen of 3D printing filament materials, both offering unique properties that attract a certain type of 3D printing enthusiast. However, the two types of filaments have many differences.

On one hand, PLA is super easy to print, requiring very low printing temperatures, but prints made with this material tend to be brittle and weak. On the flip side, ABS produces much stronger and mechanically superior parts at the expense of printability and temperature requirements.

For whatever model you’re printing, you should consider using PLA or ABS, as both materials are great options. If you want to learn more about how the two filament materials differ, read on!

Table of Contents

What Is ABS Filament?

Before we get into the differences between ABS and PLA, discussing each material individually can help in our comparison later. We’ll start with ABS, which is a type of thermoplastic sourced from petroleum and natural gas. Its scientific name is acrylonitrile butadiene styrene, but most people refer to plastic as ABS.

ABS filament is notoriously difficult to print as the plastic has a high melting point and glass transition temperature (point where the filament softens). Not only does the filament require more powerful heating components than more traditional 3D printing materials like PLA, but ABS is also a sensitive material and small changes in temperature or print settings can yield drastically different prints. Therefore, it’s recommended to have some experience with 3D printing before using ABS as you’ll need to fine tune your slicer settings to suit the filament.

However, with its increased printing difficulty also comes higher strength for ABS. Moreover, ABS prints aren’t as brittle as most 3D prints in other materials. Additionally, the plastic is also the slightest bit flexible, which is great for impact resistance most important quality of ABS. Overall, ABS is a great filament material for those with some 3D printing experience who are printing models that will face physical stresses where strength is needed.

Check out our article about how to smooth ABS prints and the best ABS 3D printers.

What Is PLA Filament?

Polylactic acid, or PLA, is another type of thermoplastic, but it’s sourced from natural plants, like corn, potatoes, and sugar cane. Largely because of its all-natural beginnings, PLA is food safe and non-toxic. PLA plastic is the most popular 3D printing filament material, due to its low cost, wide availability, and easy printability.

Furthermore, PLA has pretty low temperature requirements and doesn’t even always require a heated bed. As such, almost any 3D printer is compatible with PLA filament. Additionally, PLA isn’t very sensitive to print settings (not as much as other materials), and it’s easy to achieve decent quality 3D prints without much tuning to your machine or slicer profile.

Unfortunately, the trade-off with PLA’s super easy workability is its mechanical properties. PLA prints are known to be brittle and weak; the material also softens and deforms under UV light (e.g. sun) and hot outdoor temperatures. For these reasons, PLA is a great filament option for those just getting into 3D printing who don’t want to work too hard to achieve decent prints and those not concerned with printing high-strength models.

Check out our other articles about PLA: PLA Not Sticking to Bed & Is PLA Biodegradable.

Differences between ABS and PLA filament

Now that you know some important background information about ABS and PLA, let’s dive into how the two materials are different.

To start at the beginning (literally), ABS and PLA are sourced from significantly different raw materials. While PLA is made from all-natural substances from crops like potatoes and corn, ABS is made from non-renewable energy sources like petroleum and natural gas.

Due to ABS’s unnatural sources, it comes as no surprise that the material isn’t biodegradable. PLA, though, is biodegradable, though for parts to fully decompose will take hundreds of years. Nonetheless, PLA is the better option for those who have concerns about their environmental impact.

For the same reasons, PLA is also the more food safe option compared to ABS. While PLA is typically considered a food-safe plastic as it originates from food safe substances, ABS is widely considered a toxic or non-food-safe plastic. As such, we suggest using PLA over ABS in any case where you’ll be printing a model that will contact food, such as a fruit bowl.

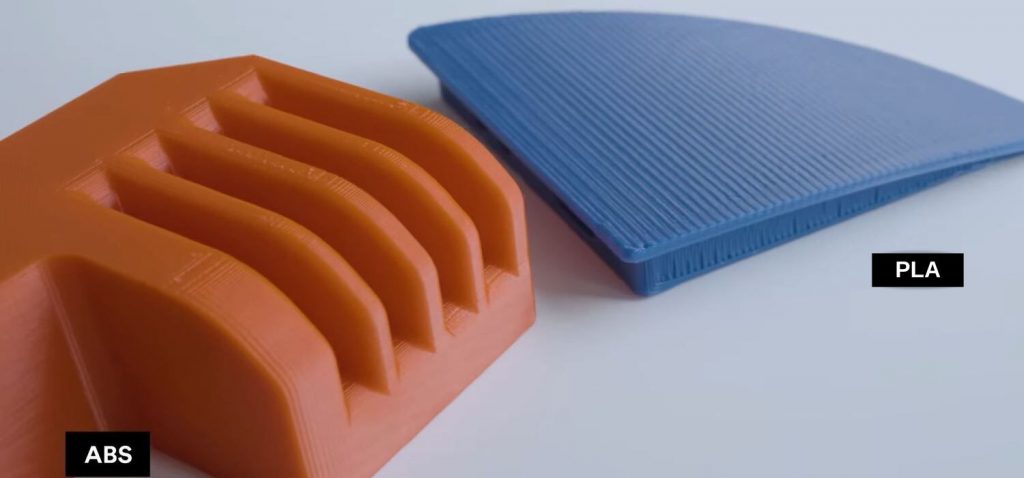

ABS also has far superior mechanical properties compared to PLA. Not only does ABS have a higher tensile strength than PLA, but the petroleum-based plastic’s slight flexibility also makes it more impact resistant. Sadly, PLA is much weaker and parts printed in this material tend to be very brittle, breaking easily under any physical stresses.

On a similar note, ABS has some other physical properties that make it a more durable material for 3D printed parts. If you print a model in PLA and leave it outside, under the sun, for a few hours, the part will likely soften and deform. ABS’s higher glass transition temperature makes it more heat resistant than PLA and it’s also more UV-resistant so sunlight won’t as easily deform the part.

The downside of ABS’s increased strength and durability over PLA is a more challenging printing experience. This starts with the required hardware to print the material.

To 3D print this material, your printer must be capable of reaching around 250 °C for the nozzle and 110 °C for the heated bed. PLA requires much lower temperatures, with 200 °C and 60 °C recommended for the nozzle and bed, respectively. This makes PLA a more compatible 3D printing filament material as basically every 3D printer can reach PLA’s suggested temperatures, but the same can not be said for ABS.

Additionally, PLA’s lower temperature requirements make for a slightly quicker printing experience because reaching a 60 °C bed temperature is much faster than reaching 110 °C for ABS. Although this doesn’t seem very significant, having to wait an extra few minutes for your machine to heat up to its printing temperatures can be pretty annoying.

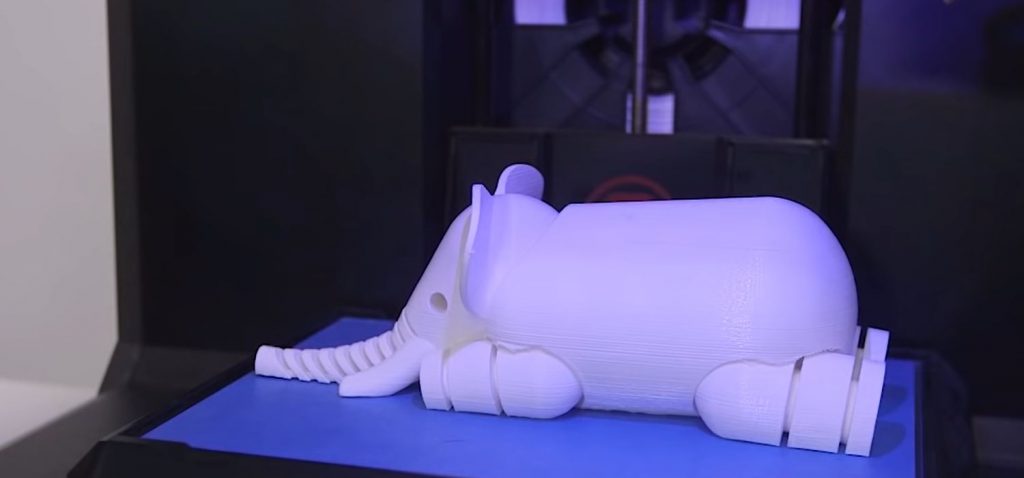

On top of a more powerful hot end and bed heater, you’ll also need an enclosure around your 3D printer to use ABS. That’s because the material is very sensitive to air drafts (e.g. wind gusts) and temperature changes and an enclosure will keep air drafts out while trapping heat in. The enclosure will ensure that your ABS prints turn out decent and if you don’t use one, your ABS prints will likely not properly adhere to the build plate, will have cracks on the sides, and more.

An enclosure is absolutely necessary to print ABS, but not many 3D printers come with one integrated into the frame, so many users have to build or buy an external one. PLA, on the other hand, isn’t as sensitive to factors like air drafts and small temperature changes, so an enclosure isn’t necessary. This is yet another indicator that PLA is the more compatible filament material!

Besides the necessary hardware to use ABS, the material is also more sensitive during the printing process. Moreover, changing your nozzle temperature just a little bit or using a slightly incorrect print setting (e.g. retraction) can cause major decreases to print quality. As such, you have to fine-tune your slicer profile to print ABS with high print quality. On the other hand, you can achieve excellent models in PLA with basically no tuning to a default slicer profile as the material isn’t as sensitive to changes in print specifications.

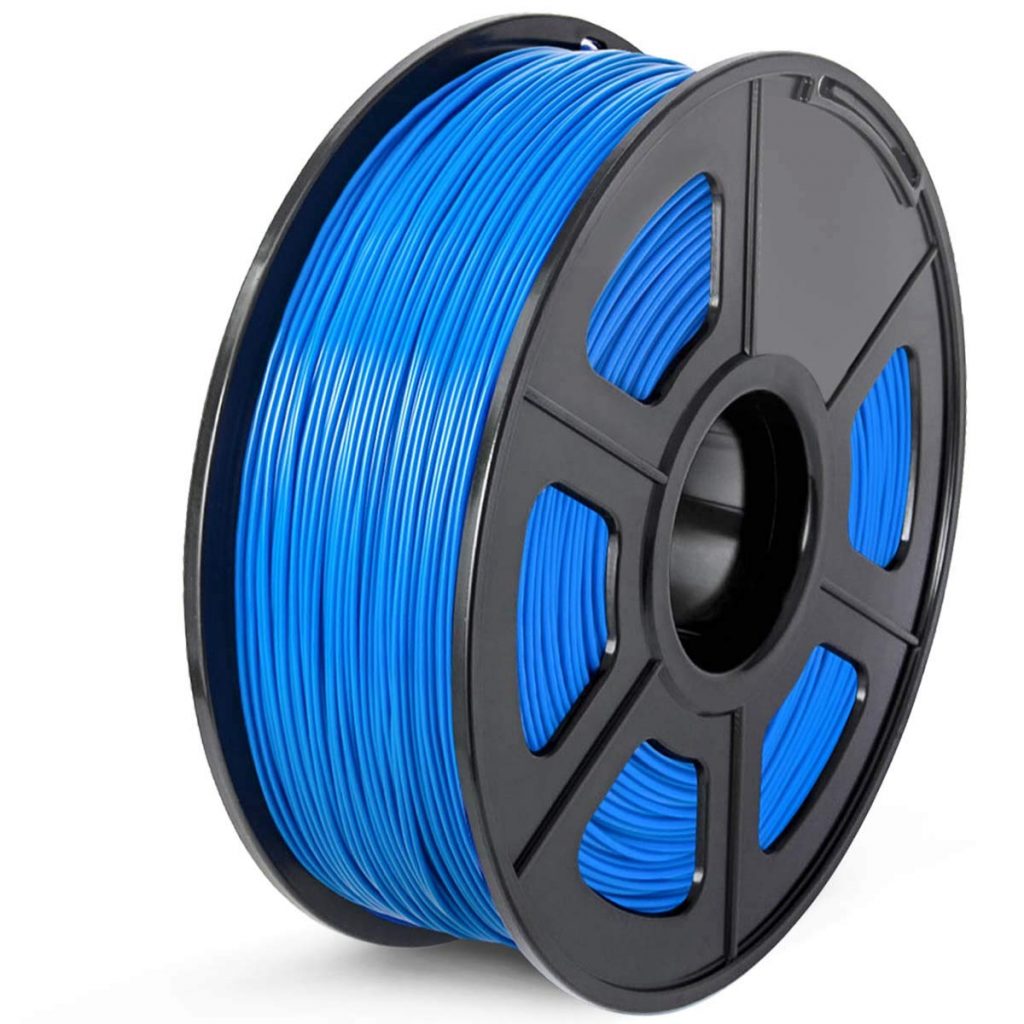

On a different note, it’s important to talk about the price of the different materials. ABS and PLA filament both cost about the same per kilogram, but ABS tends to be, on average, a dollar or two less. This is likely due to the fact that the raw materials for ABS are more commonly used in other fields, so they are easier to obtain compared to the materials for PLA.

Finally, let’s talk about how to store PLA and ABS filaments. Of the two materials, PLA is the more hygroscopic one, meaning it more quickly absorbs moisture from the air, which degrades the filament’s quality. Because of this, it’s advised to store your PLA filament in an air-tight container at all times to keep moisture out. While ABS is technically less hygroscopic, it’s still a good idea to keep the filament in an airtight container anyways.

What are the Best ABS Filaments?

Now that you know about ABS and PLA filament and their differences, let’s get into the best filament options for each material. We’ll start with ABS!

Hatchbox

Up first, Hatchbox ABS filament is one of the easiest ABS filaments to print as you can get away with using a nozzle temperature as low as 210 °C. The filament comes in over ten different colors too, including red, white, black, blue, yellow, and more. Additionally, the filament has a diameter tolerance of +/- 0.03 mm, which means you shouldn’t run into hot end jams.

But that’s not all! According to user reviews, the filament is easy to post-process as you can use acetone and other solvents to smooth the layers of your ABS 3D prints. The filament is also said to yield very strong prints and support structure pop off of models easily.

Sunlu

Second, Sunlu is a popular manufacturer of 3D printing supplies and their ABS filament is said to maintain a diameter tolerance of just +/- 0.02 mm. This is exceptionally low and indicates that there is only a very small chance that the filament will cause a hot end jam due to inconsistent diameters.

Sunlu ABS filament comes in five colors, including black, red, grey, blue, and white. While this doesn’t give you too many options, the filament makes up for it with it’s ease-of-use, and the filament only requires a bed temperature between 70 and 85 °C.

eSun

Our last ABS filament is from eSun, a popular manufacturer of 3D printing filaments. Their ABS filament is a few dollars more expensive than the other ABS filaments we mentioned, but may users consider it worth it due to eSun ABS’s excessive strength and how prints made in the material are not brittle at all. The filament comes in black, white, and grey, and also has a diameter tolerance of +/- 0.05 mm, which is fine.

Check out our article on the best ABS filament brands to learn more.

What are the Best PLA Filaments?

Next, it’s time to review some of the best PLA filaments! We’ve gone over a few of the best brands and options below!

Hatchbox

On top of making ABS filaments, Hatchbox also makes filaments in other materials, like PLA. Hatchbox PLA filament comes in almost twenty colors, like black, grey, green, lime green, yellow, and more. The filament has a diameter tolerance of +/- 0.03 mm, which is pretty good and should mean you won’t experience any (or many) hot end jams due to diameter differences throughout the spool.

The filament is known to yield somewhat weak and brittle parts, but this is more of a function of the PLA material and not the Hatchbox brand. Additionally, the filament is super easy to print with a low nozzle temperature requirement of just 180 °C. Many users cite that they were able to achieve excellent prints without much tuning to their slicer profile.

Sunlu

Just like with Hatchbox, Sunlu also makes both PLA and ABS filaments. Sunlu’s PLA filament comes in many colors, like light blue, black, glow-in-the-dark, silk silver, and more. The filament also maintains an impressive diameter tolerance of +/- 0.02 mm and is known to yield consistently high-quality models.

PolyMaker PolyMax

Lastly, PolyMaker is a developer of 3D printing filaments and accessories and PolyMax is the company’s line of extra-tough PLA filament. This blend of PLA is known for its high strength and its mechanical properties are very comparable to ABS, but with an easier printing experience. Moreover, the filament requires a bed temperature of only 50 °C with no enclosure necessary. PolyMax comes in over ten colors, like blue and white, but, sadly, it’s noticeably more expensive than the other PLA and ABS filaments we mentioned.

Check out our article about the Best PLA Filament Brands.

Conclusion

Overall, both PLA and ABS are great filament materials that you should consider using. For strong models that will face physical stresses, ABS is the better option, though you’ll need to have some more advanced hardware and some experience with 3D printing to achieve good prints. On the other hand, PLA is the better filament material if you’re new to 3D printing and want an easy printing experience and don’t need exceptional mechanical properties.