- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

The hot end is perhaps the most essential part of a 3D printer. Without it, an FDM 3D printer wouldn’t be able to melt filament, which is basically the most important step in the 3D printing process.

The hot end is perhaps the most essential part of a 3D printer. Without it, an FDM 3D printer wouldn’t be able to melt filament, which is basically the most important step in the 3D printing process.

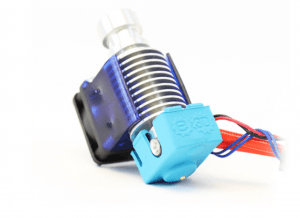

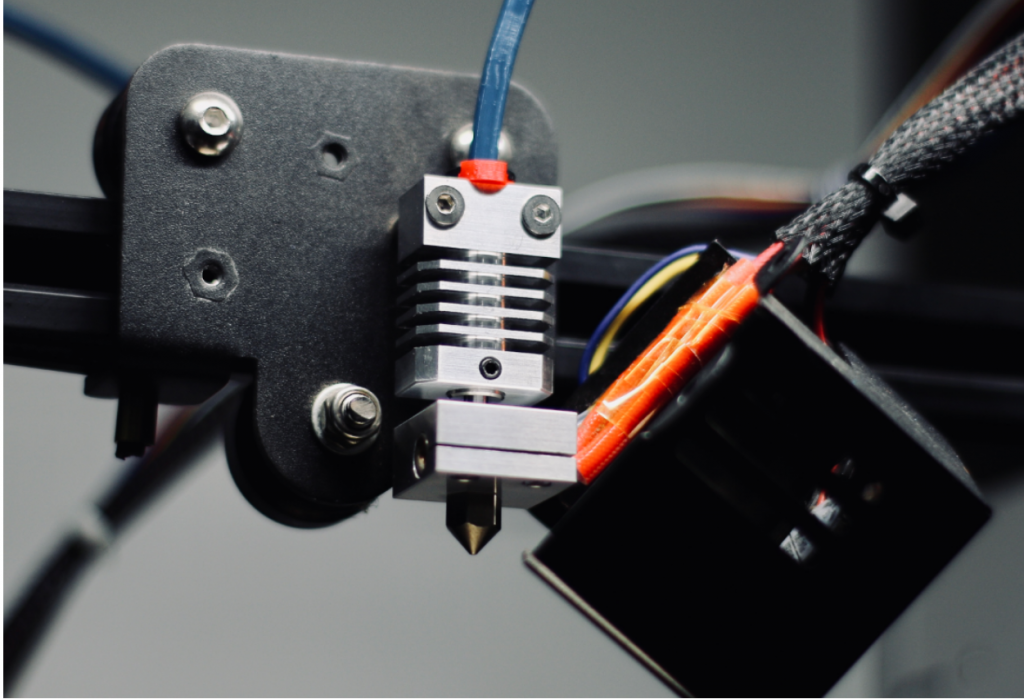

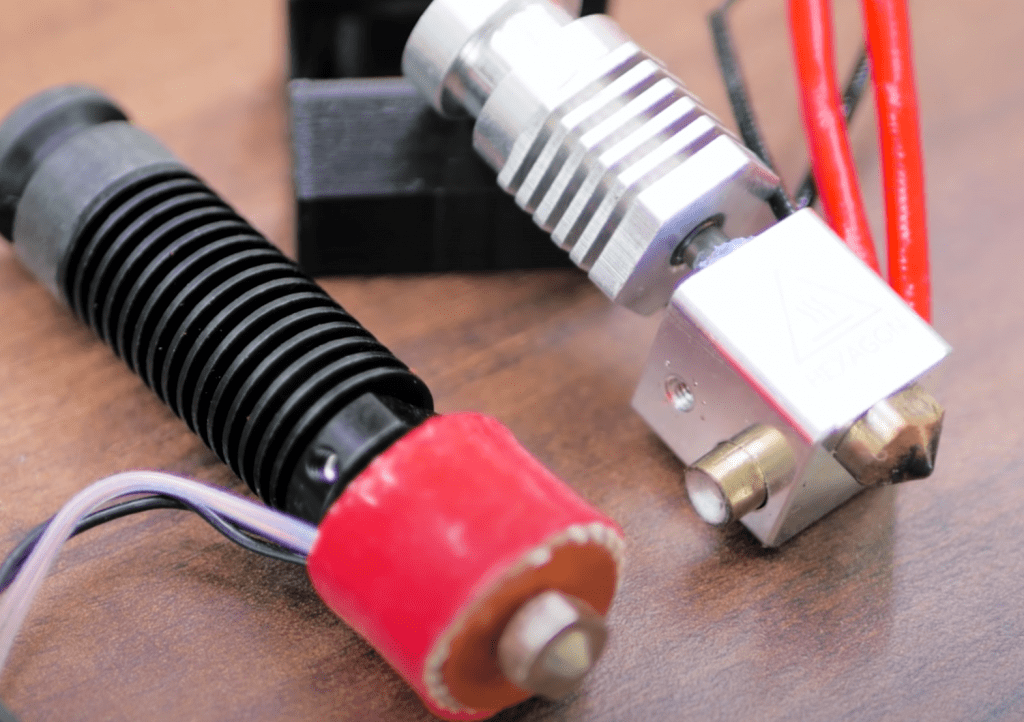

If you’re unfamiliar with the term, a “hot end” is the assembly on a 3D printer that gets very, very hot and melts your plastic filament so it can come out of the nozzle. The hot end is usually behind a fan shroud, and the nozzle is screwed into the bottom of this assembly.

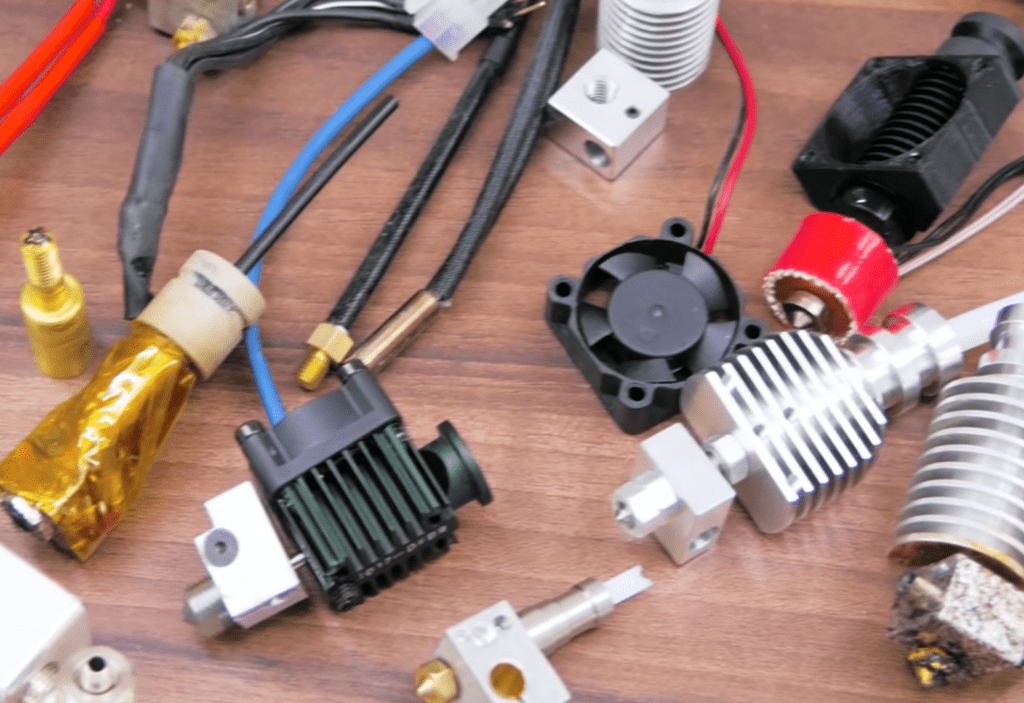

Today, there are hundreds of different 3D printer hot ends out there, each with different features, temperature capabilities, and compatible hardware. It’s important to get a good hot end because the hot end controls what filament materials you can use and the reliability of your printer’s extrusion.

If you’re in the market for a new 3D printer hot end, I strongly suggest getting the E3D V6 or E3D Revo Six. Both hot ends have very high-temperature capabilities, are compatible with many different printers and filaments, and are reliable options. The Slicer Engineering Mosquito is another great option too, with an even high-temperature limit!

Want to hear about more of the best 3D printer hot-end options? Just keep reading!

Best 3D Printer Hot End At A Glance

1. E3D V6 (Best Value)

2. E3D RapidChange Revo Six (Best Choice)

3. MicroSwiss All-Metal Hot End

4. Slice Engineering Mosquito(Premium Choice)

5. BIQU Dragon Fly

6. E3D Hemera

The E3D V6 is one of the most classic hot-end options for 3D printers. Developed by E3D, a very reputable manufacturer of 3D printer hot ends, the V6 has been around for close to ten years, and its performance is still very high-end today!

The E3D V6 is an all metal hot end, meaning it doesn’t have a PTFE liner. As such, it can reach 300 °C without any internal damage.

This is insane, considering the relatively low cost of the E3D V6. Additionally, this high maximum temperature means you can print a wide variety of filament materials from PLA to polycarbonate.

And, even while printing at 300 °C, you shouldn’t have to worry about heat creep, which is when the hot jams due to heat reaching filament too early. That’s because of the intuitively-designed cylindrical heat sink on the E3D V6 that provides exceptional heat dissipation for the assembly.

But what I love most about the E3D V6 isn’t its temperature capabilities but instead its wide compatibility. On top of working with basically any filament material, the E3D V6 can fit on basically any 3D printer through the many available user-designed 3D printable mounts for different machines.

The E3D V6 is one of the best hot ends ever made, and due to its budget-friendliness, wide compatibility, and high-temperature range, it will make an excellent upgrade for your 3D printer.

Pros

- Great community support; just check Reddit!

- Many 3D printable mounts to expand its compatibility

- Available in 12V and 24V

- Maximum temperature of 300 °C; works with any filament material

- Very reliable

- Well-designed heat sink for preventing heat creep

Cons

- Replaced by later versions (e.g. E3D Revo Six)

- Pretty weak hot-end fan

- No PTFE liner means more friction for the filament extrusion process

Next, we have another product from E3D: the RapidChange Revo Six. The Revo Six is supposed to be the replacement for the E3D V6, though the E3D V6 is still being made.

The Revo Six came out in 2021 and is one of the most innovative hot-end products out there. That’s because of the integration of E3D’s new RapidChange technology, a system that makes swapping nozzles a breeze.

Moreover, each nozzle for the Revo Six has an integrated heat break (throat), and there’s a spring at the end of the actual hot-end assembly. As such, if you want to swap nozzles on the Revo Six, all you have to do is loosen the thumbscrew on the nozzle, pop out the old nozzle, and stick the new nozzle right in!

On top of making the process a lot less physical work, you also are able to make nozzle swaps without heating up the hot end due to the integration of a heat break. It’s a total lifesaver!

Besides the RapidChange system, the features on the E3D Revo Six are similar to those of the original E3D V6, with a maximum nozzle temp of 300 °C and a cylindrical heat sink. But E3D stepped it up with the heater, using a 40W heater, which can heat up the nozzle much faster than the V6’s 30W heater cartridge.

So, if you hate changing out the nozzle or just want a cutting-edge hot end that’s powerful and reliable, the E3D Revo Six is a terrific choice!

Pros

- RapidChange technology for easy nozzle swaps

- High maximum temperature

- Powerful and fast 40W heater

- Cylindrical heat sink; provides great heat dissipation

- Very reliable

- A good bang for your buck

Cons

- Fairly new; relatively not as much community support available

- You can only use E3D nozzles

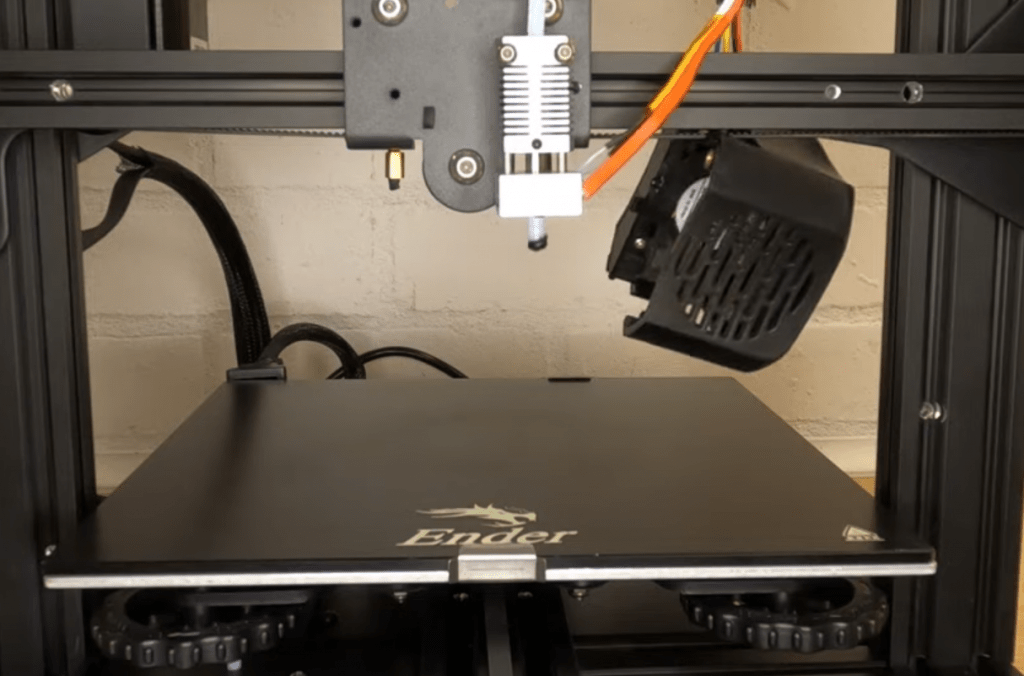

MicroSwiss makes all sorts of 3D printer hardware, including nozzles, extruder assemblies, and even a hot end. The MicroSwiss All Metal Hot End is a very reliable option that fits perfectly for the Creality Ender 3 (Pro/V2), CR-10, and many other printers.

Hence the name of the product, the MicroSwiss hot end is all-metal, with no PTFE liner. As such, you can print with the maximum temperature of 285 °C without any damage to the hot end components. While 285 °C isn’t as high as other products, it’s still enough to print most materials, like PLA, ABS, PETG, TPU, and Nylon.

But the best part of this hot end is its wide compatibility. Moreover, MicroSwiss mentions that this hot end is the same size (and voltage) as the stock hot ends on many Creality printers, as well as some by TronXY, Elegoo, Tevo, and other brands. Because of this, you can install the hot end super easily on these printers!

So, if you want a hot end that’s both easy to install and more powerful than the stock one on your 3D printer, then I suggest going with the MicroSwiss All-Metal Hot End!

Pros

- Easy to install on many 3D printers

- All-metal; won’t burn

- Reliable

Cons

- Relatively low maximum temperature

- Not very different from the stock hot ends on most 3D printers

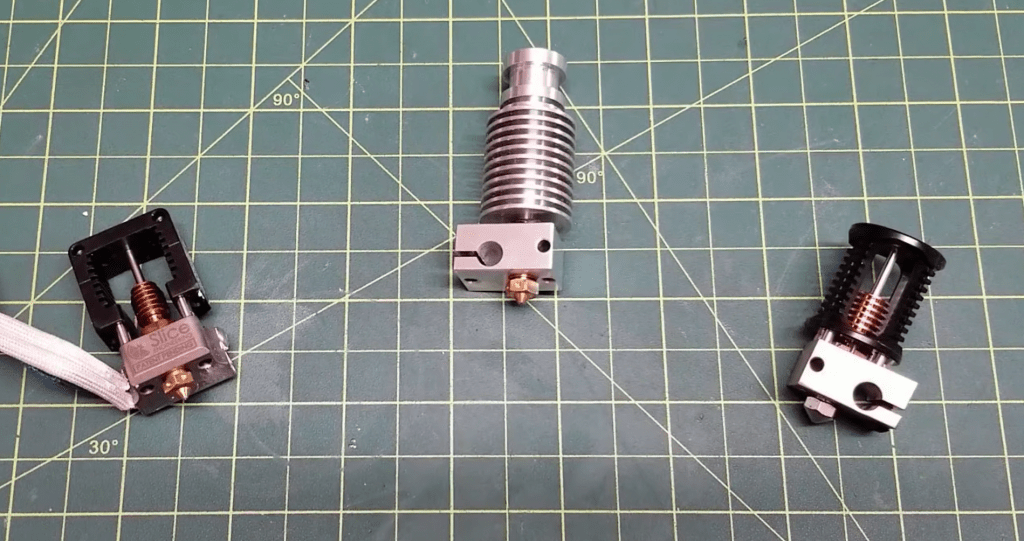

Slice Engineering is a company that specializes in making high-end 3D printer hot ends. The Mosquito is one of Slicer Engineering’s flagship products, and it’s one heck of a hot end.

With a true (and tested) maximum temperature of 500 °C, the Mosquito can handle any filament material you give it, including PETG, PC, nylon, and even PMMA! Additionally, the well-engineered heat break means extrusion flow will be super smooth.

And, if you like to just print PLA, then the Mosquito is still a great hot end, as its high-temperature capabilities mean you can use insanely high print speeds without any issues with extrusion. I’ve seen people use this hot end to print at 100+ mm/s speeds!

The Mosquito also has a very well-designed cooling system. Moreover, the heat sink on the Slice Engineering Mosquito has been designed using heavy research on heat and airflow. So, even when you use high temperatures, you likely won’t have issues like heat creep, where filament melts too early.

The only obvious downside of the Mosquito is its high price. But if money isn’t an issue, the Mosquito is an amazing choice for any printer!

Pros

- Insanely high maximum temperature

- Well-designed heat sink

- Well-engineered structure (durable)

- Very reliable

Cons

- Very expensive

- The maximum temperature isn’t very practical for most users

BIQU is a popular manufacturer of 3D printing accessories, from motherboards to hot ends. The BIQU Dragon Fly BMO is one of the company’s latest hot ends. Designed after the much-more-pricey Phaetus Dragonfly BMO, the BIQU Dragon Fly is a high-temperature hot end that’s compatible with printers like the Prusa i3 MK3S+, Creality Ender 3, and more!

The Dragon Fly hot end is specifically meant for maximum extrusion capabilities. This means it’s a great hot end if you want to print fast or use a very wide nozzle (e.g. 0.8-1.2 mm), where a high filament flow is required.

And the Dragon Fly has the specs to substantiate high extrusion flow! Moreover, according to the manufacturer, the BIQU Dragon Fly is resistant up to 500 °C, which is insane. While you probably shouldn’t put it to more than 320 °C for safety reasons, it’s still a crazy-high maximum temperature.

With this much heat, you’ll be able to print whatever filament material you want, from PLA to PC, and also use very high print speeds for maximum extrusion flow.

So definitely give the BIQU Dragon Fly hot end a chance if you’re looking for a low-cost hot end that can handle super-fast and high-flow 3D printing.

Pros

- Very high maximum temperature

- Not many mounting options available

- High-flow; can handle fast speeds

Cons

- It’s not as good as the official Phaetus Dragonfly hot end

- Likely not safe to print at a temperature of 500°C

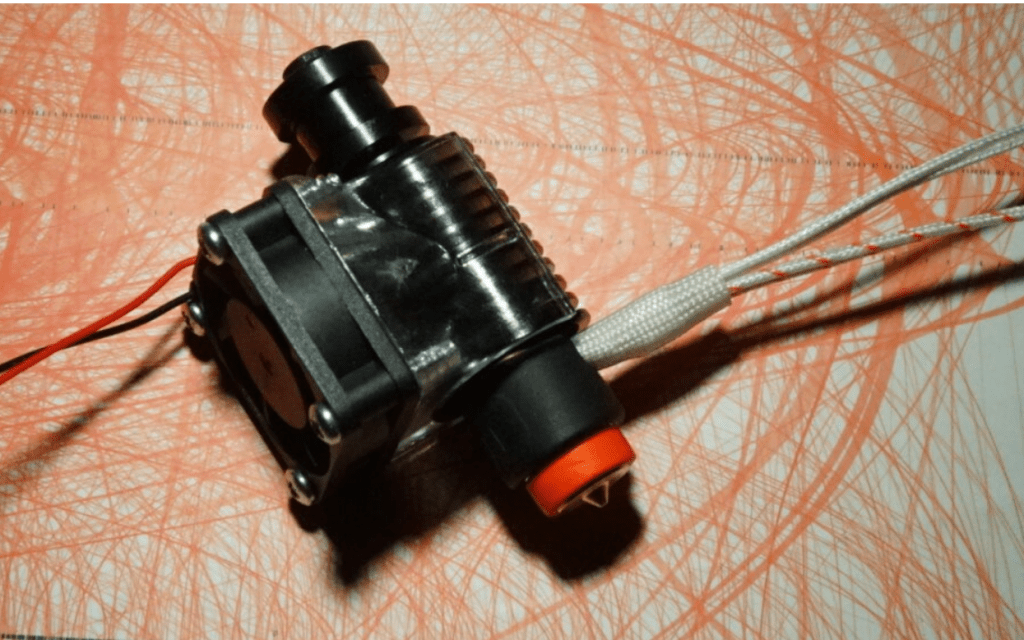

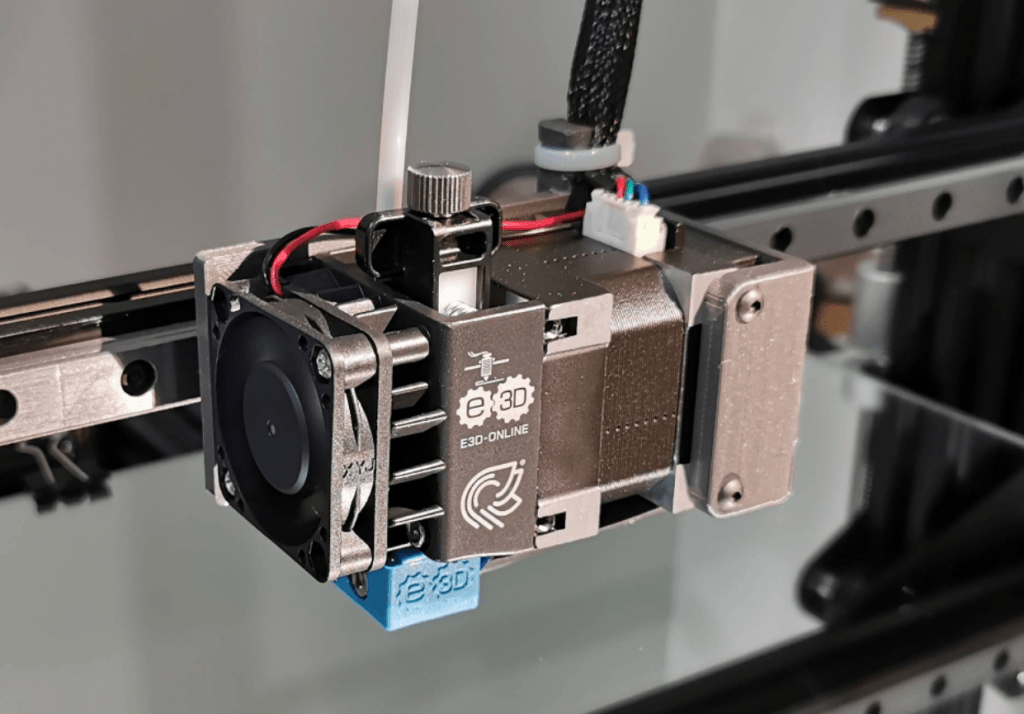

Our last hot end option is the E3D Hemera, yet another product for the famous manufacturer E3D. The Hemera, unlike some of the other hot ends on this list, is both an extruder and a hot end combined into one assembly. As such, it’s meant to be used in a direct drive configuration.

The Hemera is easily one of my top-10 favorite 3D printing products out there. That’s because the product not only performs well when it comes to the hot end side of things but also with the extruder.

Moreover, the E3D Hemera has a maximum temperature of 300 °C, so it can print basically any filament material you throw at it, from PLA and ABS to nylon and polycarbonate. And, because it’s a direct drive extruder, flexible materials, like TPU and TPE, will print very nicely.

As for the extruder, the Hemera features an E3D-custom-built stepper motor that’s geared at 3:1 for maximum pushing power. Additionally, the actual extruder assembly is dual-drive, meaning there are two drive gears rather than one drive gear and one idle bearing. As such, the Hemera provides very accurate and reliable filament extrusion.

Lastly, it’s worth mentioning that the E3D Hemera has a specialized heat sink designed using airflow research to provide maximum cooling to the hot end. This means issues like heat creep aren’t likely.

So, if you need a do-it-all hot end product that gives you high-temperature heating capabilities with an integrated extruder, then the E3D Hemera is definitely the one for you!

Pros

- Integrated extruder; direct drive

- Very powerful extruder

- Easy mounting options

- A lot of community support

- High-temperature capabilities

- Well-designed heat sink

Cons

- Heavier than a standalone hot end

- No part cooling fan included

What Is a Hot End?

A hot end is perhaps the most essential part of a 3D printer, responsible for melting filament and giving it a clear path to the nozzle.

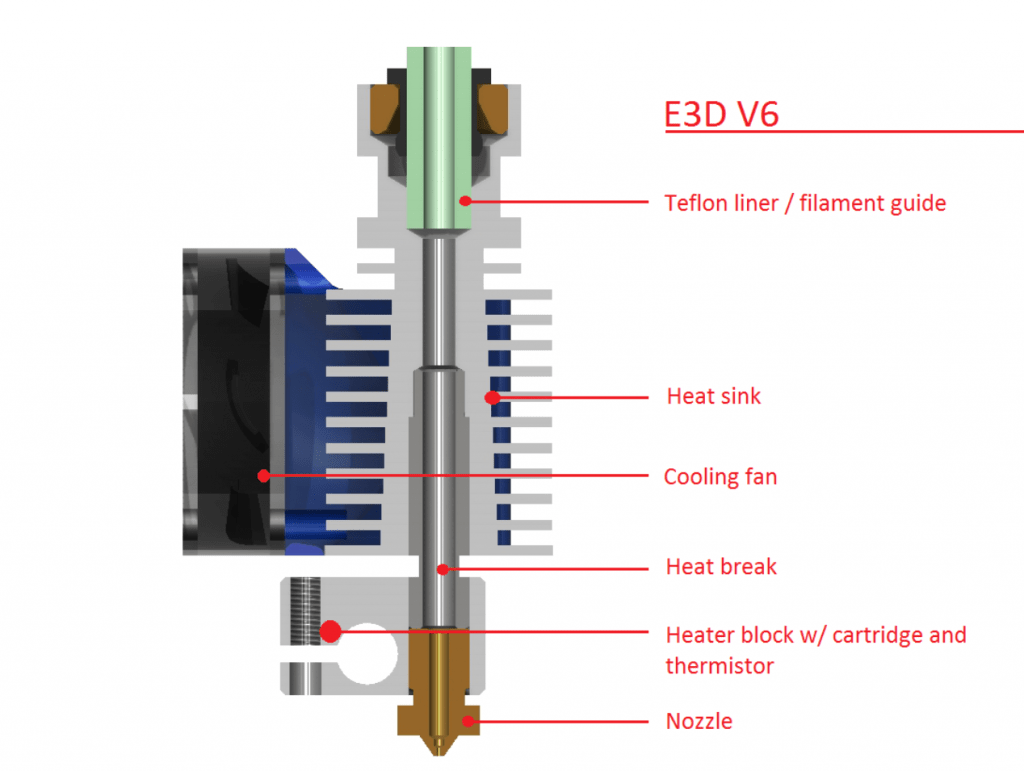

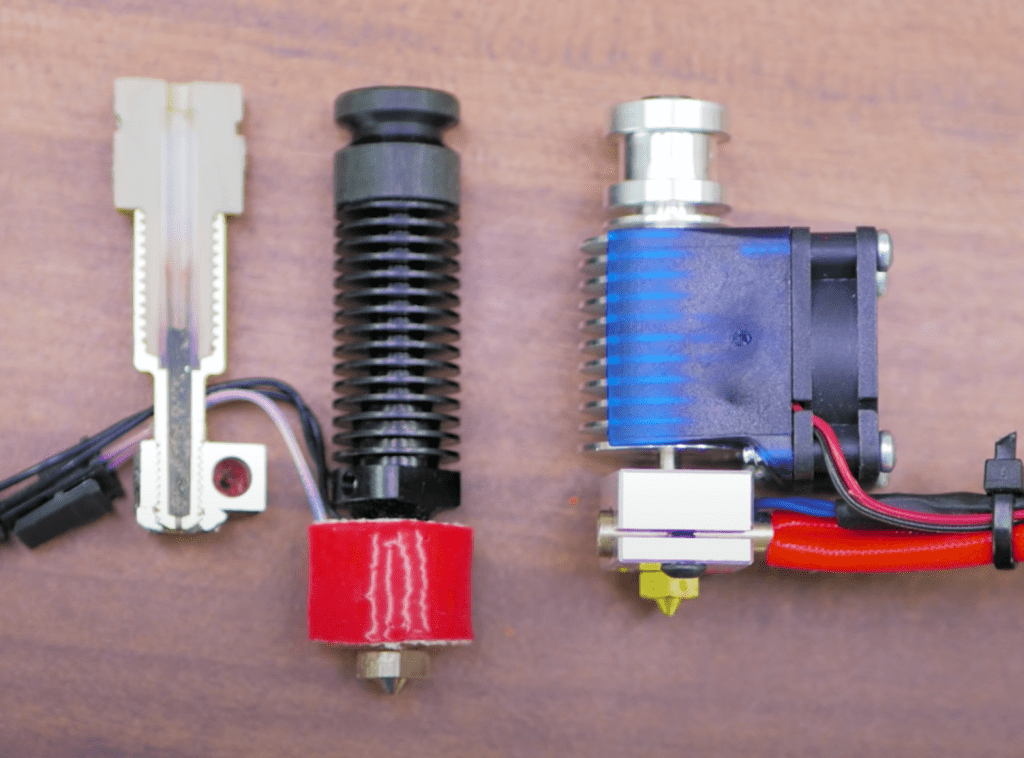

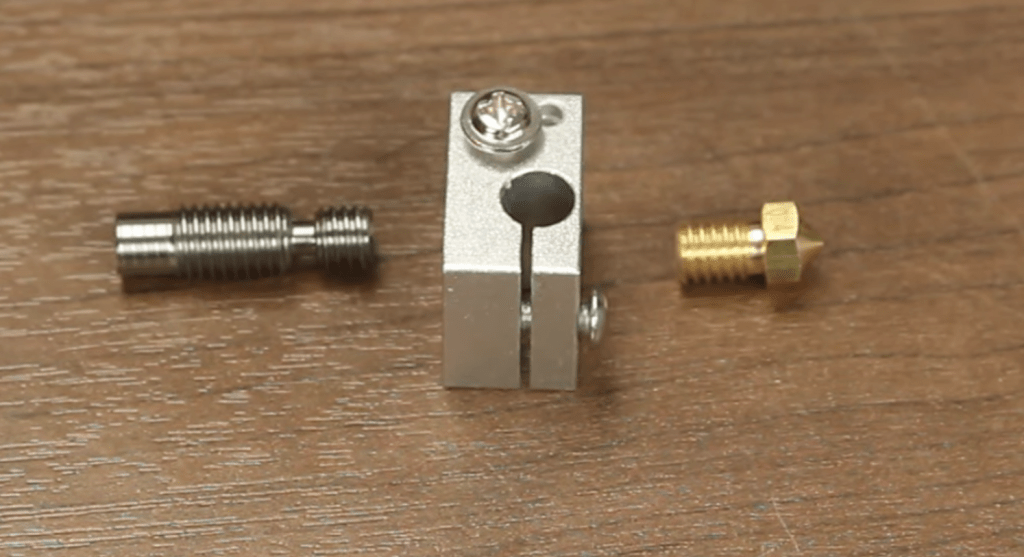

Hot ends are only on FDM 3D printers, and they typically consist of a heat sink, heat break (throat), heater block, heater cartridge, thermistor wire, nozzle, and PTFE coupler. Below you can see a diagram of a hot end with each part labeled:

Without a hot end, an FDM 3D printer simply could not function. And a low-quality one will yield very inconsistent extrusion, leading to ugly and inaccurate prints. As such, make sure you get a good one, like one of the options we went over previously!

Considerations When Picking a Hot End

When choosing what hot end to use on your 3D printer, there are a few important factors to keep in mind. I’ve gone over these considerations in the mini sections below:

Maximum Temperature

The most important element of a 3D printer’s hot end is the maximum temperature it can reach. This is usually dependent on the type of metal used for the heater block and the quality of the heater cartridge and thermistor cables.

The higher the maximum temperature, the more filament materials a hot end can handle. For example, a hot end that can only reach 250 °C can print PLA and ABS. But one that can get up to 300 °C can print PLA, ABS, PETG, carbon fiber composites, TPU, TPE, and so many other options.

3D Printer Compatibility

Not all hot ends are compatible with all 3D printers. The compatibility of a hot end with a 3D printer depends on the voltage of the hot end’s electronics, the mounting screws, and the size/shape of the assembly.

You can check the compatibility of a hot end with a certain 3D printer by looking up the following “<name of hot end> on <name of 3D printer>” and checking Reddit and other forums.

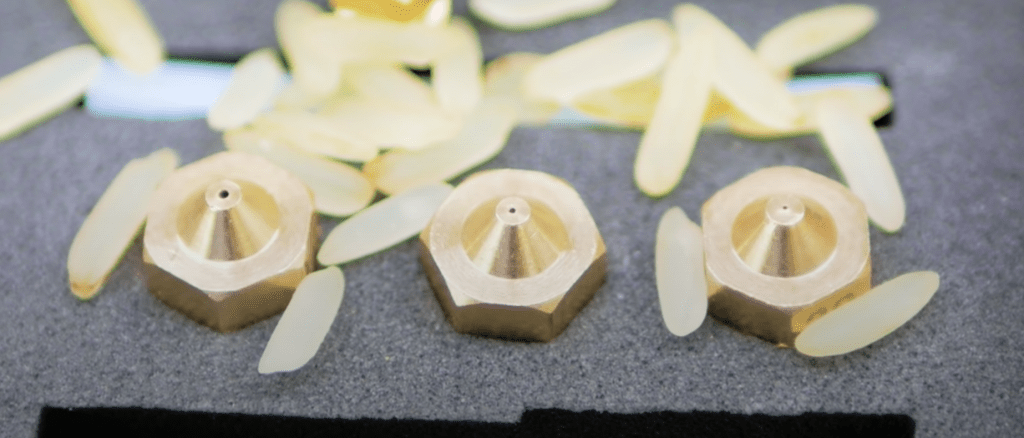

Nozzle Compatibility

On top of looking at the compatibility of a hot end on a 3D printer’s frame, you should also look at what nozzles work with the assembly. Depending on the nozzle thread of a 3D printer hot end, only certain nozzles will work.

The two most common hot end nozzle threads are M6 and M7. You also might see hot ends listed as either MK6, MK8, and MK10. The first two types have M6 threads, so nozzles are interchangeable between them. On the other hand, an MK10 hot end has an M7 thread.

Reliability

Reliability is another very important consideration for a hot end that outlines how consistent and dependable a hot end is. While there’s no easy metric for determining the reliability of a hot end, you can check the reviews to see what users have to say.

Value

Lastly, you should consider the value of the hot end you’re using. I like to think of “value” as the bang for your buck. I suggest keeping the value, or features-for-dollar, in mind, so you don’t overpay for only a slightly-better hot end.

When to Replace the 3D Printer’s Hot End?

Unlike the nozzle, replacing the hot end on a 3D printer isn’t something you should try to do every few months. Instead, you should only replace the hot end when it’s actually broken or failing you.

That’s because 3D printer hot ends can get somewhat expensive, costing anywhere from $20-200, so replacements shouldn’t be too frequent. Additionally, hot ends aren’t meant to be consumables like nozzles, so they should last you a very long time.

You’ll know when it’s time to replace your 3D printer’s hot end if the melted filament is oozing from the heater block or if any part of the assembly physically breaks. Additionally, if the threading for the nozzle is damaged, you’ll need to replace the hot end.

How to Replace the 3D Printer’s Hot End?

The process for replacing your 3D printer’s hot end will vary depending on what printer you have. However, the general process goes something like this:

- Turn on the printer.

- Heat up the hot end to your regular printing temperature.

- Remove the filament.

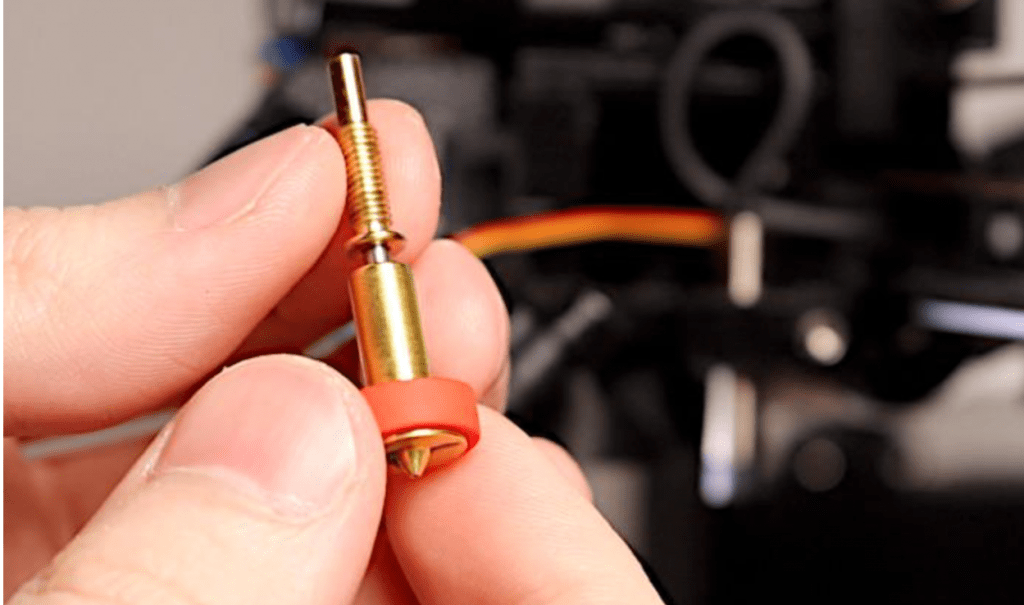

- Unscrew the nozzle.

- Unscrew the fan shroud and move it to the side.

- Wait for the hot end to cool down, and then unscrew the mounting bolts that hold the hot end assembly to the printhead carriage.

- Unscrew the PTFE tube coupler from the hot end assembly.

- Remove the PTFE tube.

- Open up the motherboard housing.

- Turn off your printer.

- Locate the hot end heater and thermistor cables on the motherboard and unplug them.

- Pull out the heater and thermistor wires and place your old hot end to the side.

- Wire the heater and thermistor wires of your new hot end to the motherboard. Plug them in securely.

- Screw the mounting bolts of the hot end into the printhead carriage. Make sure they’re very tight.

- Reattach the nozzle.

- Move the fan shroud back over the hot end assembly and screw it in.

And that’s it!

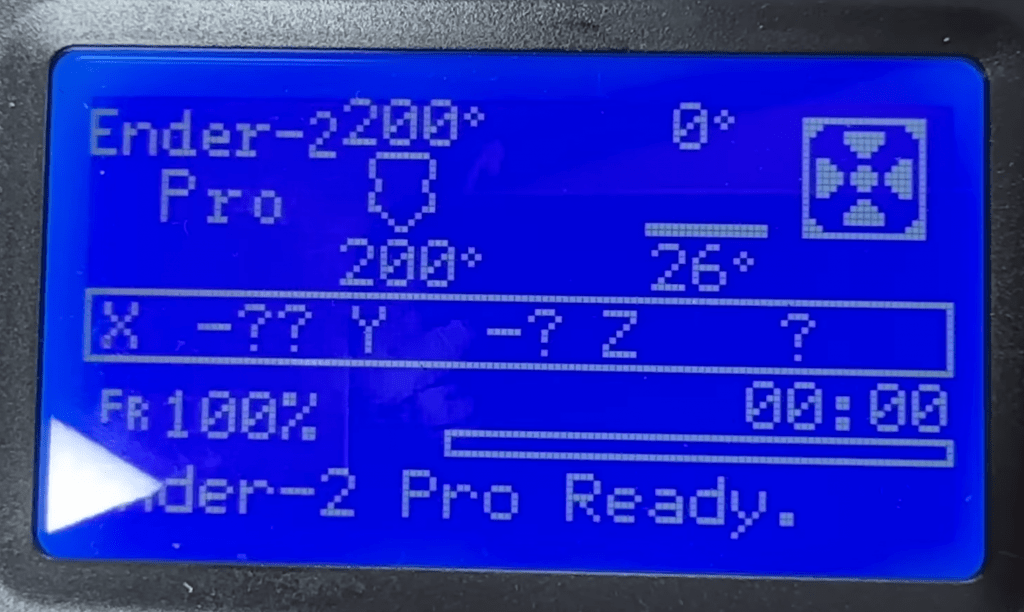

Of course, this process might not work for all printers, especially if your hot end isn’t natively compatible with your 3D printer. For example, if you’re installing an E3D hot end on a stock Creality Ender 3, you’ll need to change the firmware settings to account for the different thermistor wires.

But, for specific upgrades, you can check out the other articles on our site or the many video tutorials available online!

How to Clean the 3D Printer’s Hot End?

To clean your 3D printer’s hot end, start by turning on your printer and heating the nozzle up to your normal printing temperature. For PLA, this would be around 220 °C.

Once the hot end is actually hot, remove the filament from the printer. Make sure you pull it out of both the hot end and extruder assembly.

Next, remove the fan shroud from your printhead. You can usually do this by taking the right-size Allen Key and unscrewing the fan shroud mounting bolts.

Move the fan shroud to the side and then, with the right size spanner wrench, unscrew the nozzle. With the nozzle removed, take a peek at the inside of the hot end to see if it’s damaged at all. Damage will look like any obvious deformations to the metal.

If there’s no damage, you can start cleaning the hot end assembly. To do this, I like to get a small metal pic and tweezers and then go ham at pulling out guck from the inside of the hot end.

Once you remove all the large chunks, you can get an alcohol or acetone wipe (e.g. nail polish remover wipe), and, using the tweezers for safety, rub it around inside the hot end. If you do this while the hot end is still hot, it will be most effective. Just make sure you don’t leave the wipe there too long as it will burn if heated for too long.

And that’s it!

Difference Between the Hot End and Extruder

The difference between the hot end and the extruder is that one stays hot (the hot end, obviously), and one stays cold.

Moreover, the hot end, as we went over, is responsible for melting the incoming filament so that it can flow out of the attached nozzle.

On the other hand, the extruder, also known as the “cold end”, is the motor assembly that’s responsible for pushing filament into the hot end.

A Bowden extruder 3D printer, like the Ender 3 (Pro/V2), has the extruder on the left-hand side and the hot end on the printhead assembly. Direct drive 3D printers, like the Ender 3 S1, have the extruder right on top of the hot end assembly.

Conclusion

A hot end is super important for the 3D printing process, and because its impact on the printing process is so significant, you should make sure you’re using a high-quality hot end.

As we went over, a good hot end can reach high temperatures, fits on many printers, has good value, and is very reliable.

The best 3D printer hot end is easily either the E3D V6 or E3D RevoSix. Both products are affordable and can reach a temperature of 300 °C, which is crazy high and more than enough to print any filament material. Additionally, reliability and community support are spectacular for these products!

But, if you want the ultimate 3D printing hot end, then I’d go with the Slice Engineering Mosquito, the creme-de-la-creme of 3D printer hot ends. With an insanely high maximum temperature of 500 °C and a super effective heat sink, you’ll be unstoppable with this hot end by your side!

Enjoy!