- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

The nozzle is the last point on your 3D printer to touch the melted filament that will eventually turn out to be your 3D model.

The nozzle is the last point on your 3D printer to touch the melted filament that will eventually turn out to be your 3D model.

Using a low-quality nozzle (or the wrong type) can result in absolutely terrible prints, with issues like under extrusion and stringing running rampant.

As such, it’s vital to have the right nozzle for the job.

The E3D Hardened Steel nozzle is perhaps the best 3D printer nozzle on the market when it comes to general printing. It’s capable of handling a wide variety of filament materials, from PLA to polycarbonate, and doesn’t cost too much.

Another terrific choice is the MatterHackers CleanTip Nozzle, a very reliable option that can also print many different filaments.

If you want to learn more about the best 3D printer nozzle options, as well as what exactly makes a nozzle good for a 3D printer, keep reading!

Table of Contents

- Top 3D Printer Nozzles At A Glance

- What is a 3D Printer Nozzle?

- Why is the Nozzle Important?

- What to Look for in a Nozzle?

- What is a Bore Diameter?

- What are the Sizes/Diameters of the Nozzles?

- Nozzle Materials:

- Best Nozzle for PLA & ABS

- Best Nozzle for PETG

- Best Nozzle for TPU & Flexible Filament

- Best Nozzle for Ender 3 (V2/Pro)

- How Often Should You Change the 3D Printer Nozzle?

- Conclusion

Top 3D Printer Nozzles At A Glance

1. E3D Hardened Steel Nozzle (Best Choice)

2. MatterHackers CleanTip Nozzle (Most Reliable)

3. E3D Nozzle X (Best Premium)

4. Olsson Ruby Nozzle (Highest Durability)

5. Bondtech CHT Nozzle

The E3D Hardened Steel nozzle is my personal favorite nozzle choice and one of the best options on the market. As indicated by its name, this nozzle is made entirely of hardened steel, making it super durable and tough.

Furthermore, because it’s made of such a strong material, the nozzle can handle a wide range of filaments, including non-abrasives like PLA and abrasive materials like nylon and polycarbonate. There’s no limit to where you can use this nozzle!

And no matter what material you’re printing, you can expect consistent and high-quality extrusion from the nozzle due to the highly-precise manufacturing processes that E3D uses.

As for the compatibility of the product, the E3D Hardened Steel nozzle is meant to work on an E3D V6 hot end assembly. However, as long as your hot end has the same M6 thread, then it should be compatible.

This nozzle isn’t anywhere as cheap as your typical brass nozzle, but because the E3D Hardened Steel nozzle will last you a long time, the price is definitely worth it. You can get the nozzle in a few different diameters including 0.25, 0.3, 0.35, 0.4, 0.5, 0.6, and 0.8 mm.

So, if you need a nozzle that won’t break the bank but will last you a long time and can handle a wide range of filaments, then the E3D Hardened Steel nozzle is for you, my friend.

Pros

- Available in many different diameters

- Optimized to work with the E3D V6 hot end (works on similar assemblies)

- Can handle any filament material

- Very durable

- High-quality extrusion and very reliable

Cons

- Somewhat expensive

MatterHackers, an online retailer of 3D printing parts, isn’t known for their nozzles, but their CleanTip nozzle is a super reliable option worthy of being on this list.

MatterHackers sells an assortment of CleanTip nozzles with different diameters and thread sizes. All but one of their available CleanTip nozzles are made out of stainless steel, with the other being made out of brass with a special Tungsten coating.

As indicated by the name, CleanTip nozzles are meant to provide a clean, non-stick printing experience. In other words, any filament oozing from the nozzle won’t get stuck to the exterior of the CleanTip nozzle. This is possible because stainless steel (and Tungsten coating) are very slick metals making it difficult for any melted plastic to stick to the surface.

What’s also great about CleanTip nozzles, mainly the stainless steel options, is that they can handle a decent range of abrasive filaments. While it’s not suggested to print super-abrasive materials like polycarbonate with this nozzle, you’ll be able to safely print low and mid-level abrasive filaments like PLA, ABS, PETG, some composites, and even nylon.

Sadly, CleanTip nozzles aren’t currently available in a 0.4-mm diameter, but 0.25, 0.3, 0.35, 0.6, 0.8, 1.0, and even 1.2 mm are all still options. All of these nozzles, like the E3D Hardened Steel nozzle, have an M6 thread, so they can work on E3D V6 hot ends and similar assemblies.

Overall, I’d highly suggest getting a MatterHackers CleanTip nozzle if you want a non-messy print and are looking to print some abrasive filament materials.

Pros

- Two material options

- Anti-stick properties (cleaner printing experience)

- Comes in a many different diameters

- Fits many printers

- Extremely reliable extrusion

- Available CleanTip hot end available (optimized for the nozzle)

- The stainless steel CleanTip nozzle can handle some abrasive filaments

Cons

- Doesn’t come in a 0.4-mm diameter

- The brass CleanTip nozzle can’t handle abrasive filaments

- Can’t handle printing super abrasive filaments

The Nozzle X was released by the popular 3D printing company E3D in 2018, and it’s touted as the one nozzle to rule them all. Although it’s a bit expensive, especially when compared to traditional brass options, the Nozzle X is extremely heavy-duty.

Moreover, this nozzle can handle literally any 3D printing filament material, from PLA and PETG all the way up to nylon, polycarbonate, and carbon fiber composites. The nozzle itself is also extremely tough and rigid, so it won’t be degrading or deforming anytime soon, no matter how long you’ve been printing with it.

How is this possible, though?

Well, the Nozzle X is made of 68HRC Tool Steel, a super high-end type of steel that’s meant to be used on industrial machining equipment. The material is super durable but also conductive enough to be effectively used for a 3D printer nozzle. Furthermore, E3D states that this nozzle can be used to print any material up to 450 °C.

But what I love most about this nozzle isn’t its durability and filament compatibility but the overall reliability of the extrusion. Due to E3D’s precise manufacturing techniques, this nozzle is also very anti-stick, similar to the CleanTip nozzle, so the extrusion will be more consistent, and less filament will get stuck to the outside of the nozzle. As such, you shouldn’t ever need to get another nozzle again!

In fact, E3D is so confident that their special Nozzle X will last you forever that they’ve backed the product with a lifetime guarantee! If that’s not enough for you to get the nozzle, then I don’t know what is!

Pros

- Very durable and strong

- Can print any filament materials

- Anti-stick properties

- Can last you forever

Cons

- Somewhat expensive

- Only fits an M6 thread (doesn’t work on Ender 3 hot end)

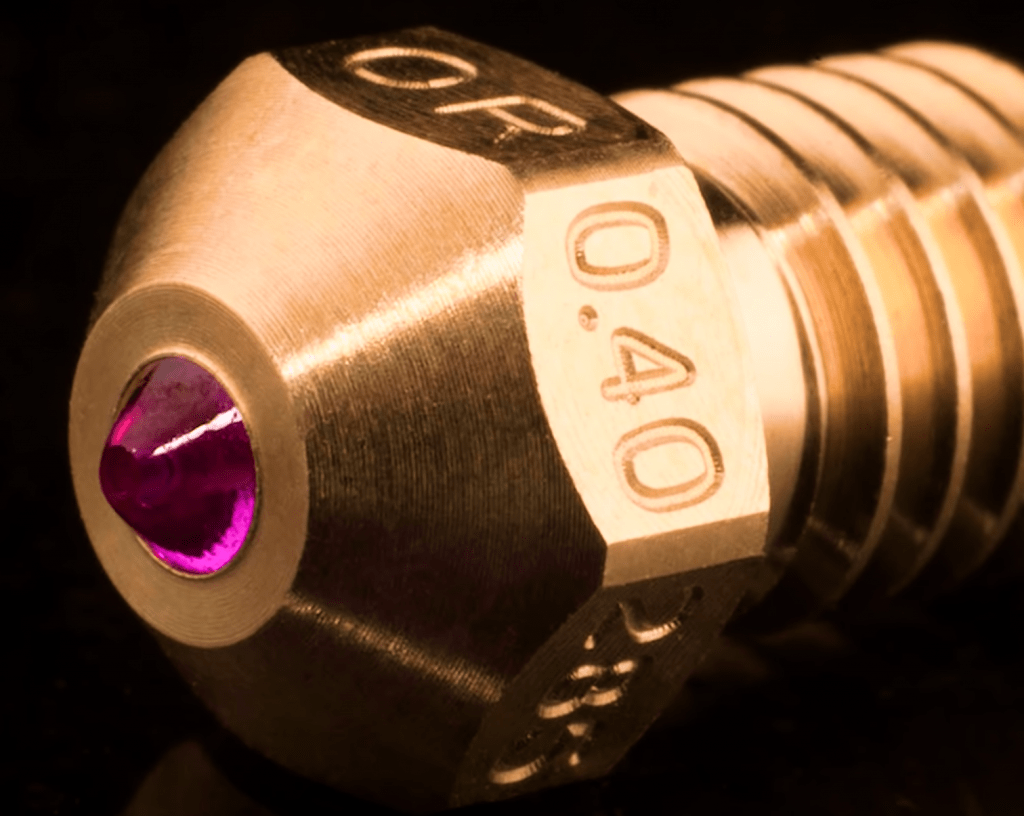

If you’re looking for the absolute best 3D printer nozzle, then the Olsson Ruby nozzle might be for you. Unlike the other nozzles on this list, the tip of the Olsson nozzle is literally made of gemstone (ruby). As ruby is extremely tough, this nozzle is super durable and is said to last a lifetime of printing (and more).

Of course, because ruby isn’t a very conductive material, the Olsson nozzle is mostly made of brass, with just the tip of the nozzle being made out of ruby. But don’t worry, as this brass isn’t the same quality of brass used in an under-$5 brass nozzle on Amazon. It’s high-end, precisely-machined brass that provides a conductive environment for the ruby tip of the nozzle.

As ruby doesn’t degrade easily, you can print with any filament material you want without any signs of degradation. This nozzle simply does not fail.

As you might expect, the Olsson Ruby nozzle costs a pretty penny, but for users who never want to deal with changing the nozzle again, it’s totally worth it!

Pros

- Can last you forever

- Can print any filament material

- High-quality and conductive brass frame

- Very durable and strong

Cons

- Expensive

- Not many options available regarding printer compatibility and diameter

Lastly, we have the CHT nozzle from Bondtech, a manufacturer of 3D printer extruder parts. While these nozzles are primarily made of brass, they’re coated with nickel to ensure durability.

Due to their enhanced strength, you can safely print a wide variety of filament materials with a CHT nozzle, including PLA, ABS, PETG, HIPS, polycarbonate, and more. Although you can print these materials, I would suggest keeping a watchful eye for nozzle degradation as the base material of the nozzle is still brass.

But my favorite part of the Bondtech CHT nozzle is the patented core heating technology (CHT). The company states that the CHT helps with better melting filament to provide smoother extrusion.

Bondtech also provides a few different types of their nozzle, including both a high-volume and regular version. It’s also worth noting that the nozzles have an M6 thread, so they can fit in an E3D V6 hot end assembly and similar products.

Pros

- Nickel-coated so it can print more abrasive filaments

- Compatible with many printers

- High-volume and regular versions available

- Core heating technology for better filament flow

Cons

- The main material is brass (subject to some degradation)

- Only one diameter available (0.4 mm)

- Somewhat expensive

What is a 3D Printer Nozzle?

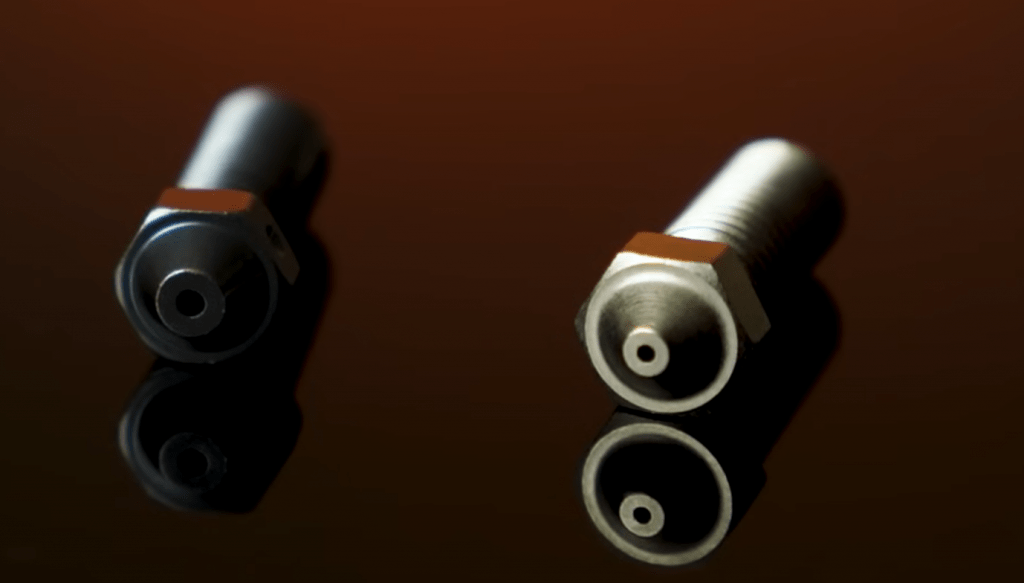

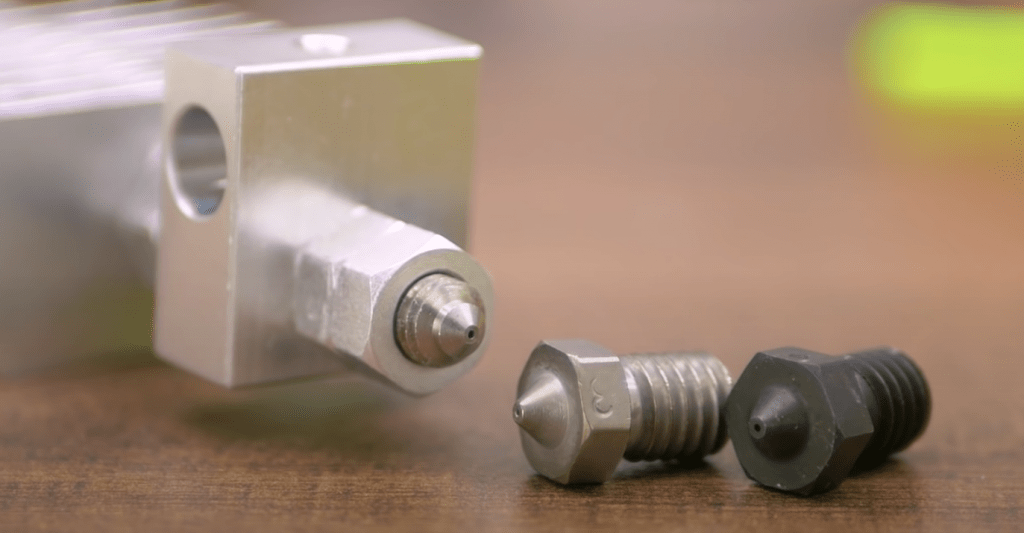

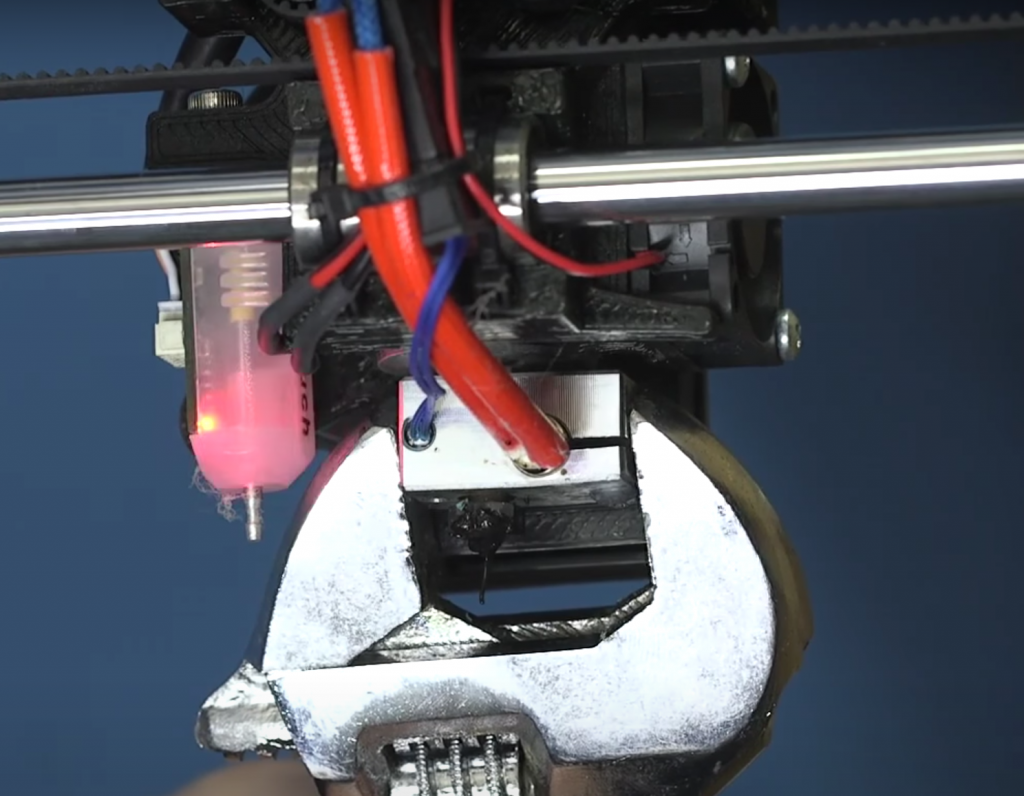

A 3D printer nozzle is the small metal component at the bottom of the hot end assembly where melted filament passes through on a 3D printer.

The primary responsibility of a nozzle is controlling extrusion. This means making sure the filament flowing out of the hot end maintains a consistent shape and size.

Without a nozzle, 3D prints would just be big blobs of melted plastic that don’t look anything like the print you expected.

Why is the Nozzle Important?

Nozzles are absolutely vital for a 3D printer for a few reasons. As we’ve already mentioned, they ensure the extrusion of a 3D printer is precise and consistent.

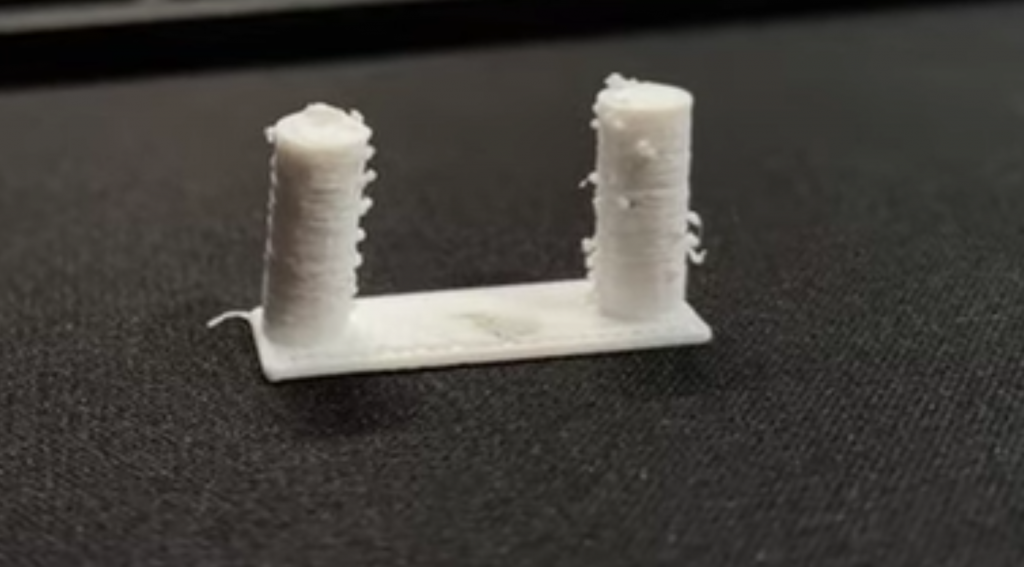

But on top of that, the nozzle also affects the overall print quality of models, such as the details and discrepancies of a model. The better the nozzle, the less stringing and under-extrusion you’ll see on prints, and the more precise, the smaller features (detail) will be on the model.

Nozzles also affect the reliability of your printer because, if they’re poorly made, they will clog more frequently, leading to more downtime for your printer. That’s why it’s important to get a high-quality nozzle, as they won’t degrade and clog as often (maybe even never).

Check out our article on how to unclog a nozzle here if you’re having troubles.

What to Look for in a Nozzle?

When looking for a nozzle, there are a handful of things to keep in mind so that the nozzle you choose is compatible with your printer, filament material and also prints well. I’ve gone over the main considerations for a nozzle in the mini-sections below.

When picking what nozzles made it on this list, I considered all of these elements, so you can be sure that the products listed won’t let you down.

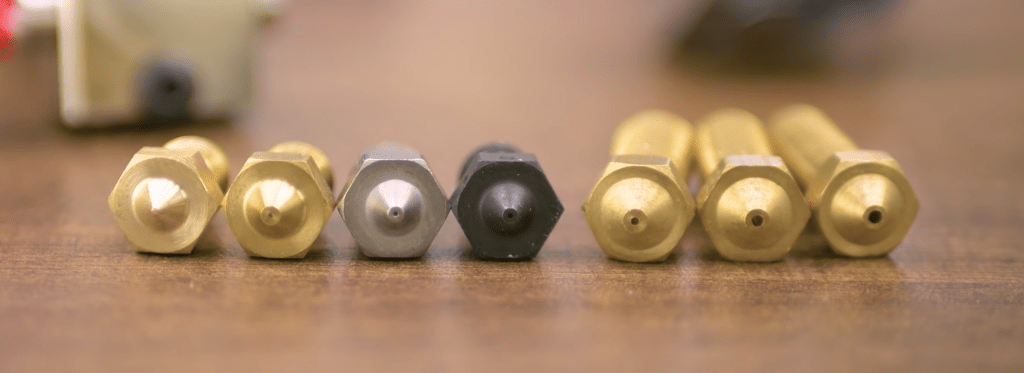

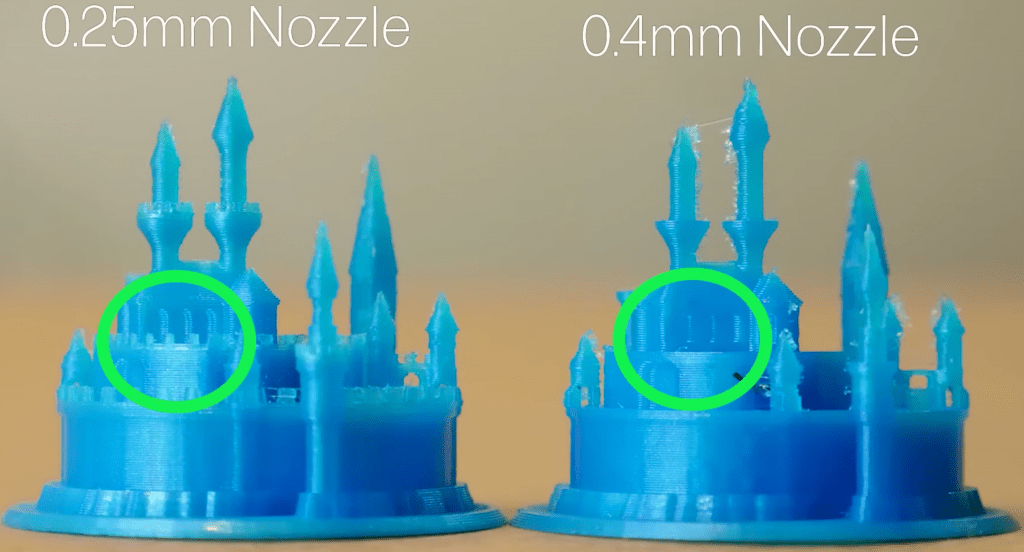

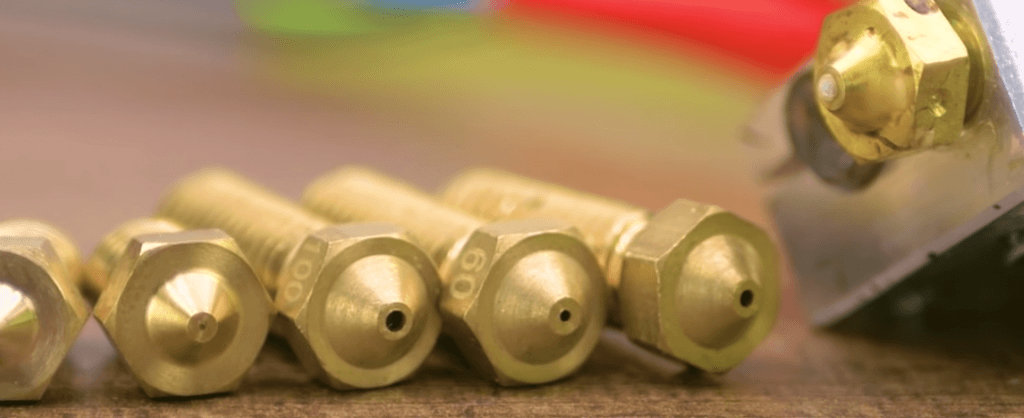

1. Diameter

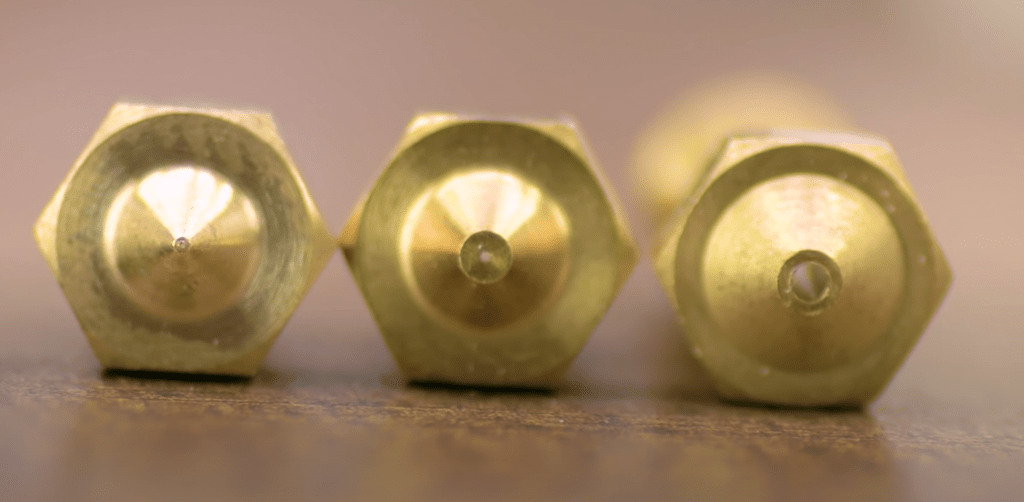

The first element of a nozzle to look at is the diameter, or how large the exit hole on the nozzle is. The larger the nozzle diameter, the more filament can flow out at once, yielding stronger prints. However, smaller diameter nozzles add a lot more detail to 3D prints because they can print smaller lines.

The industry standard nozzle diameter is 0.4 mm, which provides a good mix between strength and detail. However, if you have very specific printing requirements, you might want to choose a nozzle with a smaller or large diameter. We’ll go over the diameter options in a later section!

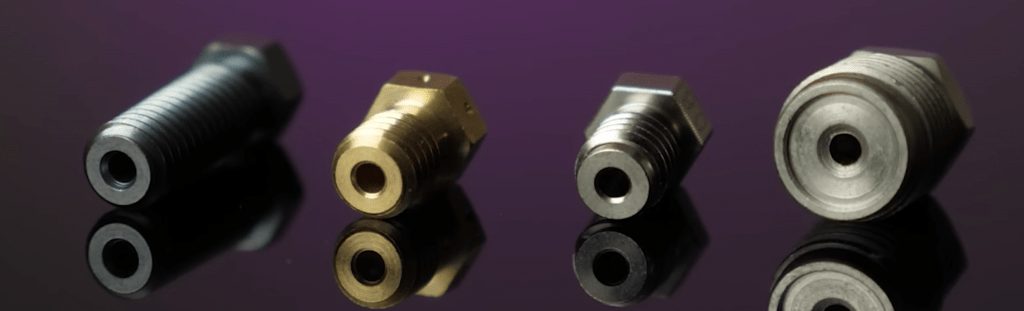

2. Material

Not all nozzles are made of the same material, and different metals offer different advantages.

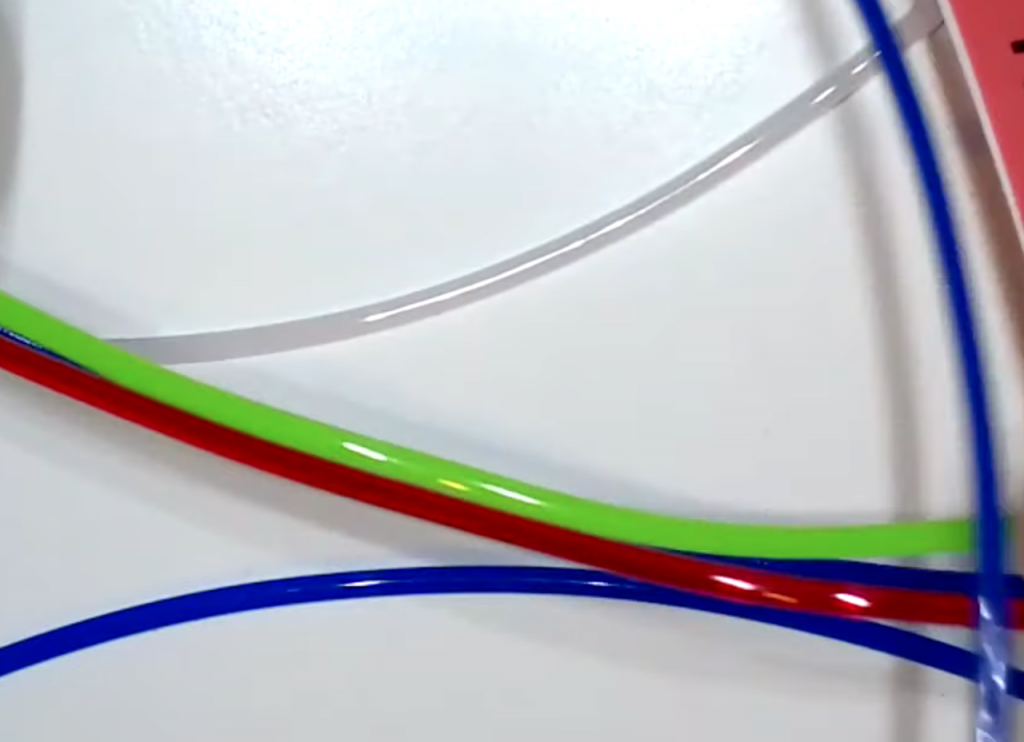

Brass is easily the most popular nozzle material because it’s widely available and super inexpensive. Sadly, they’re really only good for printing non-abrasive filament materials like regular PLA, ABS, and PETG.

If you want to print more abrasive filaments, such as glow-in-the-dark PLA, polycarbonate, or nylon, you’ll want a stronger nozzle material, such as hardened steel or even ruby.

Check out our article on the differences between brass and steel nozzles here if you want to learn more.

We’ll go more into the different nozzle materials in a later section, so keep reading!

3. Durability

The durability of a nozzle is also super important because you wouldn’t want your nozzle to deform or completely break if it ever accidentally hits something, like the print bed.

While a nozzle’s durability usually correlates a lot with the material of the nozzle, this isn’t always the case. Moreover, certain brass nozzles are more durable than other brass nozzles.

The best way to evaluate a nozzle’s durability is to look at its material and check the reviews to see what customers have said.

4. Print Quality

The print quality is another super important factor for a 3D printer nozzle, and it’s how well a nozzle performs at extrusion. A nozzle that provides a high print quality will print small features with a lot of accuracy and precision.

Similar to durability, there really isn’t a good way to gauge the print quality of a nozzle without actually using it. As such, check out the reviews of a nozzle to see what users have said about how well the nozzle prints.

5. Value

Lastly, we have the value of the nozzle. I like to think of the value as the ratio between the price and the overall utility and performance of the nozzle. You should evaluate the value of a nozzle because you wouldn’t want to overpay for a nozzle that only provides slightly better performance than a much less expensive option.

What is a Bore Diameter?

Bore diameter, more commonly known as nozzle size or nozzle diameter, is the size of the hole at the bottom of a nozzle. It controls how much filament can come out of the nozzle during the printing process. There are many different options for bore diameter which are outlined below.

What are the Sizes/Diameters of the Nozzles?

In the mini sections below, I’ve gone over the different popular ranges of nozzle diameter, covering what benefits each size range offers and when you should use them.

0.1-0.3 mm

First, we have 0.1, 0.2, and 0.3-mm nozzles, which are some of the smallest nozzle diameters available. These sizes of nozzles excel in printing small details and features on 3D models. As such, nozzles in this size range are perfect for printing small models, like miniatures and architectural designs.

0.4 mm

0.4-mm diameter nozzles are, by far, the most popular size of 3D printer nozzles, so I gave this size its own section.

0.4-mm nozzles are a good middle ground between detail in strength, making them the best choice if you’re printing a model that has some small features but also needs to have decent strength.

For example, I love using 0.4-mm nozzles to print items like a phone case, phone stand, vase, and more.

0.6-1.2 mm

Lastly, we have every nozzle size that comes after 0.4 mm, including 0.6, 0.8, 1.0, and 1.2 mm. Nozzles with bore diameters in this size, when used with the right print settings, make models that are decently strong.

Of course, the filament material you use is more impactful on the strength of a 3D print, but having a nozzle with a large diameter will allow you to use thicker walls for prints, making them stronger than if you used a smaller-diameter nozzle.

Because of their strength, I suggest using a nozzle in this diameter size range to print models that need to be strong, like a laptop stand or a bike part.

Nozzle Materials:

As I mentioned previously, there are a few popular materials for nozzles, including brass, hardened steel, stainless steel, and ruby. Of course, there are a few more-unique material options, like tungsten, but they aren’t very popular, and not many options for these materials are available.

In the mini sections below, I’ve given a brief overview of each of the popular nozzle materials.

Brass Nozzle

Brass is the most popular nozzle material by a long shot, and you can find a brass nozzle in just about any off-the-shelf printer, like the Creality Ender 3, Anycubic i3 Mega, and even MakerBots. The main reason for the popularity of brass nozzles is their overall value, providing decent extrusion properties at a total bargain price.

You can use brass nozzles for printing non-abrasive and non-sticky materials like regular PLA, ABS, and most PETG filaments. However, it’s recommended to switch to a stronger nozzle material for printing other filament materials.

Stainless Steel Nozzle

Stainless steel is another nozzle material option, and they’re naturally stronger and more durable than brass options. Because of this, they can handle some more abrasive filaments like composite PLAs and even Nylon.

However, the main strong suit of stainless steel nozzles is that they’re extremely anti-stick. As such, they’re perfect for printing sticky filaments, like PETG and TPU, because they can reduce stringing in prints.

Hardened Steel Nozzle

Hardened steel is the older and much-stronger brother to stainless steel, offering a ton of durability and strength for 3D printing. Sadly, hardened steel nozzles are a good bit more expensive than brass nozzles and don’t have the anti-stick properties of stainless steel nozzles.

But what they lack in those categories, hardened steel nozzles that make up for filament compatibility. Moreover, the extreme strength of hardened steel nozzles means you can use them to print basically any filament materials, from PLA to carbon fiber composites and polycarbonate.

Ruby Nozzle

Lastly, we have ruby nozzles, the most expensive of the bunch and also the most difficult to find. Ruby nozzles have a brass structure but with a gemstone (ruby) tip to provide the absolute best print quality and durability. It’s said that one ruby nozzle can last a lifetime of printing in any filament material.

Best Nozzle for PLA & ABS

When it comes to printing PLA, the best 3D printer nozzle has got to be a 0.4-mm brass nozzle, such as the E3D V6 Brass nozzle. This nozzle is also best for printing ABS as the two filament materials are very similar.

Best Nozzle for PETG

PETG is slightly more abrasive than PLA and ABS, and it’s a lot more sticky. As such, using brass, stainless steel, or hardened steel nozzle will all work great.

Best Nozzle for TPU & Flexible Filament

Finally, for TPU, I suggest printing with a stainless steel nozzle. That’s because, while TPU isn’t too abrasive, its flexibility makes it prone to stringing during the printing process, so the anti-stick properties of a stainless steel nozzle come in super handy.

Best Nozzle for Ender 3 (V2/Pro)

For the Creality Ender 3 (V2/Pro), I strongly suggest getting a 0.4-mm MicroSwiss A2-plated hardened steel nozzle or a similar option from Polisi. Because of the strength of both of these nozzles, you’ll be able to print whatever material you want.

The Genuine E3D Hardened Steel nozzle is also a great option, but it’s only meant to work with an E3D V6 hot end, so it might not fit on your printer’s hot end.

How Often Should You Change the 3D Printer Nozzle?

Honestly, there’s no need to change the nozzle until you start to see issues on your printer. But if you’d rather be safe than sorry and change the nozzle before your current one starts giving you issues, then changing it after every 3 months of regular use is a good time increment.

If you use your 3D printer everyday, then I recommend changing your nozzle every month at the very least.

Conclusion

Whether you’re printing PLA or polycarbonate, having the right nozzle is essential for achieving high-quality 3D prints.

If you’re printing abrasive filament materials, like nylon or PC, the E3D Hardened Steel nozzle and E3D Nozzle X are both great options that are super tough but not too too expensive.

If you want a clean printing experience with minimal stringing on prints, the MatterHackers CleanTip nozzle is a terrific choice due to its anti-stick property and overall reliability.

And lastly, if money isn’t an issue and you’re looking for the overall best 3D printer nozzle, the Olsson Ruby nozzle is the one for you. Its insane strength can handle any filament material without any signs of degradation, so you’ll never have to replace it again!