- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

Ever wonder how 3D printer filament is made?

The process starts with raw plastic, which is loaded into a special machine, called a filament extruder.

Of course, a filament extruder isn’t like the one on your typical 3D printer. These filament extruders are a lot larger, and they melt plastic pellets and extrude them out as a filament strand.

While large 3D printing filament manufacturers have super expensive (and very large) filament extruders, there are consumer-grade ones that don’t cost a fortune. These filament extruders, like the Filabot EX2 or NozTek Pro, can pump out a few spools per day, significantly decreasing how much you pay to 3D print things.

Want to learn about the best filament extruders, both DIY and purchasable? Read on!

Best Filament Extruders At A Glance

Filament Extruders: DIY

1. Felfil Evo (High-Quality Prints)

2. Filastruder Kit (DIY) (Best Value)

Filament Extruders: To Buy

3. Filabot EX2

4. 3devo Precision 350 (Best Choice)

5. Noztek Pro Desktop Extruder

6. ReDeTec ProtoCycler+ (Premium Choice)

Filament Extruders: DIY

First, we’ll go over the DIY options for filament extruders. These extruders don’t come pre-assembled in one piece. Instead, they’re kits that you assemble.

Up first, we’ve got the Felfil Evo. This filament extruder actually comes in both a pre-assembled as well as a kit version, and both are great, but the kit is less expensive and not that difficult to build, which is why I like it more.

With an extrusion rate of 100-150 grams per hour, the Felfil Evo isn’t the fastest one around, but it’s exceptional for the price. And at this rate, you can make a little more than two 1-kilogram spools per day.

As for the quality of the filament produced, Felfil states that the filament has a tolerance of +/- 0.07 mm. That doesn’t sound very good, but it’s just the right tolerance to work on most 3D printers if you’ve got the extrusion settings right.

It’s also worth noting that the Felfil Evo kit comes in a 1.75-mm filament version as well as a 2.85-mm filament version, so you can pick the one that fits your printer’s needs.

On another note, the Evo has a maximum heating temperature of 250 °C, enough to produce PLA, ABS, HIPS, and TPU (flex) filaments. Sadly, you won’t be able to make PETG as it requires a bit more heat.

But what I love most about the Felfil Evo is that it’s not that difficult to build. Of course, you’ll need a hopper and spooling device to complete your setup, but it looks sexy and is decently reliable.

So if you want a starter filament extruder to see if making your own filament is for you, then definitely give the Evo kit a shot.

Pros

- Very cool frame design

- Easy-to-use control panel

- Can make PLA, ABS, HIPS, and other filament materials

Cons

- Some assembly required

- Very slow extrusion speed

- Not very reliable

- A high (bad) filament diameter tolerance; produced filament might jam your printer’s hot end

- Can’t make PETG filament

Filastruder is a company that specializes in making their Filastruder kit, a budget-friendly extruder, as well as a few upgrades and attachments for the device.

Before we get started with the review, it’s worth mentioning that the Filastruder kit is currently out of stock with no expected restock data, but the company is working on making more. Now let’s get to it!

The Filastruder kit is easily the least expensive filament extruder on the market, costing under $500 for a fully-functional setup. And the company also sells a few attachments for the device, also at a low price, such as the Filawinder, an autonomous spooling device that goes at the end of the Filastruder, so you don’t have to manually wind filament onto spools.

Despite the low price, though, the Filastruder is one hell of a filament extruder, with a metal frame body that makes the device sturdy and visually appealing. Additionally, the 260 °C maximum temperature of the device means you can produce a wide variety of filament materials, including PLA, ABS, TPU, TPE, PMMA, and even polycarbonate.

But what’s most impressive about the Filastruder is its diameter accuracy: an impressive +/- 0.03 mm for PLA, +/- 0.02 mm for ABS and similar values for other materials. This means the filament you make with the Filastruder is literally more precise (diameter-wise) than most filaments you buy on Amazon and the like.

Sadly, the price you pay for the precision of the Filastruder Kit is the speed, as the filament extruder can only produce 1 kilogram of filament every 5 to 8 hours. Additionally, it’s known that the Filastruder is a little bit difficult to configure and isn’t too reliable compared to purchasable options.

But, with everything in mind, like the low price, precision, and potential upgrades, the Filastruder Kit is one of the best filament extruder options on the market!

Pros

- Can produce extremely precise filament

- Decently-high maximum heating temperature, so it can handle a fair amount of filament materials

- A handful of compatible attachments are available (e.g. Filawinder)

- Some components can be 3D printed

- Very low cost; a good bang for your buck

Cons

- Currently out of stock

- Some assembly required

- Very slow extrusion speed

Filament Extruders: To Buy

In the sections below, I’ll review the best filament extruders that can be purchased with no (or very minimal) assembly required.

Our first purchasable extruder is the Filabot EX2, easily one of the most well-built extruders on this list. The first thing you’ll notice about the EX2 is its visually appealing frame, a compact, green-and-orange, all-metal chassis that makes filament extrusion look a lot sexier than it is.

The Filabot EX2 has a maximum temperature of 329 °C, allowing it to melt a few different blends of PLA, ABS, PETG, HIPS, and even WAX. While this may sound like less material compatibility than other options, it’s worth noting that these are only the materials that will 100% work with a high level of quality. Of course, you could try making other filaments, but they might not come out as good.

On this note, Filabot has stated that the EX2 can maintain a diameter tolerance of under +/- 0.05 mm. While this isn’t perfect by any means, it’s definitely enough to work on practically any 3D printer, from an Ender 3 to an Ultimaker 3.

As for speed, the EX2 is a total beast, producing just under a kilogram in an hour. So you could make a full-years worth of filament in one 24-hour period, which is insane to think about!

My personal favorite part about the EX2, though, is the overall build quality of the machine. You can really tell that Filabot spent a lot of time making sure the design of the EX2 is perfect.

This is most clearly seen with the control panel on the machine, which includes a dial for the speed, temperature controller (with buttons), and switches for the main power, extruder power, and heater power. The organized and well-labeled controls make producing your filament so easy a 5-year-old could do it.

So, if you want a powerhouse of a filament extruder with a high-temperature heater, easy-to-use control panel, fast extrusion speed, and more, then the Filabot EX2 is for you. Just be ready to pay a pretty penny for these epic features.

Pros

- Well-designed, sleek, all-metal frame

- Organized and easy-to-use control panel

- Decently-high maximum heating temperature

- Super fast extrusion speed

Cons

- Pretty expensive

- A pretty bad diameter tolerance for the price

3devo is a company that specializes in making filament extruders and shredders. The Precision 350 is one of 3devo’s filament extruders, and, while on the more expensive side of the spectrum, it’s got many features that make the price worth it.

First off, the device has a maximum temperature of 350 °C, so you can use it to make PLA, ABS, PET, PETG, TPU, TPE, filaments, and more. But what’s unique about the Precision 350 is that the device has not 1, but 4 heating zones. As such, the plastic melting process is a lot more precise and controllable than on other filament extruders, hence the name of the product.

On top of high-quality cooling, the Precision 350 also features a well-designed cooling system, with two 5050-style fans placed on either side of the filament line. On top of looking really sleek, this cooling system helps produce filament more precisely.

As for the extrusion rate, 3devo didn’t provide a clear speed for the Precision 350, but it should be moderately fast given the speed of their other machines.

Lastly, it’s worth going over the frame and controls on the 3devo Precision 350. Similar to the EX2, the Precision 350 has a very appealing, all-metal frame design.

Additionally, the controls onboard the filament extruder make it super easy to configure the machine for a certain filament material. There’s also a USB port on the Precision 350 for communication via computer. 3devo also has an online interface where you can go to view extrusion data of your device.

Overall, while the Precision 350 might be expensive, it’s impossible to refute the build quality of the machine, such as the high-temperature capabilities and precise extrusion techniques.

Pros

- USB connectivity

- Four heating zones for accurate and precise plastic melting system

- Online dashboard interface

- Decently-high maximum temperature, capable of handling many materials

- High-quality cooling system

- A lot of company support (e.g. example settings)

- Sleek design

Cons

- No speed provided

- Very expensive

Noztek was one of the first companies to get involved in the consumer filament extruder business, and the Noztek Pro is an excellent machine that’s super fast.

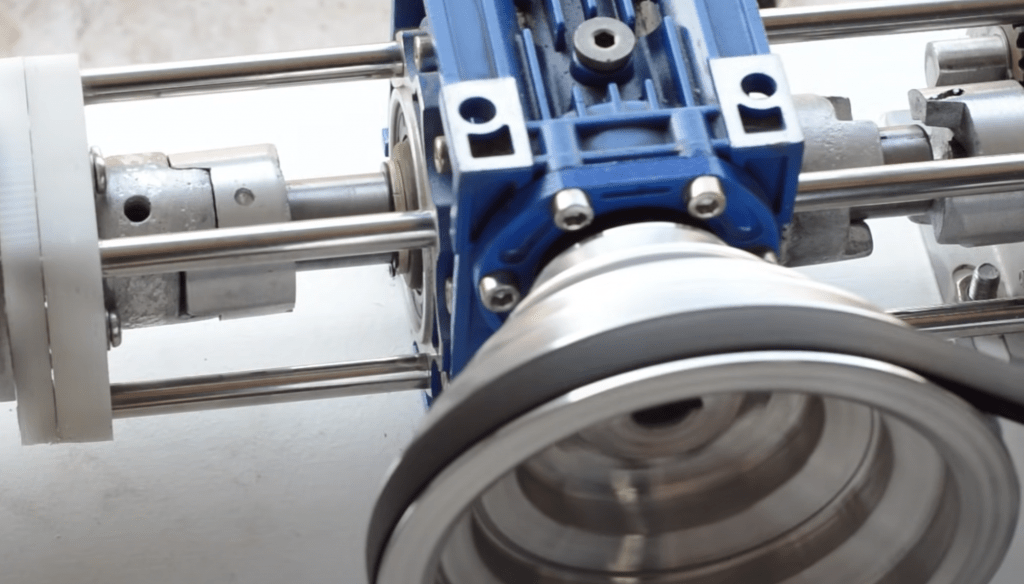

The Noztek Pro is equipped with what the company calls their fusionX extruder, a screw mechanism that can move filament pellets through a heating (and cooling) system very fast.

How fast? How about 1 kg every 2 hours fast?

But besides its insane extrusion speed, the Noztek Pro is also a very versatile machine, with a maximum heating temperature of 600°C. This is insane for costing under $2000, and it means the Noztek Pro is capable of handling pellets of PLA, ABS, PP, PET, HDPE, and other materials.

It’s also worth pointing out that the Noztek Pro comes with a 0.5-kg bag of ABS pellets, so you can get right to making filament out of the box! There are also two different extruder nozzles: one for 1.75-mm filament and one for 2.85-mm filament.

Lastly, I can’t forget to talk about the overall design of the machine, which is very sleek. The red, all-metal frame gives the Noztek Pro a fair amount of durability. And the easy-to-use controls, consisting of a few knobs and buttons, make controlling the temperature and speed of the machine a breeze.

So if you’re looking for a good value filament extruder that doesn’t cost too much but has a lot of great features all packed in a well-built frame, then the Noztek Pro filament extruder is an excellent choice!

Pros

- A good bang for your buck

- Multiple nozzle sizes available

- Reliable fusionX extruder mechanism

- Easy-to-use controls

- All-metal frame

- Decently high extrusion speed

- Super high maximum heating temperature

- Can print many different filament materials

Cons

- Somewhat expensive

- Not much company support

ReDeTec is yet another popular manufacturer of filament extruder products, and the ProtoCycler+ is their flagship product. ProtoCylcer+ is an advanced filament extruder system that includes everything you need to take a failed print (or old print) and turn it into printable filament.

Yep!

On top of having a filament extruder screw and heater, the ProtoCycler+ features a built-in grinder. This mechanism turns large metal grinders to mash up plastic parts and turn them into pellets that you can run through the filament extruder system.

Additionally, the ProtoCycler+ has an automatic winding device at the end of the extruder line. This wraps the produced filament around an empty spool so you don’t have to manually do this process, which can be very annoying.

What’s super impressive about the whole setup is that the ProtoCyler+ takes up a pretty small footprint, despite there being three different mechanisms inside. And the all-metal body of the ProtoCylcer+ looks sleek, with an open-up hatch that allows you to see the internal mechanisms.

Sadly, though, the device can only reach a heating temperature of 250 °C, which isn’t too high. But, according to the manufacturer, it’s enough to be able to make PLA, ABS, PETG, HIPS, and Nylon 12 filaments.

But the impressive speed of 1 kg every 2 hours and the spectacular diameter precision of +/- 0.05 mm certainly make up for it because this means you can make high-quality filament very fast.

Pros

- Integrated grinder (unless you choose the “Grinderless” option)

- Automatic filament winder

- Very fast extrusion

- Decent diameter tolerance for filament

- Sleek design

- Open-up hatch

Cons

- Not a very high maximum temperature

- Expensive

What is a Filament Extruder?

A filament extruder is a device that makes 3D printable filament out of ground-up bits of plastic.

Filament extruders, which are not the same as the extruder on a 3D printer (we’ll explain more later), are most commonly used by big filament manufacturers. However, in recent years, there have been efforts to develop consumer-level filament extruders so that you can make your own filament out of plastic pellets.

And many people want to get their filament extruder because a 1-kg bag of PLA pellets is so much less expensive than a 1-kg spool of PLA filament. Moreover, on wholesale sites, like Alibaba, you can get bags of PLA pellets priced at under $3 per kilogram.

How Does a Filament Extruder Work?

A filament extruder is a pretty complex system, but the easiest way to think about these machines is as an enlarged version of the hot end on a 3D printer.

The filament extrusion process starts with grinded-up plastic pellets. It’s necessary for these plastic pellets to be all of the same material and contain contaminants (e.g. metal shavings).

The pellets are loaded into a hopper, which feeds them into the screw of the machine. The screw is rotated by a big motor, pushing the pellets forwards at a controlled speed.

At the other end of the screw, shaft is a heater, which goes around the screw. The heater melts the plastic pellets into a molten form, similar to how a hot end melts filament.

Then, the molten plastic is pushed by the incoming melted pellets into a pipe, where a cooling mechanism usually lies. At the end of the pipe is a nozzle, where the finished filament comes out. But unlike the nozzle on a typical 3D printer, the diameter of the nozzle on a filament extruder is set to the desired filament diameter (1.75 or 2.85 mm).

And that’s it!

What’s the Difference Between Filament Extruder and 3D Printer Extruder?

A filament extruder, while similar in name, is not the same thing as the extruder on your 3D printer. Filament extruders are devices, large in size and high in price, that actually makes plastic filament.

On the other hand, 3D printer extruders, like the E3D Titan, are the assemblies on a 3D printer that push filament to the hot end where it’s melted.

Conclusion

Filament extruders make a great addition to your 3D printing setup, giving you the ability to produce filament for pennies!

If you’re looking for a good extruder, two of the best options out there are the Filabot EX2 and 3devo Precision 350. Both machines cost a pretty penny but have a well-built frame, high-quality extrusion process, wide filament compatibility, and easy-to-use controls.

And, if you want a full end-to-end system where you can take your failed prints and turn them into printable filament, the ProtoCycler+ is best. It features a high-quality extrusion system with a grinder for mashing up prints as well as a winder for wrapping the filament around a spool.

Now, if you’re on a budget, then the Filastruder kit is probably the better option for you. It has a sub-$500 price point, a decently-high temperature limit, and a very precise extrusion system.

Hope you enjoy!