- Last Updated: April 9, 2024

-

Jackson O'Connell

Jackson O'Connell

Interested in 3D printing your own gun or special accessories for a firearm? Well, if so, then make sure you’re using the right filament material.

Interested in 3D printing your own gun or special accessories for a firearm? Well, if so, then make sure you’re using the right filament material.

Today, there are tens of different filaments to choose from, but not just any is suitable for making gun components. Because every part in a firearm undergoes a lot of physical stress (from vibrations) as well as heat, you have to choose a durable, heat-resistant filament.

Otherwise, your 3D printed gun (or gun components) will fail after extended use.

The best material for 3D printed guns is polycarbonate, as it’s the strongest, most impact-resistant filament material on the market. As such, any gun components you print in PC filament will last a lifetime.

But, if you want an easier printing experience, then I suggest using PETG filament, as it’s also super strong, heat-resistant, and durable, but it doesn’t require an enclosure for printing. The only thing you’ll have to watch out for is stringing, but this isn’t too hard to solve.

Want to learn about more materials that are well-suited for 3D printing gun parts? Well, then, just keep reading!

Table of Contents

- Best Filament Materials for 3D Printed Guns

- Can You 3D Print an Entire Gun or Only its Parts?

- Are 3D Printed Guns Reliable?

- Can 3D Printed Guns Handle the Heat?

- How Many Shots Can a 3D Printed Gun Fire?

- Do 3D Printed Guns Have to be Serialized?

- Do 3D Printed Guns Use Real Bullets?

- Are 3D Printed Guns as Good as All Metal Guns?

- Considerations for Buying Filament for 3D Printed Guns

- Tips for 3D Printing Guns

- Conclusion

Best Filament Materials for 3D Printed Guns

1. PETG

First up, we have PETG. PETG is a modified form of the plastic commonly used in water bottles and kitchen Tupperware.

Compared to the other popular 3D printing filament materials, PETG is a relatively new filament material. But, despite this, PETG has quickly become one of the most popular filament materials due to its high strength, heat resistance, and printability.

Moreover, PETG is way more durable than PLA, with a much higher tensile strength, flexural strength, and UV and heat resistance. Plus, printing PETG isn’t much harder than printing PLA. While the material tends to string and over-adhere to the build plate, these problems are easily avoidable if you use the right print settings.

Recommended Products:

2. ABS

ABS is perhaps the most widely-used plastic material on Earth and can be found in everything from LEGOs to the interior components of cars. And ABS didn’t get popular for no reason. The thermoplastic, which can be 3D printed, is super inexpensive, costing under $20 per 1-kg spool, and is decently strong.

While the material is notoriously difficult to 3D print because it requires an enclosure and a high bed temperature, once you get the right print settings, achieving high-quality models is a breeze!

As for its strength and durability, ABS is perfect for 3D printing gun parts. The plastic is even slightly flexible, which makes parts printed in the material very impact-resistant, which is super useful for printing gun components.

Recommended Products:

3. Nylon

Nylon is another great material for 3D printing gun parts. It’s super durable, and it’s even a tad bit flexible, which makes parts printed in this plastic super impact-resistant.

As you might expect from a super-strong material, nylon is still a lot more difficult to use and print with than PETG and ABS, but it’s also a lot stronger, so it kind of evens out.

If you decide to use a nylon filament to 3D print parts for a firearm, there are two different types of nylon that I recommend using, which I’ve gone over in the sub-sections below.

Carbon Fiber Blend

Carbon fiber blend nylon, also called carbon fiber-infused nylon, is a special form of nylon filament that contains a certain percentage of carbon fiber to make the material even stronger. While carbon fiber blend nylon filament is usually very abrasive, requiring you to use an abrasion-resistant nozzle (e.g hardened steel), its strength is comparable to that of PC filament.

Recommended Products:

Glass Filled

Glass-filled nylon isn’t as strong as carbon fiber blend nylon filament, but it’s very close and is usually a bit easier to print. So, if you want a ton of strength and heat resistance for the 3D printed parts you use in your firearm, but want a slightly easier printing experience than PC or carbon fiber-infused nylon, then I strongly suggest using glass-filled nylon filament.

4. Polycarbonate

Lastly, we’ve got polycarbonate filament. This is easily the best material for 3D printed guns and gun parts, as PC filament offers the most durability, tensile strength, and heat resistance.

Polycarbonate filament is pretty popular because of its terrific mechanical properties, but it’s also very difficult to print. Moreover, to even get started with using PC filament, you’ll need a machine with a high-temperature hot end, a high-temperature heated bed, and an enclosure. And, even with this hardware, you’ll have to spend hours fine-tuning a 3D slicer profile if you want to achieve high-quality prints.

But, if you have some experience with 3D printing and want the best-of-the-best parts for your firearm, then PC filament is an excellent choice. Its strength, heat resistance, and durability are unmatched, and gun parts that you print in PC filament will likely never fail, no matter how many rounds you fire.

Recommended Products:

Can You 3D Print an Entire Gun or Only its Parts?

No. 3D printed guns are never entirely made up of 3D printed parts. Instead, they usually have a 3D printed lower receiver, which is like the bottom frame of the gun, and then all of the other parts, including those in the shooting mechanism, are purchased from a manufacturer.

Are 3D Printed Guns Reliable?

For the most part, yes!

3D printed guns function just like regular metal guns because the shooting mechanism of the firearm isn’t 3D printed. Moreover, as we’ve mentioned, only the lower receiver is 3D printed on most 3D printed firearms. As such, the actual shooting of bullets should theoretically be just as reliable on a 3D printed gun as on regular ones.

However, this isn’t usually the case because 3D printed guns usually start to wear down and break after extended use, which obviously affects their reliability. This happens because of the heat and vibrations caused by shooting a bullet from a 3D printed gun.

Can 3D Printed Guns Handle the Heat?

Yes, but it depends on what filament material you’re using.

Different filament materials have different glass transition temperatures, which is the temperature at which the plastic starts to soften. The higher the glass transition temperature of the filament material you’re using, the more heat your 3D printed part will be able to handle.

So, if you 3D print a part for your gun in a material like PLA, which has a low glass transition temperature, it won’t be able to handle nearly as much heat as if you print the part in a material like ABS or PC, which can handle much higher temperatures.

But, in general, because the only 3D printed parts on “3D printed” guns are the lower receiver and other frame pieces, the 3D printed parts don’t need to handle a lot of heat anyways. But, if you plan on using your 3D printed gun in a hot, outdoor environment or want to shoot the gun a lot (more shots equals more heat), then definitely make sure to use a filament material with a high glass-transition temperature.

How Many Shots Can a 3D Printed Gun Fire?

As many as you want! Well, at least, ideally!

There are two main factors that might limit how many shots you can fire on a 3D printed gun, including the 3D printed parts’ heat resistance and their strength.

Furthermore, if you fire shots rapidly out of a 3D printed gun, then a lot of heat will be produced, which could reach the 3D printed lower receiver of the weapon and cause it to start deforming. Additionally, the extreme vibrations caused by firing a lot of rounds out of a 3D printed gun could crack and even full-on shatter the 3D printed parts on your gun.

But both of these scenarios are pretty unlikely unless your 3D printed gun is an automatic, high-caliber rifle, which is illegal anyways. As such, there isn’t really a limit to how many shots a 3D printed gun can fire, and it should be able to handle just as many as a normal metal gun.

Do 3D Printed Guns Have to be Serialized?

No, or at least not in the United States (for most people).

In the United States, under federal law, firearms that are manufactured by a licensed manufacturer, importer, or dealer must be serialized. However, homemade, personal-use firearms, including 3D printed guns, typically don’t need to have a serial number. This makes them “ghost guns”.

However, there are, of course, many different exceptions and other regulations around this topic. For example, you aren’t allowed to sell your un-serialized, 3D printed gun.

It’s also important to note that the laws regarding 3D printed firearms are constantly evolving, so definitely check your local government’s laws about this topic before making your own 3D printed, unserialized firearm.

Do 3D Printed Guns Use Real Bullets?

Yes.

3D printed guns operate just like a regular, traditionally manufactured gun that you would buy in a store, and they shoot the same, real bullets. Moreover, 3D printed guns use the same shooting mechanism as a “regular gun”. The only real difference is that 3D printed guns have a 3D printed lower receiver, but this is essentially the frame (housing) of the gun, so it doesn’t affect how the firearm actually fires the inserted munitions.

As such, don’t think of a 3D printed gun as any less dangerous than a normal firearm. It should be treated with the same care and safety precautions.

Are 3D Printed Guns as Good as All Metal Guns?

Not exactly.

While 3D printed guns still fire the same bullets as regular, metal-assembly guns, they don’t perform as well. Moreover, 3D printed plastic parts can’t withstand the vibrations produced from a bullet leaving a gun as well as metal parts can. As such, 3D printed guns are usually less accurate and reliable than normal metal guns.

Of course, the disparity in accuracy between a 3D printed gun and a metal gun will depend on a few factors, including what filament material was used for the 3D printed parts, the slicer settings, and more. But, even if you 3D print the lower receiver of your gun in the strongest filament material (polycarbonate), using a 100% infill density, the gun you make will likely not fire as well as a metal gun.

Additionally, it’s worth noting that 3D printed guns usually break a lot faster than metal guns. 3D printed plastic parts can only withstand so many vibrations before cracking and eventually breaking, while metal components can be put under a lot more physical stress without any signs of wear.

Considerations for Buying Filament for 3D Printed Guns

When looking for filament to use for 3D printing gun components, there are a handful of factors you should consider. I’ve gone over the most important ones below:

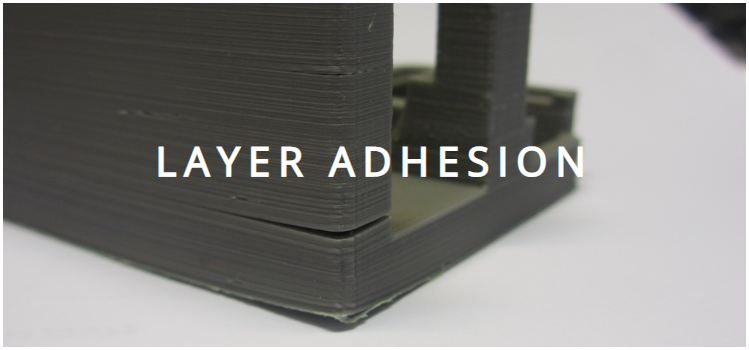

Layer Adhesion

First, you should consider the filament’s layer adhesion or how well the plastic bonds to itself. This is extremely important because if the layer-to-layer adhesion isn’t good in your print, the parts you make with the filament will be a lot more brittle.

While there isn’t one specific metric to look at to determine the layer adhesion of a specific filament, checking the suggested nozzle temperatures helps. Typically, the higher the suggested nozzle temperature of a filament, the stronger the layer-to-layer bonds of parts printed with the filament will be. That’s why PETG, which has a suggested nozzle temp of about 250 °C, is a lot stronger than PLA, which has a suggested nozzle temperature of 200 °C.

Impact Resistance

The impact resistance of a filament is also super important in the context of 3D printing gun parts. Every time you fire a round on your 3D printed weapon, the 3D printed parts will absorb a lot of vibrations; and, if the filament you’re using isn’t impact-resistant, then these 3D printed parts won’t last long.

Similar to layer adhesion, it’s difficult to measure the impact resistance of a specific 3D printing filament. But checking reviews for the filament, as well as any provided measurements or tests by the filament’s manufacturer, can help.

Tensile Strength

Next, tensile strength determines how much a part printed in certain material can be pulled before snapping. While tensile strength isn’t directly related to the performance of a 3D printed part in a gun, it definitely has an effect when it comes to how long the 3D printed parts last.

Tensile strength is usually measured in MPa and can be found in the material data sheet of the filament you’re looking at. The higher the tensile strength, the better the filament for printing gun parts.

Heat Resistance

Lastly, it’s essential that whatever filament you use for this purpose is heat resistant. If you’ve ever fired a gun before, then you know how hot the barrel and other parts of the firearm get after a few rounds have left the chamber.

Even though the lower receiver won’t be as hot as the barrel or other parts of the gun’s shooting mechanism, it will still absorb some heat. If the filament isn’t heat-resistant, the 3D printed parts in your gun will deform or even melt after extended use.

You can usually determine the heat resistance of a filament material by looking at its glass transition temperature, which is the temperature at which the material starts to soften. The higher this temperature metric, the more heat resistant the filament.

Tips for 3D Printing Guns

If you’re interested in 3D printing guns or parts for an existing firearm, then you should know that you’ll have to treat these special-purpose prints with a bit more care than your average 3D print jobs. In the sections below, I’ve gone over some helpful tips for 3D printing gun parts.

Dry the Filament

First, it’s important that you dry your filament before loading it into your machine and printing parts for your gun.

Filament materials, whether PLA or PETG, tend to absorb moisture from the air, which negatively affects the mechanical properties of the thermoplastic. And, if you don’t dry your filament before using it, the prints you make with the filament will have weak layer-to-layer adhesion (brittle) and be overall less durable.

Drying your filament involves heating it up in a controlled atmosphere to remove moisture from the inside of the plastic. You can do this by placing your filament spools in a filament dryer device or even just a conventional cooking oven, setting the temperature to between 65 and 80 °C, and taking the spools out after 4-6 hours. Then, load the filament in your printer, and you’re ready to go!

Check out our article on the best filament dryers here for more info.

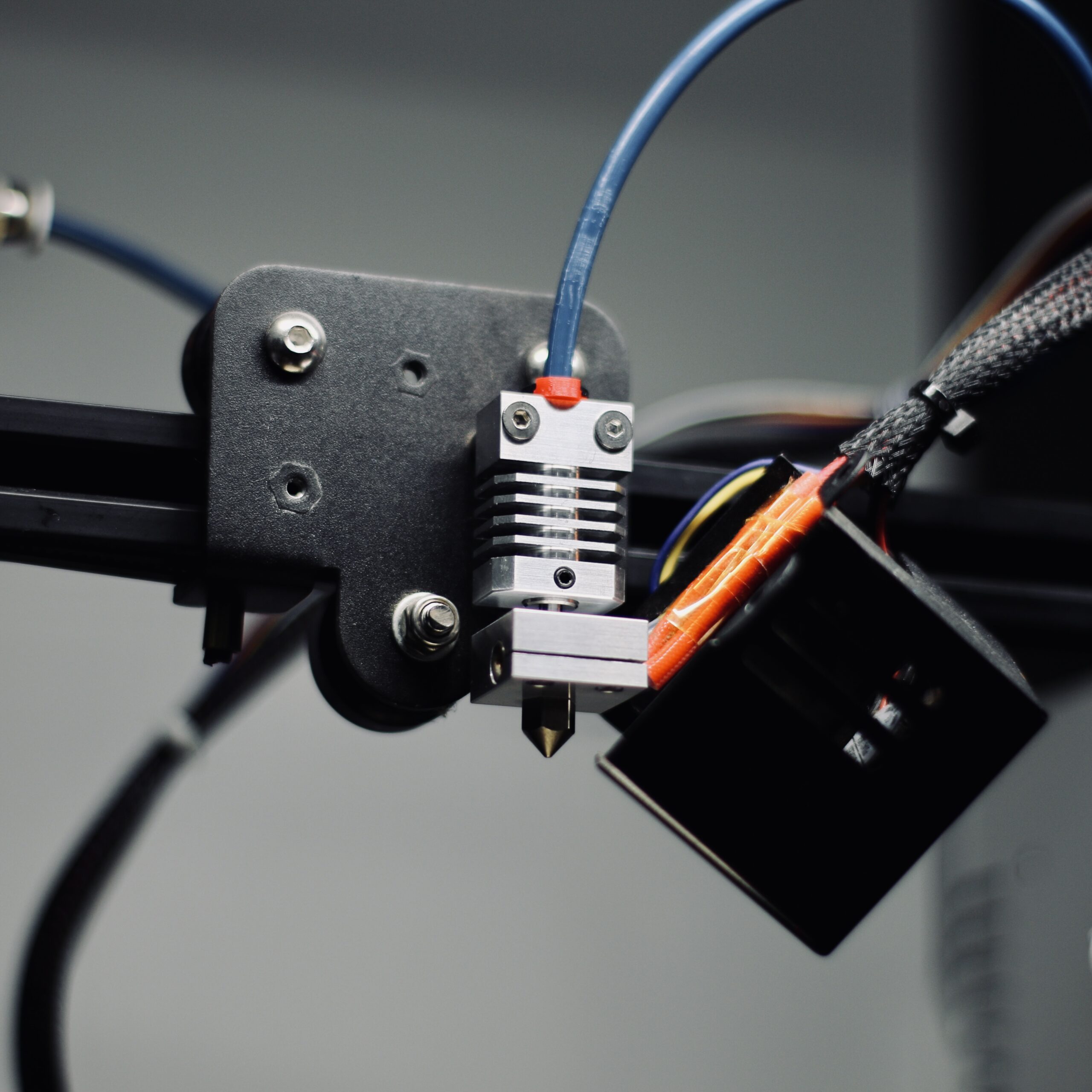

Use Hardened Steel Nozzle

If you want to print parts for your gun as strong as possible, then you should use a strong filament, like PETG, Nylon, or even Polycarbonate. And, if you’re using filaments like these, then you need to use a hardened steel nozzle.

That’s because, in general, the stronger the filament, the more abrasive it is, meaning it will wear out your 3D printer’s nozzle faster. Hardened steel nozzles, such as a Genuine E3D Hardened Steel V6 Nozzle, are abrasion-resistant, meaning they can handle high-abrasion filament materials, like nylon and PC, without wearing out fast.

While hardened steel nozzles are more expensive than brass or stainless steel nozzles, they are a good decision in the long run, because brass nozzles will wear out ten times faster.

Check out our related article on the brass vs stainless steel vs hardened steel nozzle here to learn more.

Use an All Metal Hot End

Next, it’s a good idea to use an all-metal hot end on your 3D printer if you’re making gun parts. As I mentioned in the previous tip, if you’re printing parts for a firearm, then you’re probably using a high-strength filament, like nylon or PC. And, because these filament materials require relatively high nozzle temperatures, an all-metal hot end is a good decision.

Moreover, high-temperature filament materials, such as PC, require temperatures that will cause traditional, PTFE-lined hot ends to clog. That’s because, in a PTFE-lined hot end, the Teflon liner will burn up at the temperatures required for printing high-strength filament materials. On the other hand, all-metal hot ends, like the E3D V6, don’t have a PTFE liner and can reach way higher temperatures without a chance of wearing down or clogging.

Prepare the 3D Printer’s Bed

Finally, you should make sure to do a good job when preparing your 3D printer’s bed for printing gun parts. If the first layer of your print doesn’t come down properly, the rest of the print will likely have issues. And, because 3D printed parts for guns must be super strong and precise, getting the first layer right is even more important.

Some good practices for preparing your 3D printer’s bed include cleaning the build plate and then lightly coating the bed in an adhesive, such as glue or DIY “ABS juice”. You should also make sure to level the bed and set the Z-offset, as these two factors also play a part in how well the first layer of your print comes down.

Conclusion

3D printed guns, while a bit controversial, are legal and make for a fun project for gun enthusiasts. However, whether you’re 3D printing a lower receiver or a few rail accessories, it’s extremely important that you use a durable, heat-resistant filament material to 3D print the components.

Furthermore, firearms send out a lot of heat and vibrations to their components, and if you don’t use a suitable filament material, the 3D printed parts will fail, potentially causing your gun to stop working or, at the very least, make it less accurate.

The best material for 3D printed guns is polycarbonate, as this material has the highest heat resistance, impact resistance, and tensile strength of any consumer-grade filament material. However, PC filament is very difficult to print, and you’ll need a high-temp nozzle and an enclosure on your 3D printer.

Because of polycarbonate’s printing difficulties, many people prefer to 3D print gun parts in PETG. PETG isn’t as strong as PC, but it’s still suitable for printing gun parts, with decent heat and impact resistance. And PETG can be printed on most 3D printers, such as the Creality Ender 3 and other budget-friendly machines.

Lastly, if you want a mix between PETG and PC, then nylon filament is probably the one for you. Specifically, I recommend using either a carbon fiber blend or a glass-filled nylon filament material as these two variants are the strongest and most durable forms of nylon. And, while nylon is a bit more challenging to print than PETG, it’s still way easier to use than PC.

Make sure you check out our related article on the best 3D printers for guns here.