- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Do you want gorgeous prints that would make Indiana Jones insist they belong in a museum? Then metal-filled filaments are what you’re looking for.

Do you want gorgeous prints that would make Indiana Jones insist they belong in a museum? Then metal-filled filaments are what you’re looking for.

Metal filaments give you the shiny look and weighty feel of actual metal — without the sky-high cost. As long as you have a regular FDM printer, even magnetic parts are within your grasp.

But printing metal filaments can be tough and they cost more than plastic. You don’t want to waste a lot of money on a filament that doesn’t give you the results you want.

Here are the best metal filaments in 2022 — and everything you need to know to make your prints look stunning.

Table of Contents

- Best Metal Filaments at a Glance

- Metal 3D Printing — Not Just for Factories

- What Are Metal Filaments?

- Metal Filaments VS Metal Color Filaments

- Types of Metal Filaments

- Ideal Metal Filament Use Cases

- How to Choose the Right Metal Filament

- How to Succeed in 3D Printing Metal Filament

- Pros and Cons of Metal Filaments

- Start Printing with Metal

Best Metal Filaments at a Glance

1. Proto-Pasta (Best Choice)

2. ColorFabb (Best Value)

3. FormFutura (Premium Choice)

4. Virtual Foundry

5. Gizmo Dorks

Available Filaments: HTPLA (Copper, Bronze, Brass), Magnetic Iron PLA | Nozzle Temperature: 185-215°C (365-420°F) | Bed Temperature: Max 60°C (140°F) | Spool Size: 0.5kg, 1.5kg, 2kg (Magnetic Iron PLA only) | Diameter: 1.75mm, 2.85mm

Despite its Italian-inspired name, Protopasta is an American company. But these metal filament artisti have created noodles whose strength is as delicious as the finest spaghetti.

Protopasta offers two kinds of metal-filled filaments — HTPLA and Magnetic Iron PLA. The heat-treatable PLA filaments are filled with genuine copper, bronze, or brass powder. They print easily, so you can enjoy gorgeous metallic finishes with little effort.

But did you notice that “heat-treatable” label?

Treating HTPLA prints at 110°C (230°F) for just 10 minutes makes them much harder and sturdier. After treatment, you can easily polish them or keep them in the sun without worrying about melting the plastic. Even with a metal content of around 15%, you could even use them as basic heat sinks.

The Magnetic Iron PLA, on the other hand, does what it says — it’s iron-filled and magnetic. Although you can’t heat treat it, you can polish prints to reveal the metal surface. Protopasta has instructions for aging the metal with vinegar to create stunning, rusty magnets and decorations.

Without heat treatment, though, both HTPLA and Iron filaments are very brittle. The cardboard spools — although environmentally friendly — don’t roll very well, which might cause issues.

But as long as you treat them right, Protopasta’s filaments produce relatively strong parts.

Pros

- Easy to print

- Strong after heat treatment

- Many post-processing options

Cons

- Very brittle without heating

- Cardboard spools roll poorly

- Color can stain other filaments

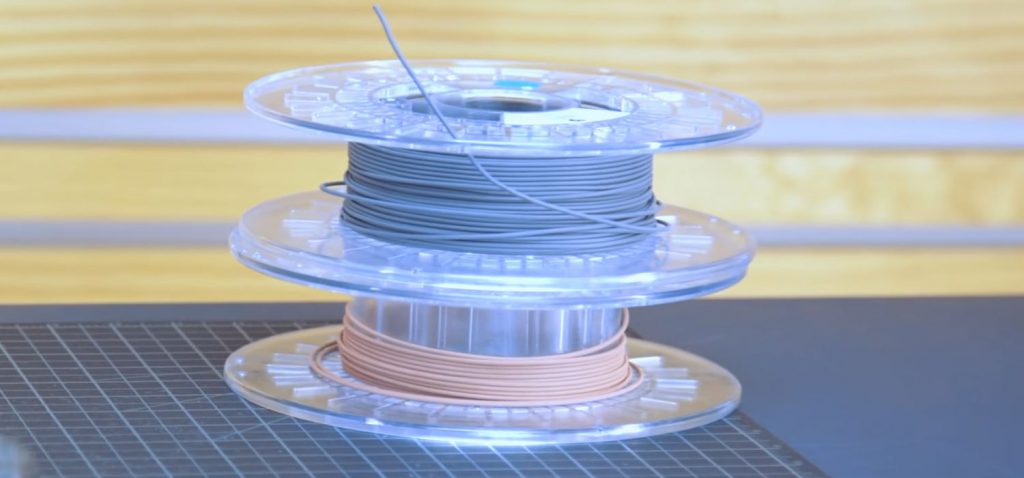

Available Filaments: BronzeFill, CopperFill, SteelFill | Nozzle Temperature: 190-220°C (375-430°F) | Bed Temperature: 50-60°C (122-140°F) | Spool Size: 0.75kg, 1.25kg | Diameter: 1.75mm, 2.85mm

ColorFabb released its first metal-filled filament — BronzeFill — already in 2014. The company has since expanded its metal filament range with CopperFill and SteelFill. Its veteran status shows — these filaments produce deceptively metal-like prints.

Each of these metal-filled filaments has a fairly high ratio of metal powder, from 30-40%. This gives them nice, real metal-like heft. With the sintered appearance of raw prints, you just might mistake them for real metal.

The filaments can withstand plenty of post-processing, from sanding to filing and polishing. You can make your prints look brand new or ancient and corroded with ease.

You’ll have to put in some effort to get on Easy Street, though.

Although ColorFabb’s metal filaments are simple to print, they need precise settings. You’ll end up with a few failed prints as you figure out what works for your printer. They’re also quite abrasive so do yourself a favor and buy a wear-resistant nozzle.

Once you’ve found the right settings, the filaments flow out of the nozzle like regular PLA. With a bit of trouble, you’ll get prints with beautiful, metal-like finishes.

Pros

- Look and feel of real metal

- High metal content

- Prints well with the right settings

Cons

- Needs precise settings

- Very abrasive

- Low-ish detail quality

Available Filaments: Classic Copper, Ancient Bronze | Nozzle Temperature: 200-230°C (392-446°F) | Bed Temperature: Up to 60°C (140°F) | Spool Size: 0.25kg, 0.75kg, 1.5kg | Diameter: 1.75mm, 2.85mm

FormFutura’s MetalFil metal-filled filaments are available in two different varieties — Classic Copper and Ancient Bronze. If you’re looking for metal filaments with high metal content, look no further.

FormFutura’s filaments have a by-weight metal content of 80%. They give ColorFabb’s high-metal filaments a run for their money — and beat some of them.

As you’d expect, the high metal ratio gives these filaments a very authentic metal look and feel. Your prints will also be three times heavier than regular PLA parts. If you want to print a gorgeous paperweight with an emphasis on weight, this is your material.

FormFutura’s Classic Copper and Ancient Bronze aren’t the easiest to print. They require carefully dialed settings to give successful results.

But as an upside, they’ll work just fine with practically any printer with the right settings.

Although most metal-filled filaments can be post-processed, these ones need to be. The raw prints are pretty dull and — honestly — don’t look particularly metallic. But after some sanding and aging, you’ll get incredibly realistic objects.

FormFutura’s products are a great choice if you’re looking to put heavy metal into metal filaments.

Pros

- Very high metal content

- Authentic metal look

- Good detail quality

Cons

- Sticks to printing bed way too tightly

- Needs post-processing

- Challenging to print

Available Filaments: Copper, Stainless Steel, Bronze, Aluminum 6061, High Carbon Iron | Nozzle Temperature: 205-235°C (400-455°F) | Bed Temperature: 40-50°C (104-122°F) |Spool Size: 0.25 kg (Aluminum 6061), 0.5kg, 1kg | Diameter: 1.75mm, 2.85mm

Virtual Foundry sets its metal-filled filaments apart from the other listed materials in two ways. First of all, the company has the widest range of available metal filaments.

Secondly — and more impressively — Virtual Foundry’s metal filaments can produce 100% metal parts.

The variety of different filaments gives you a lot of options for your parts. You can get practically any metal finish you want, so you can let your creativity go wild.

But it’s the post-processing possibilities that should make you excited. After printing, you can put the parts in a kiln or furnace to burn away the remaining plastic binder.

After sintering, you have in your hands a sturdy, all-metal part. How many other options do you have for printing actual 100% metal at home?

But as you may guess, printing with these filaments isn’t as simple as many others. To begin with, the filament is very brittle and snaps easily. You also need precise settings to get it to print smoothly.

The surface quality is porous after printing and sintering, so be prepared to do more work on your parts. And finally, there’s the price — these are very expensive materials.

But it’s all worth it to make full-metal parts at home.

Pros

- Can make 100% metal parts

- Sintered prints are decently strong

- Many metal options

Cons

- Expensive

- Brittle filaments are challenging to print

- Needs post-processing

Available Filaments: Copper Fill, Bronze Fill | Nozzle Temperature: 190-225°C (374-437°F) | Bed Temperature: Up to 70°C (158°F) | Spool Size: 1kg | Diameter: 1.75mm, 2.85mm

Metal-filled filament can be expensive — but they don’t have to be. Gizmo Dorks’ two materials offer an affordable option for printing metal-filled filaments.

Not only are these filaments competitively priced, but they also print easily compared to many of the other listed brands. You’ll still have to tune your settings right but they print much like regular PLA.

If you don’t like the headache of messing with your printer, these are the metal filaments for you. The easy printing has a flipside, though — Gizmo Dork has included only 5% metal powder content in the filaments.

But that doesn’t mean you can’t get good-looking prints out of them.

Despite the low metal content, you can print fine-looking objects with these materials. The finish looks and feels decently metallic, so you can print gorgeous decorations. It can also be more challenging to weather or age the prints since they don’t have that much metal.

But if you’re looking for a solid low-cost metal-filled filaments, you can’t do much better than these.

Pros

- Affordable

- Easy to print

- Good print quality

Cons

- Low metal content

- Not great for post-processing

- Brittle filament

Metal 3D Printing — Not Just for Factories

You may think metal 3D printing is something reserved for industrial manufacturers with expensive special metal 3D printers. But that’s not true — if you use metal-filled filaments.

Metal-filled filaments allow anyone with an FDM 3D printer to start printing metallic parts and objects. They’ll have all the features of metal you’d expect — the look, the weight, and they can even be magnetic.

But using metal 3D printer filament isn’t quite as straightforward as regular plastic materials.

Let’s take a deep-dive into what metal-filled filaments are (and aren’t), what they’re good for, and what you need to start producing hefty metal prints.

What Are Metal Filaments?

Let’s clear one common misconception right off the bat. We’re not talking about pure, 100% metal filaments here. Some manufacturers market these filaments as “metal” but that’s not entirely accurate.

Instead, the term “metal-filled filaments” gives you a more appropriate idea of what you’re dealing with. Metal-filled filaments consist of actual metal powder infused into a plastic binder.

You could theoretically use any plastic as the carrier material. Most manufacturers, however, go for standard PLA for its ease of printing, machine support, and physical characteristics.

How much metal powders are in the filament depends entirely on the brand and the filament itself. Manufacturers measure the metal powder content as a percentage based on weight or volume.

And this is where you have to be careful when purchasing metal-filled filaments.

It’s common for manufacturers to use weight measurement for the metal content — because it gives you a bigger number. After all, metal is much heavier than plastic. When you look at the by-volume metal content, it can be significantly lower.

Let’s assume “Metal Filament X” has a touted 90% copper content. But when you look at the density, it’s only 3.5g/cm3, far below copper’s 8.96g/cm3 density. This tells you that the by-volume metal content is actually somewhere above 30%.

That’s still pretty good for a metal filament. But this discrepancy is something you should be aware of.

Metal Filaments VS Metal Color Filaments

It’s good to know that metal-filled filaments aren’t fully metal. But you should also make sure that your filament has some metal in it.

Some companies sell “metal filament” that doesn’t actually have any metal. They simply have a metallic coloring to give prints the superficial appearance of metal.

Particularly customer-oriented companies will indicate when their metallic color filaments don’t contain any metal. But the labeling isn’t always exactly clear.

You can avoid wasting your money on filaments you don’t want by keeping a sharp eye on the labels.

When buying metal filaments, look for materials labeled as “metal-filled” or “composite.” These terms indicate the filament has metal in it.

Types of Metal Filaments

Any metal can be used to make metal-filled filaments. That said, some more exotic metals are so expensive that you’ll never see them in these applications. The most common metal filament types are copper, bronze, brass, and stainless steel.

- Copper: Copper-filled filaments contain pure copper powder and are popular options for creating sculptures and other decorative objects. It’s possible to corrode copper with, for example, vinegar and salt to give it an aged, turquoise patina — like that on the Statue of Liberty.

- Bronze: Bronze — an alloy of copper and tin — is another popular option for making decorations. It, too, can be aged with chemicals and grinding for an ancient look.

- Brass: Brass filaments contain a mixture of copper and zinc. They behave much like bronze filaments but have a more yellowish color, so you could use them to imitate a golden surface.

- Stainless Steel: Stainless steel-filled filaments can’t be aged since — as the name implies — they resist stains and rust. However, they’re your only option if you want to print magnetic parts.

Ideal Metal Filament Use Cases

Despite what you may expect, metal-filled filaments are a poor choice for printing tough and strong parts. Although they’re heavy like metal, they’re usually more fragile and brittle than plastic parts.

The parts are flimsy because the metal powder generally doesn’t melt. As a result, there’s less plastic to fix the print layers to each other.

So, what can you actually use metal-filled filaments for?

Metal filaments are ideal for decorative objects. What they lack in strength, they make up for with an authentic, gorgeous metallic finish. They’re great material options for printing:

- Paper weights

- Sculptures and artwork

- Museum replicas

- Theater props

- Cosplay accessories

- Ornaments

- Fridge magnets

How to Choose the Right Metal Filament

Metal-filled filaments are rather niche materials, but you still have multiple options available. Consider these factors when picking a filament so you don’t waste money on materials that don’t work:

- Finish: If you want your finished prints to look aged or corroded, choose a copper-based filament. Stainless steel filaments are borderline impossible to corrode, but they can be polished to a shiny, modern steel look.

- Part Geometry: Metal-filled filaments aren’t great for printing overhangs or bridges since the weight of the material will cause it to sag. If you must print complex parts, pick a filament with lower metal content.

- Magnetic Parts: If you want magnetic parts, stainless steel is your only option. Other kinds of metal filaments will not come out as magnetic.

How to Succeed in 3D Printing Metal Filament

You can print metal-filled filament with a regular FDM printer — with some precautions. Here are some great tips for printing with metal filaments that will save you time, money, and nerves.

- Use a Wear-Resistant Nozzle: Metal powder is abrasive and will quickly wear out ordinary brass nozzles. Upgrade your printer with a hardened steel nozzle before attempting to print these filaments. Check out our best 3D printer nozzle guide here if you want to learn more about nozzles.

- Up the Nozzle Size: Although you can print metal filament with an ordinary 0.4mm nozzle, the metal particles can easily clog it. Since you already need to buy a hardened nozzle, you may as well get one with a 0.5mm or 0.6mm diameter.

- Ensure a Straight Filament Path: It’s not just the final prints that are brittle — the metal filament itself is also very fragile. Consider moving your filament spool or buying a separate filament holder to avoid any sharp bends in the filament path.

- Avoid Bridging and Overhangs: Metal filaments are very heavy and can easily droop or slough off while molten. If your part requires bridging or overhangs, consider whether you should use metal filament in the first place.

Pros and Cons of Metal Filaments

Pros

- Unique and beautiful part appearance

- Works with standard FDM printers

- Many colors and finish options

- Cheaper than actual metal 3D printing

Cons

- Filaments and prints are brittle

- Abrasive materials

- Poor overhangs and bridging

- More expensive than plastic filament

Start Printing with Metal

Printing with metal-filled filaments lets you create beautiful objects that look and feel like real metal — without the costs and difficulties of actual metal 3D printing. With some practice, you’ll print gorgeous decorations, sculptures, and props at home at a relatively low cost.

If you’re still wondering which filament is right for you, here are my recommendations:

- Protopasta’s heat-treatable filaments give a bit more strength than others.

- FormFutura and ColorFabb are both great choices for good-looking prints.

- For low cost and easy printing, Gizmo Dorks is your choice.