- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

Resin is the fuel for SLA 3D printers. And, just as there are many different types of FDM 3D printing filaments, there are also a handful of different types of resins.

Resin is the fuel for SLA 3D printers. And, just as there are many different types of FDM 3D printing filaments, there are also a handful of different types of resins.

Some are meant for detailed prints, others for rapid prototyping, and so on and so on. The best resin for you depends on what properties you’re looking for in a resin.

If you don’t have any particular features in mind, I suggest going with a Standard resin, like Elegoo Standard resin, which comes in a handful of colors and is a terrific all-around pick. But, if you’re printing miniatures and want to maximize detail in your resin prints, then an 8K resolution resin, like Phrozen Aqua 8K, would be a more suitable option.

And, for strong prints, a tough resin, like eSun Hard Tough Resin, would be best as it provides significantly more tensile strength than most other options. There are other types of resins, too, such as flexible, fast (draft), and water-washable resins, each catering to a different audience.

To learn more about the best resins for each type or feature, whether it’s flexible, standard, high-detail, or another category, just keep reading!

Best Resins for 3D Printers At A Glance

Standard

1. Elegoo Standard Resin (Best Choice)

2. Sunlu Standard Resin

Flexible

3. 3DMaterials SuperFlex (Flexible)

Tough

4. eSun Hard Tough Resin (Strongest)

5. Anycubic Tough Resin (Premium Choice)

Fast

6. Siraya Tech Fast Resin (Fastest)

Water-Washable Resin

7. Elegoo Water Washable Resin (Easiest to Use)

8. eSun Water Washable Resin

8K Resin

9. Phrozen Aqua 8K Resin (Best Value)

Standard

First, we’ll go over some Standard resins, which are resins that are overall good options but don’t have any particularly interesting properties. These resins are usually best for print quality, and I suggest using a Standard resin if you’re new to SLA 3D printing.

Elegoo is one of the biggest companies in the consumer resin 3D printing space, and their Standard Resin is one of the most popular resins on the market. This resin was actually the first bottle I ever bought for my first resin printer (an Elegoo Mars 3), and I continue to use Elegoo Standard Resin because I love it so much.

This resin is just, overall, an amazing material. It’s decently strong, yields exceptional detail, especially for 4K printers, and prints pretty fast too. I was able to make one heck of an Eiffel tower model using a layer exposure time of just 2.5 seconds, which is way above the typical 5-second exposure time that most resins need.

But what I love most about this resin is how many color and size options you have. Moreover, Elegoo sells their Standard resin in eleven colors, including unique options like clear blue, clear red, clear green, maroon, and beige. Additionally, you can buy bottles in either 500 or 1000 grams.

So, if you need a resin that’s good in every way, including print quality, speed, strength, and price, then I strongly suggest Elegoo Standard Resin!

Sunlu mainly focuses on making FDM 3D printers and filaments, but their Standard Resin is surprisingly a beast of resin.

Sunlu Standard Resin is widely compatible with resin printers, including both 4K and 8K machines. Furthermore, the print quality yielded by this resin is honestly insane, given the price. For under $25, you can get a full 1-kg bottle of resin that you can use to make super detailed prints.

Additionally, Sunlu told us that their resin is good for lowering post-printing curing times. This isn’t that big of a deal because UV light curing for resin prints usually takes max 5 minutes. But it’s always a good property to have for resin!

Flexible

Below, I’ve reviewed the best flexible resins, which are 3D printable materials that yield elastic, bendy, or otherwise flexible prints. These are super fun to use and come in handy for printing toys as well as functional models.

3DMaterials isn’t a super well-known manufacturer of 3D printing resins, but their SuperFlex resin certainly lives up to its name, yielding very stretchy and bendy 3D prints.

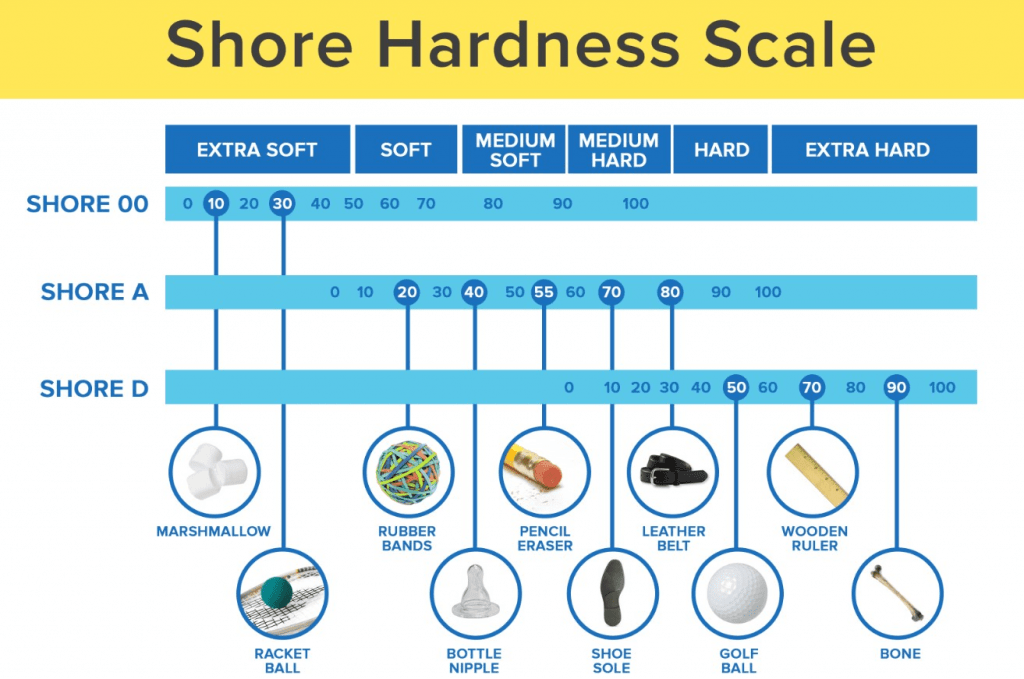

According to 3DMaterials, SuperFlex resin has a Shore Hardness rating of 80A, which falls in line with the rigidity of a rubber shoe heel. You can check out our section on Shore Hardness near the end of this article to learn more about this scale. But, for now, all you need to know is that SuperFlex makes insanely flexible models.

Personally, I love to use flexible resin to make fun toys and objects. But, for more professionally-focused makers, SuperFlex is very useful for making prototypes that need to be impact-resistant and flexible.

Tough

If you want to print strong models in resin, then a tough resin is for you. Below, I’ve reviewed two of the best high-strength and durability resins.

eSun is a company that primarily makes FDM 3D printers and filaments, but they also devote some effort to making SLA products. Their Hard Tough Resin might not have the best name, but it’s, by far, one of the strongest resins money can buy (for consumers).

According to the manufacturer, this resin has a Shore Hardness rating of 75-81D, which is similar to the hardness of a construction hard hat. And the tensile strength of prints made of eSun Hard Tough Resin has been tested to go as high as 60 MPa. For reference, Anycubic’s Standard Resin+ has a tensile strength of about 43 MPa.

As such, eSun Hard Tough Resin is significantly stronger than your typical 3D printing resin. This is likely because this specific resin was developed to have similar properties to ABS, a popular filament material known for its strength.

So if you’re printing a model that needs to be strong, such as a laptop stand or door hinge, and want to use an SLA 3D printer, definitely give eSun Hard Tough Resin a shot!

Anycubic is another very prominent company in the consumer 3D printing space, and their Tough Resin is another very strong option.

First off, I’d like to point out that Anycubic Tough Resin costs a pretty penny compared to most resins out there, making it more of a premium choice for consumers. But this resin has many good properties that make up for its price.

Moreover, according to Anycubic, their Tough Resin has a tensile strength of up to 45 MPa. While this isn’t as strong as eSun’s Tough resin, it’s worth noting that this resin offers very good print quality.

Don’t take my word for it, though. Just check the reviews, which are full of good reviews about how well this material prints and pictures of high-detail models that are also strong.

Fast (Draft)

Draft resin is a resin that can be printed fast, with a low layer exposure time. It’s super useful if you need to produce models, like prototypes, as fast as possible. In the section below, I’ve gone over my favorite draft resin!

You might not have heard of Siraya Tech, but they make one hell of a fast-printing resin. I’m not kidding when I say Siraya Tech ABS-Like Fast Resin is one of the speediest resins in the consumer SLA 3D printing market.

You can make high-quality models with Siraya Tech Fast Resin using an exposure time of around 2.5 seconds, which is extremely fast. Most resins require exposure times of around 5 seconds, but this resin needs literally half this time, and models still come out with decent print quality.

Additionally, this resin has very similar properties to ABS, hence the “ABS-Like” in its name. As such, the resin is also noticeably stronger than other resins.

Water-Washable Resin

Most SLA prints need to be washed with a solvent, like acetone or isopropyl alcohol, before being cured. But water-washable resin is a lot easier to work with because you can just use water instead of a smelly and dangerous chemical. I’ve gone over my two favorite resins in this category below!

Another product from Elegoo is their Water Washable Resin, which is definitely one of the easiest-to-use resins on the market.

As it’s a water-washable resin, you won’t need any acetone or IPA to wash prints made in Elegoo’s Water Washable resin. Instead, just fill up a Tupperware container with water and drop your finished print in for a few minutes.

While the ability to wash this resin with water might not sound super significant, I promise you it makes life so much easier. And it greatly reduces the smell of post-processing SLA prints because typical solvents (e.g. acetone) leave a strong stench. And these solvents can damage your skin and eyes because of the vapors they produce.

But despite how easy this resin is to work with, Elegoo Water Washable resin still is an overall good pick when it comes to print quality and other features. Moreover, I wasn’t able to notice a difference in quality or strength between prints made with this resin versus Elegoo’s standard resin. The only downside is that it costs a few bucks extra over a “Standard” resin.

eSun also makes a water washable resin, and it’s very similar to Elegoo’s Water Washable resin. However, I was able to achieve slightly better print quality using this resin over the other resin we covered in this category.

But both options are still with including because eSun’s water-wash resin is slightly more expensive than Elegoo’s option, so the choice between quality and price is up to you. Additionally, it’s worth mentioning that eSun Water Washable Resin is available in a few colors, including beige, black, gray, transparent, and white.

8K Resin

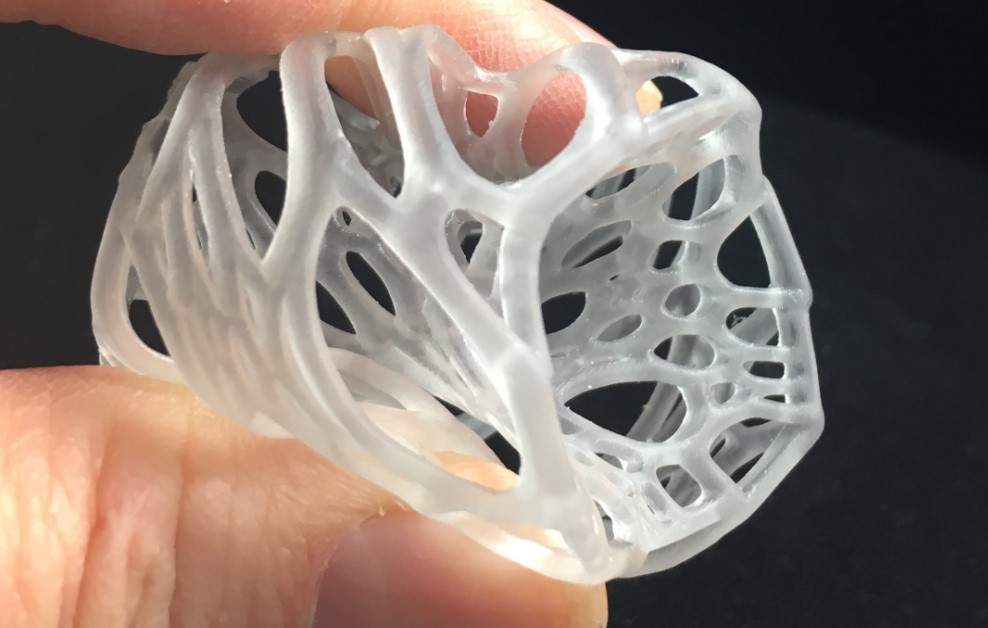

Lastly, 8K resin is one of the latest innovations in the SLA 3D printing industry, and it yields insane amounts of detail in models. I’ve gone over the best 8K resin below!

Our last product on this list is Phrozen Aqua 8K, a resin optimized for being printed with an 8K pixel resolution. This resin easily outperforms virtually any other option on the market when it comes to print quality.

You’ll get the most amount of detail and the best print quality out of this resin if you’re using an 8K resolution 3D printer, like the Elegoo Saturn 2 or Phrozen Sonic Mini. But you can still use this 8K-optimized resin with printers that have sub-8K LCD screens, such as the Elegoo Mars 3. It’s just that the model won’t technically have an 8K resolution; it will have the maximum resolution of the printer.

But, still, this 8K resin is still a great option if detail and print quality is your main concern for 3D prints. And it also comes in four colors, including snow gray, vanilla, clay red, and normal gray, which is a nice bonus!

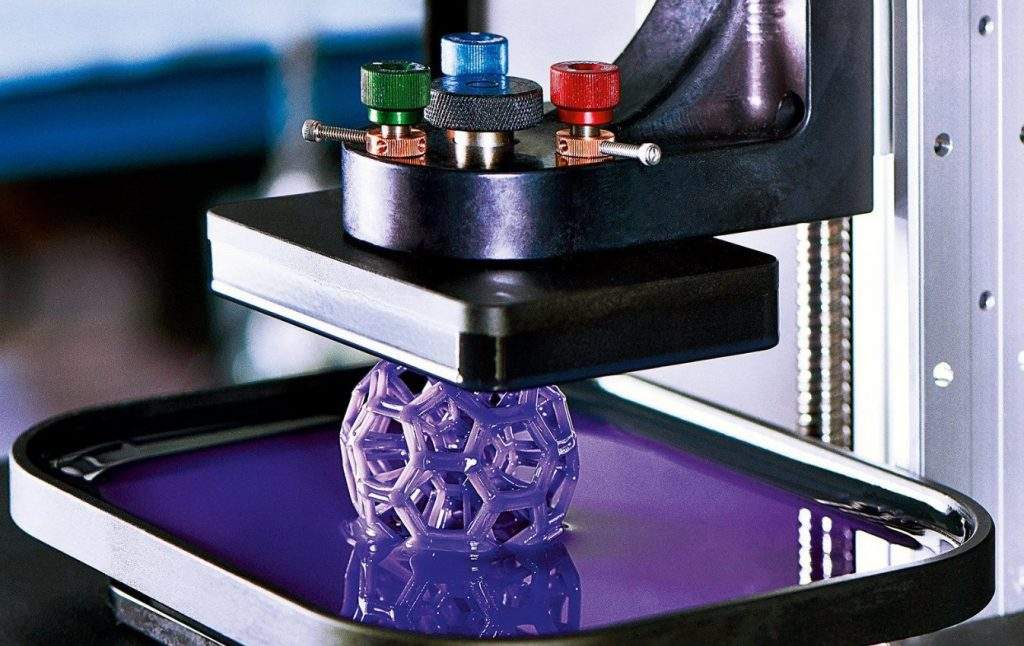

What is 3D Printer Resin?

3D printer resin is the material you use on an SLA resin printer, also known as an LCD or DLP printer. In other words, just like you need filament for FDM 3D printers, you need resin for LCD/DLP printers.

The difference is that filament is a stringed, solid material, while resin is a viscous, liquid material because resin 3D printers use light rather than raw heat to make 3D models.

3D printer resin is basically just as inexpensive as 3D printer filament, costing anywhere from $15 to $50 typically for a 1-kg bottle. To use the liquid resin on an LCD printer, you need to pour it (with a filter) into the VAT, which your printer uses to make your 3D print.

Considerations for Resin:

When it comes to picking a 3D printer resin, there are a few important factors to keep in mind, which I’ve gone over in the mini sections below.

Printer Compatibility

One of the most important factors for a 3D printer resin is its compatibility with your specific 3D printer.

Technically any 405nm resin, which is almost any resin on Amazon, works on a typical resin 3D printer. However, if a resin doesn’t have the same wavelength as your printer, then you can’t use it.

Another thing that influences the compatibility of a resin with your printer is the resolution the resin is meant to be printed with. Moreover, some resins are optimized to be printed on a machine that has an LCD with a certain pixel resolution. For example, Elegoo 8K Standard resin is best printed on a printer with an 8K screen, like the Phrozen Sonic Mini 8K.

But you don’t have to worry about this too much because a 4K resin will print just fine on an 8K printer, and an 8K resin will print fine on a 4K resin. But just know that the lower of your resin and printer LCD determines the actual resolution of the prints you make. As such, try to match up your printer’s LCD resolution with the resolution of your resin.

Print Quality

The print quality of a resin is how well the material prints and how much detail the model can handle. This is usually determined by the pixel resolution of the resin (if it has one stated), which I explained in the previous point. You can also determine the print quality of a resin by looking at the reviews because not all manufacturers are honest (what a shocker!).

Strength

Strength also matters for resins, just like it does for 3D printing filaments. If you’re planning to print functional models, like a laptop stand, then you’ll want a resin with a decent amount of strength.

You can usually check how strong a resin is by looking at the reviews. And, if provided by the seller, you can check the tensile, flexural, or compressive strength of the material. Most resins have a tensile strength of around 30 MPa, so anything higher is relatively strong.

Flexibility

Some resins are also flexible, so if you want to print bendy, stretchy, or otherwise flexible models, you’ll want to make sure your resin is as flexible as you want.

Flexibility for resins (and filaments) is usually measured using the Shore Hardness Scale, which I’ve provided a picture of below (with examples):

Make sure the resin you buy has a Shore Hardness rating near what you want your prints to have.

Curing

Curing is super important for the resin printing process because, once a print is finished, you need to expose it to UV light to ensure the model is completely solidified. Some resins respond better to curing than others. And some also need less time under UV light.

While the curing time of a resin doesn’t matter too much because it’s usually under 5 minutes, you might still be interested in this. You can also check the reviews to see how well a resin print looks after the curing process is complete.

Different Types of Resins:

There are a few different types of resins, each with its own set of unique properties and features. I’ve gone over the main types below:

Standard

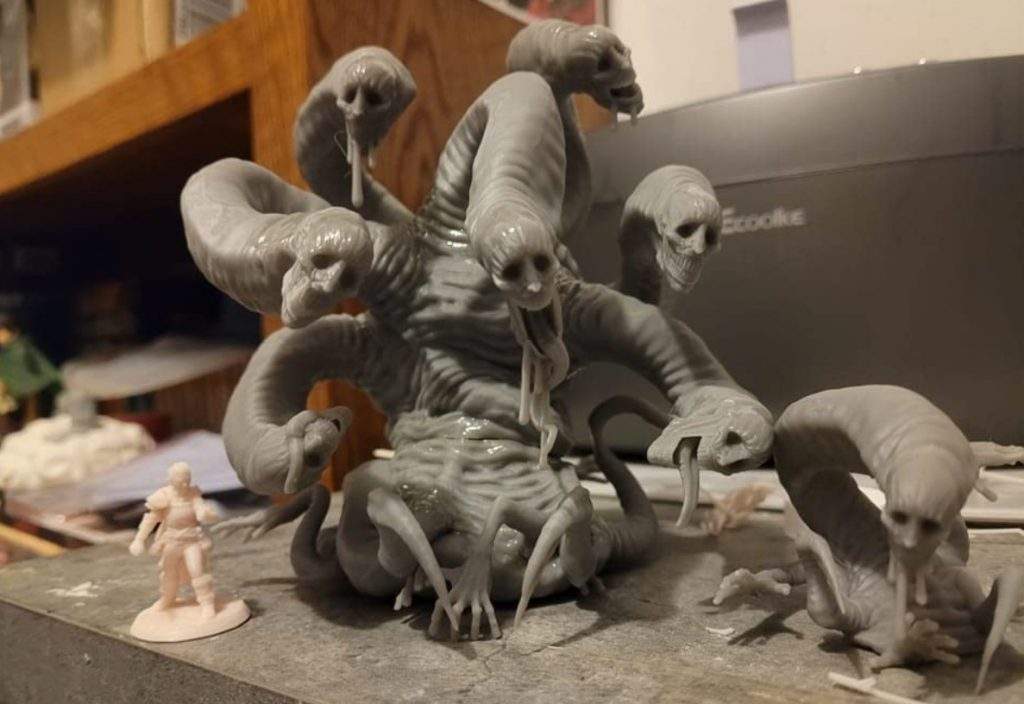

A standard resin is just your typical 3D printing resin. These resins don’t really have any particularly interesting features. They’re just solid, semi-strong, and non-flexible. But, it is worth noting that most standard resins fare pretty well when it comes to printing detailed models, like miniatures.

Flexible

Flexible resins have a low Shore Hardness rating, meaning prints made in this material will be more stretchy, bendy, and elastic. These resins are usually best for printing impact-resistant models or parts that need to be flexible, like a bracelet.

Tough

Tough resins, as the name indicates, are strong resin materials that have higher tensile, compressive, and flexural strengths compared to normal (standard) resins. These resins are usually based around an inherently strong polymer, like ABS or polyurethane, to provide more strength than a standard photopolymer resin.

Tough resins are obviously popular for printing functional models, like a laptop stands or door locks.

Fast (Draft)

Lastly, fast resin, also called draft resin, is a resin optimized for speed. As such, these resin materials can be printed using lower layer exposure times, meaning prints will take less time. They’re especially popular for prototyping because you can make models a lot faster!

Is Resin Food Safe?

No!

No, no, no! And an extra “no” if you missed the first four.

Moreover, 3D printing resin is considered toxic. While curing a resin 3D print can make a print more food-safe than pre-curing, it’s still not safe because of the inherent food-safety risks from the resin printing process (releases chemicals from resin).

Even if it’s ABS-based, I strongly advise you not to mix any resin 3D print with food, water, or any other edible substance. One possible workaround would be covering a model in a food-safe coating, but even with this, I’d still be wary.

Advantages and Disadvantages of Using Resin

If you still can’t decide if it’s a good idea to 3D print with resin using an SLA printer, don’t worry. To help you reach your consensus, I’ve made a list of the benefits and downsides of using resin below:

Advantages

- Super detailed 3D prints. Way more detail than FDM 3D printing.

- Resin 3D printers aren’t expensive and are often cheaper than FDM machines.

- Resin material is widely-available, comes in many colors, and is just as cheap as filament.

- You don’t have to fiddle with many slicer settings. Achieving high-quality prints is wayyyy easier using resin than filament.

- Resin technology improves every day at a much faster rate than consumer FDM printers.

Disadvantages

- You have to wash and cure resin prints after they’re done printing, which can be annoying and require additional hardware.

- Resin smells. It’s very noticeable!

- Resin isn’t as strong as most FDM 3D printing filaments.

- Resin isn’t food-safe.

- Resin can be difficult to handle due to its risks (don’t spill it!).

Conclusion

Choosing a resin for a 3D printer can be an intimidating process. Seeing terms like “405nm”, “tensile strength”, and “4k pixel resolution” makes the purchasing process a lot more difficult than it really is.

There are really only a handful of different types of resins, including standard, flexible, water-washable, tough, fast (AKA draft), and 8K (or high-detail) resin.

Standard resin is good for most general 3D prints and offers a mix of properties, including speed, print quality, and strength. This is the type of resin I recommend for anyone looking to make a normal 3D print or new to the SLA 3D printing space. And, if you don’t know what standard resin to get, I definitely recommend Elegoo Standard Resin, as it comes in many colors and is superb for print quality.

For flexible resin, you should check out 3DMaterials SuperFlex resin, as it has a low Shore Hardness rating that provides a lot of elasticity for prints. And, for strong prints, a tough resin, like eSun Hard Tough ABS-Like resin, should do the trick, as models printed in this material have a very high tensile strength.

Enjoy!