A nozzle is easily one of the most important parts of a 3D printer. After all, it’s the last part of the machine that touches the filament before it’s laid out on the print bed and turned into your desired model.

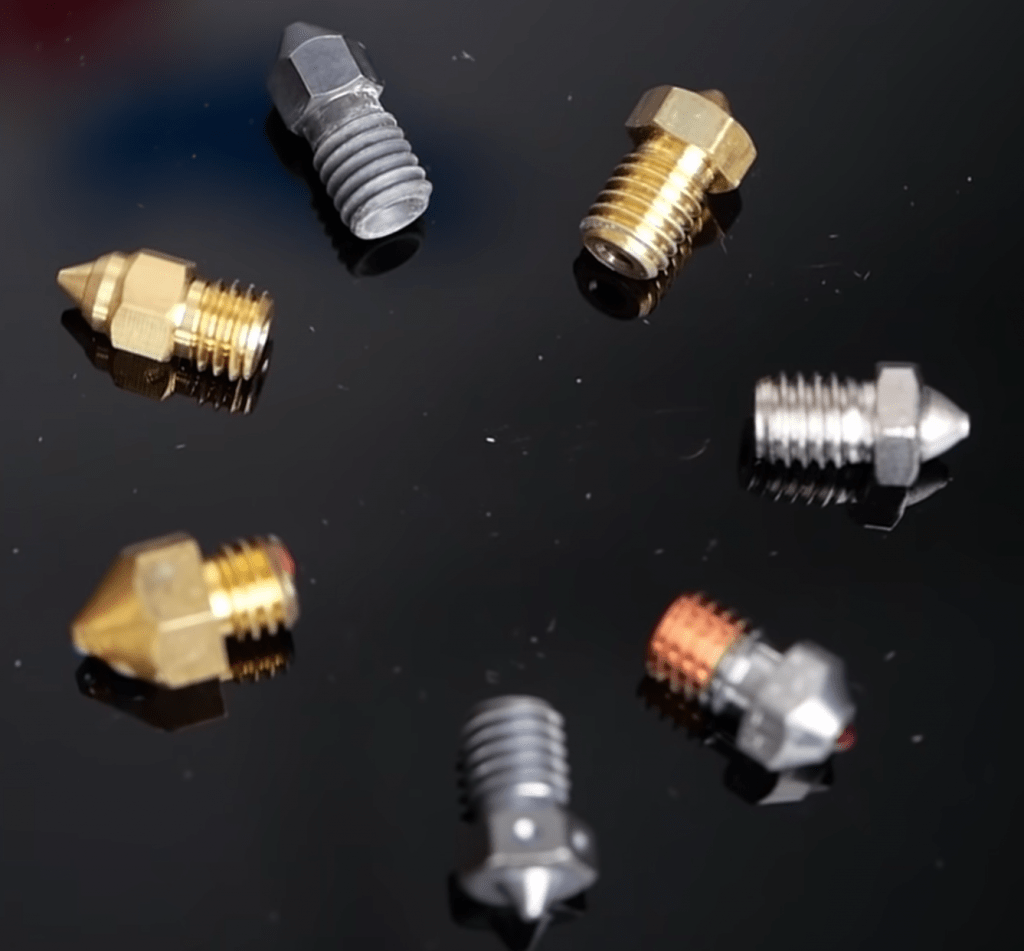

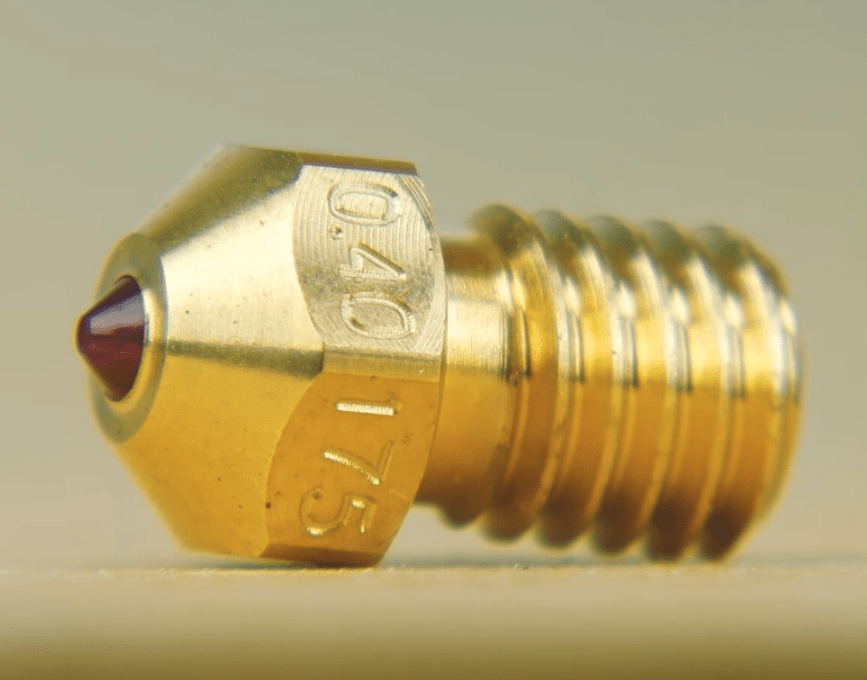

As you probably know, nozzles vary in a few ways, such as their output diameter (e.g. 0.4 mm), thread size, shape, and, of course, their material. While most 3D printers come with a brass nozzle, there are a handful of other suitable nozzle materials, including stainless steel and hardened steel.

Brass is the least expensive but also the least long-lasting. A hardened steel nozzle is much more rigid, abrasion-resistant, and long-lasting than a brass one, making it perfect for printing strong materials like polycarbonate, nylon, or carbon fiber composite. Finally, a stainless steel nozzle is good for printing food-safe parts as the metal doesn’t let any contaminants stick to its surface.

Want to learn more about 3D printer nozzles and the differences between brass, stainless steel, and hardened steel nozzles? Well, read on then!

Table of Contents

What is the Use of Nozzle on a 3D Printer?

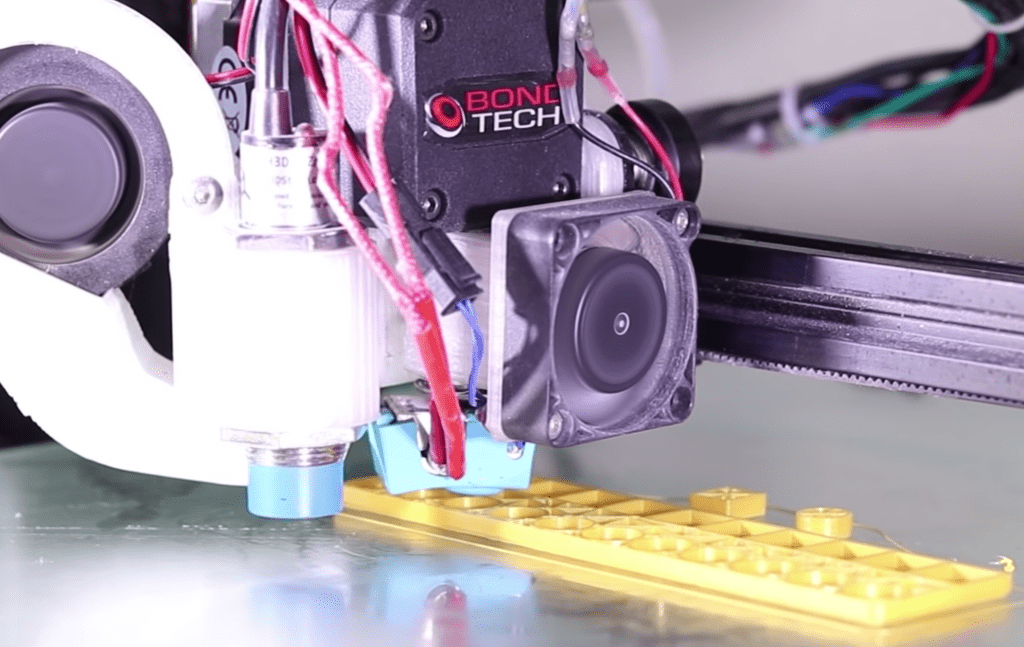

A nozzle is used on a 3D printer to control the flow of filament after it’s passed through the hot end and melted. As I mentioned, the nozzle is the last point the filament touches before it starts forming the desired model.

Without a nozzle, the melted filament would come out very messy, and the printer would have very little control over where filament is and isn’t.

The nozzle screws onto the bottom of the hot end assembly and forces the melted filament to flow out of a specific-diameter hole (usually 0.4 mm). This restricted flow, along with the precise motion of the printhead during a print job, allows a 3D printer to be very precise in where material goes.

Why is the Nozzle Material so Important?

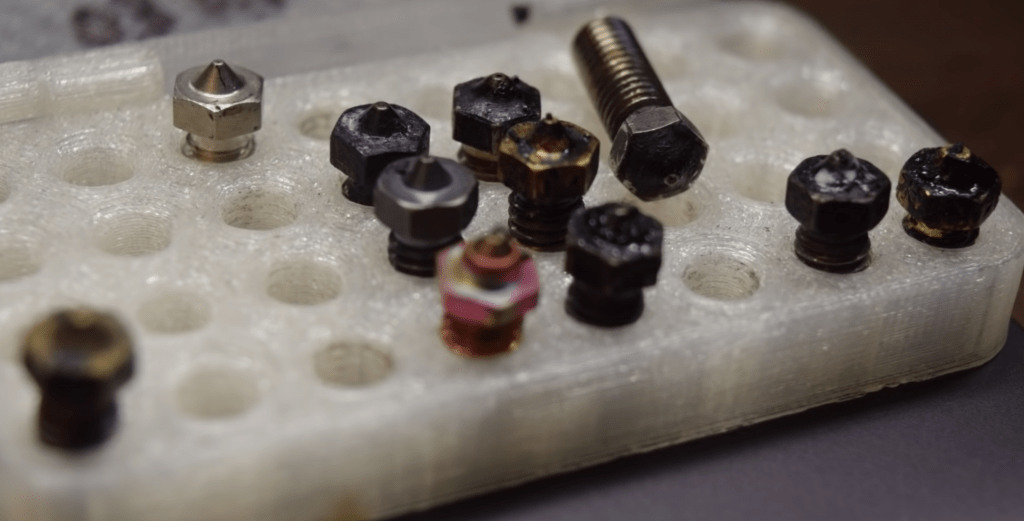

One of the most important elements of a nozzle is the material it’s made of. The material of the nozzle mainly affects the durability and longevity of the nozzle, which is how long it lasts before deforming or breaking.

Moreover, if you use a weak nozzle material, such as bottom-of-the-bucket brass, your nozzle might start to degrade in a matter of days or after a few prints. On the other hand, a high-end steel nozzle can last months or even years before any print quality issues ever show face.

On a similar note, the material of the nozzle you’re also using controls which filaments you can use. That’s because some 3D printing filament materials, such as polycarbonate or carbon fiber composite, are more abrasive and rough and will only work well if printed with a nozzle made of a strong material.

So, if you have a brass nozzle, which is relatively weak, you’re limited to printing the less-abrasive filament materials, like PLA and ABS. But if you have a hardened steel nozzle, you can basically print whatever filament material you want without having to worry if the nozzle will degrade and start causing print quality issues.

You may have noticed that the nozzle materials we referenced are all metals. Metal is the most popular type of material for 3D printer nozzles because it has a relatively low price, and its conductive properties ensure that the inflowing filament stays melted. But, it is worth noting that nozzles do not technically have to be metal and could be made of another material as long as it’s conductive enough.

The most popular nozzle materials are brass, stainless steel, and hardened steel. If you want to learn more about these three nozzle materials, then read on!

1. Brass Nozzles

First up, we have brass. Brass nozzles are definitely the most popular for 3D printers, and this stems from many reasons, but mainly because they’re so inexpensive and available basically anywhere (e.g. Amazon, 3D printer stores, etc.).

So, just how cheap are brass nozzles? Well, a quick search on Amazon will show you products that have 25 brass nozzles for only $10. However, higher-end brass nozzles, such as those from E3D and DiamondBack, can get as expensive as $20 or $25 a pop.

On a related note, I recommend that you look into the reviews of whatever brass nozzle you’re buying. Typically, the less expensive nozzle sets will degrade a lot quicker than the more expensive and name-brand options due to a difference in the quality of the brass used and the manufacturing methods involved.

As for printing, brass nozzles aren’t that bad and extrude non-abrasive filament materials, like PLA, super well. I usually never see the need to replace my brass nozzle until after a few months of printing PLA or ABS.

However, I’d stay away from brass nozzles if you want to print abrasive materials like nylon, PC, or composites (e.g. carbon fiber-infused PLA). That’s because brass doesn’t hold its structure super well when these materials are rubbing against it, leading to rapid nozzle degradation and printing issues (e.g. clogs, inconsistent extrusion).

Another benefit of choosing a brass nozzle is that, because it’s the most popular, it comes in so many variations. Brass nozzles come in basically any nozzle diameter, whether it be 0.05 mm or 1.2 mm. Additionally, this type of nozzle comes in many variations (based on the screw thread) to work on a wide range of printers, such as the Creality Ender 3, Anycubic i3 Mega, Anet A8, and loads more.

Overall, I love brass nozzles because they’re a terrific bang for your buck. For under a dollar a piece, a brass nozzle can yield amazing prints in non-abrasive filaments and you can find them basically anywhere, in any variation.

2. Stainless Steel Nozzles

Stainless steel is probably the least popular nozzle material of the three discussed in this piece, but nonetheless, it’s still an exceptional option. It just has a very specific purpose: food safety.

Moreover, the chromium composition inside stainless steel makes it very hard for any contaminants or substances to stick to the surface of the metal. This is why this type of steel is so popular for kitchen utensils (e.g. cutting knives). For the same reasons, stainless steel is the perfect nozzle material for printing food-safe or food-contact models, like a fruit bowl or a knife sheath.

Regular 3D printer nozzle materials, like brass or hardened steel (which we’ll get into later), tend to pick up dust, excess plastic, and other contaminants as the nozzle moves around during a print. These contaminants are likely to stick to the surface of the 3D print, making it less safe for food/drink contact. But nozzles made of stainless steel stay clean throughout the print and won’t accidentally add contaminants to a 3D print.

In addition to their food safety properties, though, stainless steel nozzles are also very durable. These nozzles last longer than brass ones and are strong enough to print all non-abrasive filaments like PLA and ABS as well as handle moderate use of abrasive materials like PC. So, if you want to print abrasive materials all the time, look for a stronger nozzle material (hardened steel).

While they’re perfect for printing food-contact items, stainless steel nozzles don’t come in many variations. As such, finding stainless steel nozzles with untraditional diameters, such as 1.2 mm or larger, will be difficult. This is mainly because stainless steel nozzles aren’t super popular, so not as many manufacturers produce them.

Despite their low popularity in the 3D printing community, stainless steel nozzles are still pretty inexpensive. And you can find a pack of 10 nozzles made of this material for just under $10.

Not a bad deal!

Sadly, though, stainless steel is not as conductive as brass. While your printer should still be able to heat the nozzle to your desired temperature, it will take longer and more time than if you were to heat a brass nozzle to the same temperature.

At the end of the day, I’d recommend a stainless steel nozzle to anyone who wants to print food-safe items, as this type of metal prevents contaminants from infecting the surface of your prints. But, while stainless steel nozzles can handle light printing of abrasive materials, I’d go with a stronger nozzle material for heavy and long-term printing of nylon, PC, or composite filaments.

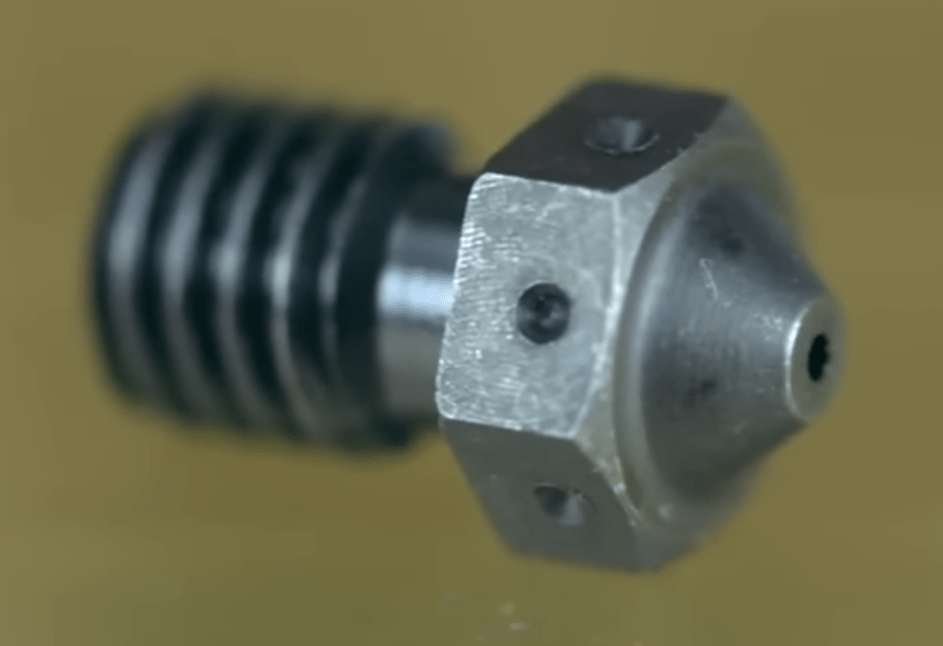

3. Hardened Steel Nozzles

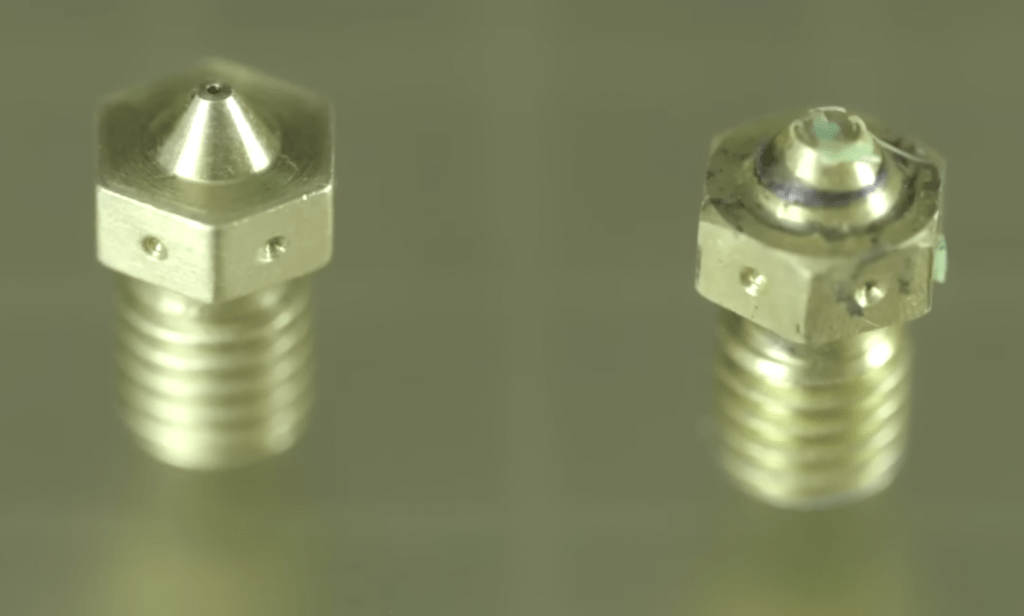

Lastly, we have hardened steel nozzles. Hardened steel is the strongest and most durable nozzle material on this list, and one of the strongest you can find, with the exception of ruby and tungsten nozzles.

The term “hardened steel” is pretty broad, but for 3D printer nozzles, it usually refers to a steel nozzle with a Mohs’ hardness scale rating (a scale that measures how hard a material is) between 6 and 8 Mohs. For reference, stainless steel and brass nozzles only have hardness ratings of 5 and 3 Mohs, respectively. As such, a hardened steel nozzle is significantly more rigid, capable, and durable than the other metal nozzles we discussed.

But what does this strength actually mean?

Well, with this hardness rating, you can print basically any 3D printable material, abrasive or not, without running into an issue.

In fact, I’ve used the same MicroSwiss hardened steel nozzle to print polycarbonate filament for over a year. Although not all hardened steel nozzles will last this long while printing a filament material as abrasive as PC, they will certainly last a lot longer than a brass or stainless steel option because of how much physical stress and wear the material can withstand.

Additionally, I always get spectacular print quality with these nozzles because their exit diameter is more rigid and doesn’t lose its shape.

But every product has its downsides, and the big one for hardened steel nozzles is its price, which is tens of times higher than a typical brass nozzle. For a decent hardened steel nozzle, be ready to pay around $10-15 a pop. However, you can get some lower-quality (not name-brand) nozzles in this material for $2 per piece.

So, if you want a nozzle that basically won’t ever die on you and can handle any material you throw at it, get a hardened steel nozzle. While the initial cost is annoying, I can tell you from experience that it’s a joy never having to replace the nozzle and being able to print anything with it.

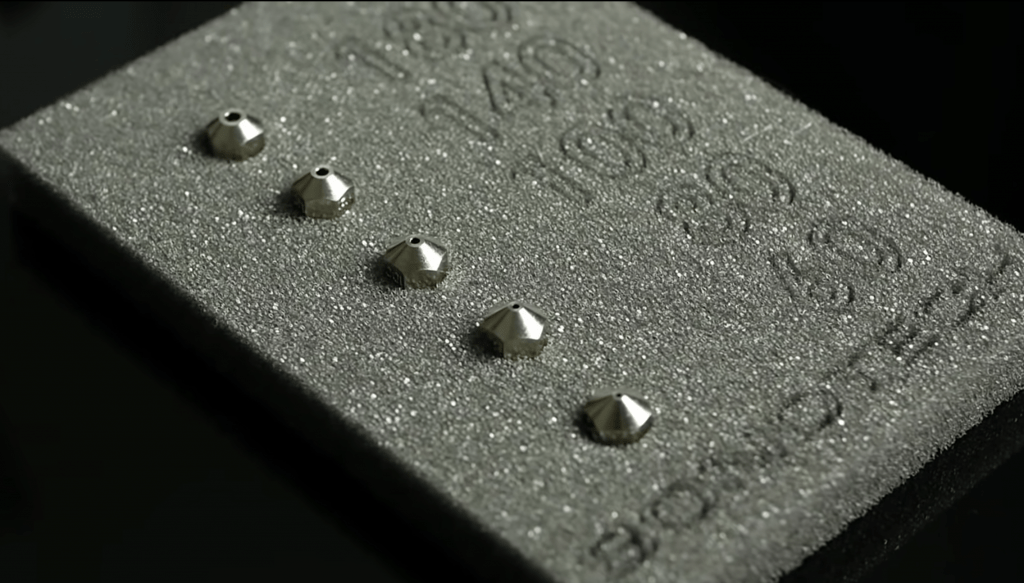

4. Ruby Nozzles

While not included in our main comparison of nozzle materials, a ruby nozzle is another great nozzle material you can choose. Ruby nozzles are, by far, the most expense nozzle material, but they’re also they most durable. Moreover, companies say that one ruby nozzle can last you a lifetime of printing.

But how is this possible? Ruby nozzles feature a nozzle tip made out of ruby gemstone which is extremely durable, hence why it’s used in many wedding rings. The rest of the nozzle, though, is usually made out of high-quality brass to give the nozzle its conductive properties.

There aren’t many ruby nozzles to choose from, but the Olsson Ruby Nozzle is a terrific option. I also liked the Polis3D ruby-tipped nozzle, and it’s also a little bit less expense than the Olsson Ruby option.

Best Nozzle Material

Now that you know about brass, stainless steel, and hardened steel nozzles, it’s time to dive into which nozzle materials are best for which purposes. We’ve listed a few situations in the sections below and described which nozzle material works best in each. Enjoy!

1. Regular Parts

Regular parts are your everyday 3D prints, like a desk toy, a headphone stand, and anything else that has a pretty general purpose. For these types of 3D prints, I recommend using a brass nozzle.

That’s because you’ll be printing these types of models in traditional filament materials, like PLA or ABS, where a brass nozzle performs fine. You’ll also save money because brass nozzles are the least expensive out of all the options. Additionally, by choosing brass, there’s no doubt that you can find a nozzle that fits your printer and has the diameter you want.

2. Strong Parts

For prints that you want to be strong, such as a gate hinge or a doorstop, you’ll want to use a hardened steel nozzle. A hardened steel nozzle is perfect for printing strong models because it can handle the strong filament materials that you’d want to use, such as PC, acrylic, and nylon. And, with a hardened steel nozzle, you can always switch back to printing non-abrasive, more traditional filament materials like PLA or ABS without an issue.

A ruby nozzle also works very well because of how abrasion-resistant and durable it is. But it does cost a lot more than most nozzles, including hardened steel ones.

3. Flexible Parts

Next, if you’re printing flexible models, chances are you’re using either TPU or TPE filament. And, for these flexible filament materials, you’ll want either a brass or a stainless steel nozzle.

That’s because TPU and other traditional flexible materials are usually not super abrasive, so you can get away with using a brass nozzle. However, you might want to use a stainless steel nozzle instead of a brass one to prevent the filament from sticking to the exterior surface of the nozzle, as this is common with flexible models.

Also, if you’re printing semi-flexible materials, like Nylon, then definitely go with a stainless steel nozzle over a brass nozzle. That’s because these semi-flexible materials, unlike TPU and TPE, are actually abrasive, so you’ll want the increased strength and rigidity of stainless steel.

4. Food-Safe Parts

Lastly, I highly recommend using a stainless steel nozzle to print food-safe parts or really any model that will touch food, water, or other substances that you don’t want to be contaminated.

As we went over, stainless steel nozzles are safer than any other type of nozzle because this type of metal is anti-stick. This makes models printed with stainless steel nozzles more food-safe because the nozzle won’t pick up debris during the printing process and contaminate the print.

Conclusion

Today, there are hundreds of different 3D printer nozzles to choose from, and each is different. One of the biggest differences between nozzles is what material they’re made out of, and the three most popular materials include brass, stainless steel, and hardened steel. Each of these three nozzle materials offers their own unique properties and is best for different types of prints.

A brass nozzle is the least expensive, so if you’re trying to minimize your spending, go with this option. With this nozzle material, you’ll be able to put out some excellent prints, but only in non-abrasive filament materials like PLA and ABS. But do note that brass nozzles are the most conductive, meaning they can heat up the fastest.

Now, if you’re looking to print strong materials, which tend to be more abrasive, then I’d suggest using a hardened steel nozzle. Hardened steel is significantly stronger and more durable than brass and other types of steel, so you can print abrasive filament materials like PC and Nylon without the nozzle degrading fast. Of course, with any higher-end product, you’ll pay a higher price, but I really think it’s worth it for many users.

Lastly, a stainless steel nozzle is best suited for those looking to print food-safe models. This type of metal is non-stick, so you can achieve contaminant-free models. Additionally, nozzles made of stainless steel don’t cost that much and are also pretty strong and capable of light printing in abrasive filament materials.

I hope you found the right nozzle material for you and enjoy your printing experience!