- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Thunderbolts and lightning are very, very frightening. So conquer your fears and confine that electric power into your 3D prints with conductive filaments.

Thunderbolts and lightning are very, very frightening. So conquer your fears and confine that electric power into your 3D prints with conductive filaments.

Using a conductive filament lets you print functional circuitry at home. You don’t need to buy expensive circuit boards and figure out how to construct your parts around them — print the circuitry directly into the part.

But these filaments can be expensive and tough to print. You must pick your filament carefully or you might waste a lot of money on a material that leaves your electronics non-functional.

Read on and find out what’s the best conductive filament for your needs in 2022!

Top Conductive Filament Materials At a Glance

You might think conductive filament is a niche material. And you’d be right — relatively speaking, it is.

But that doesn’t mean you don’t have options. There’s a surprising number of conductive filaments available. We’ve listed the 6 best options to help you get started.

1. Protopasta Electrically Conductive PLA (Best Choice)

2. Sunlu Conductive ABS (Best Value)

3. Multi3D Electrifi Conductive Filament (Most Conductive)

4. Recreus Conductive Filaflex (Flexible)

5. Amolen Conductive Filament (Eco-Friendly)

6. 3dk.berlin 3dkonductive (Fastest Printing)

Hot End Temperature: 419-446°F (215-230°C) | Bed Temperature: 32-122°F (0-50°C) | Spool Size: 0.5-3 kg | Diameter: 1.75mm, 2.85mm | Resistivity:15 Ω/cm

Protopasta is well-known filament manufacturer and the renown is deserved. This conductive composite PLA rules at the top of the roost.

This filament prints like regular PLA. That means you can get well-detailed and relatively strong parts, as long as you tune your printer right.

But what about the most important thing — conductivity?

Protopasta’s conductive PLA filament has good conductivity across the board. The resistance rises the longer and thinner you print, though, so this stuff is best for printing, say, button pads. The filament is also pretty abrasive, so it might be smart to invest in an all-steel nozzle.

Overall, if you’ll ever buy one conductive filament, make it this one.

Pros

- Good conductivity

- Prints like regular PLA

- Produces good-looking parts

- Works with 3D printers and 3D pens

- No need for heated bed

- Lot of spool sizes

Cons

- Needs fine-tuned settings

- Abrasive

- Pricey

Hot End Temperature: 428-464°F (220-240°C) | Bed Temperature: 68-248°F (20-120°C) | Spool Size: 1kg | Diameter: 1.75mm | Resistivity: ~1,000 Ω/cm

Looking to supercharge your 3D prints on a budget? Sunlu Conductive ABS has your back.

Sunlu is known for making high-quality 3D printing materials and its conductive filament is no different. As an ABS filament, this material makes for stronger, more solid parts with greater impact resistance when compared to PLA, like Protopasta.

If you need parts that conduct electricity and can take a punch, this is a good option.

The filament is conductive, but only mildly so. Don’t expect to print circuitry, but it performs well with electroplating and similar applications.

But the best part is the price.

Sunlu’s conductive ABS is very affordably priced. The value for money is excellent, and you can funnel the savings into the high-temperature extruder you’ll need to print ABS.

This filament offers a great value proposition with its price, strength, and conductivity.

Pros

- Affordable

- Strong

- Heat and chemical resistance

- Suitable for vapor smoothing

Cons

- Requires a high-temp extruder

- Rather low conductivity

Hot End Temperature: 266-320°C (130-160°C) | Bed Temperature: Room temperature | Spool Size: 0.1-0.5 kg | Diameter: 1.75mm, 2.85mm | Resistivity: 0.006 Ω/cm

Looking to print actual circuitry? Then you need Multi3D Electrifi, the best conductor on the electric train.

The manufacturer boasts that this is the world’s most conductive 3D printing filament.

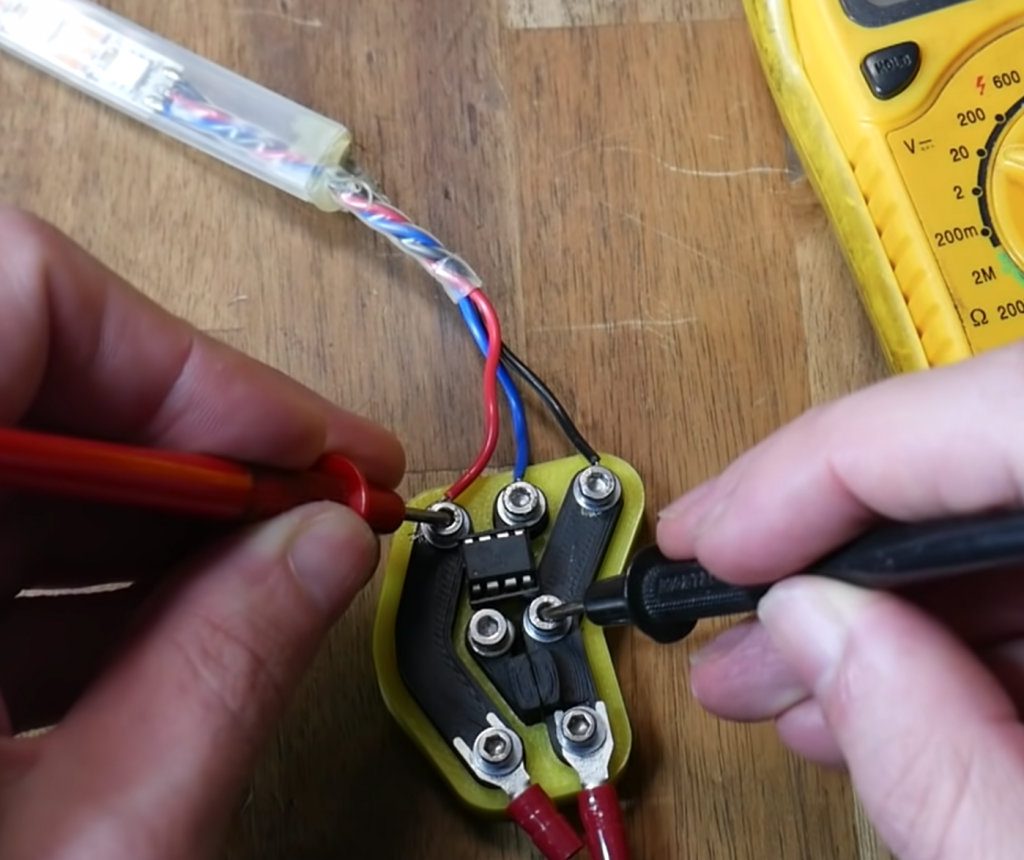

Electrifi consists of a biodegradable polyester mixed with copper. This unique composite structure makes it extremely conductive and lets you print fully functional circuits.

You can print LED signs or displays, lamps, interface sensors, game controllers… You know, working electronics.

The filament has low temperature requirements, but the metal content makes it abrasive. Print carefully to avoid clogs.

Electrifi can’t handle massive currents, so it’s best for small projects. That’s doubly true when you consider its cost. The high conductivity comes at a high price.

But for the most conductive 3D printer filament you’ll ever see, the price just might be worth it.

Pros

- Outstanding conductivity

- Produces functional circuits

- Works with low-temp extruders

Cons

- Very expensive

- Only comes in tiny spools

- Challenging to print

Hot End Temperature: 473-482°F (245-250°C) | Bed Temperature: 122-140°F (50-60°C) | Spool Size: 0.5 kg | Diameter: 1.75mm, 2.85mm | Resistivity: 3.9 Ω/cm

It twists, it turns, it flexes. Recreus Conductive Filaflex bends but won’t break.

This TPU filament has great conductivity. It pales in comparison to Multi3D (like everything else) but still channels enough electricity to make circuits for wearable electronics, LED boards, or keyboards.

As TPU, Filaflex is technically weaker than PLA filaments, like Protopasta. It does have shore hardness of 92A, though, so it’s not like it’s puny.

But Filaflex makes up for pure strength with flexibility.

Filaflex bends enough to withstand impacts and even works for flexible electronics. You can print durable circuitry that can bend with body movements — or wrap around pipes, for example.

As a cherry on top, this TPU is easy to print. You need a high nozzle temperature, but the filament extrudes without issues.

For flexible abd durable circuits, Recreus Conductive Filaflex is the partner you need.

Pros

- Good conductivity

- High durability

- Can make flexible circuits

- Easy to print

Cons

- Pricey

- Comes only in 0.5 kg spools

- Only suitable for low currents

Hot End Temperature: 428-482°F (220-250°C) | Bed Temperature: 32-122°F (0-50°C) | Spool Size: 0.2 kg | Diameter: 1.75mm | Resistivity: 1.42 Ω/cm

These days, being eco-friendly can be an important marketing point. Amolen conductive PLA can give you that eco edge.

The filament is made out of recycled PLA and graphite fibers. Although Amolen doesn’t give out exact details, that should make this PLA less environmentally taxing.

The filament produces prints of decent quality. You don’t need a heated print bed to get good results, and your prints will have little shrinking, warping, or bubbling.

Some users have reported layer separation issues, though. Take the time to dial your settings in carefully to save wasting material from the already small spool.

The graphite fibers can also wear nozzles down quickly. But thanks to this PLA’s low cost, you can afford an all-steel nozzle!

This is a decent filament that lets you print conductive parts while saving a little bit of the environment.

Pros

- Good value

- High print quality

- Recycled source materials

Cons

- Prone to layer separation

- Abrasive

- Small spools

Hot End Temperature: 392-446°F (200-230°C) | Bed Temperature: 32-158°F (0-70°C) | Spool Size: 0.3 kg, 1 kg, 2 kg | Diameter: 1.75mm, 2.85mm | Resistivity: 24 Ω/cm

Waiting is the hardest parts. Fortunately for you, 3dk.berlin’s 3dkonductive PLA filament lets you print conductive parts without waiting too much.

The manufacturer says 3dkonductive supports print speeds up to 90 mm/s. Naturally, the actual real-life speed depends on what you’re printing, with which machine, and on what surface.

But 3dkonductive nonetheless works with higher speeds than other filaments on this list.

This material is designed for high printability, so you can produce circuits without issues. As a nice bonus, it has electromagnetic shielding and antistatic properties.

The filament can clog nozzles, though. Even 3dk.berlin itself reminds users to clean the nozzle while the material is still hot.

If you need to print circuits in a rush, 3dk.berlin 3dkonductive is the filament you want.

Pros

- Fast printing

- Simple to print

- Many spool sizes

- Antistatic

Cons

- Can clog nozzles

- So-so conductivity

Add a Spark to your 3D Prints with Conductive Filaments

Conductive 3D printing filaments seem like something that shouldn’t exist. Plastic is naturally insulating, so how could the filaments conduct electricity?

If there’s one thing material engineers love, it’s overcoming challenges. Thanks to technological innovations, they’ve come up with plastic 3D filaments that are conductive.

But how have they achieved that? Let’s take a closer look at conductive 3D printer filament.

What is a Conductive Filament?

The plastic itself isn’t conductive. As such, you’ll never be able to print a circuit board with regular 3D printing filaments, whether PLA, ABS, TPU, or any other thermoplastic.

But conductive filaments aren’t pure plastic.

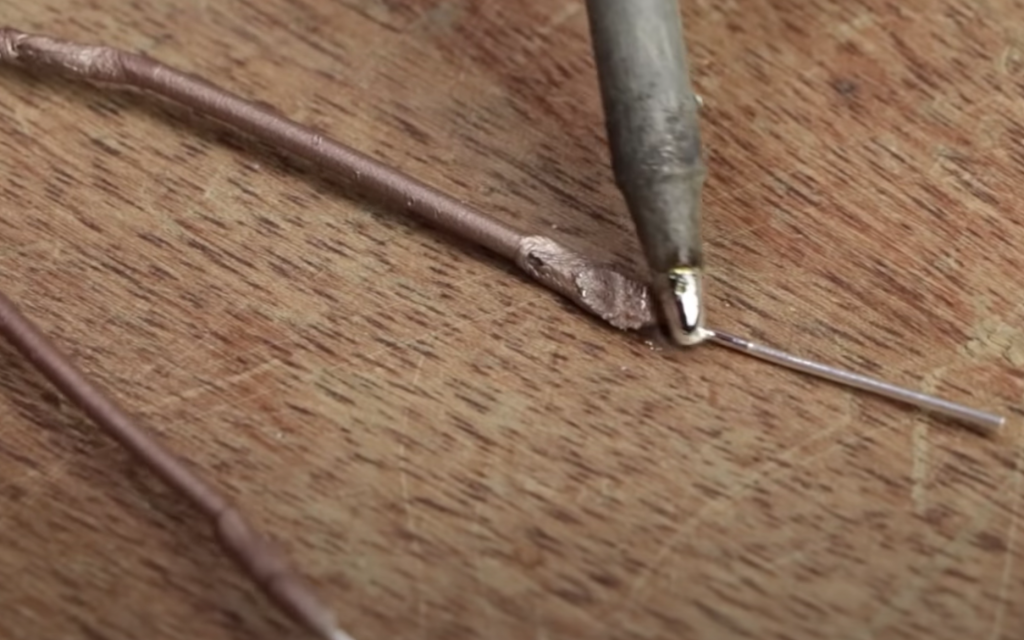

They’re composite materials consisting of a plastic base — often PLA or ABS — mixed with conductive fibers. Usually, the conductive material is either graphite or carbon.

Some more expensive filaments include actual metal, like copper, for higher conductivity. Finally, there are industrial-grade conductive filaments made of pure metal or other superconductive materials, but those are beyond home users’ budgets and printing capabilities.

There you have it, though — the mystery is solved. Plastic only gives the final print structure while the fibers take care of the conducting.

That’s how conductive filaments do it.

What Can I Do With Conductive Filaments?

Conductive filaments allow you to print functional electronics at home without buying separate circuit boards. You can explore creative electronic solutions at a relatively low price.

In essence, they’re dream materials for both enterprising DIY tinkerers and small electronics businesses.

Conductive filaments work well for nearly any small electronics project, depending on the properties of your chosen filament. The more conductive a filament you use, the more advanced circuitry you can build.

On the basic end of things, you could print a decorative bust with glowing LEDs for the eyes. In more professional applications, you can create flexible, wearable electronics — like smart sensors, for example — with the circuitry printed into the device.

Some examples of the kinds of things you can create with conductive filament include:

- Light-up sculptures and decorations

- Small lamps

- LED signs or boards

- Keyboards or touchpads

- Game and device controllers

- Key chains

- Sensors

- Electroplating-ready parts

- Prototype circuits for electronics

What are the Limitations of Conductive Filaments?

Although conductive filaments make it possible to print functional circuitry, they aren’t a silver bullet solution to homebrew electronics production. The filaments often came with quite a few caveats.

The first issue is conductivity itself. Many filaments marketed as “conductive” actually aren’t very conductive. They also can’t handle very high currents.

Pay close attention to the resistivity and other properties of the filament you’re buying. Otherwise, you might print a circuit that won’t work any better than one made of pure plastic.

Next, conductive filaments are more difficult to print than regular ones. Some low-end printers may not reach the high nozzle temperatures these filaments need due to their conductive fiber content. Additionally, the fibers are abrasive so you should invest in an all-steel nozzle.

Finally, conductive filaments generally cost a lot more than non-conductive filaments. They also tend to come in very small spools, so even a single misprint can end up costing you.

But don’t let the challenge discourage you. If you put in the effort, you can print fun and creative electronic projects in your garage.

Pick the Conductor You Need

Conductive 3D filaments are a great way to incorporate electricity into your prints. Most of them work with practically any printer, so you can easily start using a filament that serves your needs regarding conductivity and price.

If you’re still a bit lost about which filament to choose, here are our recommendations:

- Protopasta PLA offers you the best overall performance.

- Sunlu ABS offers you the filament with the best value.

- Multi3D Electrifi brings to the table unmatched conductivity.

- 3dk.berlin 3dkonductive prints conductive parts fast.

Related Articles: