I’ve worked with Ender 3s since the first one came off the assembly line in 2018. And I can tell you for a fact that the most excruciatingly annoying problem I’ve had to deal with is extruder skipping.

Click! Click! Click!

That’s the noise my extruder on my Ender 3 made right before I almost threw the entire machine on a concrete floor. Just kidding…kinda.

But on a more serious note, extruder skipping is a very bad problem for any 3D printer, and it can cause under-extrusion prints, leaving you with terrible 3D models that have holes in the layers.

But don’t worry because you can skip the hours of pain I went through with this printing problem because I’ve found the solutions for you. The most effective way to stop extruder skipping on an Ender 3 is to clean or replace the nozzle and increase the nozzle temperature. This usually does the trick, but if not, you can also try re-leveling the bed and lowering the print speed!

Want to hear some other solutions for Ender 3 extruder skipping? Well, just keep reading!

Table of Contents

What is Extruder Skipping?

Extruder skipping is a problem for 3D printers where the extruder motor isn’t able to push the inserted filament, resulting in the motor skipping, which is when it clicks due to the axle not being able to rotate properly.

Extruder skipping can happen on any FDM 3D printer, but it’s especially common on the Creality Ender 3 (Pro/V2). That’s likely because the Ender 3, while a great printer, is made of pretty low-quality components (e.g. plastic extruder assembly), making for the perfect storm for extruder skipping to occur.

It’s also worth mentioning that extruder skipping typically results in your filament grinding, leaving a pile of filament grounds around your extruder assembly.

What Causes Extruder Skipping?

Extruder skipping can be caused by a whole assortment of different factors and events, from a clogged nozzle to a print speed that’s too high. It’s important to know what, specifically, is causing the extruder to skip on your 3D printer so we can apply the proper solution to the problem.

In the mini sections below, I’ve gone over the most popular cause of extruder skipping on the Ender 3 (Pro/V2).

1. Clogged Nozzle

The most common cause of extruder skipping on the Ender 3 (Pro/V2) is a clogged nozzle. Whether a full or partial clog, if the exit hole on the bottom of the nozzle is, in any way, blocked, it will restrict filament flow. As such, the extruder won’t be able to move the filament as fast as the print speed requires, resulting in the motor skipping.

2. Poor Bed Leveling

Bed leveling is an all-too-familiar issue for Ender 3 users, and besides poor first-layer bed adhesion, an improperly-leveled bed can also cause extruder skipping.

That’s because if the nozzle is too low to the bed, the filament won’t have enough space to properly flow out the nozzle’s exit hole. And, similar to a clogged nozzle, if this filament flow is constricted, then extruder skipping could occur.

3. Printing Too Fast

The faster the print speed, the faster filament comes out of the nozzle. But if the filament isn’t properly melted in time to exit the hot end, then it will clog (until it’s melted), resulting in the extruder skipping.

4. Low Printing Temperature

Similar to printing too fast, if your hot end temperature is too low, then the filament won’t melt fast enough to come out of the nozzle. And if this happens, then you’ll have a hot end clog, or your extruder will start skipping. Or both!

5. Broken Extruders

If the extruder is broken on your Ender 3, which is pretty common as it’s plastic, then extruder skipping may occur.

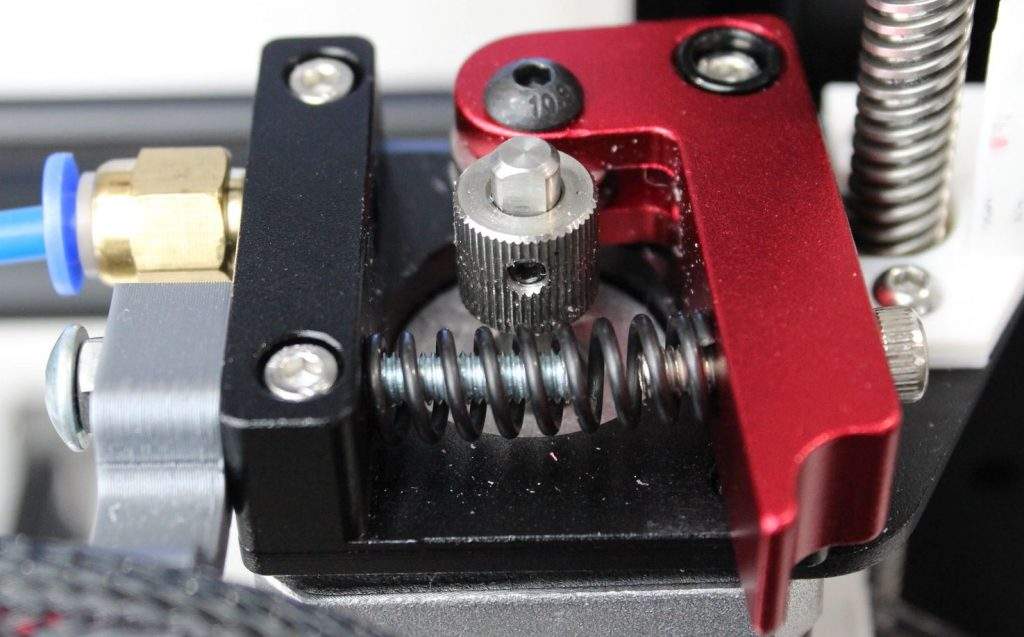

To check if your extruder is broken, see if the driver gear and idle bearing rotate properly. Also, check to make sure that there’s still tension on the spring that pushes the driver gear closer to the bearing. If these parts aren’t right, your extruder is probably messed up, which might be the reason for your case of a skipping extruder.

Additionally, the Creality stock extruder on the Ender 3 (Pro/V2) is known to be pretty low-quality, and it tends to wear after a few months of printing. So, even if it’s not actually broken, it might just be worn down enough to cause extruder skipping.

6. Weak Extruder Spring

If you look at the stock (or upgraded) extruder on your Ender 3 (Pro/V2), you’ll notice a spring going from the handle to the base of the assembly. This provides tension from the extruder drive gear and bearing on the filament strand that goes in between. But, if the spring isn’t tight enough, there won’t be enough pressure on the filament, causing the extruder to skip.

7. Faulty Stepper Motors

On top of the extruder assembly being a potential cause of a skipping extruder, if the stepper motor for the extruder is faulty or too weak, then it won’t be able to push the filament through the hot end. And if this happens, then your extruder will start skipping as it’s trying to push the filament but doesn’t have enough force to do it.

8. Bowden Tube is Clogged

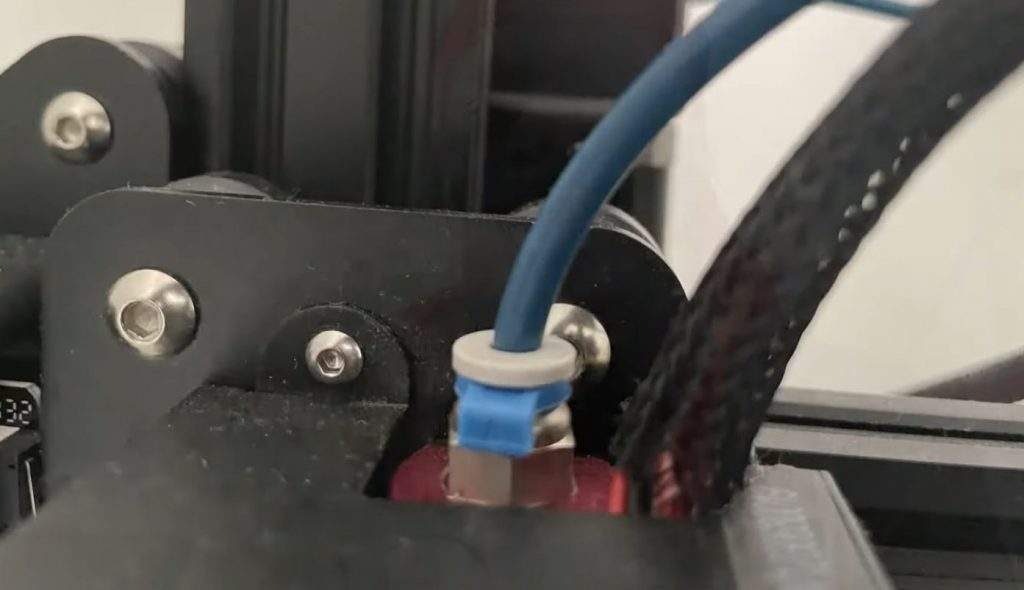

Lastly, a clogged PTFE tube (AKA the Bowden tube) can also cause your extruder to skip. For reference, the PTFE tube is the tube that connects the extruder to the hot end, and if it has too much of a bend or is clogged, then the flow of filament from the extruder to the hot end will be limited. And because of this, your extruder will start skippings steps and making a “click, click, click” noise.

How to Solve Extruder Skipping? 9 Simple Ways

Just as there are many potential causes for Ender 3 extruder skipping, there are also many potential solutions. In the sections below, I’ve gone over the most effective ways to stop your Ender 3’s extruder from skipping and how you can use/follow them.

1. Clean/Replace Nozzle

The first thing you should do is check the nozzle on your 3D printer to see if it’s dirty or clogged. Whether or not you see anything on the nozzle, though, I suggest cleaning it just for good measure.

To clean the nozzle, start by removing any gunk on the outside of the nozzle. You can do this by heating up the nozzle and going at it with a metal pick, scraping away any unwanted contaminants stuck to the surface of the nozzle.

To clean the inside of the nozzle, heat it up to regular printing temperature, remove the filament, and unscrew the nozzle. Then, take some small pliers and a metal pick and use them to remove any excess plastic inside. Once you reinstall the nozzle, take a thin metal needle and stick it up the nozzle hole, moving it up and down to ensure nothing is clogging the exit hole.

And, if nothing you’re doing is cleaning the nozzle well, then it might be time to replace the part entirely. Luckily, nozzles, especially brass ones for the Ender 3 (Pro/V2), are super inexpensive, so you’ll only be set back a few bucks to get some replacements.

2. Level Bed

Leveling the bed seems to be the solution for everything on the Ender 3, and the same is true when it comes to extruder skipping.

To level the bed, start by clicking “Auto Home” on the printer’s LCD to bring the printhead to its home position. Next, click “Disable Steppers” so the motor isn’t locked.

Then, move the printhead to the four corners of the bed area, and, at each point, gauge the distance between the nozzle and the print surface with a sticky note (or piece of paper). As you go along, use the four adjustment knobs on the underside of the print bed to adjust the position of the bed so that the distance between the build plate surface and the nozzle is the same throughout the entire printing area.

Also, make sure you set the Z offset setting correctly. You can do this either on your printer’s LCD, your slicer profile, or by sending G-code commands.

If you want to learn more, make sure to check out our article on manually leveling the Ender 3.

3. Lower Print Speed

Lowering the print speed is an easy way you can prevent your extruder from skipping. Doing so will give the filament more time to melt in the hot end so it can flow out of the nozzle much more easily.

You can adjust this setting in your 3D slicer, and I suggest trying a 20% drop in speed and seeing if that fixes your problem. If not, try 30% and then 35%.

But I don’t suggest dropping your original print speed by more than 40% because if you’re at that point and still not seeing a fix to your problem, then the print speed probably isn’t the issue.

4. Increase Nozzle Temperature

The nozzle temperature is directly correlated with filament flow. Moreover, the higher the nozzle temperature, the more filament can flow because it will melt faster. As such, increasing your nozzle temperature is a great way to prevent the extruder on your Ender 3 (Pro/V2) from skipping.

For PLA, I suggest increasing your nozzle temperature initially by 10 °C and then in increments of 5 °C until you’re 20 °C higher than your original nozzle temp. That’s because any higher above your normal printing temperature would indicate that the nozzle temp isn’t the reason your extruder is skipping.

Also, try to stay within the provided nozzle temperature range provided by the manufacturer of your filament, as this range usually works best.

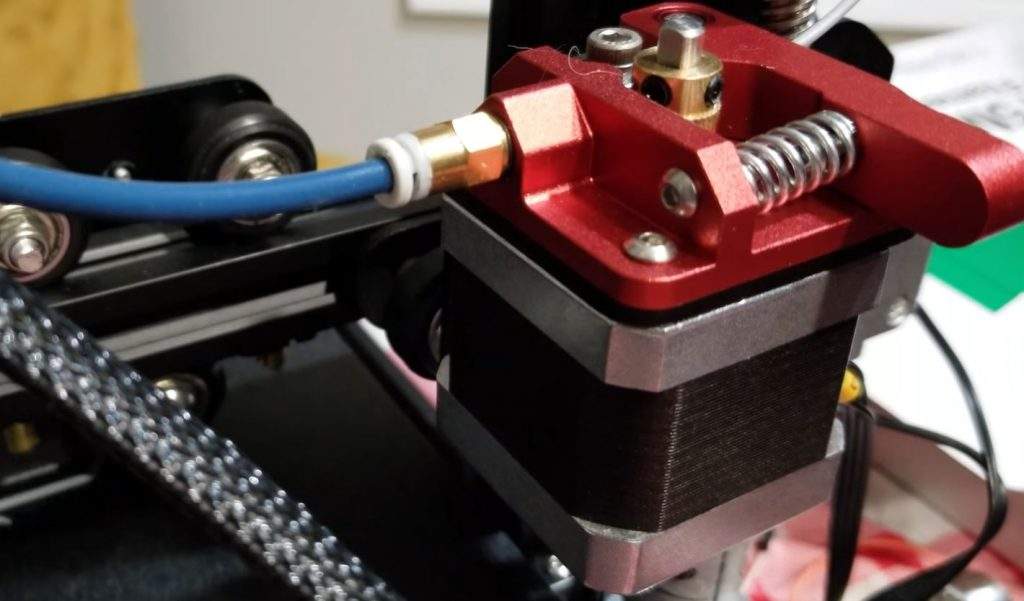

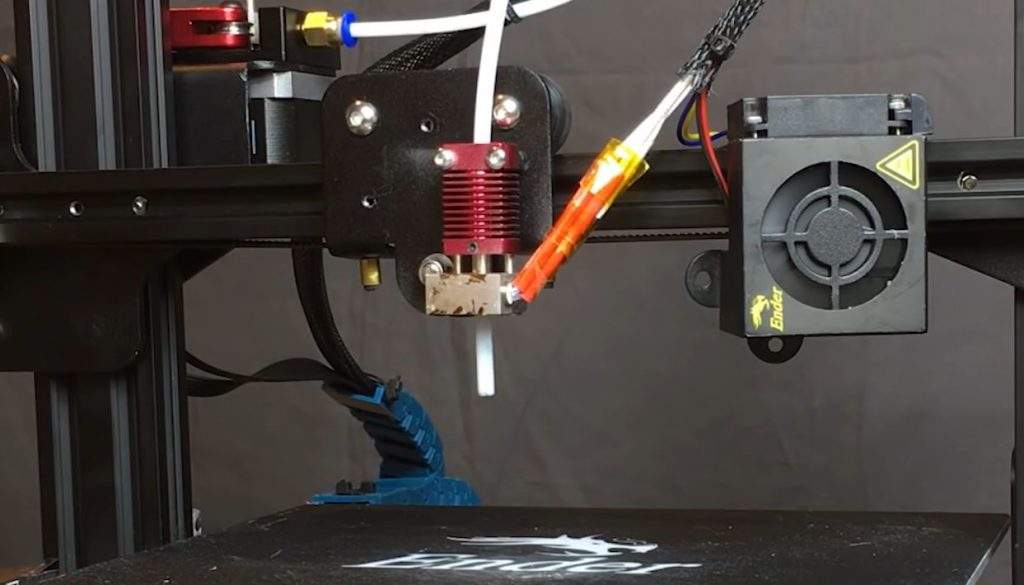

5. Change the Extruder

The plastic extruder on the Ender 3 (Pro/V2) isn’t really built to last more than six months of consistent printing. So, if you notice that a part of your extruder assembly is broken, cracked, or severely worn down, then it’s probably time to change out the extruder.

There are many different extruder options for the Ender 3, and I suggest getting a metal one as these extruder assemblies will be much stronger and won’t wear down fast. Creality sells an official all-metal extruder assembly, but the off-brand ones, such as the WinSinn dual-drive option, also work perfectly!

6. Tighten Extruder Spring

Tightening the spring on the extruder assembly will push the drive gear closer to the inserted filament, giving it a better grip for pushing the filament to the hot end.

While the spring on the stock extruder on the Ender 3 (Pro/V2) isn’t technically adjustable, you can make it tighter by adding a washer in between the two points where the extruder touches the assembly. For example, I like to use this 3D printable spacer option.

7. Check Stepper Motors

Make sure you give the extruder stepper motor a good look, too, just in case they’re broken. Moreover, while a broken stepper motor is unlikely, every now and then, I see a post on Reddit about someone’s Ender 3 extruder motor overheating and getting permanently damaged.

If you think this happened to your motor, I suggest switching the extruder motor with a replacement NEMA-17 stepper motor.

8. Check Bowden Tube

As we mentioned, the Bowden tube can also cause Ender 3 extruder skipping. As such, you should check the Bowden tube to make sure it’s not burnt, bent too much, or messed up in any other way.

I also suggest removing the tube from the inside of the hot end and seeing if the end is burnt, as this is common on Ender 3s. If it is, take a sharp knife, PTFE tube cutter, or scissors and remove 1-2-cm from the bottom of the tube.

Just make sure you don’t cut off too much otherwise, the tube might not be long enough for the printer to reach across the entire X-axis.

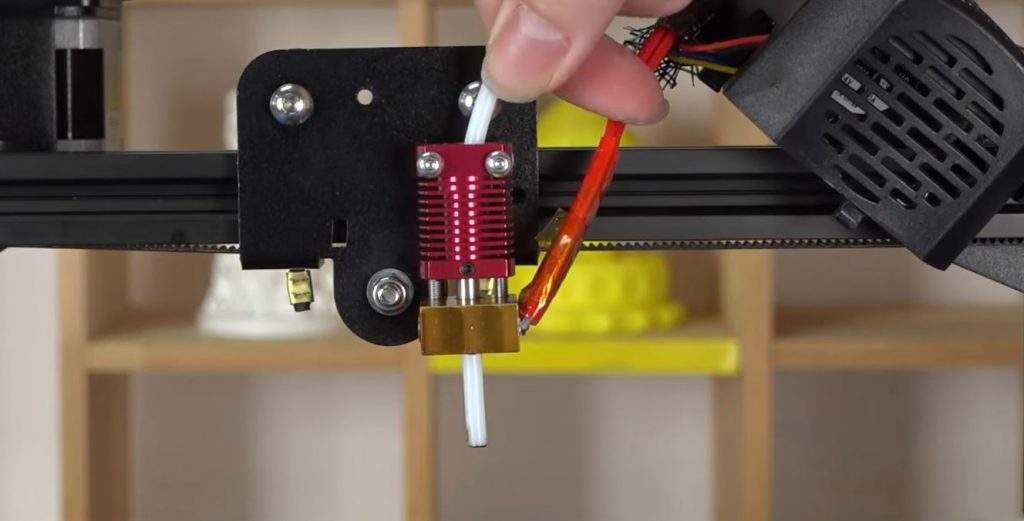

9. Clear Out Hot End

Finally, I suggest cleaning out the hot end assembly. After a lot of printing, a fair amount of excess melted filament and other gunk can get stuck in the hot end, potentially causing the extruder to skip. Cleaning it out will remove any partial clogs inside the hot end to provide the smoothest flow of filament.

To clean your hot end, start by heating it up to your regular printing temperature. Once hot, remove the PTFE coupler, PTFE tube, and nozzle from the assembly.

Then, take a skinny screwdriver or metal pick and stick it down the hot end heat break (throat). This will push out any unwanted gunk from the assembly.

While I’m at it, I also like to clean the nozzle, which we already discussed how to do in an earlier section.

Conclusion

If the extruder on your Ender 3 (Pro/V2) is skipping or making a clicking noise, don’t panic!

While extruder skipping is a very frustrating problem that causes under-extrusion and other print quality issues, it’s pretty easy to solve once you identify the cause of the problem.

First, you should check that your nozzle isn’t clogged, and if it is, make sure to thoroughly clean it or simply replace it. Make sure to also clean out the hot end, as gunk can get in there over time, and this might cause a clog.

You should also increase the nozzle temperature for your prints. Doing so will melt the incoming filament faster, so it can more easily flow out the nozzle and not stall the extruder.

Lastly, I suggest increasing the extruder tension and leveling the bed.

Hope this helps!