The nozzle is the last part that touches filament before it’s turned into a 3D print, so it only makes sense that you make sure you’re using a good one. Nozzles can vary in a few ways, like the size of the exit hole (hole on the bottom), the material they’re made of, and more.

The Creality Ender 3, including the Pro, V2, and S1 versions of the machine, comes with a 0.4-mm diameter brass nozzle. This type of nozzle was likely chosen for its low manufacturing price, but it’s also reasonably reliable.

However, you might be interested in upgrading to a larger or smaller size nozzle on your Ender 3. If you want to print larger models, then a nozzle diameter, such as 0.8, 1.0, or even 1.2 mm, will achieve breakneck print speeds to help you print big. And if you want the most details and small features on prints, then a smaller nozzle size such as 0.1-0.3 mm will do you justice.

Want to learn more about nozzle sizes and materials for the Ender 3? Just read on!

Table of Contents

Why Does Nozzle Size Matter?

Nozzle size is an extremely important element on a 3D printer because it controls the extrusion.

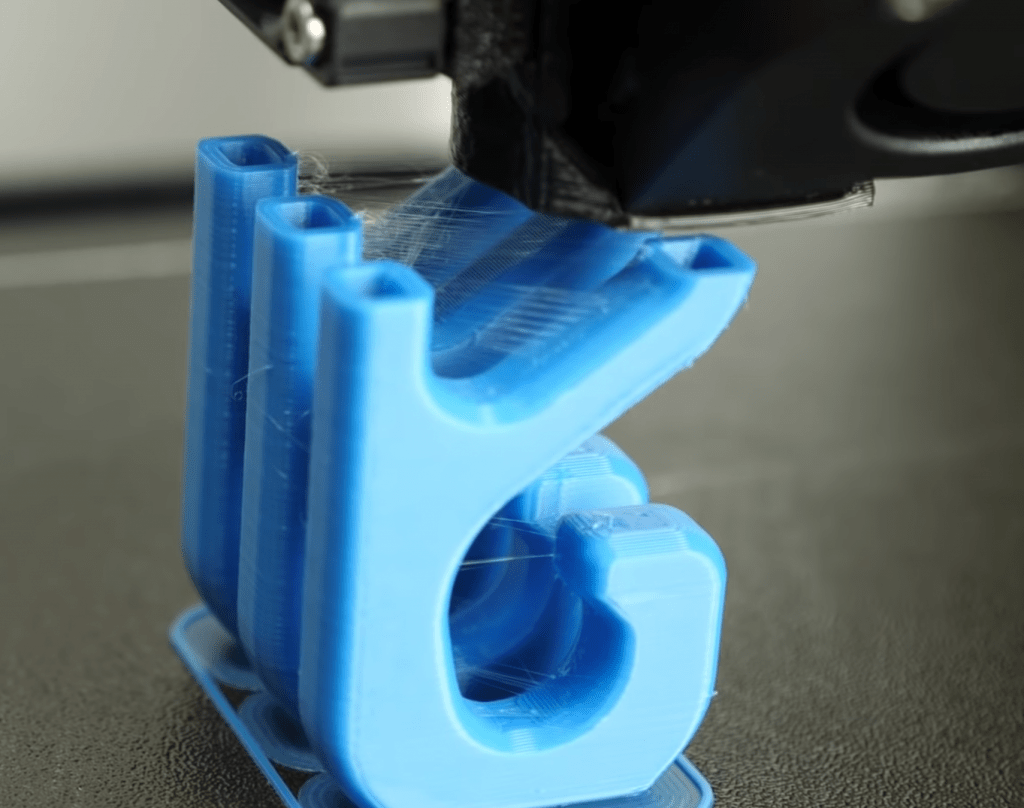

The larger the exit hole, which we call the diameter of the nozzle, the more filament can be pushed out the nozzle and onto the print bed, resulting in the ability for faster prints. On the flip side, a smaller nozzle diameter means your Ender 3 print jobs will take longer because the nozzle will have to take more passes (or go-arounds) to finish all the layers of a model.

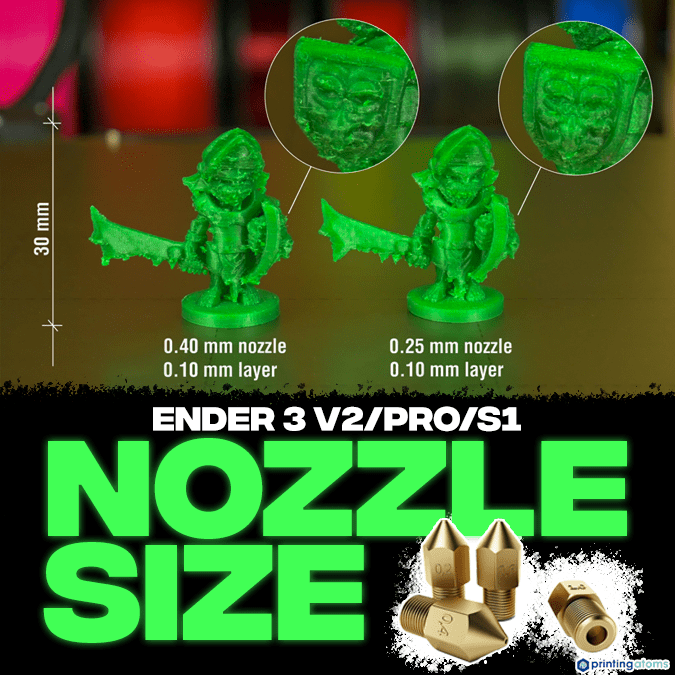

But the nozzle size doesn’t just control speed; otherwise, everyone would use larger nozzles. Moreover, the nozzle size also controls the level of detail capable on 3D models. Smaller models can print smaller features than a large nozzle can, which is why a smaller nozzle is often used for printing tiny models with a lot of details, like a typical miniature D&D model.

Additionally, the nozzle size also matters because it regulates what layer height (how tall each layer of a print is) you can use. A larger nozzle allows you to use a larger layer height and vice versa.

As a result of this, the nozzle diameter also affects the strength of prints. That’s because a large layer height means that there are fewer layers on a print and thus fewer points where the print can break. So if you want to print strong models, go for a larger nozzle with a diameter above 0.6 mm.

Supported Nozzle Sizes on the Ender 3 (V2/Pro/S1)

The Creality Ender 3 can handle almost any normal nozzle size, which ranges from as low as 0.1 mm to as large as 1.2 mm in diameter. This versatility stems from the Ender 3 being open-source, meaning that you can use 3rd-party hardware on the printer.

But not just any nozzle will fit on the stock Ender 3. The hot end that comes with the Creality Ender 3 has an M6 thread. So any nozzle that you want to attach to the default hot end on the Ender 3 (V2/Pro/S1) must have an M6 thread fitting on the top, or else you’ll have to use a different one.

Some popular nozzle manufacturers that fit on the Ender 3 (V2/Pro/S1) include Creality, the maker of the printer, as well as 3rd-party manufacturers like E3D, MicroSwiss, and more. You can usually see if a nozzle will work on the Ender 3 by searching “Ender 3” on the product page. But you can also find out by seeing if the nozzle has that M6 thread that’s necessary for the nozzle to fit.

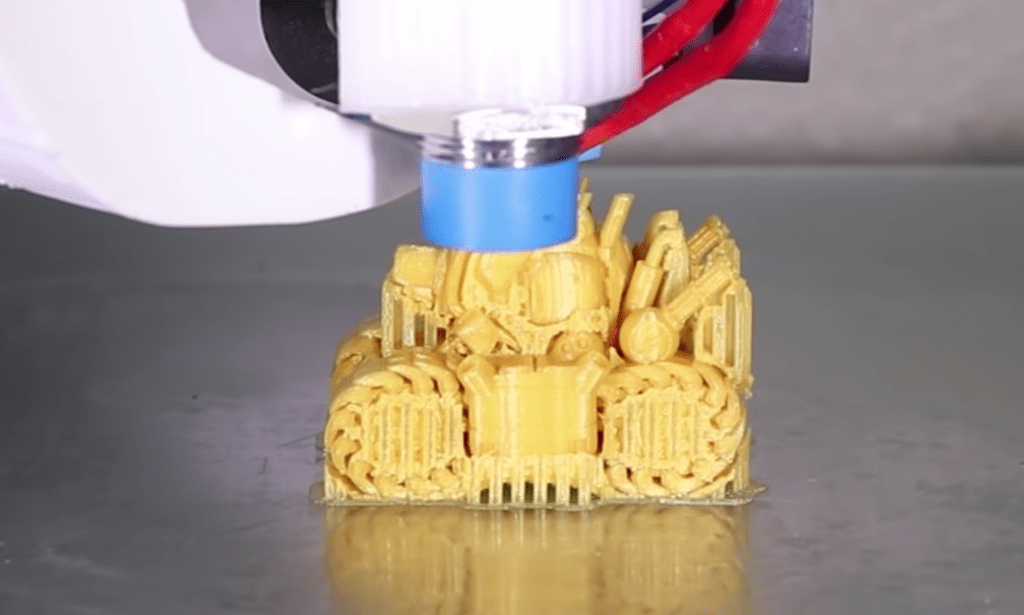

When To Use a Large Nozzle Size

It’s best to use a large nozzle size when you want to print large models. That’s because, if you print huge parts, such as a furniture piece or pencil holder, with a regular 0.4-mm nozzle, your print time will easily be over 24 hours. But simply switching to a large nozzle, say 1.0-mm, then you can cut down print time by over 50%!

As we also mentioned, using a large nozzle also helps with strength on models because larger nozzles allow you to use larger layer heights. So if you’re printing a part that will face a lot of physical stresses, such as a doorstop, then using a large nozzle size is a great idea.

Sadly, though, a large nozzle size will result in extra filament usage. That’s because a larger nozzle size will print models that have thicker walls, which takes more filament compared to if you use a smaller nozzle size.

If you’re wondering how large to go, a 0.8-mm nozzle is a pretty reliable option. It cuts down your print times by a good bit but also can achieve a decent level of detail on prints. For maximum strength and speed, though, consider going up to a 1.0 or even 1.2-mm nozzle.

Advantages

- Stronger parts (thicker layer height)

- Faster prints

- Lack of detail is unnoticeable in large, simple prints

Disadvantages

- Can’t produce a lot of detail on models

- Increase material usage

When To Use a Small Nozzle Size

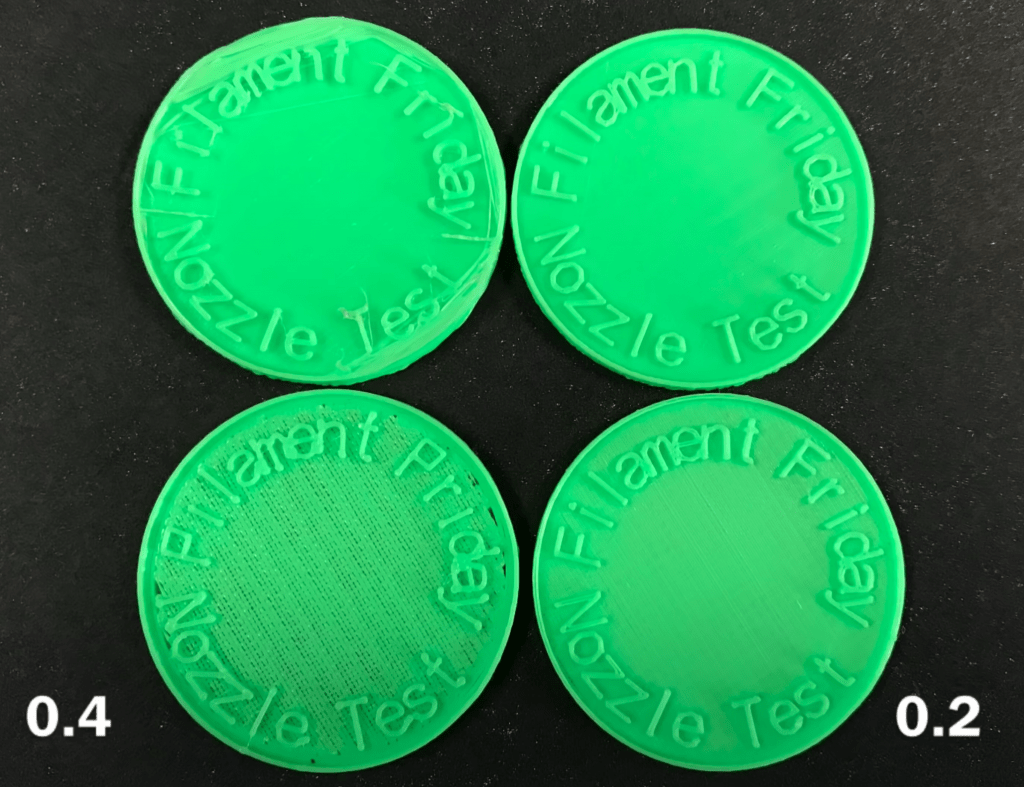

You should use a small, under-0.4-mm nozzle size when detail is the goal. So if you’re printing very small models with a lot of small features and the default Ender 3 nozzle size of 0.4 mm just isn’t cutting it, drop it down a few 0.1 millimeters.

While your print time will increase a lot with a small nozzle size, the detail can be immaculate. I’m serious! Miniatures look so much better when printed with a 0.1-mm nozzle versus a 0.4-mm nozzle.

This increased level of detail is because a small nozzle size enables smaller layer heights. So with a 0.1-mm nozzle, you can use a layer height as small as 0.05 mm, which is a lot smaller and provides a lot more detail in prints than the standard 0.2-mm layer height.

An additional benefit of using a smaller layer height is reduced material usage. Yep! A smaller layer height actually uses less filament per model compared to a normal or larger nozzle size because these prints have thinner walls.

Of course, these prints won’t be as strong, but that’s the price you pay for detail in prints.

I’ve found that a 0.2-mm diameter nozzle works great for printing miniatures on an Ender 3 (V2/Pro/S1). But you can also use a 0.1-mm nozzle for even more detail or a 0.3-mm nozzle for a little more speed and strength.

Advantages

- A lot more detail for prints

- You can print smaller features (smaller layer heights are possible)

- Not a very expensive switch

- Decreased material usage

Disadvantages

- Models are weaker (more potential break points)

- Longer print times

Why Does Material Matter?

Now that you know about the importance of nozzle size, it’s also good to mention that the material of the nozzle matters. The nozzle material controls the overall quality of the nozzle’s extrusion.

The more conductive, durable, and abrasion-resistant a nozzle material is, the better your extrusion will be. On the flip side, if you use a shitty nozzle material, such as bottom-of-the-bucket brass, the quality of the extrusion will also be pretty shitty. This will result in more frequent nozzle clogs, inconsistent extrusion, and other issues.

While not every material can be used for 3D printer nozzles, there are a handful of different options, from brass to even gemstones. In the mini sections below, we’ve briefly gone over some of the most popular nozzle materials.

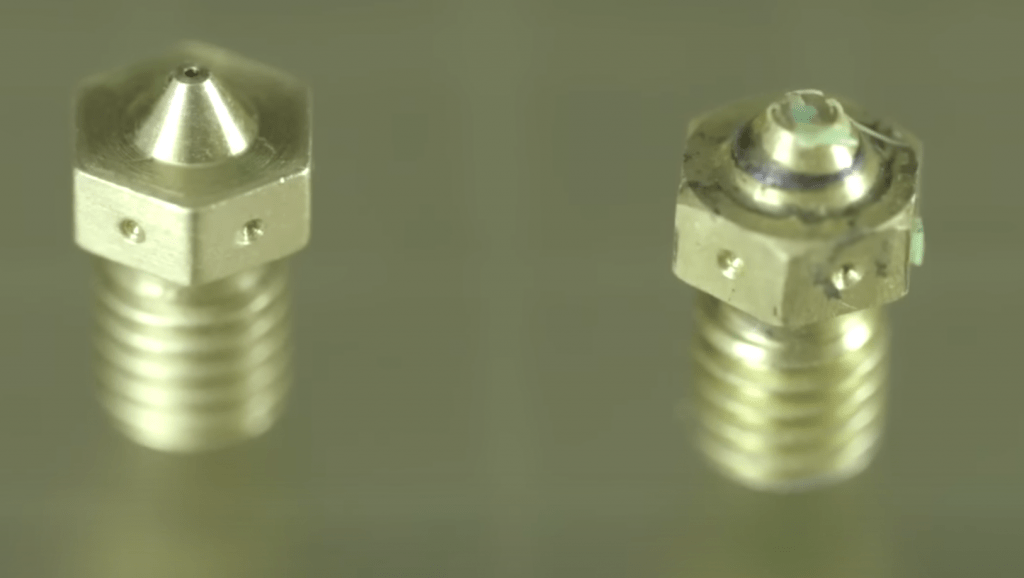

Brass

First up, we have brass, the cheapest – I mean most “budget-friendly” – option. Brass is easily the most popular nozzle material, with most consumer-grade 3D printers, like the Ender 3 or Anycubic i3 Mega, equipped with brass nozzles.

And, despite their low price, brass nozzles aren’t always bad. Of course, if you search “brass 3D printer nozzle” on Amazon and filter by lowest price, the first option won’t be that good. But, in general, brass is actually not a bad option, with your typical brass nozzle lasting a few months of regular (PLA) printing before showing any signs of wear or clogging.

Sadly, though, brass nozzles aren’t suggested for printing materials other than PLA or ABS. That’s’ because brass is a pretty soft and weak metal, and printing more abrasive (rough) materials will lead to frequent clogs and other issues. So if you’re printing composite filaments, like carbon fiber-infused PLA, or high-abrasion materials like PC, avoid brass nozzles.

Steel

Steel is the second most popular nozzle material, and it comes in two varieties: stainless steel and hardened steel.

The former offers a stick-free extrusion process, perfect for printing models that you want to be free of unwanted contaminants. As such, stainless steel nozzles are especially popular for printing PLA and PETG prints that will contact food or liquids.

On the other hand, hardened steel nozzles are the better steel choice for printing generally abrasive materials, whether it be TPU, nylon, or even polycarbonate. The most common hardened steel nozzle is an A2 Hardened Steel nozzle, but they come in other options too.

So, for printing parts that will contact anything that needs to be away from contaminants, go with a stainless steel nozzle. And for maximum longevity for a nozzle as well as printing abrasive filament materials, go with a hardened steel nozzle.

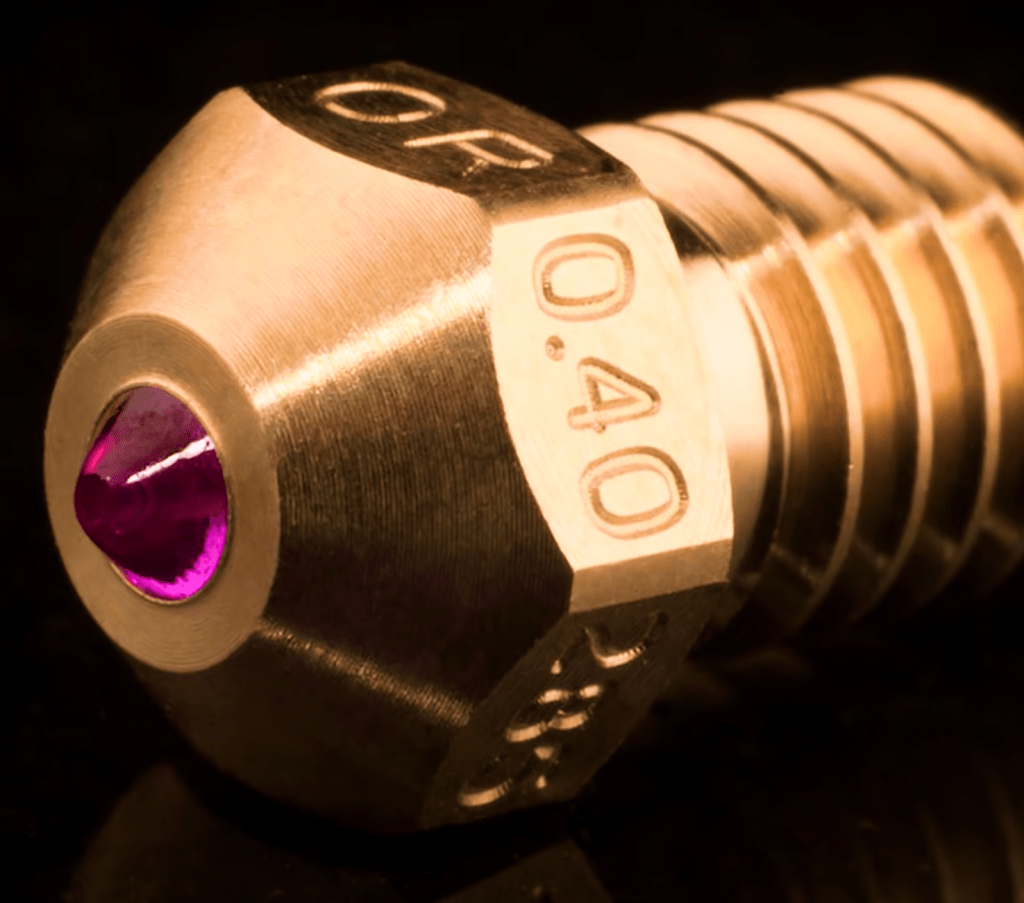

Ruby

Lastly, we have the ruby nozzle. Though not super popular due to its insanely high price, a ruby nozzle is easily the most long-lasting and abrasion-resistant. Manufacturers of this gemstone-based nozzle state that one ruby nozzle should last you a lifetime of printing. And they’re not wrong!

Whether you’re printing traditional non-abrasive materials like PLA and ABS or the most abrasive filament materials like PC, carbon fiber composite, or even acrylic, the ruby nozzle won’t let you down.

So if you’d rather spend around $120 for a nozzle upfront and never have to worry about replacement costs later down the road.

How Often Should You Change the Nozzle?

How often you should change the nozzle varies by your printer and setup, but it should be between 1-4 months.

Of course, if you only print a few times a month using only PLA (or another non-abrasive filament), then it’s easily possible for your nozzle to last years. But for most users who print a few times a week and maybe don’t use PLA, then changing the nozzle every 1-4 months should work fine.

Personally, I only change the nozzle on my printer when I start having issues, and this isn’t a bad method. But consistently changing it every 1-4 weeks, even when you’re not running into issues, is the safer option.

Conclusion

The stock Ender 3 nozzle size is 0.4 mm, which is a great diameter for most prints. But if you want more detail on models or stronger parts, then you’ll need to change your Ender 3 nozzle size.

As the Ender 3 can use basically any size of nozzle, you have a lot of options. I recommend using a 0.2-mm nozzle diameter on your Ender 3 if you want to print models with a lot of detail, such as miniatures. This size is also good for reducing material usage.

And if you don’t need a lot of detail in models but want faster prints or much stronger prints, then go for a larger Ender 3 nozzle size, such as 0.6 or 0.8 mm. The print quality won’t be as good, but many users find it worth it.