Today, most filaments are sold in 1 kg spools. But this measurement is abstract. I mean, how many of you actually know the true feeling of 1 kilogram, much less how many different 3D models you can make with it?

But don’t worry because I’ve carefully tested and measured how long 1 kg of filament lasts and am here with answers for you.

A 1 kg roll of filament lasts anywhere from 5-20 weeks, depending on how much you’re printing. As for the number of prints, a 1 kg spool of filament should produce somewhere around 75-125 successful 3D prints, depending on their size.

Of course, the true longevity of a 1 kg roll of filament depends on many factors other than just how frequently you print and the size of the models. Furthermore, slicer settings, like infill density, as well as the rate of print failures, also have an impact.

Want to learn more about how long a 1 kg spool of filament lasts and how you can make it last even longer? Just keep reading!

Table of Contents

How Long Does a 1KG Roll of Filament Last?

For the typical maker, a 1 kg roll of filament will last between 5 and 20 weeks or about 1-5 months.

Of course, it’s impossible to estimate the true time a 1 kg spool of filament will last you because everyone prints different parts and not at the same frequency. Someone who prints a few parts every week will burn through a spool of filament much quicker than someone who prints only a few times a month.

But 5-20 weeks is just an average range. A filament spool can be printed much quicker or much slower than this, depending on how much downtime you give your machine.

If you were printing non-stop, it would only take between 2.5 and 3 days to burn through an entire spool of filament, depending on your slicer settings (e.g. print speed). But it’s unlikely that any “typical” maker is printing a model that takes an entire kilogram of PLA filament.

A more realistic scenario is that you’re printing a handful of small or mid-size models every week or two. At this rate, you might be going through 100 grams of filament, or 10% of a 1 kg spool, every 1-3 weeks. And, if you do the math, you’ll find that, with these assumptions, a 1 kg spool will last between 10-30 weeks.

However, we estimate a range of 5-20 weeks because we also need to consider the fact the prints will fail mid-way through and that you’ll re-print the item, leading to more filament usage. And, every once in a while, you might be printing a rather large 3D model, which would burn through more filament than your usual prints.

With these additional factors in mind, 5-20 weeks seems to be a good estimate for how long a 1 kg roll of filament will last the typical person.

How Many Prints Can I Make with 1 KG of Filament?

Besides the length of time a 1 kg filament spool will last you, you might also be wondering how many 3D prints you can make with this much filament.

The answer? It depends on what types of models you’re printing!

In the sections below, I’ve gone over the number of 3D prints you can make with a 1 kg spool of filament based on the approximate size of the model, which I’ve grouped into three categories.

Miniatures

MINIATURES

The first class of size of 3D prints is miniatures, which, as the name suggests, are relatively-small 3D printable models. Miniatures are one of the most popular types of models to print, and common examples include tabletop game figurines, like War Hammer characters. But miniatures might also be small functional models, like a cable holder or a washer.

While there’s no hard size limit for what makes a model a miniature, typically, miniature 3D models are no larger than 30 x 30 x 30 mm in volume. Furthermore, most of these models, based on 3D slicer estimations, will consume roughly 5-10 grams of filament.

Factoring in a reasonable amount of failures and re-prints, you should be able to print about 100-175 miniature 3D models with a 1 kg spool of filament.

Additionally, it’s worth noting that most miniatures need to be printed at slower speeds than regular models to ensure the small features on the model come out well. Because of this, the total print time you can get out of a 1 kg spool of filament if you’re exclusively printing miniatures can be pretty long.

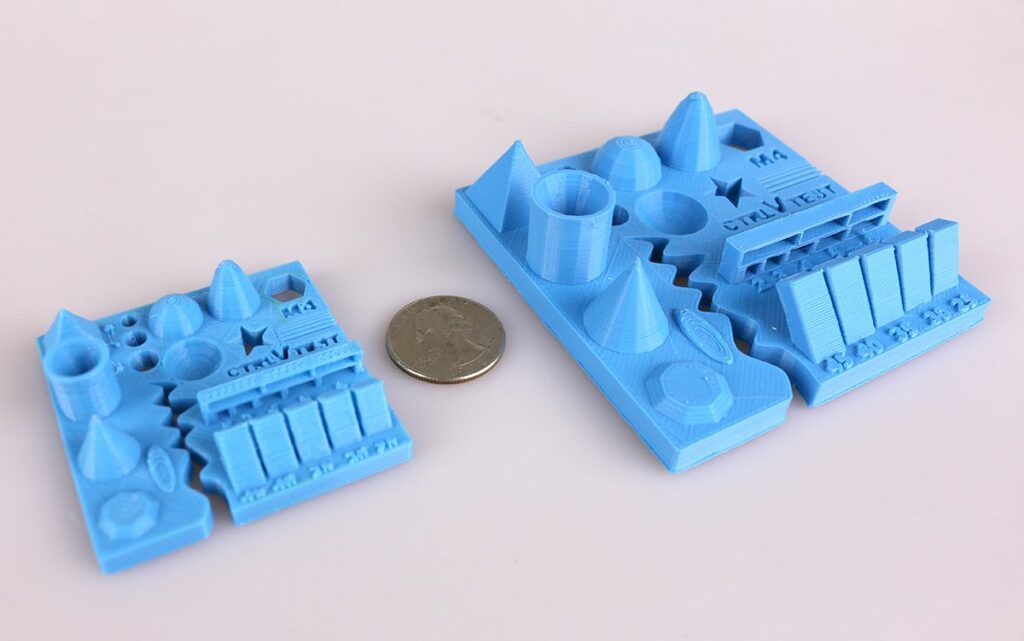

Regular Prints

REGULAR PRINTS

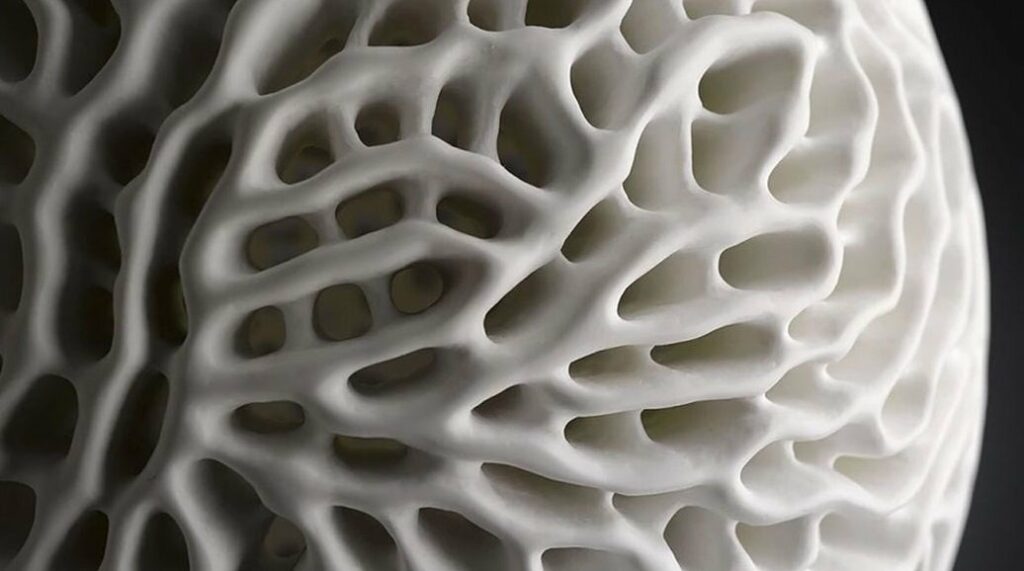

Next, regular prints are 3D models that are bigger than a miniature but not exactly what you’d call a large print. This range of sizes of 3D models includes most of the parts you’re probably printing, like phone stands, carabiners, battery organizers, and vases.

These models are usually larger than 30 x 30 x 30 mm but smaller than 100 x 100 x 100 mm. As for filament consumption, most regular prints take about 20-60 grams of filament.

Using these parameters and factoring in possible print failures, I estimate that you should be able to get between 20-40 regular 3D prints out of a 1 kg spool of filament.

Large Prints

LARGE PRINTS

Finally, large prints are…you guessed it…3D models that are fairly large. These models are bigger than your typical 3D print, and examples include a helmet piece for cosplay, a bust of a superhero, or a set of shelves.

Larger objects typically have dimensions greater than 100 x 100 x 100 mm, and, based on slicer estimations, take anywhere from 80-200 grams of filament.

The downside of large prints is that they have a higher rate of print failure because they require your machine to function, without a clog or other issues, for long stretches of time. As such, I estimate that you can get 5-12 successful large 3D prints from a 1 kg roll of filament.

Factors that Affect the Usage of Filament

As I’ve mentioned, there are a handful of different factors that affect the usage of filament, including slicer settings, elements of the 3D model, and more. I’ve gone over the main factors in the sections below:

3D Print Size

3D PRINT SIZE

The factor that has the largest impact on the longevity of a spool of filament is the size of your 3D prints. The larger the parts, the fewer you’ll be able to pump out with a single spool of filament.

Additionally, as I mentioned previously, larger prints have a higher rate of failure. As such, it’s likely that more filament will be wasted on failed prints if you’re only printing larger models compared to if you’re printing miniature or regular-sized models.

Supports

SUPPORTS

Supports are slicer-generated features that allow you to 3D print models with steep overhangs. Supports aren’t part of the actual part you’re printing and only add to the amount of wasted filament material.

Furthermore, you get more out of a filament spool when you don’t use support material on prints. Of course, turning off supports isn’t always possible, depending on the model you’re printing, but you can minimize the use of support structures, as I’ll go over later.

Complexity of 3D Model

COMPLEXITY OF 3D MODEL

The complexity of the part you’re printing also plays a part in determining how much filament you can use in a 1 kg spool. Moreover, more complex designs usually have higher print failure rates and require more supports, which increases the amount of filament waste.

Additionally, more complex 3D models, like miniatures with a lot of detail, need to be printed slower than more simplistic parts (e.g. phone stand). As such, the time it takes for you to burn through a spool of filament goes up when you’re printing more complex models. This isn’t necessarily a good thing, though.

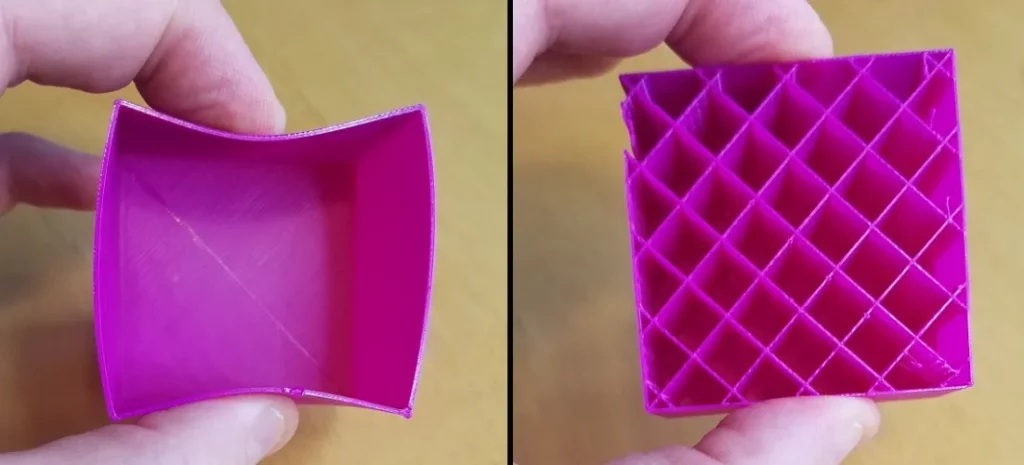

Infill Density

INFILL DENSITY

Infill density is a setting in your slicing software that controls how full the inside of your 3D print is. An infill density of 0% will yield a hollow 3D print, while 100% will make your model completely solid. Using a low infill density, like 10%, will make your 3D prints consume less filament and also lower the print time.

However, don’t just change the infill density willy-nilly. This setting also has an effect on the strength of your 3D printed part, so keep this in mind.

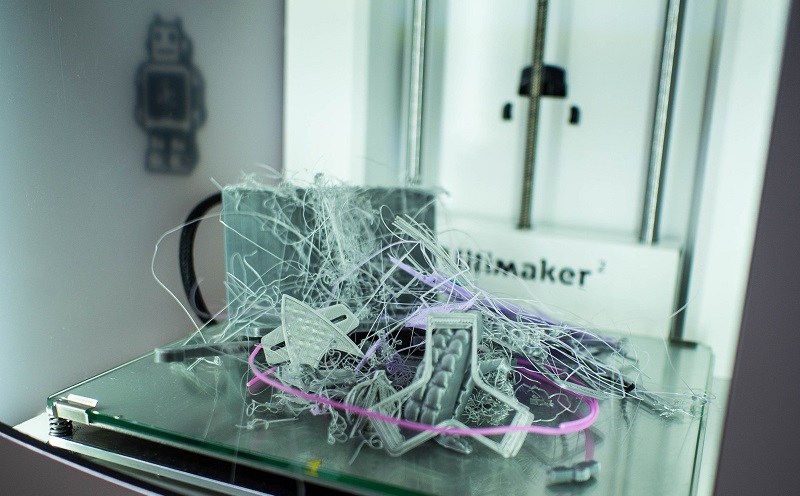

Rate of Failed Prints

RATE OF FAILED PRINTS

Lastly, the rate of failed prints also is extremely important in determining how much filament in your spool you can use. The more failed prints you have, the more filament in the spool goes to waste, and the less you can use.

We all know that 3D printers, especially budget options like the Creality Ender 3, can fail frequently. It’s in your best interest to lower the rate of failed prints if you want your filament spool to last longer and pump out more successful models. I’ll go over how you can reduce the chance of failed prints in a later section.

How to Make Filament Last Longer

Making your filament spool last longer helps both you and your wallet. Moreover, if you can get more successful prints out of a 1 kg filament spool, you won’t have to buy another spool as often (lowers material cost), and you won’t be frustrated with your 3D printer as often.

In the sections below, I’ve gone over a few different ways to get as much filament out of your spool for actual print jobs as possible!

Lower Infill Density

The first and perhaps easiest method for making your filament last longer is lowering the infill density. You can do this in your 3D slicing software by lowering the infill density setting (expressed as a percentage) to around 10-20%.

I don’t suggest going lower than 10% as infill densities lower than this might cause your 3D print to be excessively weak. On this note, if you’re printing a part that needs to be strong, I also don’t recommend lowering the infill density solely to preserve filament material. It’s better to print the model once and be done than print it with a low infill density, the part breaks, and then have to print the model again.

Minimize Supports

Next, supports are a complete waste of filament material, so minimizing the amount of support structures on your 3D prints is very effective in making your spool last longer.

You can minimize supports by trying to print only models that don’t have steep overhangs, which would require support structures. But, if you have to print a model with significant overhangs, try to adjust the model’s orientation in your 3D slicer so that the least amount of support material is used.

Additionally, you can try using custom supports, a feature available in both Cura and PrusaSlicer, so that support structures are only used where you think they are necessary.

Reduce Skirt, Brim & Raft

Skirts, brims, and rafts are other slicer-generated features that are wastes of filament material. Reducing how often you use one of these adhesion assistants will make your filament spool last longer.

Of course, sometimes a skirt, brim, or raft is necessary to ensure proper bed adhesion for your print. But if the model you’re printing is small, then warping is unlikely, so you can deactivate an adhesion assistant in your 3D slicer.

Reduce Failed Prints

Finally, it’s important to reduce the amount of failed prints you have. Doing so will reduce how much filament in your spool is wasted, so you have more material for the prints you need.

While there’s no way to eliminate the chance of print failures, you can reduce it by calibrating your extruder, tuning your slicer settings, and using high-quality parts, such as a metal extruder.

Conclusion

A 1 kg filament spool costs around $20 on Amazon but can last anywhere from 5-20 weeks of 3D printing. Of course, the true longevity of a filament spool depends on how frequently you’re printing, but if you’re only making a few small or mid-size models a week, then a 1 kg spool will easily last you at least 10 weeks.

And, in this span of time, you can get as many as 125 (or more) successful prints out of a 1 kg roll of filament.

But you can make your filament spool last even longer if you make a few changes, like reducing the amount of supports on models, lowering the infill density, and making your printer more reliable!