The marvels of 3D printing have opened up a whole new world of creative possibilities and just as many challenges.

Like a paper jam, but a lot more expensive, tedious, and maddeningly frustrating, tangled or knotted filaments can destroy your 3D print job halfway through the process.

But that unfortunate reality doesn’t have to kill your spirit or dampen your enthusiasm for 3D printing. It’s a problem that comes with simple solutions and preventative measures that work for master printers and beginners alike.

Here we will explore the causes of knots and tangles, how to untangle filament, how to fix knotted filament, and how to prevent filament tangles in the future.

Table of Contents

What Is Filament and How Is It Used?

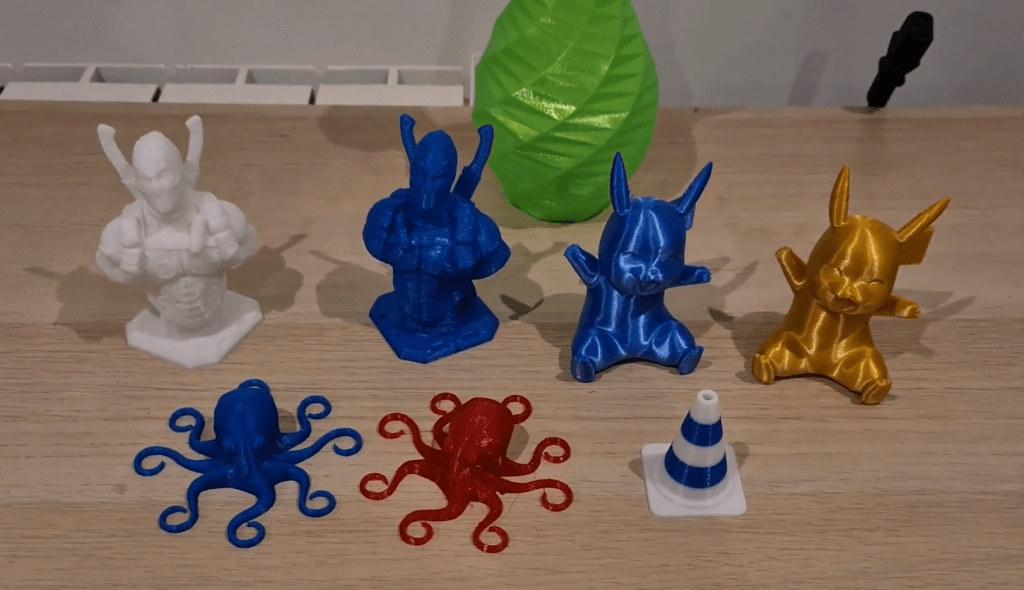

Although 3D printed items may look as if they appeared by pure magic, there are many specific materials and technology that go into creating each object.

Thermoplastics are polymers that melt and become sculptable when heated, then settle into a solid form and harden when cooled. Filaments for 3D printing use thermoplastics to create the desired shape.

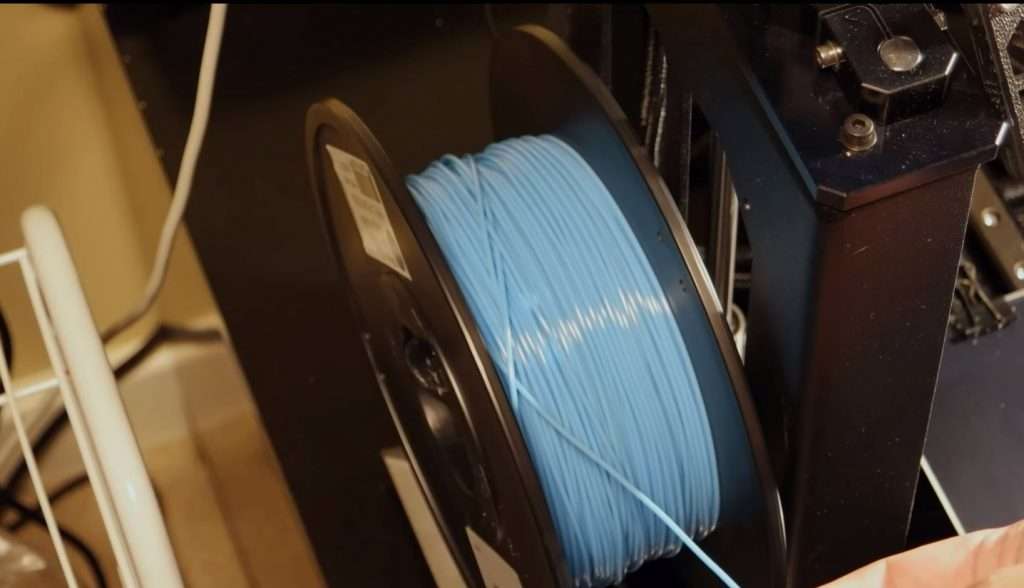

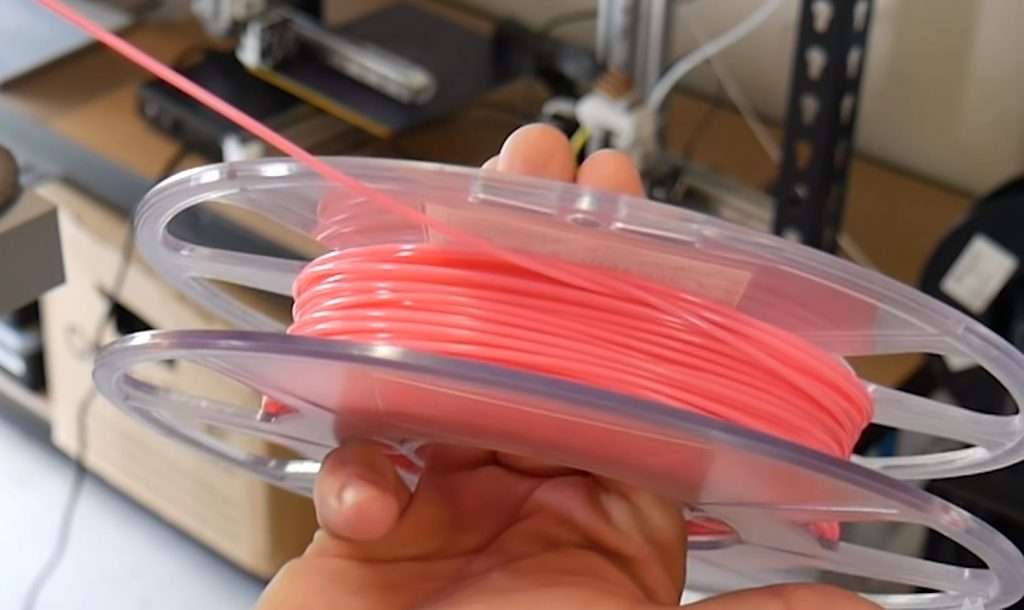

This process occurs when the filament (which comes spooled like thick plastic thread) is fed through the printer and heated until it melts inside the chamber. Next, the melted filament gets squirted through the machine’s extruder assembly.

That is where the magic happens! The liquid plastic creates the 3D object layer by layer with guidance from the programming technology. Once it cools, you have a solid three-dimensional item that originates from a spool of plastic.

Filament Types

There are many types of filament (not even counting the colors) with scientific-sounding names abbreviated for clarity and simplicity. After you pick your 3D printer, finding the most suitable filament might feel quite confusing, but it doesn’t have to be.

The most important thing to look for in filament is a combination of strength and flexibility. Beginner printer hobbyists and folks who like to keep it simple are smart to go for one of the two most common kinds of filament.

Most consumer-grade 3D printers work with filament made from polylactic acid (PLA) or acrylonitrile butadiene styrene (ABS). These types of filaments are strong, flexible, and inexpensive.

What Causes the Filament Knot?

Understanding the process of how filament’s purpose in 3D printing, it is easy to understand why knots or tangles in the thermoplastic material could do much greater damage than a paper jam in a traditional printer. One knot or tangle could mess up the whole process and destroy the job.

It’s worthy to note that a rookie mistake is to blame the manufacturer for the tangle in what appeared to be an otherwise good spool of filament. Filament spool designs keep these issues in mind, so the filament cannot get tangled inside the spool from the factory.

One of the reasons spools of filament come with the end of the thread taped down is keeping it taught and preventing the filament from slipping under a coil. That’s the leading cause of knots and tangles. So it is crucial that you keep things tight and don’t allow the spool to unravel.

If it’s still a difficult concept to grasp, think of how easily your headphone or other plastic wires get tangled even though they started tightly wound fresh from their packaging. Like little snakes, the rings of the filament, once shifted, seek to settle in a cozy spot resulting in a tangled mess.

Once unspooled, the filament can get tangled up fast, but you might not notice that a knot has taken hold of your filament until you have begun your print job, and it suddenly locks up. That is where the frustrations can reach a boiling point hot enough to melt the thermoplastic over again!

How Do You Untangle Filament?

If it sounds aggravating and hopeless, fear not; all is not lost. There are solutions. Here’s how to fix a tangled filament:

The first thing to do is to detect the tangle as soon as you can. It is best to catch the problem while the print job is processing before it causes the machine to lock up. However, some printers have features that allow you to pause, unload, and reload the filament.

Once you notice the knot has occurred, ideally, there will still be some filament slack between the spool and the machine’s extruder assembly. Untangling the issue will require the right amount of space to wrap the filament loops neatly and tightly around the spool’s edge.

Continue that until there is one clear path, not two or three, as you might see initially. That’s the best way to indicate the tangle is taken care of unless there are multiple knots. When all knots are out, begin to rewind the filament holding the end taught. Be sure to use tape or another fixture to hold it in place.

An Important Tip

Resist the urge to unwind the entire spool in a desperate attempt to locate the tangle. That will exacerbate the problem, and you’ll likely end up with more knots and tangles in the filament.

If you unmount the spool and bring it closer to the feeder’s entrance, you’ll have more control over the amount of slack. That allows you to untangle the knotted filament while the other end feeds into the machine. You can do this without stopping the print or unspooling the filament entirely.

How to Prevent Tangled Filament in the Future

As with everything, prevention is far better than a cure. No one wants to have a panic attack in the middle of a 3D printing job while attempting to keep calm and recall the steps to untangle the filament.

Essentially, it’s down to the ends. The best way to ensure your filament doesn’t get knotted or tangled is to hold onto its end until it feeds into the extruder assembly. Be sure it attaches tightly. Even when you cut the filament end, keep a firm grasp on it.

Also, be sure to keep your spools coiled taught so that there is no room for the shifting that can cause knots and tangles. That is the most common way such aggravations occur. The main takeaway: keep it tight.

However, if you get tangled during printing, you have the tricks to get you and your 3D object out of a jam.