You already have a lot of stuff that would make sleeping difficult… your 3D printer should not be one of them. If your printer stays in your bedroom, office space, or other room where you do things besides 3D printing, you don’t want the machine’s noisiness to distract you from whatever you’re doing.

Sadly, 3D printers aren’t known for being ninjas and their noise level is similar to someone speaking in a normal tone.

So how do you make it quieter?

Well, first, I always slap a set of rubber feet on the bottom of all my printers to reduce the vibrations they make. And, for the printers that I really want to keep quiet, like the ones in my office or bedroom, I upgrade the stepper motor drivers as this significantly reduces the motor noise. Lastly, if I still need to cut down by a few decibels, I replace the stock cooling fans with silent Noctua fans.

But these aren’t the only ways to make your 3D printer quieter! In the following sections, we’ll go over some more ways to reduce the noise output of your mini manufacturing machines!

Table of Contents

How Noisy is a 3D Printer?

Before we dive into more solutions for quieting your printer, though, it helps to first review how loud a 3D printer is in the first place. While the answer obviously varies depending on the specific printer, it usually ranges in the 40-50 decibel range. For reference, the average speaking tone is about 55 decibels, so your printer is more like a loud whisper.

However, how loud your printer also depends on what it’s doing and where it is. The 40-50 decibels describe the printer when it’s at work, but the machine runs more like 30 decibels when it’s on standby.

Also, if the printer is on a very wobbly surface, the vibrations produced by the machine will only make each movement louder. So, you can expect above 50 decibels if your 3D printer is placed on a wobbly plastic table, but under 40 if it’s on a rubber pad.

Where is the Source of the Noise?

It’s also important to review what exactly makes your 3D printer noisy. That’s because this will help us find the proper solutions to quieting the machine. There are three main causes of noise on a 3D printer, including stepper motors, fans, and the moving carriages on the machine.

Stepper Motors

The first cause, stepper motors, is usually the single most noisy element of a 3D printer and occurs because the torque from the motors isn’t always constant. Because of this, a phenomenon called torque ripple occurs, sending very audible vibrations throughout the frame of the motor. Often, these vibrations sound very high-pitched or robotic, but, nonetheless, are pretty loud and distracting.

Fans

Second, the fans on a 3D printer also make the machine noisy. Most consumer-grade printers, such as the Ender 3 V2, have at least three fans, including one for the motherboard, one for the hot end, and the part cooling fan. However, because most manufacturers use low-quality plastic for the fans, they end up being pretty noticeable and noisy.

Moving Parts

Lastly, the moving parts, such as the hot end carriage or print bed, also cause a fair amount of noise on a 3D printer. That’s because, whenever they move, they cause vibrations along the axis they’re running along. While this isn’t super noticeable 100% of the time, it definitely can be heard in a silent room.

Of course, there are also other causes of noise on a 3D printer, but they are usually externalities and vary printer-to-printer.

How to Make Your 3D Printer Quieter?

Now that you know how loud a typical 3D printer is and what causes the noise, it’s time to get into the solutions. In each of the next few sections, we’ve gone over a different way you can lower the noise levels on your printer.

While you’ll never be able to completely silence your 3D printer, it’s easily possible to get your printer in the sub-35 decibel range. For most people, you can easily sleep through this or not notice it in the background.

Now, let’s get started!

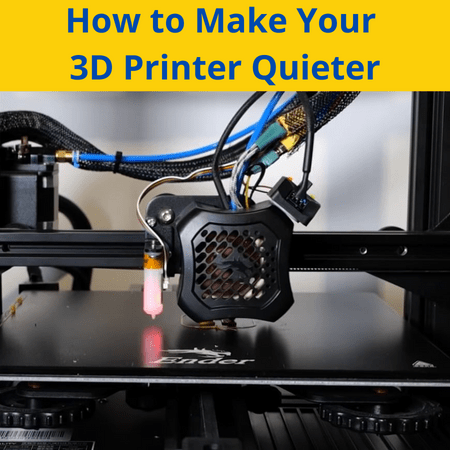

1. Upgrade the Stepper Motor Drivers

Our first recommendation is to upgrade the stepper motor drivers on your 3D printer. If you’re unfamiliar with the term, the stepper motor drivers on a 3D printer are located on the machine’s motherboard and control how power is given to the connected stepper motors.

Stepper drivers directly impact how loud the motors are, so the more advanced the drivers, the less noisy the motors.

If you have an older budget 3D printer, like the Anycubic i3 Mega or original Ender 3, then the stock stepper motor drivers (e.g. A4988s) probably do very little to silence the motors. As such, upgrading to some of the newer, more advanced stepper drivers, like some TMC2209s or TMC2225s will significantly drop your printer’s noise levels (almost 20 decibels).

You can check out our article about the best stepper motor drivers to figure out which ones fit your needs.

I only suggest upgrading your stepper motor drivers, though, if your current motherboard has really old or ineffective ones. If you have a newer 3D printer like the Ender 3 S1, which already comes with pretty good drivers, upgrading to newer drivers won’t lower the noise levels by too much.

If you do decide to upgrade the drivers, though, you’ll have to check if you can remove the drivers from your motherboard. Many printers (e.g. original Ender 3) have a motherboard with integrated stepper drivers meaning you can’t remove just the drivers. In this case, you’ll have to replace the board entirely, with one that has better drivers.

2. Change the Fans

Changing the fans is another great way to lower the noise levels on your 3D printer. As we mentioned, most 3D printers contain poorly-made stock fans, which result in a noisier printer. Replacing the stock fans with higher-quality options can help silence your printer.

However, not just any right-size fan on Amazon will be quieter than the ones already on your printer. There’s really only one brand I trust (#NotSponsored) for silent fans and that goes to Noctua.

Noctua fans are known for being the quietest on the market, and the company offers fans of the same size as many 3D printer cooling fans.

While these fans are pretty expensive compared to an OEM option on Amazon, I promise you they will be a lot quieter. To best lower the noise level of your 3D printer fans, you’ll have to replace all of the stock fans, including the one on the motherboard, the one on the hot end heat sink, and the part cooling fan pointed towards the nozzle. As Noctua fans aren’t really meant for 3D printers, you might need to 3D print a fan duct, but there are many models online that you can use.

3. Install Rubber Vibration Dampers

Sound is all about vibrations, so the more your printer makes, the noisier the machine will be.

Rubber dampers are small pads that go on the bottom of the frame of your printer and are meant to absorb the vibrations produced by your 3D printer. Adding them to your printer will not only lower the noise levels of the machine but also potentially improve the quality of prints because the vibrations will help keep the print bed more stable (less layer shifting).

There are many different types of rubber pads you can use, including squash ball feet, furniture pads, generic rubber slates, and even flexible 3D printable feet (TPU filament). All of the different options, though, are very cheap and won’t set you back more than $10.

When installing them, make sure to place one on each corner of your 3D printer’s frame. Also, make sure that your printer’s base doesn’t tilt or wobble, and, if it does, put a few napkins under one of the feet to keep the base balanced.

While not the same as rubber feet, stepper motor dampers are another way to absorb the vibrations produced by your printer. Stepper motor dampers are small rubber contraptions that are meant to be attached to the frame of the motor and absorb some of the vibrations from the motor to reduce noise.

4. Lower the Print Speed

When you’re driving a car, the faster you go, the louder the car gets. The same concept applies to a 3D printer, and the faster the print speed, the louder the machine. As such, lowering the print speed is an easy way to lower the noise levels on the printer.

It’s worth noting that this isn’t always the most efficient way to reduce noise from your printer.

Moreover, depending on your printer, it may take a 20 mm/s (30%) decrease in print speed to cut the sound by only a few decibels. Nonetheless, if you’re going for the quietest printer possible, every decibel counts!

If you’re printing with PLA filament, the standard print speed is around 60 mm/s. But, if you want to make the printer quieter, try going down to 35-40 mm/s. And, then, depending on the results, change the speed in increments of 5 mm/s until you get the noise level you want.

Whenever you change the speed setting, though, make sure to also adjust the nozzle temperature because lower speeds require a lower nozzle temperature. If you don’t do this, you might experience some over-extrusion.

You also should lower the travel speed to around 75 mm/s as this might also help.

5. Change to 0.9 Degree Stepper Motors

As we mentioned, the stepper motors are the single largest generator of sound on your 3D printer. While using stepper drivers can reduce noise from this part, you can go a step further and change the motors entirely.

Most stepper motors on 3D printers have a 1.8 degree angle, meaning it takes 200 steps (incremental rotations) for the shaft to make a full rotation (1.8 x 200 = 360 degrees). Changing to stepper motors with a 0.9 degree angle can help reduce the noise on your printer by smoothing out the motion.

Moreover, with a 0.9 degree angle, it takes 400 steps to make a full rotation and each step has a smaller rotational distance. As such, rotations can be split into smaller movements to smooth it out. This smoother motion reduces the vibrations and makes them less significant yielding a lower noise level from the motors.

This upgrade is quite expensive as 0.9 degree stepper motors can range from $20-40 a pop. However, like with changing the fans, this solution might be useful if you want to make the quietest printer possible.

6. Lubricate Moving Parts

One of the easiest ways you can lower the noise production on your printer is by lubricating all of the moving parts. This includes the printhead carriage, print bed carriage, extruder motor shaft, and more.

Every time one of these carriages moves across its respective axis on the 3D printer, it creates vibrations that you can hear. Adding a lubricant to the carriage, bearings, or axis track reduces the friction caused by the movement. As such, the parts glide a bit more, meaning there are fewer and less significant vibrations and thus less noise.

As for the “how” for this solution, it’s simple! Take a lubricant like WD-40 or another grease and apply a light coating on the axis track, such as the aluminum extrusion rail. You can also apply the lubricant to the bearing and other moving parts on the 3D printer.

7. Use Linear Rails

Most printers, especially budget ones like the Ender 3, use bearing wheels on aluminum extrusion tracks to move parts. This system is very inexpensive to make, which is why it’s so popular. However, it’s not the best for noise reduction.

Linear rails are a smoother motion system that uses small bearing balls fitted into a metal carriage that runs along a stiff metal track. On top of yielding more accurate and higher-quality prints, linear rails also are noticeably less noisy than the typical bearing-and-track approach.

Sadly, this upgrade is a little pricey but you might find it worth it if you also want to improve the quality of your prints. If you decide to pursue this upgrade, though, make sure you find a tutorial for your printer as the upgrade can be pretty complex and intensive.

8. Use a Yoga Mat

Yoga mats are a great way to get some exercise in, but they also make for an excellent and very sound-proof base for your 3D printer. That’s because as a byproduct of yoga mats being soft and foamy, they are also great sound absorbents.

The more absorbent the table or mat that your 3D printer is resting on, the less vibrations will be audible because they can’t spread as far. For the best noise reduction, look for a thick yoga mat because the more foam/rubber on the base, the quieter your printer will be.

What is the Quietest 3D Printer?

Don’t have a 3D printer yet? Well, you can skip the upgrade process by just getting a printer that’s silent from the get-go.

The Dremel DigiLab 3D45 is a very quiet machine due to its built-in enclosure and sturdy and vibration-minimal motion system.

However, if you’re on more of a budget, the Ender 3 V2 is a less expensive option that’s also pretty quiet. Moreover, the Ender 3 V2 comes with integrated TMC2208 drivers that do an amazing job at keeping motor noise low, and there are also pretty good rubber feet on the base of the printer.

For some more quiet printers, you can check out my article all about the least noisy 3D printers on the market!

Conclusion

Not many 3D printers in their stock form are quiet enough not to distract you if you’re working or sleeping in the same room. But, don’t worry because there are many things you can do to lower the noise levels of your printer.

The first thing I’d recommend doing is adding some rubber feet to the bottom of your printer. Second, if you’ve got some extra cash to spare, invest in some high-end stepper motor drivers if your printer doesn’t already have ones. I promise this works miracles when it comes to the noisiness of your printer.

Next, make sure to put your printer on a vibration-absorbent base like a thick yoga mat, and spray some WD-40 to the axes on your printer. Finally, if you still want to cut down by a few decibels, consider lowering the print speed, using quieter fans, and maybe even changing the stepper motor.