Almost everyone can agree that PLA is the most popular plastic for 3D printing filament.

However, the environmentally friendliness of the material is a lot more controversial a topic.

While many manufacturers of list that their PLA filament is biodegradable, this statement often goes unchecked, leaving 3D printing enthusiasts to wonder the truth.

Although Polylactic Acid (PLA) is all-natural, sourced from crops like corn and sugar, the plastic isn’t biodegradable the same way you’d say a banana is. With this in mind, we suggest you refrain from dumping your failed prints into your garden. Moreover, PLA can only biodegrade in very specific environmental conditions, and, even then, parts made of this material take hundreds of years to fully biodegrade.

If you’re interested in learning more about PLA and the biodegradability process for the plastic, read on! We’ve also got a lot of information about the overall environmental friendliness of the material such as recyclability, emissions, and more!

Table of Contents

What Is PLA?

If you’ve got a 3D printer, chances are you know a thing or two about PLA. However, for those new to this material and those who’ve never even heard of it, you might want to read up about this plastic to get some background info.

PLA is shorthand for Polylactic Acid, which is the sciency name for this 3D printable thermoplastic. While PLA is probably most well-known as the king of 3D printing filaments, it’s also commonly used in the food packaging industry due to its food-safe-ness.

Perhaps the most notable quality of PLA as it relates to 3D printing is its easy printability. Furthermore, PLA has a pretty low melting temperature and doesn’t usually require a heated bed, making it compatible with basically any 3D printer on the market. Additionally, you can achieve high-quality prints without much tuning to your printer or slicer settings, making it very easy to use.

Check out our review of the best PLA filament brands here.

The main flaw in PLA is that it’s not a very strong or durable plastic. Simply exposing a PLA print to sunlight for an hour or more can deform the model as PLA is sensitive to UV rays and warm temperatures. PLA also has a low tensile strength and is associated with poor layer-to-layer adhesion, making parts printed in this material very brittle and weak.

How Is It Produced?

The reason most sellers tout that their PLA filament is “biodegradable” is because PLA plastic comes from natural beginnings.

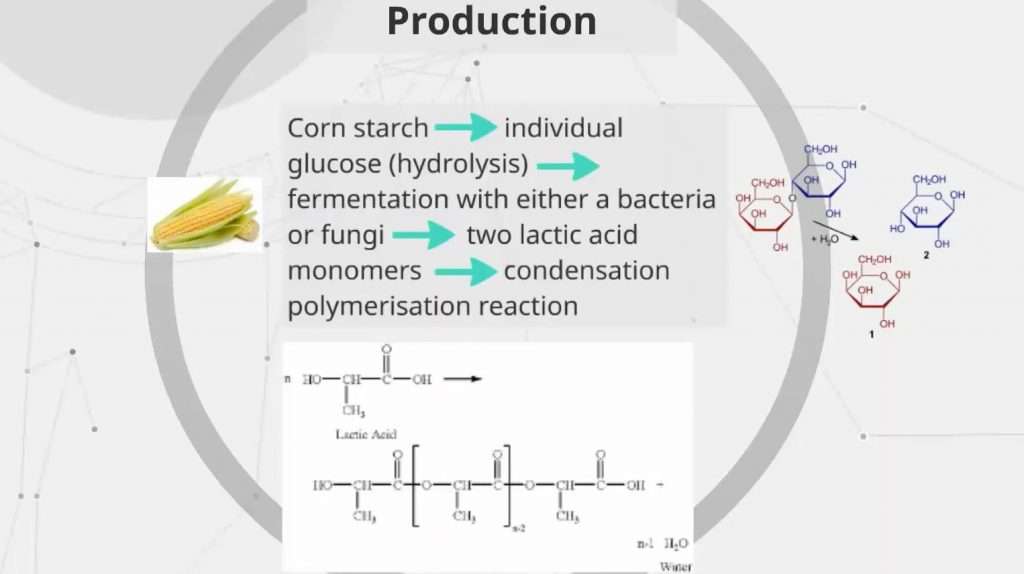

The main resource used to make raw PLA plastic is crops, such as corn, sugar, beet, and wheat.

So how do these all-natural and renewable resources turn into the 3D printable plastic hanging by your 3D printer?

The first step of the PLA production process is the extraction of starch from the crops, which is done through a process known as wet milling. After the starch is acquired from the plants, it’s mixed with a few special chemicals and enzymes to incite a reaction that produces a special kind of sugar (Dextrose).

The sugar is then fermented with more enzymes, which results in the creation of lactic acid. With only the prefix “Poly” left to add to make the plastic, the lactic acid is polymerized. This process uses heat, mixing, and even more enzyme chemicals to combine the lactic acid monomers to finally form raw PLA plastic.

Although raw PLA plastic is the main ingredient for PLA filament, it’s not the only one. Most filament manufacturers buy the raw PLA plastic and mix in a few substances, which we call additives. Additives affect the raw PLA plastic in different ways, such as changing the color or enhancing the plastic’s strength.

The blend of raw PLA and additives is then melted and pushed through a machine called a filament extruder (not the same one on your printer) to take on the string-like form of what we call filament.

Finally, the material is wrapped onto a spool, packaged, and shipped to your doorstep!

Can You Really Say that PLA Filament is Biodegradable?

So, with the natural origins of the biomaterial in mind, one might assume that PLA filament is biodegradable. And, it’s true, PLA plastic can technically biologically break down. However, it wouldn’t do justice to simply leave our discussion at that.

PLA isn’t biodegradable the same way as an apple, orange, or other fruit. In order for the plastic to actually biodegrade, a very certain set of environmental conditions must be met.

For this reason, a better label for PLA is “compostable” rather than “biodegradable”.

Compostable means that a material, such as plastic, can biodegrade but only significantly when in a controlled environment, such as a composting facility. These compositing facilities offer a controlled environment that meets the environmental conditions required for PLA biodegradation.

Conditions for PLA to Biodegrade?

As we mentioned, PLA will only biodegrade when certain conditions are met, and there are two main ones.

The first condition is a warm climate. PLA has a low glass transition temperature (the temperature where the plastic softens), and a warm environment can help soften up the material. This makes the PLA part more malleable, allowing the air inside the model to release, thus shrinking the part.

The second main condition is the presence of microbes, which are microorganisms that assist in the biodegradation process. A lot of microbes will chemically break down the PLA plastic faster. Microbes are usually present in the soil, but, for an optimal PLA biodegradation environment, an unnaturally high number of microbes is required.

Due to the lack of natural areas that meet both conditions, if you want to have a PLA part biodegrade, your best bet is to send it to a biodegradation facility.

How Long Does it Take for the PLA to Degrade?

The amount of time it takes for a part printed in PLA filament to degrade varies on a few different factors, with perhaps the most significant one being the environment. If your PLA part isn’t in a warm and microbe-rich environment, the biodegradation process might never really start (or at least not noticeably ever). For example, you could bury a small 3D print deep in the soil for years without noticing a physical difference in the part.

And, even when these naturally unoccuring conditions are met, parts made of PLA still take months to years to fully break down chemically and go back into the Earth. For some perspective, you could throw a ripe orange in your backyard and see very clear signs of biodegradation in a matter of days. On the other hand, it would take at least 6 months for a PLA 3D print to biodegrade in a controlled composting environment.

Additionally, it’s worth pointing out that PLA isn’t the only chemical component of a “PLA” filament. So even if all of the Polylactic Acid of a part fully biodegrades, the additives used in the filament, which aren’t likely to be biodegradable, will still remain. Of course, additives only make up a small composition of a PLA filament, but it’s still worth mentioning.

If you want a filament with the least number of additives, avoid PLA+ and PLA Pro variations as these almost always contain more additives than regular PLA filaments. “Natural” PLA filaments usually contain the least additives because no add-in substances are used for the filament’s color.

Learn more about the differences between PLA+ vs PLA here.

Another factor that affects the time it takes for a PLA part to fully biodegrade is the size of the part. As you probably expect, the larger the model, the more time it will take for it to biodegrade.

For all of these reasons, it’s very hard to estimate the time it takes for a PLA model to biodegrade. However, it can be expected that a small-medium-size model 3D printed in regular PLA filament will take at least 75-100 years to fully biodegrade in the wild. And, 6-12 months if in a composting center with a controlled environment.

So, if you had plans of chucking your prints in your garden, consider putting them on your annoying neighbor’s lawn instead because they won’t be going anywhere in your lifetime.

Can PLA be Recycled?

While PLA isn’t super biodegradable, you might be wondering if you can recycle this plastic to reduce your environmental footprint another way. Luckily, you can!

If you’ve got some PLA scraps from 3D printing and want to recycle the plastic, you can drop it off or ship it to a recycling plant that accepts this form of plastic. Sadly, not too many publicly-available recycling centers accept PLA due to its niche applications and those that do often charge a fee.

Another way you can recycle your PLA plastic is by making new filament out of the scraps. While this requires some special hardware, such as a grinding machine to chop up the PLA part into small bits and a filament extruder to make the filament, it allows you to close the loop of 3D printing waste by using old prints to make new ones.

If you don’t want to make the decently-large invesment (around $1,000 at least) into fialment-recycling equipment, another way you can reduce your environmental footprint is by using recycled filament.

Company’s make recycled filaments with the scraps and excess PLA plastic from their regular PLA filament production process to limit their waste. A few examples of this are 3D-Fuel’s ReFuel filament, Prusament’s Recycled PLA filament, and 3DJake’s rPLA filament.

There are also recycled filaments that are made with actually-recycled PLA plastic that are taken by a company from a recycler center and made into filament again. Reflow is one of the most popular brands of this type of recycled filament and they have a lot of options for PLA filament with different colors.

PLA 3D Printing Emissions

Emissions from 3D printing is another environmental concern that enthusiasts have. Generally speaking, the 3D printing process produces very little emissions. However, this varies based on the material of the filament being used.

Certain materials like ABS can produce a lot of emissions. Even worse, the fumes that come out of heating up ABS and 3D printing the material are considered toxic and are definitely not environmentally friendly. In fact, Users have reported getting headaches from being around their printer while it’s printing ABS filament.

As for PLA, the chemicals emitted into the air during the printing process are actually more toxic than those from ABS. However, PLA emissions are considered less harmful because there are significantly less of them produced compared to ABS and other materials.

For this reason, you shouldn’t worry too much about the air quality around your printer if you’re using PLA filament. Of course, having an air filter in the room where your printer is located is certainly a good idea, but it’s not necessary as long as you have some form of ventilation in the room.

Learn more about 3D printer fumes here.

Is PLA Environmentally Friendly?

So, the final question: is PLA environmentally friendly?

Well, I’d say so, at least relative to other 3D printing materials.

For one, PLA is sourced from renewable resources (crops) and not oils like other filament materials are (e.g. ABS, PETG). While creating PLA filament does take away from the crops that can be used for food, this doesn’t directly negatively affect the environment.

Second, PLA is compostable and, if you really want to keep your environmental footprint low, you can send PLA parts to special facilities to allow them to biodegrade quickly. Alternatively, you can also recycle PLA, and turn old prints into new filament.

Third, recycled PLA filaments are available, allowing you to reduce the waste produced by the PLA filament industry while still being able to 3D print. Finally, printing PLA doesn’t emit many fumes.

With all of this in mind, I think it’s safe to call PLA environmentally friendly, or, at worst, not significantly environmentally harmful.

Conclusion

PLA will likely remain the most popular 3D printing filament for at least the foreseeable future.

While it’s not as biodegradable as PLA filament manufacturers probably want you to think, it’s a compostable material that can biodegrade under the right conditions.

PLA is also environmentally friendly in other ways because you can recycle it, buy recycled PLA filament, and it doesn’t produce a lot of emissions.