Want to 3D print a model that will go outdoors, like a tent stake, lantern casing, or even a GoPro holder? Well, you probably want those parts to be waterproof if they’re going to be exposed to rain. So that begs the question: is PLA, the most popular filament material for 3D printing, actually waterproof?

Yes! Kind of…

PLA won’t degrade from water, which is nice. However, naturally, parts 3D printed in PLA don’t hold water well because the 3D printing process, along with the properties of PLA, makes for very porous 3D models.

But luckily, PLA can be made to be waterproof and hold liquids without leaking! Want to learn how to make waterproof PLA parts? Read on!

Table of Contents

- Will PLA Dissolve in Water?

- How Long Will PLA Last in Water?

- 9 Ways to Make PLA Waterproof

- 1. Alternative: Use a Waterproof Filament

- 2. Increase Your Layer Height

- 3. Increase Wall Thickness or Perimeters

- 4. Increase Flow Rate/Extrusion Multiplier

- 5. Increase Printing Temperature

- 6. Use a Wider Nozzle Diameter

- 7. Increase Infill Density Percentage

- 8. Apply a Coat of Epoxy Resin

- 9. Use SLA 3D Printing

- FAQ

- Conclusion

Will PLA Dissolve in Water?

PLA won’t degrade in water, so, no, PLA parts won’t dissolve in water like sugar. That’s because water isn’t a solvent for plastics like PLA.

However, there are a few liquid chemicals to watch out for, such as ethyl acetate and some isopropyl alcohols. That’s because these chemicals, as well as a few other hardly-worded ones, do, in fact, serve as solvents for PLA, so PLA parts can dissolve in them. But don’t worry because these chemicals aren’t just going to be falling from the sky or in your nearby stream.

How Long Will PLA Last in Water?

Though PLA won’t degrade in water in the short term, parts made of this plastic material can change a bit if submerged in water for a long time.

If you place a PLA part in water, over time, the part will start to swell and slightly expand. That’s because the PLA polymer will start to absorb the water, increasing the volume of the part.

On a similar note, if you place the PLA part in warm water or in a place where sunlight still reaches, the model will start to soften up and become more malleable.

But, for the most part, you should be good if you print a model in PLA that you think could be rained on or even completely covered in water for hours or even days.

9 Ways to Make PLA Waterproof

Luckily, there are a few ways you can 3D print fully liquid-storing and waterproof PLA parts. In the sections below, I’ve gone over the processes and tips I like to use when making a part that I want to be waterproof!

1. Alternative: Use a Waterproof Filament

The first and most common cause of under-extrusion is a low nozzle temperature. The hotter the nozzle, the faster filament will melt so that it can be pushed out of the nozzle. But if it’s not hot enough to melt filament fast enough to keep up with the printing speed, you’ll have under-extruded parts.

PETG

Our first waterproof material is PETG, a very strong and rigid material that’s also amazing for holding liquids. This filament material is actually derived from the same plastic found in many water bottles and Tupperware containers. Though printing it is a little bit more difficult than printing PLA, you basically won’t have to do anything to make PETG parts water resistant.

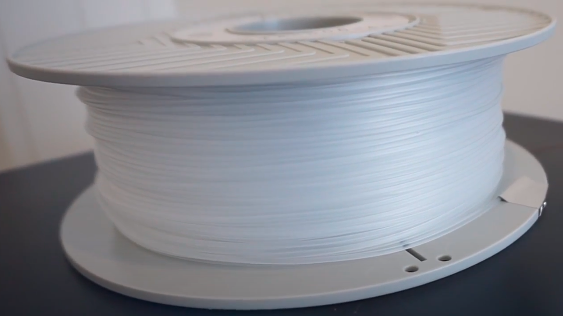

Polypropylene (PP)

Polypropylene is another perfect material for making water-resistant parts because, like PETG, this plastic is very naturally water resistant. It’s also super hard to print, but it comes with some other benefits, too, like very high durability and visible transparency (most PP filaments are clear).

GF30-PP (Polypropylene with glass fibers)

My third suggestion for an alternative filament to make water-resistant parts is a niche one: GF30-PP. This is a special type of composite filament that’s based on polypropylene but with some glass fibers mixed in. On top of providing additional strength over PP filament, it also makes for even more water-resistant prints.

If you choose to change to one of the materials I talked about above, then you really can stop here because parts printed in those filaments will hold water well right off the get-go. But if you’re sticking with PLA, keep reading, soldier!

2. Increase Your Layer Height

The first thing to do if you’re trying to achieve perfect waterproofness with PLA is to increase your layer height. This will make the layers thicker and better hold back and resist water from getting inside the walls of the model.

Additionally, increasing your layer height on prints will also make the model stronger because fewer layers equal fewer possible breaking points.

You can change the layer height in your slicer program (e.g. Cura), and I suggest using a layer height of 0.28-mm minimum. Personally, I like to use 0.32 mm for the layer height, so don’t be afraid to go higher than 0.28.

3. Increase Wall Thickness or Perimeters

The walls on a 3D print separate the outside world from the infill within a model. Walls are 100% solid (unlike infill), so the more walls you have, the less likely water is to get into your model. This is extremely important for any 3D printed containers with sensitive electronics or other non-waterproof parts inside.

Most default slicer profiles use a wall thickness of 0.8 or 2 walls with a 0.4-mm nozzle (the standard nozzle diameter). For PLA parts, I suggest increasing the wall thickness to at least 2 mm (5 walls) if you don’t want water getting through.

But feel free to go as high as you want! For example, if your model is very thin, consider putting the wall thickness at the width of the part so that it’s completely solid.

4. Increase Flow Rate/Extrusion Multiplier

The flow rate, also known as the extrusion multiplier in some slicer programs, is a percentage value that determines how much of the expected filament should be used. While the 100% flow rate that’s the default in basically all slicer programs is theoretically correct, it can cause under extrusion in parts, making the model more porous and likely to leak water.

Increasing the extrusion multiplier to 105% or even higher will ensure that no under extrusion occurs and that your model is sealed shut. Of course, over extruding your print will leave zits and blobs on the surface of your model, but you might find this visual imperfection worth it for the waterproofness of your model.

5. Increase Printing Temperature

As you probably know, the higher your nozzle temperature, the faster filament is melted and the faster it can come out of the nozzle. But what you might not know is that if you raise the printing temperature without changing the print speed, your model will have better layer-to-layer adhesion. This means there’s a stronger bond between the individual layers of your print.

On top of making your model more durable and strong, increasing the printing temperature also makes the model more waterproof. You can achieve terrific results by increasing your nozzle temperature by just 5 °C, but feel free to go up to 10 °C for even better results.

Do beware of the potential for over-extrusion and poor detail on prints, as these can both be caused by too high a printing temperature.

6. Use a Wider Nozzle Diameter

A wider nozzle diameter allows you to use a larger layer height, and if you read our second tip, then you know that this can improve how waterproof your PLA model is. Most printers come stock with a 0.4-mm diameter nozzle.

Increasing to a 0.6, 0.8, 1.0, or 1.2-mm diameter nozzle will allow you to use layer heights outside the range of what you can reasonably achieve on a 0.4-mm nozzle. For making waterproof prints, I like to use a 0.8-mm nozzle with a 0.4-mm layer height, but you can go higher or lower depending on how waterproof your prints turn out.

Just make sure to increase the printing temperature and lower the printing speed if you go up in nozzle diameter, though, as this is necessary for high-quality prints.

7. Increase Infill Density Percentage

The infill density defines how solid a 3D printed model is behind the walls. The higher the infill, the more filament used, but the more solid the print. While infill density doesn’t technically make a model more resistant to water getting on the inside, it will allow a PLA 3D print to keep its form more. This way, you can put a model underwater for longer without it deforming or swelling.

In my experience, an infill density of 60-100% works well for prints that you plan on putting underwater. I also suggest using a three-dimensional infill pattern, such as cubic, as this will provide the most all-around strength for your model.

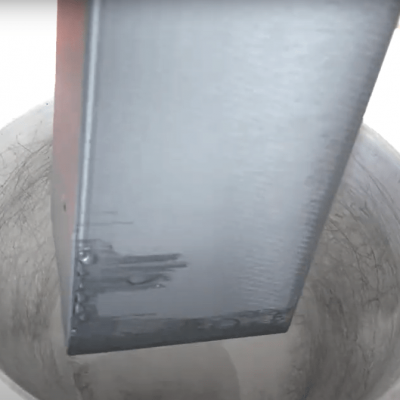

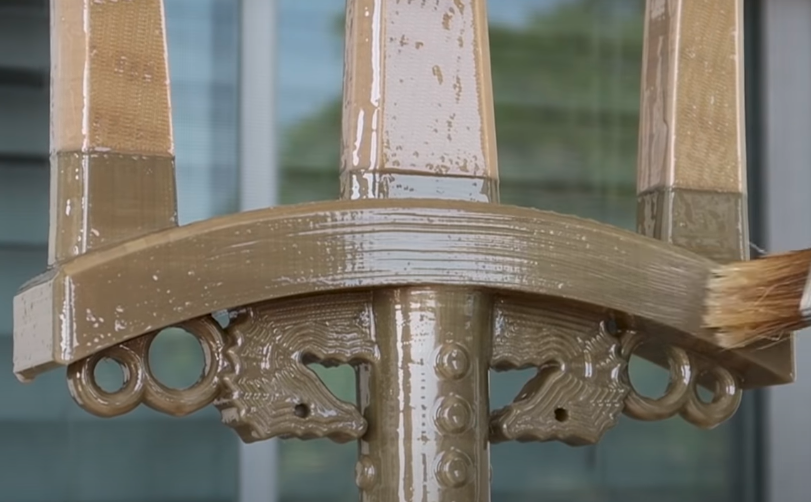

8. Apply a Coat of Epoxy Resin

Just like wood, you can give a PLA 3D print a coat of Epoxy resin or a similar substance to make the part even more waterproof from the outside. Epoxy is a decently popular post processing technique, so if you’ve never used it before, don’t worry because there are many tutorials online.

All you have to do is paint the resin on every inch of the surface of your model. It’s best to give the model a few coats of the resin as this will provide the most water resistance as well as add a shiny look to the model.

9. Use SLA 3D Printing

Our last tip is to use an SLA 3D printer over a traditional FDM machine. SLA machines produce models with practically invisible and almost non-existent layer lines, meaning there’s almost no way a liquid can get through a print. Of course, this is technically “cheating” because you wouldn’t be using PLA, but it’s just a tip if you want a super waterproof model.

FAQ

Now that you have some tips at hand for making your PLA prints waterproof, you might have a few random questions. We’ve taken some of the most popular questions about PLA and waterproof-ness and answered them below:

Is a PLA Vase Waterproof?

It can be!

If you want to print a vase in PLA, I’d definitely recommend checking out Cura’s vase mode as it turns models into 100% solid vases with a single wall. Just make sure to use a high printing temperature to get the best seal between the layers, and consider doing some post processing, like applying Epoxy resin to the exterior of the model.

Alternatively, you can print the model regularly and apply some of the tips we mentioned above to get a vase that won’t leak!

Is PLA Safe to Put Liquids In?

Yes!

One of the reasons PLA is so popular is because it’s food-safe and won’t contaminate any water or other substance that it comes in contact with. Of course, if there are excess filament bits in the model, those will go into the water. So as long as you wash and clean your PLA model after it’s done printing, you’re safe to put whatever liquids you want inside.

Can I Acetone Smooth PLA Prints?

Acetone smoothing is an excellent way to remove the layer lines on prints made in ABS and ASA, but it won’t work with PLA. That’s because PLA isn’t soluble in acetone (nail polish remover), so the layer lines on the model won’t dissolve, and your part won’t become any more waterproof than it was before.

Conclusion

At the end of the day, printing PLA on a regular 3D printer with default slicer settings won’t make the model waterproof. However, you can pretty easily make completely waterproof PLA parts if you make a few modifications.

The biggest suggestions I have for those looking to make waterproof PLA prints are to use a large layer height, increase the wall thickness, and use a high printing temperature. But even after the model is done printing, be sure to complete some post processing steps such as coating your model in Epoxy resin.