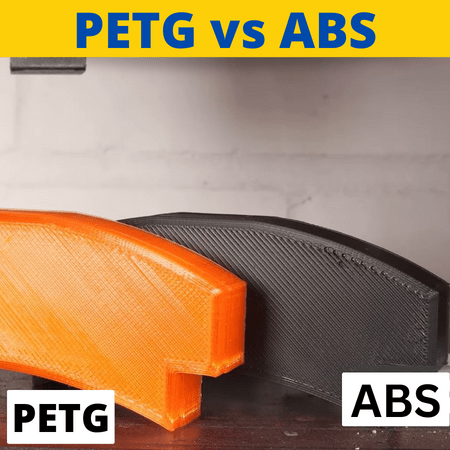

Today, there are 10+ different 3D printing materials, all with their own unique abilities, material properties, and other characteristics. While PLA might be the most popular consumer filament material, PETG and ABS are definitely close behind and are well-liked and commonly used by the 3D printing community.

Both plastics offer a lot of strength (literally) over PLA filament, but what are the differences between PETG vs ABS?

Well, for one, PETG is easier to print than ABS because it requires lower printing temperatures, doesn’t need an enclosure, and bed adhesion issues (e.g. warping) are less common. On the other hand, ABS prints will be more impact resistant than PETG prints due to ABS’s slight flexibility, and you likely won’t experience stringing on ABS prints like you will with PETG.

While these differences are the main ones, there are many more. In the following sections, we’ll dive deeper into how PETG vs ABS are different so you can make a knowledgeable decision about which type of filament you want to get for your 3D printer.

Enjoy!

Table of Contents

Background

Before we get into the differences between PETG and ABS, covering some background information about these two plastics will help you gain a better understanding of each plastic individually. In this section, we’ll do just that, starting with PETG!

What is PETG?

PETG stands for Polyethylene Terephthalate Glycol and is a thermoplastic that’s a modified version of PET, the plastic used in most water bottles and Tupperware.

The only difference between PET and PETG is a glycol modification, which lowers the plastic’s melting temperature to make it more easily 3D printable. PETG is known for being rigid and having some printing issues like stringing, but it’s overall a well-liked printing material and a great option!

What is ABS?

On the other hand, Acrylonitrile Butadiene Styrene, known as “ABS”, is another thermoplastic and is one of the most widely-used plastics, seen in everything from LEGOs to the interior pieces in a car.

Although it’s very popular in general, it’s not as popular for 3D printing due to the difficulties associated with printing this material. On this note, the challenges of printing ABS make it slightly less liked than PETG in the 3D printing community, but its strength and slight flexibility make it the perfect option for printing mechanical components.

Now that you know some background info about the PETG and ABS, let’s compare the two on the battlefield!

What’s the Difference Between PETG and ABS?

So, what are the differences between PETG vs ABS? Well, as we mentioned, there is a good bit of them.

First, PETG is sourced from the by-products of oil and is considered an eco-friendly material by many filament manufacturers due to its 100% recyclable-ness.

ABS is also oil-based and, like PETG, parts made in plastic won’t biodegrade. However, because ABS isn’t recyclable, it’s not considered eco-friendly, which might be a point to keep in mind if you’re considering your environmental footprint when looking at filaments.

Strength

Recyclability isn’t where the differences stop, though, and many of the differences between these two plastics come from their material properties.

Most notable, PETG is a more rigid material than ABS. Many studies point to parts printed in PETG being stronger than those printed in ABS. PETG has a stronger tensile strength (~7000 PSI) in comparison to ABS (5000-6000 PSI).

However, because ABS is just a tad bit flexible, parts printed in this material technically are a little bit more impact-resistant than those printed in PETG.

Durability

PETG also takes the cake when it comes to overall durability compared to ABS.

That’s because PETG is resistant to UV rays (e.g. sunlight), high temperatures (up to 80 °C), solvent chemicals (e.g. acetone), whereas ABS has only a high temperate resistance going for it (up to 100 °C). Ultimately, this makes PETG the better option for printing models meant for outdoor use because they won’t deform under some sunlight and other stresses.

Parts printed in PETG also usually hold water pretty well and the material is considered water-resistant. ABS can hold moisture fine, but just not as well as PETG. As such, if you’re printing any container that will hold a liquid, PETG is your best bet.

Check out our review of the best PETG filaments here.

Temperature Print Settings

However, the biggest category of differences between PETG vs ABS is how they’re printed. Both materials require considerably more heat to print than PLA but in different amounts. It’s recommended to print PETG with a nozzle and bed temperature of 230 and 75 °C, respectively.

On the other hand, ABS needs more heat and it’s recommended to use a nozzle temperature of 240 °C and a 110 °C bed temperature.

Most consumer-grade 3D printers these days can reach PETG’s necessary temperatures but less printers can reach ABS’s high bed temperature requirements, meaning it’s not as compatible.

Additionally, you’ll want an enclosure around your printer if you want to have high-quality prints because ABS is sensitive to temperature changes and air drafts and enclosures prevent these. An enclosure requirement further makes ABS the less compatible filament material because PETG doesn’t need one.

Print Difficulty and Common Issues

PETG has its fair share of printing issues, though, and stringing, where tiny string-like structures surround the areas of prints, is a common occurrence while printing this material.

You likely won’t face stringing with ABS, but this material is notorious for poor bed adhesion so getting the first layer of prints to stick might be an issue.

Conversely, PETG is known for over-adhesion and prints made in this material are usually difficult to remove. This also means parts printed with PETG will be less likely to break apart where the layers come together once the mechanical stress is added.

Odor

Another printing factor is odor. You don’t want a smell infecting the place where you work on your 3D printer or the same room where you do other things like sleep.

Luckily, PETG filament is considered odorless. However, the same cannot be said for ABS and many users report the smell of burning plastic after they print ABS, which is probably not something you want to have around your printing space, especially if it’s in your room.

Storage

While it might seem like PETG is taking the dub in many of these comparisons, ABS is the winner for storage. PETG is naturally more hygroscopic, meaning it more quickly will absorb moisture from the air, degrading the quality of the plastic.

It’s basically necessary to store PETG filament in an airtight container, but you can leave ABS out in the open for a good bit before it starts to degrade in quality.

Availability & Price

The last area of difference between ABS and PETG is the plastic’s availability, price, and variety.

To start with the first point, it’s hard to say whether PETG or ABS is the more available option. A simple Amazon search for “PETG filament” yields a few more results than a search for “ABS filament”, but as the difference was so minute, it’s safe to say that the two have basically the same popularity in the 3D printing community.

Second, when it comes to price, both PETG and ABS have almost the same exact price of just above $20 per kilogram spool. If there had to be a winner, though, it would be ABS as a spool of plastic is, on average, a dollar or two less expensive than a spool of PETG.

Unique Properties

Finally, it’s important to go over the different composites or special variations of each type of filament. By this, we mean how many PETG-based and ABS-based filaments there are that offer other unique properties like conductivity or extra strength.

For PETG, there are a handful of special variations like carbon-fiber-infused PETG and PETG made from recycled plastic.

ABS also comes in many variations like carbon-fiber-infused and conductive, and this plastic probably wins in the number of variations available. This means you’ll likely be able to find more special ABS filaments that suit niche purposes compared to PETG.

Is It Environmentally Friendly?

As we mentioned, both PETG and ABS are sourced from oil or the by-products of oil.

Of course, as oil is an unrenewable resource, these materials are, to some degree, not very environmentally friendly. However, it wouldn’t do justice to the materials if we stopped our discussion of the environmental friendliness of the thermoplastics there.

It’s important to mention that parts printed in PETG are recyclable, just as the base material, PET is. So, while making PETG might cause some damage to the Earth initially, at least you can continually make something out of the plastic rather than just throw it out.

On the other hand, ABS isn’t recyclable and nothing really can be done to parts made of ABS that no longer have a purpose.

Is It Food Safe?

PETG is the way to go if you’re looking to print food-contact models like Tupperware or a water bottle.

While an FDA approval for 3D printing filament is hard to come by and not many filaments have it, PETG is naturally considered a food-safe plastic. This makes a lot of sense considering that its parent/base material, PET, is the plastic used for Tupperware, water bottles, and other plastic food-contact items.

Unfortunately, ABS isn’t considered food safe. While you’re not likely to start throwing up if you let your food touch a piece of ABS, continually using the filament to store food could potentially cause health risks.

So, if you’re looking to 3D print a food-contact item and are deciding between ABS and PETG, go with the latter. For the most food safety, you can use a PETG filament that has FDA approval.

Advantages

Now that we’ve gone over ABS and PETG, their differences, and answered a few questions about the materials, let’s sum up the information. In this section and the following one, we’ve listed the advantages and disadvantages of both ABS and PETG.

ABS

- Very strong

- High temperate resistance up to 100 °C

- Slightly flexible which provides excellent impact resistance

- Stringing and non-temperature related issues aren’t common

- Very inexpensive

PETG

- Resistant to high temperatures (80 °C)

- Resistant to UV rays like from the sun

- Very strong and durable

- Resistant to solvent chemicals

- Not too difficult to print

- Food safe

- Excellent layer adhesion

- 100% recyclable

Disadvantages

Of course, every filament material has its fair share of downsides too. Below, we’ve listed some disadvantages of ABS vs PETG.

ABS

- Not recyclable and oil-based

- Not food safe

- Requires an enclosure and high temperatures to print

- Sensitive to changes in slicer settings

- Poor layer adhesion

PETG

- Comes from oil

- Stringing and over-adhesion are common issues

- Hygroscopic so you need to store it in an air-tight environment

- Slightly more expensive than ABS and PLA

Applications

With the advantages and disadvantages of both materials in mind, it’s important to review the applications of each material. We’ll do just that in this section.

First up, due to its high strength and slight flexibility, ABS is probably the best material for printing strong parts that will undergo physical stresses. However, because parts printed in ABS can quickly deform under UV rays, we suggest only using the material for printing components that will function indoors or in low-sunlight environments.

Additionally, because it’s not super eco-friendly nor food safe, we advise not using this material if you’re concerned about your environmental footprint or are printing food contact items. A few examples of parts that ABS would be the ideal material for include gears on a robot, a headphone stand, or a shelf.

Due to its many durability-focused properties, PETG is also a great material for making parts that will undergo stress. However, the plastic’s resistance to external factors like UV light, high temperatures, wear, water, and solvents make it better for printing outdoor parts that will face a harsher environment than indoors. So, to list a few examples, we suggest using PETG to print tent stakes, a birdhouse, rope hooks, and similar models.

For most people, PETG is the way to go because it is as strong (if not stronger) than ABS, more durable, and it’s easier to print. ABS is only necessary if you absolutely need the 100 °C temperature resistance (i.e. boiling your print in water to sterilize it) or its ability to be glued and painted.

Otherwise, it’s difficult to justify the printing difficulties involved. If you already have an enclosed 3D printer and want the challenge of printing ABS then have it.

With whatever filament material you pick, we hope you succeed in your 3D printing adventure and we’ll always be here to help you with any issues.

Enjoy!