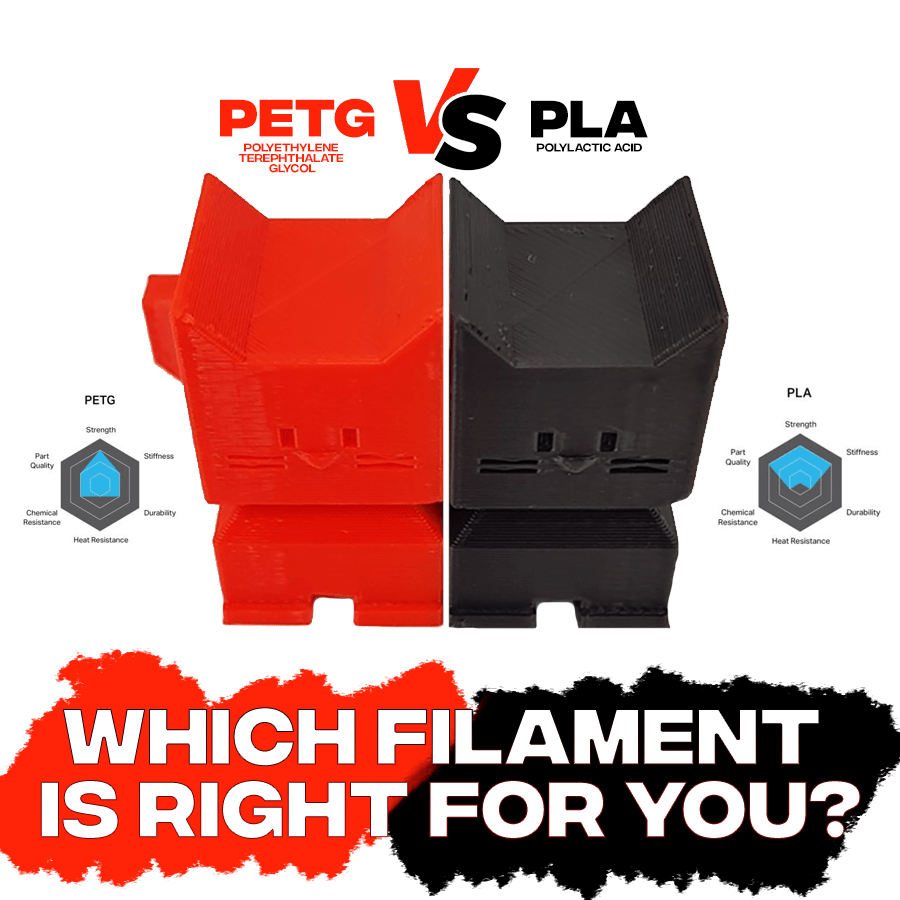

Can’t decide what type of filament to use? Nowadays, there are hundreds of different materials you can 3D print with, but few are as useful as PLA and PETG.

Both PLA and PETG are prevalent types of 3D printing filament, each with their own set of benefits and disadvantages concerning part strength, 3D print-ability, and model quality.

Using the right filament material for your needs is crucial, and the wrong decision could lead to 3D printed parts that don’t satisfy their purpose. Let us help you make the right decision between PLA and PETG filament as we dive into a comparison of the two materials!

Table of Contents

Background

Before we dive into our point-by-point comparison between the two filament materials, let’s first meet our contestants and learn a little about their history!

In the red corner stands PETG, known by his nerdy friends as Polyethylene Terephthalate Glycol-modified. PETG is a version of the plastic PET, altered to make the material more easily 3D printed. While these super sciency names of plastics may sound random, you’ve probably interacted with PET as it’s the primary material used in most plastic bottles.

In the blue corner, discovered in the early 1900s, stands PLA, AKA Polylactic Acid. However, this isn’t a dangerous type of acid, and PLA is typically sourced from plants, making it biodegradable. Today, PLA’s main purpose is 3D printing, but it’s also commonly used in the medical and food-packing industries.

What’s the Difference Between PLA and PETG?

No material in the universe is a boring one and they all have their advantages and disadvantages. PLA and PETG are no different and their best used for different applications based on their strengths and weaknesses.

Most notably, PLA is easier to 3D print than PETG, which is the main reason why PLA filament is more popular. In fact, PLA is considered the easiest material, and this is partially because of the material’s low printing temperature of around 180 °C with no heated bed required (or 60 °C if available). The low temperature requirements make extrusion easier and allow the material to be used on more 3D printers.

In addition to low printing temperatures, PLA is also easy to print due to the material’s natural flexibility when it comes to print settings. In other words, it’s pretty easy to achieve a decent quality 3D print with PLA without tuning your slicer profile or settings. This makes PLA the natural pick for people just getting into 3D printing or those printing parts for fun who want a seamless experience.

On the other hand, PETG is much more difficult to print and requires a bit higher temperatures for printing than PLA. Moreover, it’s recommended to use a bed temperature of about 70 °C and a nozzle temperature of 240 °C to print PETG. Unlike PLA, not all printers are capable of reaching the necessary temperatures for printing PETG, so some people can’t use the material. You still won’t need a closed chamber (enclosure) for printing PETG, though!

The material is also a lot more sensitive to how it’s 3D printed compared to PLA, and minor adjustments to the temperature or slicer settings (e.g. retraction) can result in massive changes to print quality. Because of this, you’ll have to spend more time tuning and testing your slicer settings to achieve high-quality prints. There are a few common printing issues associated with PETG, such as stringing, which can cause print defects, as well as over-adhesion to the build plate, which, in extreme instances, can damage your machine’s printing surface.

While PLA may have printability on its side, PETG takes the cake when it comes to physical properties. PETG is a stronger and more rigid plastic than PLA, so parts printed in the material can withstand more physical stresses than PLA parts, which tend to be brittle. Because of this, PETG is an excellent material for making functional models that will face physical forces.

On top of raw strength, PETG also offers other properties that make it a very durable material, such as UV and temperature resistance. While leaving a PLA model under the sun for a few hours will likely cause the part to deform, this won’t happen with PETG prints.

Additionally, PETG parts are water resistant and can hold liquids better than parts printed in PLA, making the material great for 3D printing containers and bottles. Due to the raw materials used to make the material, PETG is also resistant to chemicals like solvents that can deform PLA prints. This is yet another indicator that PETG is the superior option if you’re looking to print models for outdoor use or industrial applications.

Unfortunately, PETG’s natural chemical resistance limits how you can post-process parts made in the material. Moreover, unlike with PLA, you won’t be able to use solvents like acetone or isopropyl alcohol to smooth the layers of PETG prints. Instead, you’ll have to rely on less accessible and harder-to-pronounce chemicals, like methyl ethyl ketone and cyclohexanone, to layer smooth PETG parts.

How is it Made?

Just like some people like to know where their food came from, you may be interested in how your filament was made. We won’t be covering the process of turning processed materials into filament spools, as this is the same for all materials. Instead, we’ll be focusing on how the actual processed PLA and PETG materials are created.

We’ll start with PLA. The main ingredient in PLA is typically cornstarch, but it can be made with any natural starch. While this starch comes from plants, this doesn’t exactly make PLA all-natural as many unnatural processes are necessary to turn the starch into a roll of 3D printable filament.

Once the starch is isolated and extracted from a plant, a few different chemical enzymes are mixed with the filament to bring out the sugar in the material. Then, in a slightly (very) different way than with wine, the sugar, scientifically known as Dextrose, is fermented to release lactic acid polymers. Lastly, these polymers are turned into a malleable and solid form of processed PLA material through polymerization.

As for PETG, the process is similar to PLA, but instead of being sourced from natural starch, the raw materials for PETG come from crude oil and natural gas. Two key chemicals known as ethylene glycol and terephthalic acid are extracted from oil and gas. These materials are heated and mixed together to form processed PETG pellets which can be turned into filament.

Is it Food Safe?

Many people like to 3D print items to hold food, like a candy bowl or chip platter. If this sounds like you, then you should note that both PLA and PETG are usually considered food-safe, but PLA is the only one sourced from natural materials. Still, before printing anything you want food to touch, we suggest making sure the specific filament you’re using is FDA approved.

Is it Environmentally Friendly?

If you’re concerned about the environmental impacts your 3D printing endeavors may cause, then you probably were relieved to know that PLA is biodegradable. However, it’s not like you should just start chucking failed PLA prints out the window as the full biodegradation process for PLA plastic can take tens or even hundreds of years. Still, PLA is a lot more environmentally friendly than PETG, which isn’t biodegradable at all.

Although PLA and PETG aren’t super environmentally friendly, there are ways you can use these types of filaments while reducing your environmental footprint. The most popular option is using a recycled filament that is sourced from recycled PLA or PETG materials.

Prices & Options

Of course, we can’t forget about the price of the filaments. We know this is probably the factor that people look at first when looking for filaments, and, luckily, both PLA and PETG filaments don’t cost too much dough.

Your typical first-page results for “PLA filament” fall in the range of $20-30 per kilogram, with most on the lower end of the spectrum. On this note, if you’re looking for some great PLA filament options that offer excellent print quality and fit any budget, then make sure to check out our review of the best PLA filaments.

PETG isn’t far behind, only costing a dollar or two more per kilogram PLA on average. These prices make both PLA and PETG great deals considering that a kilogram of filament can last you months.

However, price isn’t the only consideration when it comes to purchasing your filament, and the brand and blend of PLA filament also matter. As there’s a larger market for PLA filament than PETG, it makes sense that there are more options for filaments in this material.

And by more options, we’re not just talking about some extra colors. There are many unique types of PLA filament not available in a PETG form, like wood-infused, marble speckled, UV-color-changing, and dichromatic filament. PLA is also more widely available than PETG, and few 3D printing companies don’t sell their own blend of filament.

Properties

Now that we’ve gone over the main differences between PLA and PETG let’s do a quick re-cap with some pros and cons bullet points for each material.

PLA

Pros:

- Very easy to 3D print and achieve decent print quality without much tuning

- Requires no heated bed and a low nozzle temperature making it compatible with most 3D printers

- Low cost per kilogram and available in many variations

- Can be easily post-processed (e.g. layer smoothing) using popular solvents like acetone and IPA

- Biodegradable and sourced from a renewable resource (plants)

Cons:

- Prints are brittle and pretty weak (unless you increase infill percentage)

- Not very water-resistant

- Parts deform when under UV light or in warm environments

- Takes a long time to biodegrade fully

PETG

Pros:

- Very strong and rigid for print durability

- UV resistant so prints won’t deform under sunlight

- Can withstand high temperatures without deforming

- Resistant to many chemicals like solvents

- Water-resistant and great for holding liquids

Cons:

- Slightly higher cost per kilogram than PLA

- Less available and fewer filament options

- Limited and more complex techniques required for post-processing

- More challenging to print due to issues like stringing and over-adhesion

- Requires higher printing temperature that might not be possible on some printers

- Sourced from environmentally unfriendly raw materials and not biodegradable

Applications

Still can’t decide which filament to use? As we mentioned, what filament is best for you depends on what you plan on 3D printing.

If you’re looking to print fun models like small toys and gadgets or basic prototypes, then PLA might be the one for you because it’s the cheaper option, and you won’t need much part strength. PLA is also the better option for people new to 3D printing as the filament is easy to 3D print and less sensitive to print settings.

On the other hand, we recommend using a PETG filament if you need strong parts, like functional prototypes or mechanical assemblies. PETG is also better suited for those with some experience in 3D printing as it will require more fine-tuning to achieve a decent print quality.

No matter what material or brand of filament you choose, we hope that you succeed in your 3D printing adventure and have some fun along the way. Enjoy!