PLA isn’t considered a very strong type of 3D printing filament and it lacks decent mechanical qualities. However, PLA’s cousin, PLA+, is an enhanced version of regular PLA with a few improvements.

While PLA and PLA+ are sourced from the same material (PLA thermoplastic) and only differ by one character in their name, the two have many differences.

Most notably, PLA+ is the superior filament for mechanical applications as it offers increased strength and durability. With this comes a slightly more difficult printing experience compared to regular PLA, but there are many other differences too!

Read on for a detailed explanation of the differences between PLA vs PLA+ filament so you can make an informed decision about which type of PLA filament is the one for you!

Table of Contents

What is PLA?

Before we compare PLA and PLA+, we must go over each material individually, and we’ll start with the more well-known option.

Regular PLA, which we’ll simply refer to as just “PLA”, is the most common filament material for 3D printing.

PLA is a pretty weak material and parts printed in regular PLA tend to be very brittle. But PLA also has many upsides too. Most notably, PLA is super easy to 3D print and has a low melting temperature that makes the material compatible with basically any 3D printer. Additionally, as the filament is sourced from plants like corn and potatoes, PLA filament is inexpensive and food-safe.

So, while many users complain that PLA is mechanically insufficient, its ease of use and other properties make it the best option for beginners to 3D printing, those who want to print food-contact items like candy bowls, and 3D printing enthusiasts on a budget.

What is PLA+?

As a by-product of PLA’s popularity in the 3D printing community, there are many variations of PLA filament each with its own material composition.

Except for 100% pure PLA filaments, almost every filament contains other substances (additives) besides raw PLA plastic, which the manufacturer uses to alter the filament’s properties, like its color or strength. PLA+ is a special variation of PLA filament with certain additives that improve the strength, durability, and other mechanical properties compared to regular PLA filament.

While the specific additives used for PLA+ vary based on the manufacturer and are a bit too sciency for us, their main purpose is to boost the mechanical properties of the base PLA material. On top of its strength, PLA+ is pretty easy to print, has reasonably low-temperature requirements, and is also reasonably affordable.

This makes PLA+ a great filament option for those who want to print parts that will undergo physical stresses, like pieces of a mechanical assembly.

Differences Between PLA and PLA+

Now that you know about PLA and PLA+ individually it’s time to go over their differences.

Before we get started, though, it’s worth mentioning that there really isn’t a one-fits-all type of filament. PLA and PLA+ each have their respective audiences.

Strength

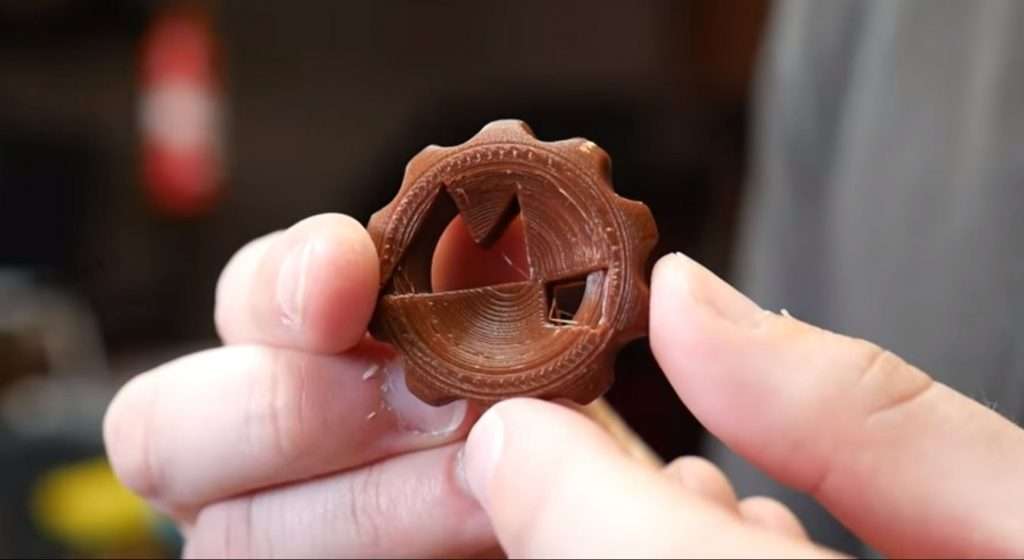

First up, as we’ve indicated, PLA and PLA+ are the latter yields models that are much stronger. Models made with regular PLA are usually brittle, so they snap easily. But PLA+ has increased tensile strength and this isn’t a generalization. You can usually expect a close-to-double increase in your PLA+ model’s strength compared to the regular PLA model.

Unfortunately, better physical properties for filaments, like strength, often are correlated to a more difficult printing experience, and PLA+ is no exception. PLA+ is more challenging to print than regular PLA, usually requiring an average of 5-10 °C higher nozzle and bed temperatures.

As this difference is pretty small, though, PLA+ should still work on basically any 3D printer as PLA.

On top of requiring higher temperatures, PLA+ is a more abrasive material due to the additives used in the filament and this can lead to faster wear and degradation of your nozzle. Furthermore, PLA+ is more likely to clog your hot end than normal PLA, though the chance of this happening is still pretty low.

While you lose some ease-of-printing for enhanced mechanical properties with PLA+, the exchange rate isn’t exactly 1-to-1. As we mentioned, PLA+ offers almost double the strength of regular PLA, but it’s not two times more difficult to print. In fact, despite the increasing difficulty to print compared to normal PLA, PLA+ is still considered one of the easiest filaments to print.

Flexibility

Besides raw strength (usually referred to as tensile strength), PLA+ also has other mechanical advantages over PLA, such as increased flexibility. Don’t get me wrong, PLA+ is still a rigid material, especially when compared to truly flexible filament materials (e.g. TPU, TPE). However, the slight increase in flexibility over normal PLA makes models printed in PLA+ more impact resistant and a better filament choice for parts that will face physical stresses.

Heat Resistance

Another difference between the two materials is their resistance to heat. If you’ve ever printed a model in PLA and left it out in the sun for more than an hour or two, you likely came back to a deformed part with droopy features. That’s because normal PLA has a low melting point, and, although this makes it easier to print, it also means that PLA parts can’t take heat well.

On the other hand, many PLA+ filaments include special additives that increase the filament’s melting point and possibly increase its UV resistance. Of course, a higher melting point means a higher nozzle and bed temperature is necessary, but it also makes PLA+ better for printing outdoor models that will be exposed to sunlight.

Storage

Storage is another area where PLA and PLA+ differ, though not by much. When a filament absorbs moisture from the air (e.g. steam), the quality of the material is degraded, yielding poor ports. How much moisture a filament absorbs from the air is known as its hygroscopicity.

PLA isn’t as hygroscopic as some 3D printing materials like PETG, but it’s still pretty hygroscopic so it’s a good idea to store your normal PLA filament in an air-tight container where moisture can reach your thermoplastic filament. PLA+ filaments are often said to be less hygroscopic, meaning you don’t have to take as many precautions when storing the filament. However, it’s worth pointing out that not all PLA+ filaments are less hygroscopic than normal PLA and it depends on the specific PLA+ filament you choose.

Color Choices

While it doesn’t relate to the usability or performance of a filament, the available colors also differ between PLA and PLA+ filaments. The more colors a filament material comes in, then the more useful and practical the filament is. As we’ve explained, PLA+ is a subset of PLA filament, so it makes sense that the filament comes in way fewer colors than normal PLA filament.

Moreover, PLA filament comes in basically any color you can think of and many you probably don’t expect. For example, you can get PLA in all of the basic colors as well as specialty hues and surface finishes (e.g. sparkly, matte). On the other hand, PLA+ mainly comes in the main basic colors like red, green, blue, and more.

Print Quality

The final difference we’ll cover between PLA and PLA+ is the overall print quality, and, by this, we mean how detailed 3D prints come out. The potential print quality of a filament is usually a result of its sensitivity to slicer settings, temperature requirements, and physical properties.

With this in mind, PLA is the better option for producing high-quality and detailed models as you can achieve great prints without fine-tuning your slicer profile and it’s overall easier to print than PLA+. That said, while PLA+ is great for printing tough models, normal PLA is better for yielding prints with a smooth and fine finish that contains a lot of detail.

Which One Is For You?

Overall, both PLA and PLA+ are great filaments! But which one is the right choice for you is dependent on the type of models you plan on printing.

Normal PLA filament is probably the way to go if you want the most effortless 3D printing experience as you can easily achieve a decent-quality 3D print without fiddling with your print settings (e.g. temperature) a lot. PLA is also the better option for those who want to save every dollar on filament or those who plan on printing models that won’t face many physical stresses or sunlight.

On the flip side, PLA+ is the better of the two for those who want enhanced mechanical properties for their 3D models and are okay with having a slightly more difficult printing experience. PLA+ offers superior strength, durability, and impact resistance, making it the preferable choice between the two for printing parts that will face physical stresses or models that will go outside.

What Options Are There?

If you know whether PLA or PLA+ is the right one for your needs, you might be wondering what your options are. As we explained, there are more options for normal PLA, but there are still many for PLA+. Below, we’ve gone over a few excellent options for normal PLA and PLA+ filaments, discussing each filament’s strengths, weaknesses, and more!

Overture PLA

Overture PLA is a popular brand of PLA filament that’s pretty inexpensive and offers decent print quality according to Amazon reviews. The filament is available in over twenty colors, including black, white, and every color on the rainbow!

According to the manufacturer, Overture PLA shouldn’t clog your hot end as it has a very consistent diameter with a tolerance of just +/- 0.03 mm, which is very good.

You should be able to print the material with a nozzle temperature between 190 and 220 °C, which is the normal range for PLA. It’s also worth mentioning that Overture has posted the different types of strength for all of their filaments and their regular PLA filament has a Charpy Impact Strength (one measure of strength) of 2.7 kJ/m2.

Sunlu PLA

Sunlu is a manufacturer of 3D printers and accessories and their PLA filament is a great option for those who want a stress-free printing experience. The filament comes in almost 25 different colors, like sea green and even glow-in-the-dark.

Additionally, the manufacturer states the spools maintain a diameter tolerance of +/- 0.02 mm, so your hot end shouldn’t clog during printing.

Hatchbox PLA

Hatchbox is a manufacturer of a wide range of 3D printing filaments, and their line of normal PLA is a great option that boasts easy printability. The filament has a tolerance of +/- 0.03 mm, so you shouldn’t run into any hot end clogs, as stated by the manufacturer. The filament also comes in over ten colors, like blue, red, orange, light green, and more.

eSun PLA+

Our first PLA+ filament is from eSun, a developer of 3D printer accessories like filaments and dry boxes. eSun PLA+ filament prints with a temperature between 210 and 225 °C and have a diameter tolerance of +/- 0.03 mm. According to the manufacturer, the filament has an excellent Charpy impact strength of 7 kj/m2..

Overture PLA Pro (PLA+)

Overture PLA Pro is Overture’s PLA+ filament and it has a lot of mechanical benefits like a Charpy impact strength of 13.4 kj/m2., which, according to Overture, is five times higher than typical PLA filament. Surprisingly, the filament also prints with temperatures close to typical PLA, with a suggested nozzle temperature of 190-220 °C.

Duramic PLA+

Our last filament is Duramic PLA+, which comes in almost twenty different colors, like lime green, silk blue, purple, red, and more. According to the manufacturer, Duramic PLA+ has much better impact resistance and raw strength than regular PLA filaments, and it also uses higher printing temperatures. The filament also should have a diameter tolerance of +/- 0.03 mm, which should reduce the risk of hot end jams and clogs.