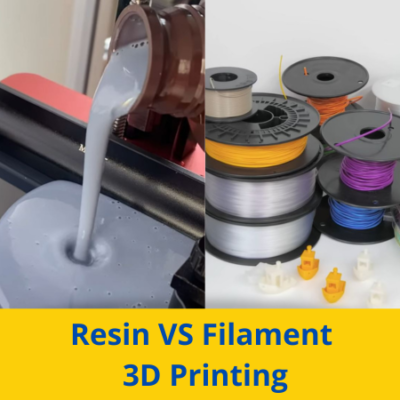

The 3D printing space has blown up in the past decade, with 3D printers being more affordable, precise, fast, and easy to use than ever. But, if you’re going to buy a 3D printer, you have to make a critical decision: filament or resin.

Filament and resin 3D printing are the two main groupings of 3D printer technology, and they differ drastically, not just in how they work but also in the quality of the prints they produce and the overall user experience.

Filament, or FDM, 3D printers use heat to melt plastic and lay it down, layer by layer, to form a part. On the other hand, resin 3D printers use a UV light source to solidify liquid resin into the desired 3D model. Both technologies offer numerous advantages too!

Filament 3D printers boast a wider range of compatible materials, including many that are pretty strong. However, resin 3D printers can make much more detailed models with super smooth finishes.

Want to learn more about the differences between these two types of 3D printing? Just keep reading!

Table of Contents

Filament (FDM) 3D Printing

Fused deposition modeling (FDM) 3D printing, also known as filament 3D printing and fused filament fabrication (FFF), is what most people think of when they think “3D printer”. For years, FDM 3D printers have ruled the consumer 3D printing industry as they’re affordable, yield decently-precise parts, and can print in a wide variety of materials.

In the sections below, I’ve gone over everything you need to know about filament 3D printing, including how the technology works, the different styles of FDM printers, what materials you can print, and more!

How Does it Work?

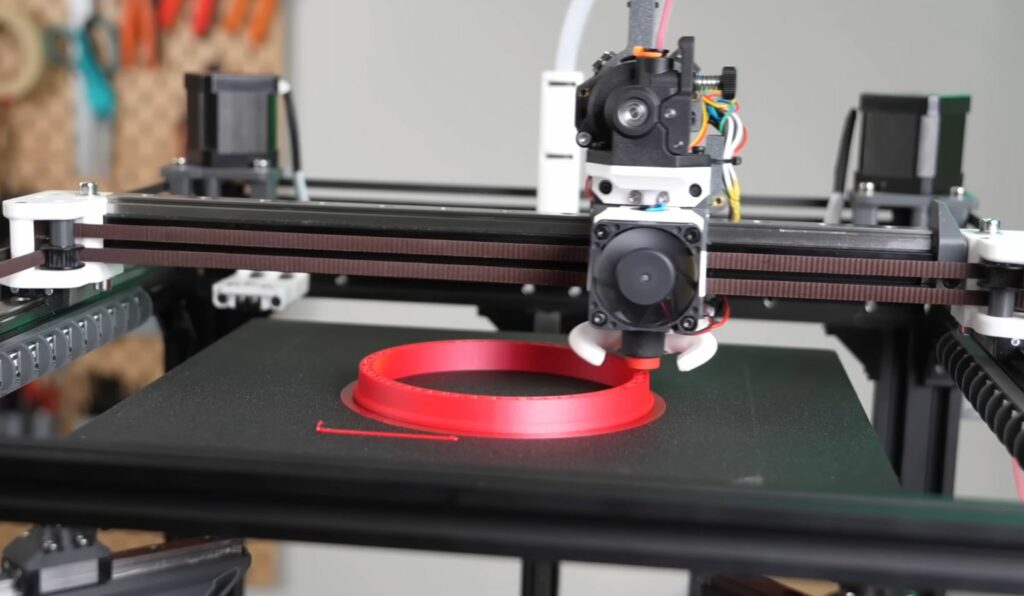

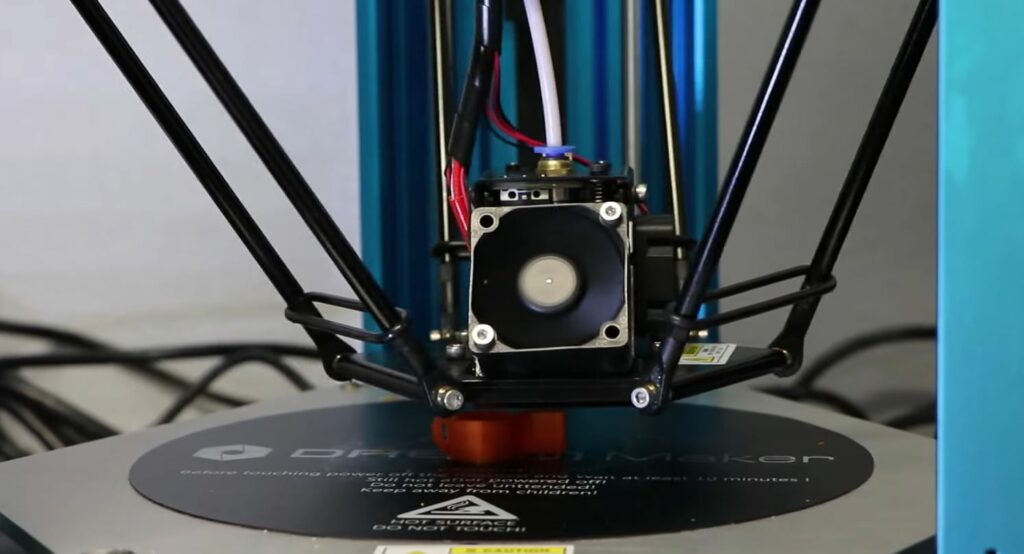

Fused deposition modeling 3D printers work by melting filament, the stringed thermoplastic material, and pushing it out of a nozzle. The nozzle is moved across the X/Y plane, depositing the melted material onto the print surface in a specific pattern, based on the 2D layer information from the slicing software.

After each layer is printed, the printer moves the nozzle up (along the Z-axis), and the next layer begins. This process repeats until the print job is complete and you’re left with your desired 3D model.

Obviously, FDM 3D printers contain hundreds of different components that contribute to the filament printing process. I’ve listed and briefly described some of the most important parts of an FDM printer below:

- Print Bed: The print bed, sometimes called the build plate or print surface, is where the first layer of a part is printed on FDM machines. It’s kind of like the base of the printer.

- Hot End: The hot end is the sub-assembly on an FDM 3D printer that melts the inserted filament. Within the hot end are a few parts, including the heater block, throat, heat sink, and hot end fan. It’s worth noting that the nozzle screws into the bottom of the hot end assembly.

- Nozzle: The nozzle is the part on a 3D printer that controls the width of the outflow of filament, and it’s the last component that contacts the molten filament before it’s laid out onto the bed. 3D printer nozzles come in a variety of different (conductive) materials, including brass, hardened steel, stainless steel, and even ruby.

- Extruder: The extruder is another sub-assembly on an FDM 3D printer, and it’s responsible for pushing filament through the hot end and out the nozzle. Included in this sub-assembly are the extruder motor, tension spring, drive gear, idle gear, and extruder frame (which connects all the parts).

Types of FDM 3D Printing

Within the FDM 3D printing technology, there are a handful of different printer configurations. While I can’t go over every way FDM 3D printers can vary because that would take ages, I will go over the different motion systems for FDM printers as this is probably the most significant of differences between FDM machines.

Cartesian (i3-Style)

Cartesian, also known as i3-style or “bed slinger”, is easily the most popular motion system for FDM 3D printers, seen on many machines, such as the Creality Ender 3 (Pro/V2/S1). This motion style entails the nozzle moving across the X and Z axes, with the print bed moving across the Y-axis. Cartesian FDM printers tend to be the most affordable of the different FDM printer styles, but they aren’t very good at printing circles as the X and Y-axis movement on the machine isn’t synchronized.

Inverse Cartesian

Inverse Cartesian is very similar to the Cartesian style, but the nozzle moves across the X and Y axes with the bed moving up and down along the Z-axis. This motion system requires a larger frame than for i3 printers, which is why inverse cartesian printers, such as the Creality Ender 5, cost a bit more. However, because the nozzle moves more fluidly across the X and Y axes, circle shapes come out better on these types of printers.

CoreXY

Next, CoreXY 3D printers look very similar to inverse cartesian FDM printers, but with one key difference: the belt system. Instead of the X-axis and Y-axis movement on the printer functioning independently, CoreXY printers use a complex belt system so that truly fluid X/Y motion is possible. These printers are a bit pricier than inverse cartesian machines and are more complicated to fix, but they yield some of the highest-quality prints.

Delta

Next, delta is a type of FDM 3D printer that uses three telescope arms to move the nozzle across the X, Y, and Z axes all at once. These printers are considered faster than the other types of FDM 3D printers but typically have smaller print spaces.

Others

Besides the four FDM motion styles I described, there are also a handful of other, more-niche options. These include SCARA, Polar, and more. Typically, FDM printers that follow these systems are more of personal projects for makers rather than manufacturing machines.

Materials

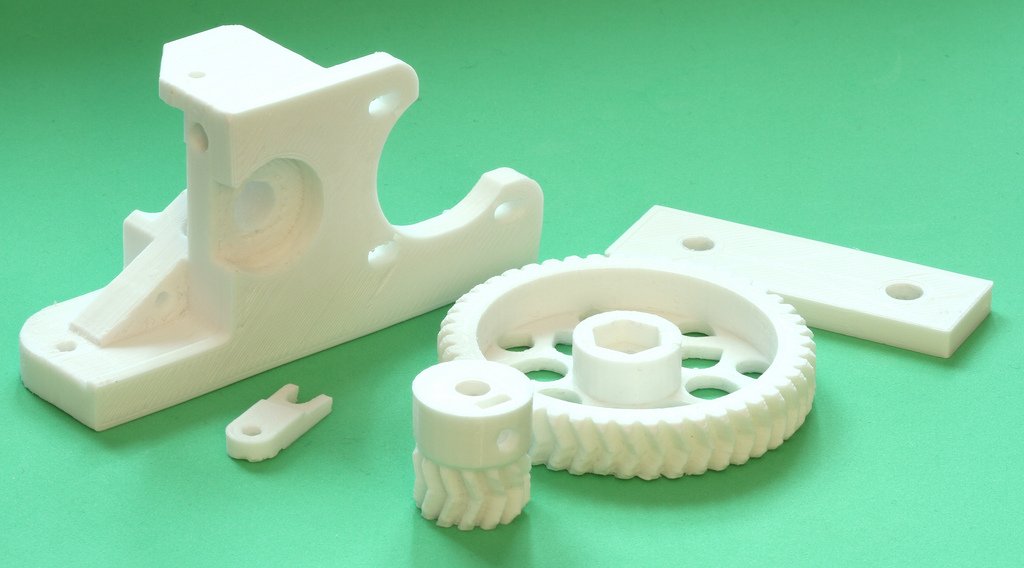

FDM 3D printers work with a wide range of filament materials as there are hundreds of different thermoplastic materials available in filament form. By far, the most popular filament printing material is polylactic acid or PLA. PLA is so popular because it’s super easy to print and, even if your FDM machine and slicer settings aren’t fine-tuned, you can still achieve high-quality prints in this material.

However, PLA is very weak and has a low tensile strength, which is why many FDM 3D printer users eventually switch to printing other filament materials, like PETG or ABS. These materials are much stronger than PLA and are great for printing parts that require decent levels of strength, such as a gear or a bike pedal.

Some other materials you can print on FDM machines include ASA, polycarbonate (PC), nylon, nylon composites, TPU, TPE, wood-infused materials, and more! It’s worth noting that some of these materials will require some hardware changes, such as an enclosure or higher-durability nozzle.

Print Quality

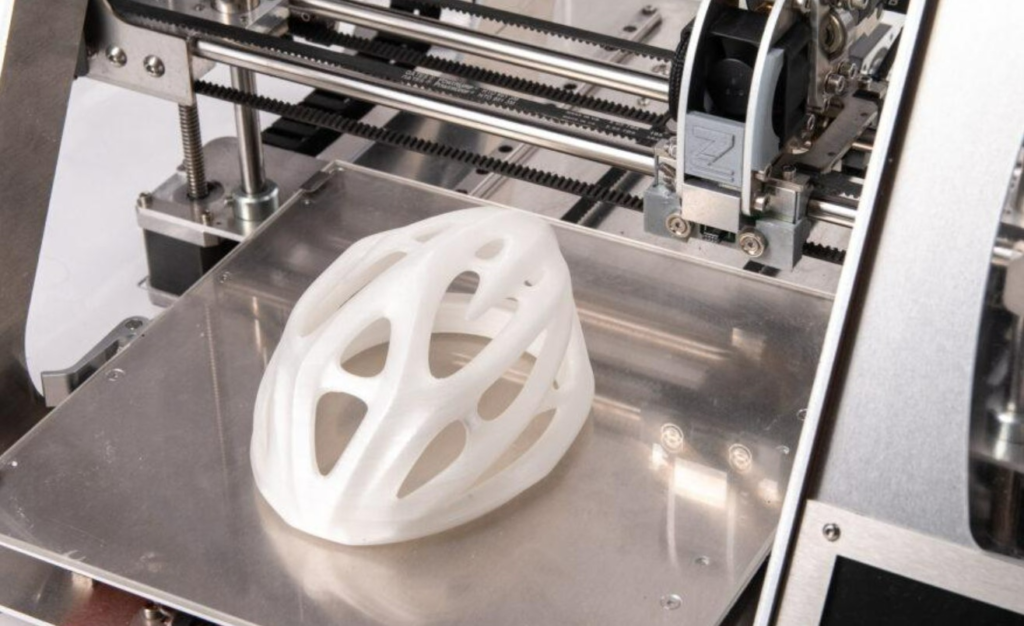

FDM 3D printers can handle medium-sized and large parts very well, but printing small details is not their specialty. Moreover, FDM printers tend to have a precision of around 0.1-0.2 mm, so any details on a model smaller than this will not come out well.

Additionally, it’s worth noting that FDM 3D prints will almost always have noticeable layer lines, which are the physical differences between the layers of a print. In other words, parts printed on FDM machines have a somewhat rough surface texture.

Part Durability

As I mentioned, FDM 3D printers are compatible with many decently-strong thermoplastic filament materials. While parts printed in PLA will be pretty brittle, if you use a higher-strength filament material, like PETG, ABS, or PC, I think you’ll be pleasantly surprised by the strength, impact resistance, and overall durability of your prints.

When to Use

With everything considered, FDM 3D printers are perfect for printing parts that require some strength and durability but don’t contain too much detail or small features. Additionally, FDM 3D prints have a pretty rough surface texture, so be prepared to sand down any parts if you want them to look good.

Resin 3D Printing

Resin 3D printing is the other large category of 3D printing technology, and it includes any 3D printer that uses liquid resin to make parts. Resin 3D printing actually predates FDM 3D printing, but it’s only blown up in the consumer space in recent years due to the significant drop in the cost of LCDs and the other electronics required for this type of printing.

Below, I’ve gone over everything you should know about resin 3D printing, including the different technologies, materials, and more!

How Does it Work?

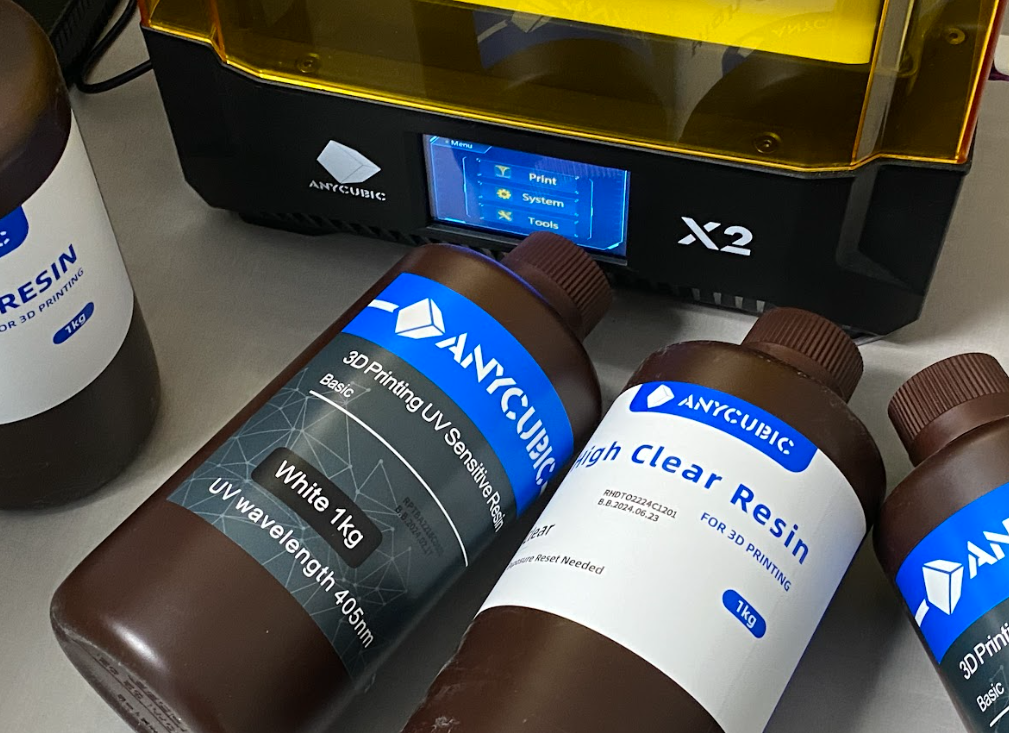

Resin 3D printers work using a process known as photopolymerization, where they project UV light onto photosensitive resin. When the liquid resin is exposed to the targeted UV light for long enough, it solidifies. Similar to FDM 3D printers, resin printers make parts layer by layer, solidifying resin for the first layer, and then the second, and so on.

It’s worth noting that the industry standard for the wavelength of the UV light used on resin 3D printers is 405 nanometers (nm).

And, just like FDM 3D printers, there are a handful of important parts on any resin printer. Knowing the different terms for these parts will go a long way in making your printing experience easier, so here are the most important ones and a description for each:

- Resin: Resin is the 405-nm liquid photopolymer material used on resin printers.

- VAT: The VAT is the resin tank on resin printers, and it’s where you pour your liquid resin in before starting a print.

- Light Source: The light source, also called the LCD screen or projector, is the electronic component on all resin printers that projects UV light to solidify the liquid resin.

Types of Resin 3D Printing

There are a handful of different types of resin printers, which use slightly different technology, specifically the system for projecting light, to make 3D printed parts. I’ve gone over the basics of the most popular types of resin 3D printing technology below:

SLA

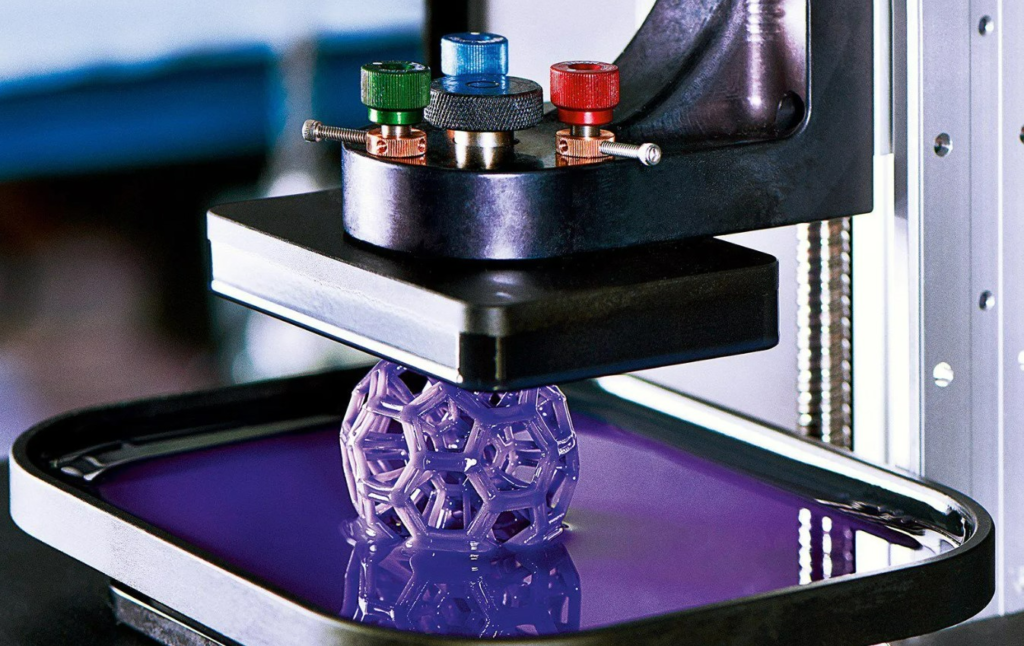

Stereolithography, or SLA, is the oldest form of resin 3D printing. These 3D printers use a UV light laser along with a singular mirror that moves to adjust what section of the base layer of the VAT is solidified.

LCD (MSLA)

Liquid crystal display (LCD), sometimes called MSLA (masked SLA), is perhaps the most popular style of resin 3D printing for consumers, known for its low price and terrific detail capabilities. This 3D printing technology uses an LCD screen to mask the UV light to solidify each layer of a print. In other words, each layer is solidified basically all at once.

DLP

The third and final form of resin 3D printing is digital light processing (DLP) and it’s the least popular of the three. DLP 3D printers use a UV light projector in conjunction with an array of super small mirrors, known as micromirrors, which move in a super precise manner to coordinate the direction of the UV light to solidify each layer.

Materials

Resin printers can also work with a wide range of resin polymer materials. However, it’s worth noting that the different resin materials are much more similar to each other than the different filament materials you can use with FDM 3D printing.

The most popular material for resin 3D printing is standard resin, which is a mixture of a few different chemicals that have names way too complex to mention. But what you should know is that standard resin is widely-compatible, and prints easily, but isn’t super strong.

Some of the other resins available for consumer-grade resin machines include water-washable resin, plant-based resin, ABS-like resin, transparent resin, performance-quality resin (e.g. 8K resin), and tough resin.

Check out our related article on the differences between Water Washable Resin & Normal Resin here to learn more.

Print Quality

The most notable aspect of resin 3D printers is their print quality. I can’t even express in words how immaculate the detail on a resin 3D print can be. So I won’t! Here’s an image of a miniature resin 3D print, made on a consumer-grade machine:

And, unlike FDM 3D prints, resin 3D prints come out with a super smooth surface texture. It’s so smooth, you don’t even need to sand prints before painting them!

The best way to gauge the print quality of a resin printer is by looking at the pixel resolution of its LCD screen. The higher the better! 4K is currently the industry standard, but 8K resin printers are on the rise, and they can yield even higher-quality detail on parts.

Check out our article about the Best Resin for Miniatures here.

Part Durability

Unfortunately, resin 3D prints aren’t very strong or durable. I strongly advise against printing any parts that require even the slightest degree of strength on a resin printer, unless you’re using a designated tough or ABS-like resin as these are specifically meant for higher strength.

But, it’s also worth noting that, naturally, all resin 3D prints are very sensitive to UV light. As such, I don’t recommend printing outdoor parts with resin because, if they are exposed to sunlight (which contains UV rays), they will probably deform.

When to Use

You should use resin 3D printing when you want to make high-detail 3D prints as resin 3D printers are super precise and accurate. However, you should make sure that whatever you’re printing doesn’t need to be strong as resin 3D prints aren’t very durable and deform under sunlight. But, if you’re printing miniatures like War Hammer characters or D&D figurines, resin 3D printing is perfect!

Conclusion

If you’re buying a 3D printer, you’ll have to decide between using a filament or a resin printer. And this decision is not one to be overlooked! While FDM and resin printers cost around the same nowadays, these two categories of 3D printing technology are very different in how they work as well as their printing performance and user experience.

Furthermore, fused deposition modeling 3D printers use a heated nozzle to melt plastic filament and then create the desired part by laying down the material layer by layer. Conversely, resin printers use precisely-directed UV light to solidify liquid resin, layer by layer, to make a part.

Inherently, resin 3D printers are significantly more precise than filament 3D printers, making them superior for printing high-detail models, like miniatures. Plus, the layer lines on resin prints are basically invisible. However, 3D printed resin parts require a good bit of post-processing, including washing and curing completed prints.

FDM 3D printers have their benefits too, though. For example, FDM 3D prints are typically much stronger and more durable than resin prints, stemming from the fact that there’s a much wider variety of filament materials than there are resin materials.

No matter what type of 3D printer you choose, though, make sure to properly research a machine before purchasing it.