- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

There are many different parts on a 3D printer, but few are as important as the extruder.

If you’re unfamiliar with the term, “extruder” refers to the assembly on a 3D printer that pushes filament through the hot end. While extruders are separate from the hot end on a Bowden 3D printer (e.g. Creality Ender 3), these assemblies might be connected if you’re using a direct drive extruder.

The extruder is super important for a 3D printer because it heavily impacts how well prints turn out. Without a good extruder, filament won’t consistently flow out the nozzle, yielding prints with under or over-extrusion and other issues.

The best 3D printer extruder is easily the E3D Hemera due to its powerful drive gear ratio, integrated powerful stepper motor, and available attachment screws. The Creality Sprite Pro, a rather new entrant into the market, is another great choice, boating a clean visual appearance with powerful, geared-up extrusion force.

Want to hear about more of the best 3D printer extruder options? Just keep reading!

Table of Contents

Best 3D Printer Extruders At A Glance

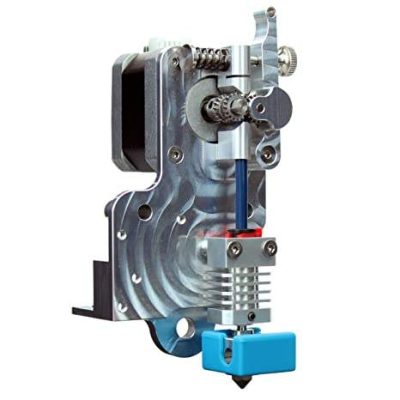

1. E3D Hemera (Best Choice)

2. BIQU H2 V2 (Best Value)

3. Micro Swiss Direct Drive Extruder with Hot End (Premium Choice)

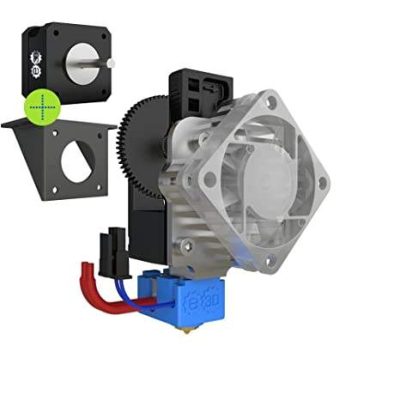

4. Creality Sprite Pro (Best for Beginners)

5. E3D Titan Aero

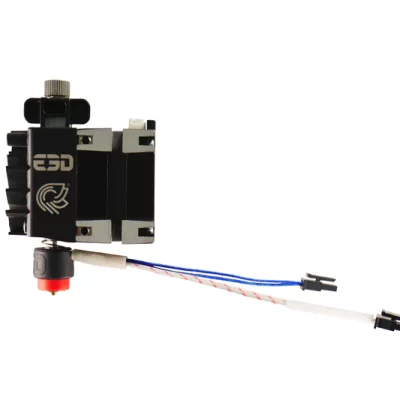

6. E3D Revo Hemera XS

7. Bondtech BMG (Excellent Build Quality)

E3D is one of the biggest names in the game when it comes to 3D printer nozzles, hot end, and extruders. The Hemera is one of E3D’s flagship products, leading the market for high-end consumer extruders.

The Hemera, like all the products on this list, is a direct drive extruder, meaning it contains both an extruder assembly and a hot end assembly. As such, we need to go over both the extruder-related and heating-related aspects of the product.

First, the Hemera has a special heat sink, carefully designed by E3D’s team to maximize heat dissipation and cooling to the hot end while minimizing the amount of airflow near the nozzle. As such, when you attach a hot end fan to the assembly, you won’t experience heat creep, and there won’t be any unintentional over-cooling over your model.

Additionally, when it comes to pushing force, the E3D Hemera is a powerhouse. With a 3:1 gear ratio and an integrated NEMA-17 stepper motor, the Hemera pushes the inserted filament with a lot of power, to reduce the chances of issues like under-extrusion from occurring. The dual-drive system on the Hemera, which incorporates not one, but two drive gears, also helps with this!

The hot end side of the Hemera is also exceptional, with a maximum temperature of 300 °C. This is more than enough heat to print PLA, ABS, PETG, TPU, and even polycarbonate! Additionally, the hot end is compatible with a wide selection of nozzles, including E3D’s V6 series of nozzles and more!

So, if you want an extruder that’s super powerful, can be configured in direct drive, and has a high maximum temperature, then I highly recommend the E3D Hemera. And it’s also worth noting that you can buy a version of the Hemera that’s specific for Bowden configurations.

Pros

- Very powerful

- Amazing print quality

- Extremely reliable

- Compatible with many nozzles

- Wide support for printers due to large community backing

Cons

- Expensive

After the release, and almost immediate success, of the E3D Hemera, many other 3D printing companies came out with similar direct extruder products. BIQU, a manufacturer of budget 3D printers and motherboards, released their H2 V2 extruder hot end, and, I’m not gonna lie, it’s actually pretty good. Even more so when you see the under-$70 price tag of the BIQU H2 V2.

Similar to the E3D Hemera, the BIQU H2 V2 has a rather wide rectangular shape, mainly due to the integrated stepper motor that makes the assembly direct drive. It’s worth noting that the stepper motor used is actually weaker than most NEMA-17 extruder motors.

But don’t worry because BIQU used a 7:1 gear ratio on the motor to ensure that it’s more optimized for torque than speed. BIQU also used a dual-drive system for the H2 extruder, meaning the motor is pushing the inserted filament from two sides instead of one like most stock extruders on 3D printers. These two factors make extrusion issues, like under extrusion, super unlikely!

Sadly, though, the included hot end on the BIQU H2 isn’t the best. While BIQU sometimes states that it can be used at up to 400 °C, official documentation indicates that you’re not supposed to use it for temps higher than 270 °C. While 270 °C is a little higher than what most printers can handle, it doesn’t expand what filaments you can use by that much.

But, if you’re looking for a good bang for your buck, you won’t find one better than the BIQU H2. It’s super reasonably priced, and you get one heck of an extruder. You just have to be okay with the low temperature limits of the product.

Pros

- Great bang for your buck

- Powerful gear ratio

- Dual drive

- Small footprint

- Sleek design

Cons

- Low maximum nozzle temperature

- Cheaper parts used (weaker stepper motor)

Micro Swiss is considered one of the most reputable manufacturers in the 3D printing accessory market, and their Direct Extruder with Hot end is a perfect example. While this product doesn’t have a super sexy name, it’s one of the more premium direct extruders out there.

Made almost completely out of precisely CNC machined parts, the Micro Swiss Direct Extruder is super durable. Sadly, because all of the parts are metal, the assembly is pretty heavy. As such, it’s best if you’re using it on a printer with a stable frame, like an Ender 3, rather than a Prusa Mini.

As for the extrusion capabilities, it really depends because the Micro Swiss Direct extruder is actually a kit, and it fits onto your printer’s extruder stepper motor. So, if you have a weak stepper motor, then the extrusion won’t be as good as if you were using a premium-quality NEMA-17 stepper motor.

But the kit should at least improve the extrusion on your printer a good bit because it uses a dual-drive system with two full-metal gears. As such, the filament is forcefully pushed down by the extruder assembly to provide accurate and reliable printing capabilities.

The hot end is a typical Micro Swiss All-Metal hot end. As it’s an all-metal hot end, it doesn’t have a PTFE liner, so it can reach up to 300 °C safely (no PTFE burning). This means you can print basically whatever filament material you want, from PLA and ABS to nylon and PC. The hot end also has a titanium heat break, so it won’t degrade as fast as most hot ends.

So, if you want a direct extruder and are looking for a long-lasting, premium-quality product, I can’t think of a better option than the Micro Swiss Direct Extruder with Hot End.

Pros

- All-Metal hot end included

- Very durable

- Dual drive gears

- Good print quality

- All-metal extruder assembly

- Wide printer compatibility

Cons

- Stepper motor not included

- Heavy assembly (limits print speed)

If you’re a part of the 3D printing space, you’ve probably heard of Creality, the manufacturer behind many popular printers like the Ender 3 and CR-30. Another one of their products is the Creality Sprite Pro, a do-it-all extruder assembly configured in direct drive and perfect for beginners!

The Creality Sprite Pro is built very similarly to the E3D Hemera or BIQU H2, but a key difference is that all of the wirings is simplified through ribbon cables. Moreover, the printhead assembly has an onboard circuit, so all of the electronics for the extruder and hot end plug into there. As such, there isn’t a long or complicated wiring process for this product.

And the extrusion capabilities of the Sprite Pro are exceptional. With an integrated stepper motor, dual-drive gears, and a torque-increasing 3.5:1 gear ratio, the Sprite Pro can push filament with force up to 80N. While this isn’t as much as the E3D Hemera, it’s still insanely high and more than enough to stop problems like under extrusion.

The Sprite Pro also comes with two fans, including one meant for cooling the hot end to prevent problems like heat creep and another for cooling filament from the nozzle. Both are well-placed to perform their job well, which is something I have to give credit to Creality for.

As for the hot end, it can go up to 300 °C, which seems to be the norm for products on this list. But I promise you that 300 °C is relatively high compared to most 3D printers’ stock hot ends. And 300 °C is easily high enough to print the filament materials you want, like PLA, ABS, PETG, and more!

And, what I love most about this product, is that it’s got the Creality community of support, which is super large. Having a large community behind an extruder means more 3D printable attachments, mounts, and upgrades. This is especially useful if you’re a beginner because there are a lot of guide for installing the Sprite Pro on different printers.

Pros

- Large community backing

- Easy to install

- Powerful pushing power

- Integrated stepper motor

- Well-placed fans

- Onboard circuit for easy wiring

Cons

- Expensive

- Compatibility is currently limited to mainly Creality printers

Another product from E3D is the Titan Aero, which is basically the company’s older version of the Hemera. The Titan Aero is actually one of my favorite extruders for daily use, and the same one has lasted me almost five years without many issues!

The Titan Aero is a combination between E3D’s Titan extruder and their V6 hot end, configured for direct drive use. As such, it’s popular for printing flexibles and other materials.

The modified version of E3D’s Titan extruder on the Titan Aero is very well-built. While it uses only a single drive gear, it has a 3:1 gear ratio to increase the pushing torque of the extruder. And, the integrated stepper motor is pretty beefy, giving you plenty of oomph for eliminating problems like under extrusion.

As for the V6 hot end side of the Titan Aero, it’s an all-metal hot end with a max temp at 300 °C. And, because it’s a true V6 heater block, the hot end on the Titan Aero is compatible with just about any V6 nozzle, whether from E3D or other manufacturers.

But what I personally love most about the Titan Aero is the diamond-shaped heat sink design, designed by E3D for efficient cooling of the hot end. This helps get rid of heat creep (hot end clogs), which is one of my least favorite issues to deal with on a 3D printer.

Overall, the Titan Aero is a beast of a 3D printer extruder and can be used to print all sorts of filaments. It’s also super compatible!

Pros

- Very reliable

- Powerful 3:1 gear ratio

- Well-designed heat sink

- Supports many different nozzles

- Many mounts available online

Cons

- Single drive gear

- Weak hot end fan

- Older technology; fading support

The last product I’ll cover from E3D, who seems to be dominating this list, is the Revo Hemera XS. The Revo collection of products, including the Revo Six, Revo CR, and more, is E3D’s latest innovation.

What makes the Revo series of hot ends, and the Hemera XS so special is their integration of E3D’s RapidChange technology. This means that all of the Revo hot ends use specially-designed nozzles (Revo nozzles) that have an integrated heat break.

This difference allows you to swap nozzles on a Revo hot end, which has a max temp of 300 °C, without actually heating the assembly up. And now, you can solve a hot end clog or a nozzle clog (or both) by simply changing the nozzle.

The E3D Revo Hemera XS takes the advantage of the Revo hot ends and combines them with the power of the Hemera extruder assembly to bring you the best printing performance on the market.

Moreover, almost everything on the Revo Hemera XS looks the same as the original Hemera, from the well-designed heat sink to the powerful extruder. On this note, I just want to reiterate the 3:1 gear ratio, dual drive gear setup, and integrated stepper motor on the Revo Hemera XS.

But E3D made some slight changes to make this new version 92 grams lighter and 11 mm shorter than the original Hemera, hence the “XS” in its name. These changes mean you can use faster print speeds with the Hemera XS because it won’t weigh down the printer’s gantry as much.

Pros

- Lightweight and small

- Powerful and reliable

- Dual drive

- Direct drive

- RapidChange for easy nozzle swaps

Cons

- Expensive

- Limited community support

- Not many nozzle options available

Lastly, the Bondtech BMG is the only extruder on this list that’s not meant to be configured in direct drive. While it’s commonly used for direct drive printheads, it doesn’t have a built-in hot end, so you can very easily use it in Bowden setups!

The Bondtech BMG is perhaps the extruder on this list with the highest build quality due to the high-end metal parts used on the famous BMG extruder. Moreover, the BMG extruder is completely enclosed, giving it a sleek look and protecting the drive gears from any unwanted contaminants or debris (e.g. dust).

But under the hood, the Bondtech BMG extruder is a beast, with two hardened metal drive gears and a power-increasing 3:1 gear ratio. Many users, including myself, have found that the BMG provides unparalleled pushing force for filaments, yielding an amazing print quality for models!

Sadly, though, the BMG extruder kit doesn’t include a stepper motor, but it fits any NEMA-17 motor, so your printer’s stock motor should fit fine. As for the hot end compatibility, the BMG is meant to work with any E3D hot end, but you should be able to use other hot ends with this extruder too!

Pros

- High build quality

- Precise and accurate extrusion

- Very reliable and powerful

- Sleek visual design

Cons

- Doesn’t come with a stepper motor

- Doesn’t include a hot end

- Expensive

What is the Purpose of a 3D Printer Extruder?

The purpose of a 3D printer extruder is the assembly on a 3D printer is to push the inserted filament through the hot end so it can be made into your desired 3D model.

Without a 3D printer extruder, including both the assembly and corresponding stepper motor, you would just have a machine that moves around with no filament coming out.

Or, if you have a low-quality 3D printer extruder, your prints will have a lot of issues because extrusion is perhaps the most important element of the 3D printing process. Moreover, if the extruder is bad, your prints may be over or under-extruded, leaving blobs of excess filament or gaps in the layers.

What are 3D Printer Extruders?

3D printer extruders are the assembly that attaches to a stepper motor to provide pushing force for the inserted filament so it can be pushed through the hot end.

3D printer extruders are also known as the cold end of a 3D printer because, unlike the hot end or nozzle, they aren’t heated up.

Extruder assemblies can either be completely separate from the hot end or integrated with the hot end, which I like to call a combo extruder.

In this article, we reviewed the best combo extruders, which are products that have both an extruder and a hot end configured in a direct drive.

Types of Extruders

There are two different ways you can configure an extruder on a 3D printer, including Bowden and Direct Drive. I’ve gone over the two configuration styles in the sections below:

Bowden

A Bowden extruder configuration involves having the extruder assembly placed away from the hot end. A Bowden (PTFE) tube allows the filament to flow between the two assemblies so it can be printed.

Because of the separation between the cold end and hot end, higher retraction settings (e.g. retraction distance, speed) are required for Bowden extruder configurations. However, with this type of extruder setup, you can use faster print speeds because the printhead assembly is lighter.

Bowden extruder configurations are also much less expensive than direct drive setups. And they’re wayyyy easier to fix and repair because the assemblies are separated and less compact. But, you will struggle to print flexibles, like TPU filament, with this style of extruder due to the large extruder-to-hot end gap.

Bowden extruder configurations are common on budget 3D printers, like the Original Ender 3 or Anycubic i3 Mega.

Direct Drive

Direct drive is the alternative to Bowden extruder configuration. Rather than separate the extruder assembly and hot end, it places the extruder directly above the hot end for a minimal PTFE tube distance.

Due to the proximity of the extruder and the hot end, you can get away with using smaller retraction settings with a direct extruder setup. Sadly, though, you’ll be more limited in what print speed you can use because a direct extruder setup means a heavier printhead assembly.

Many users, including myself, notice an increase in the overall quality of prints on a direct extruder. This is likely due to the better extrusion accuracy associated with placing the extruder closer to the hot end. Additionally, a direct drive extruder configuration is better for printing flexible filaments due to the decreased gap distance.

Direct extruder configurations are more popular on higher-end 3D printers, like the Prusa i3 MK3S+ or Qidi Tech X-Max. You can check out our article about the best direct drive 3D printers to learn more!

Direct or Bowden: Which is Better?

There isn’t one superior extruder style as the best one for you depends on your needs.

If you want to print flexible filaments, like TPU or TPE, a direct drive extruder will suit you best. That’s because direct drive extruders give filament less room to stretch because there isn’t a significant gap between the two assemblies, making the extrusion accuracy much better.

However, if you don’t plan on printing flexibles but want to use fast print speeds, a Bowden extruder configuration might be more your speed. That’s because Bowden setups have lightweight printheads, enabling higher print speed values. And they’re much easier to work with because they’re not as compact and they’re also less expensive.

What is a Dual Extruder 3D Printer?

A dual extruder 3D printer is a machine that has not one but two extruders (usually direct drive extruders). This enables printing two filaments at once.

You can use dual extruder 3D printers to make 3D models that are multi-color. Or, you can use them to print parts that have two different filament materials. For example, you could print a phone stand that was flexible and rubbery (TPU) at the ends but super strong and rigid (ABS) in the middle.

While dual extruder printers aren’t super popular today, they’re growing in popularity, especially because they’re becoming less expensive. Some good options for dual-extruder printers include the Flashforge Creator Pro and Geeetech A10M. Check out our piece about the best dual extruder 3D printers to learn more about this style of machine.

Considerations When Picking an Extruder

When picking what extruder you want to get for your 3D printer, there are a few important elements to keep in mind. In the sections below, I’ve discussed the most important ones!

Extrusion Power

The first thing about an extruder that you should look at is the extrusion power. The extrusion power defines how well an extruder can actually push the filament. It’s an important consideration because if an extruder doesn’t have good extrusion power, you might run into under-extrusion and gets low-quality prints with gaps in the layers.

You can usually determine the extrusion power of a 3D printer extruder by looking at the gear ratio for the assembly. A 3:1 gear ratio is popular for extruders and provides a lot of torque (pushing power) for inserted filament.

The extrusion power is also dependent on the power of the motor, so make sure, if the extruder has an integrated stepper motor, that the motor is pretty powerful and strong.

Size and Compatibility

Second, the size and compatibility of an extruder are important because how are you supposed to use an extruder if it can’t fit on your printer?

While most extruder products won’t fit perfectly onto your printer’s frame, there’s usually a mount you can buy or 3D print that allows you to fit the extruder onto your printer. Check Reddit, YouTube, or Thingiverse for mounting options!

Also, make sure that the extruder stepper motor (if it has a built-in motor) is compatible with your printer’s firmware.

The easiest way to determine the overall compatibility of an extruder with a printer is to look at the reviews for a specific product or the manufacturer’s website.

Maximum Temperature

If you’re buying an extruder combo product, like the options I reviewed, then your extruder will also have a built-in hot end. As such, it’s important to look at the maximum temperature of this hot end.

The maximum temperature is important because it controls what filament materials you can use. A higher maximum temperature is better because it means you can use a wider range of filaments.

I’d suggest only getting an extruder with a hot end that has a maximum temperature of at least 285 °C. That’s because, at 285 °C, you can print a good amount of filament materials, from PLA to some polycarbonates.

Modularity

![]()

The modularity of a hot end is how easy it is to modify or add on to. For example, if you wanted to add on an automatic bed leveling sensor, like a BLTouch, how easy would it be to attach it to your extruder assembly (for direct drive configurations)?

Make sure that there are mounting screws on the extruder assembly so you can potentially make some upgrades, attachments, or modifications.

Difficulty to Repair

How difficult it is to repair an extruder is also very important because a part of your extruder might eventually break, especially if you plan on using your machine a lot. And, if a part breaks, you’ll want to be able to fix it or install a replacement.

While there’s not really a key metric that determines how difficult it is to repair a specific extruder assembly, checking the reviews to see how proprietary the hardware for the product is usually helps.

Filament Size

Lastly, make sure to check that the extruder you’re using can handle the filament diameter that you want to use. For most of us, this is 1.75 mm, which is what all of the extruders on this list are meant to handle.

How to Replace Your 3D Printer’s Extruder?

Replacing your 3D printer’s extruder can be a slightly difficult process, but you can follow the set of instructions below, which go over the typical extruder replacement process. Note that these steps aren’t specific to any 3D printer and are meant to be used as a general guide.

- Heat up the hot end and remove the filament from the hot end and extruder assemblies.

- Turn off your 3D printer and wait for it to cool down.

- Use the correct wrench or Allen key to unscrew the bolts holding your extruder assembly in place.

- Hold the motor so it doesn’t fall and place your old extruder assembly to the side.

- Take your new extruder assembly and align it with your printer’s extruder screw holes. This is the time to use a mount or adapter fitting if you need one to attach the extruder to your printer.

- Place the extruder stepper motor beneath the extruder assembly and screw in the respective extruder screws. Make sure that the extruder assembly is securely fastened to the extruder stepper motor.

- Make sure that the drive gears for the extruder assembly are properly oriented.

- Turn on your 3D printer and load the filament back in.

And that’s all it takes to replace your extruder.

Of course, there are more steps that are more specific to your setup, but the steps above provide a general overview of the process.

Also, before you start printing, make sure that your extruder rotates the right way because if your new extruder has a gear ratio, but your old one does not, then the extrusion direction might be inverted. You can change this in your 3D printer motherboard’s firmware.

Conclusion

The extruder is easily one of the most crucial components of a 3D printer. Without a good extruder, your prints will almost definitely have problems like under extrusion, with gaps in the layers and other defects.

If you want the best print quality, I’d suggest getting the E3D Hemera. It’s my, along with thousands of others, favorite 3D printer extruder due to its powerful 3:1 gear ratio, small footprint, and wide printer compatibility.

But if the value is your main concern, definitely check out the BIQU H2 V2 extruder, as it’s one of the best bangs for your buck when it comes to direct drive extruders. The extruder is very similar to the E3D Hemera at a fraction of the cost. The only major difference is a weaker stepper motor, but most people have loved the extruder!

Lastly, if you’re looking for an easy setup process, then consider getting the Creality Sprite Pro. This extruder is very high-quality, with well-placed fans for proper cooling, a powerful 3.5:1 drive gear ratio, and wide support for Creality printers.

Enjoy!