- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

3D printers are capable of creating gorgeous pieces of work; all they need is materials and a blueprint, and they can get right to work with the push of a button. It’s a fascinating thing to watch them work, too. Arms and levers work in unison with a single whole to create something.

3D printers are capable of creating gorgeous pieces of work; all they need is materials and a blueprint, and they can get right to work with the push of a button. It’s a fascinating thing to watch them work, too. Arms and levers work in unison with a single whole to create something.

Ceramic 3D printing is where engineering meets art.

It’s common to sometimes find yourself not only watching videos of printers and getting into discussions on forums about the best filament but even researching other kinds of printers. It can get very confusing very quickly.

This list of the best ceramic 3D printers for artistic and industrial use should help you find the right printer for you.

Best Ceramic 3D Printers At A Glance

3D Printers for Ceramic and Clay Arts:

1. Delta WASP 2040 Clay (Best Value)

2. StoneFlower 3.0

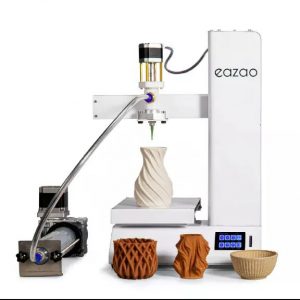

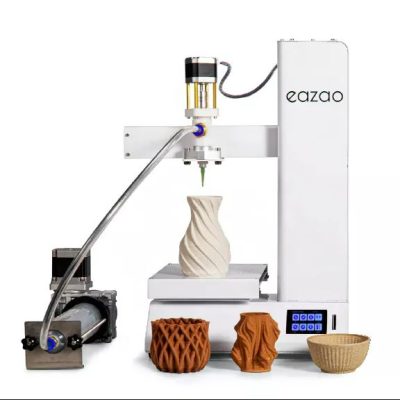

3. Cerambot Eazao Zero (Best Choice)

4. VormVrij LUTUM 5

3D Printers for Technical Ceramics:

5. 3DCream C3600 Ultimate

6. Tethon3D Bison 1000

7. ExOne X1 160Pro

8. Voxeljet VX1000 (Premium Choice)

9. XJet Carmel 1400C

10. Lithoz CeraFab Lab L30

3D Printers for Ceramics and Clay Arts

Let’s take a look at some of the best printers for artistic work:

3D Printer Type: FDM/LDM | Materials: Porcelain, Earthenware, Gres & Clay | Build Volume: Ø200 x h 400 mm

Delta WASP 2040 Clay is a top-of-the-line piece of hardware. It’s got a lot of good features that should come in handy during various scenarios, so it is one option you should consider.

One thing I like most about this unit is its “resurrection” system which helps the machine resume a build even after it has stopped entirely. This makes it a relatively solid purchase because it doesn’t matter the reason. Maybe the cause is a power outage, or you need to hit pause on the project, but you can always get right back into it.

Its print speed is 150 mm/s, meaning it can finish its work faster than most others. The machine has an open design, so it’s easy for the creator to interact and adjust their piece as needed.

The machine is capable of producing pieces made of ceramic mixtures. The printer can do porcelain, earthenware, and clay. Its versatility is to be appreciated. The LCD touchscreen and wi-fi connectivity make it easy to use.

The price of this unit isn’t suited to those brand new to ceramic 3D printing, but it is a solid option as a step up from older printers. This makes it suitable for enthusiasts who are looking to expand their horizons.

Pros

- Competent machine that has excellent finesse

- The Resurrection System means work can easily be stopped and resumed

Cons

- Costly for hobbyists and enthusiasts

- An average capacity that doesn't stand out from peers

3D Printer Type: Extrusion | Materials: Clay, Porcelain, Concrete, Paste & Paints | Build Volume: 480 x 480 x 500 mm

The StoneFlower 3.0 is a product of the German company StoneFlower. It’s the third in their line of ceramic 3D printers, which is the company’s specialty. Their StoneFlower 3.0 model does stand to show what they learned, seeing as how it is a marked improvement from previous models.

The most notable thing about the StoneFlower 3.0 is its solid metal frame. It does make the machine quite heavy, but it offers a surprising amount of stability for the device. It also makes the machine – the frame, at least – somewhat resistant to damage.

Another big thing the machine has going for it is the open-source software. The open-source software means the machine’s code is publicly available, opening up many opportunities for modding for the programming-inclined enthusiast.

The printer’s max speed is above average for those in its class, but the build volume is a whopping 115 L, which should be enough to complete your big projects. The precision is also worth noting. Its layer thickness ranges from .3 mm to 3 mm, giving it some versatility.

This printer is best for those already well-versed in Ceramic 3D printing. It demands more know-how than other units, but it can also produce some great work.

Pros

- High stability when working

- Good production speed for its size

Cons

- A heavy unit you can't easily move

- Heat generation can become an issue

3D Printer Type: DIW (Direct Ink Writing) | Materials: Pottery Clay & Porcelain Clay | Build Volume: 150 x 150 x 240 mm

The Cerambot Eazao Zero is a Kickstarter-backed project. The first Cerambot experienced a successful launch and released good reviews for a low price of the first machine. The sequel product, the Cerambot Eazao Zero, is an excellent follow-up to their first printer.

One of the most fantastic things about the Cerambot Eazao Zero is that it comes fully assembled out of the box, making installation easy. However, it would help if you still put some pieces together, like plugging in power and attaching the filament. You can even use your microwave as a kiln.

The Cerambot Eazao Zero is a small machine making it very portable and limiting its print size. It is notably slower than other machines, with a print speed of around 10 to 40 mm/s. The low rate makes it the slowest on our list and the one with the lowest volume.

Another problem is that it doesn’t come preloaded with software, meaning you have to install it yourself, but industry standards like Cura work just fine for the machine.

While those are definite downsides, the biggest upside to the Cerambot Eazao Zero is its wonderfully small price tag. It’s less than a quarter of the cost of the other printers listed, making it a safe starter bet for someone who’s not sure they want to get into ceramic 3D printing.

This machine is geared toward newcomers to ceramic 3D printing. Its small price tag means there isn’t too much risk on purchase, and its ability to make beautiful prints for cheap makes it suitable for those just learning how to do ceramic 3D printing.

Pros

- Easy to use, making it great for beginners

- The price isn't too steep, making it a great starting point

Cons

- It doesn't come pre-installed with software

- Slow printing speed

3D Printer Type: Extrusion | Materials: Ceramic & Clay | Build Volume: 430 x 450 x 500 mm

VormVrij may be a tongue twister of a company name, and that’s because they’re from the Netherlands. The LUTUM 5 is the newest installment in their LUTUM line of printers, so the company’s experience is showing with this one.

The LUTUM 5 is a top-of-the-line piece of hardware capable of some unique prints. It is definitely in the category for professional 3D ceramic prints, making it ill-suited for newcomers.

Two noteworthy features of the LUTUM 5 is its automatic leveling plate which will help ensure your prints come out exactly as they need to and its industrial-grade machinery. The printing head doesn’t just move fast; it is capable of astounding precision with it to boot.

The max build volume it supports is 430 x 450 x 500mm, giving it ample room, and its speed of 150 mm/s is astounding. Combine that with an XY accuracy of .1 mm, and you’d be hard-pressed to find a machine so capable.

These features don’t come cheap, as the LUTUM 5 is strictly professional. Its price tag can hurt all but the fattest of wallets. It’s also not that small of a machine, meaning you will need a decent amount of space to put it.

This printer is geared toward those who already have printing experience and are willing to sink more money into their printer for better results. It’s well suited to that due to its large build volume and high speed.

Pros

- Amazing capabilities with good speed and finesse

- Large build volume and accuracy good for complex creations

Cons

- Very expensive

- Complicated to use, making it ill-suited for beginners

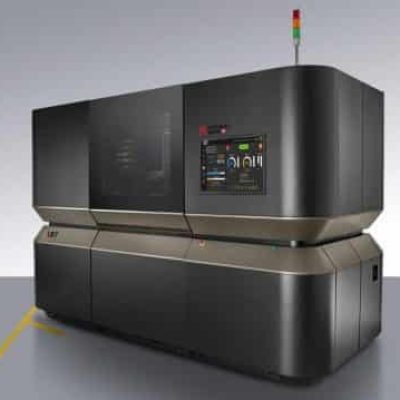

3D Printers for Technical Ceramics

Let’s take a look at some popular technical 3D ceramic printers:

3D Printer Type: SLA | Materials: Ceramic | Build Volume: 600 x 600 x 300 mm

The C3600 Ultimate is an impressive addition from 3DCeram, which specialize in making ceramic 3D printers. It’s the newest in their “C-series” line and bodes well for their future endeavors in the industry.

Unlike the 3D printers in the previous section, this one is specifically industrial grade, meaning it’s geared towards manufacturers rather than just enthusiasts. This, of course, comes with the upside of better specs but also a larger price tag.

The machine uses lasers to help it detect where the printer should be going. The lasers are so precise that they can detect things up to 60 micrometers. The machine’s ability to self-adjust helps ensure your print comes out correctly.

This machine is capable of doing some amazing things. Its minimum layer thickness is just .025 mm. A thickness that small really does get into the nitty-gritty details of any print job.

The major downsides to the machine are, of course, its price and its size. The other downside is its size. The unit weighs in at 4000 kg, which is around 800 pounds, so it’s definitely not something you can move all that often.

This printer is geared towards serial printing, meaning companies that need to print a lot of one specific part would do well with this. It is well out of the range of all but the richest 3D printing hobbyists, which is to be expected since it is geared for industrial work.

Pros

- Capable of large production

- 3DCeram offers training alongside your purchase

Cons

- A large machine that can't be easily moved

- Complicated to use, meaning training would be advised

3D Printer Type: DLP | Materials: Metal & Ceramic | Build Volume: 110 x 60 x 138 mm

Tethon3D is an American-based company that specializes in ceramic 3D printing. Their experience doesn’t just extend as far as building machines but also developing filament powders for your ceramic printing needs.

Their Bison 1000 printer model is a compact thing. Able to fit onto most desks alongside a computer. Combining that with its ability to do ceramic and metal 3D printing means it has good versatility to boot.

What makes this printer unique is that it comes with a heated vat. The heated vat helps ensure that whatever material you’re using to print stays at the proper viscosity to reduce mistakes. You can even control the heat level to maintain your desired viscosity.

The Bison 1000 also comes with remote monitoring from your phone. This should help give you some leeway when walking away from your printer. If you notice anything wrong, you can quickly zip back to your printer to deal with it.

The biggest issue with this printer is its small size which limits what kind of stuff can be made with it. If you need a machine capable of producing large things, then the Bison 1000 isn’t the best choice.

The Bison 100 is geared toward those that need to make small-scale but highly detailed prints. Its ability to do ceramic and metal printing also gears it toward those who desire high versatility, like medical manufacturing or complex engineering that requires multiple small parts.

Pros

- Very compact size makes it easy to fit and store

- Good versatility with metal and ceramic with precision to match

Cons

- Its small size prevents it from making large things

- Not the fastest printer available

3D Printer Type: Triple ACT (Advanced Compaction Technology) | Materials: Metal & Ceramic | Build Volume: 800 x 500 x 400 mm

ExOne is a veteran of the 3D printing industry, having been in business in 1995. This experience is fully displayed with their X1 160Pro ceramic 3D printer.

The printer can do metal and ceramic printing with heated dual extruders. This makes it a solid choice for those looking for a versatile machine capable of doing both things on a more significant industrial level. The heated vats are a nice bonus too.

The print volume of the printer is 800 x 500 x 400 mm, which is by far the largest on our list. The machine’s print speed is estimated at around 10,000 cm3/hour, although the rate is impacted by the material it’s working with.

Like most other industrial printers, this one isn’t cheap. It’s also not that small. You’ll have to set apart some floor space just for this behemoth of a machine. It’s also geared more toward metal printing rather than ceramic printing.

It’s geared toward those working in the aerospace, defense, and automotive industries. The system’s cloud connectivity also helps share info from one printer to the next or even access it from another device. This makes it well suited to large businesses.

Pros

- A huge machine that's great for large print jobs

- Info sharing from one device to another makes data easy to share

Cons

- The machine is large enough that you can't just stick it anywhere

- The price tag can wear on your wallet

3D Printer Type: Binder Jetting | Materials: Sand, Plastic & Ceramic | Build Volume: 1000 x 600 x 500 mm

Voxeljet is another veteran of the 3D printing field, having gotten their start 20 years ago in Munich, Germany. They make printer filament and replacement parts, but their VX1000 is their latest foray into the field of ceramic 3D Printers.

The VX1000 is a standout unit for printing on an industrial scale. The production volume is 1000 x 600 x 500 mm, making it rather good for printing large-scale things. However, by Voxeljet on admission, it is more suited to building prototypes than other uses.

The minimum layer for thickness is only .15 mm, which is pretty good. The VX1000 will reliably be able to produce the more delicate parts of its projects. The VX1000 also has High-Speed Sintering, which speeds up the process by a noticeable margin.

The printer favors sand-based ceramic but can also work with metal to suit all the user’s needs. It can also print with nylon and TPU through Voxeljet’s support, giving it a wide range of versatility that other printers might not be able to match.

Like most of the other industrial printers on this list, the VX1000 is large and in charge, meaning you’ll need to find space for it. Its customization also comes with the downside of being complex in its use.

This unit is suitable for engineers in a variety of fields. The ability to quickly make prototype models comes in handy during the long haul for developing new equipment. It is capable of small to medium-sized orders, as well.

Pros

- Large production volume for large printing

- HSS decreases the time for a build to be complete

Cons

- Its size means you'll have to make space for it

- Its versatility gives options but also a lot of complexity

3D Printer Type: NanoParticle Jetting )NPJ) | Materials: Ceramic | Build Volume: 500 x 280 x 200 mm

Xjet is a leading name in the printer business. They sell printer parts but also manufacture their line. They produce metal and ceramic systems, with the Carmel 1400C being their primary ceramic 3D printing offer.

The build volume is an ample 500 x 140 x 200 mm, and it’s got two of them. The build trays give the machine a lot of room to work with when printing out desired projects. Be sure you’re buying the ceramic printer online because the similarly named 1400M is Xjet’s metal 3D printer.

What’s unique to this printer is Xjet’s proprietary NanoParticle Jetting which is supposed to give the Carmel 1400C greater accuracy than other systems. If its layer thickness of 10 microns is anything to go by, it allows for extreme precision.

This system is best suited for those solely looking for ceramic printing since it lacks the ability also to do metal like other printers on this list. Its precision and size make it well suited for those who want to create larger, intricate pieces.

Pros

- A tremendous ceramic dedicated printer

- The precision offered by NanoParticle Jetting means prints can be very intricate and delicate

Cons

- Specifically, do ceramic 3D printing mean it lacks the variety of some other units listed

- An expensive option you should ensure suits your needs before purchasing

3D Printer Type: DLP | Materials: Ceramic | Build Volume: 76 x 43 x 170 mm

Lithoz is another European printer company. This company is based in Austria, and this company specializes specifically in making ceramic 3D printers. Their CeraFab Lab L30 is one of their newest products, released in 2021.

The CerFab Lab L30 is explicitly focused on producing ceramics, so it’s lacking in versatilitay when compared to other printers on this list. It has a heated build chamber to keep your projects at the ideal temperature and Independent Dual Extruders for increased accuracy.

The printer is much smaller than almost every other industrial printer we have listed. This, unfortunately, means it doesn’t have as large of a build space as others. The CerFab Lab L30 is limited to 76 x 43 x 170 mm.

Rather than size, it specializes in being precise—those that desire highly-detailed equipment, but not large pieces of equipment. Fields like medicine definitely should look into this one.

Pros

- The heated build chamber keeps your prints at the ideal temperature

- A very accurate system that can capture prints in detail

Cons

- The limited build space limits you to small to medium projects

- The build speed isn't very quick either

What is Ceramic 3D Printing?

Ceramic 3D printing is a fantastic thing! Unlike other kinds of 3D printing, which use metal or some plastic polymer, ceramic printing uses ceramic as filament. The filament is often made of powdered silicone and polymer to help it stick together.

Two common compounds used to make the filament is Silicon Carbide, AKA: oz SiC, the standard go-to ceramic filament. It has a good multipurpose set of qualities like hardness and corrosion resistance, making it ideal for many situations.

What are the Uses of Ceramic 3D Printing?

You should note that 3D-printed ceramic has far more uses outside of just art, even outside the industrial field. For example, car-enthusiast has something to look forward to thanks to Si3N4, which has its own set of benefits different from SiC.

Another standard filament, Si3N4 is also known as Silicon Carbide. Rather than being an excellent all-purpose tool like SiC, Si3N4 is more specific. It’s mostly used for industrial purposes in making parts of machinery that are hard to produce. Examples of such things are engine parts, ball bearings, and metalworking.

What to Consider when Buying a Ceramic 3D Printer

The kind of filament is essential, but you also have to ask yourself what kind of machine you want to use. Certain printers prioritize certain qualities that might make them more suited to your printing needs.

If you’re into the more artistic side of printing, you might want to pick a printer with a large build volume. The higher volume can accommodate larger works, or maybe you’d like to emphasize precision to make sure your works are as accurate to your blueprints as possible.

The casual printer might want a machine that emphasizes speed over other qualities. 3D printing can take a long time, and if you’re not printing anything super important, minor mistakes aren’t that much of a deal-breaker. If the printer also has an easy-to-understand user interface, then it’s even better.

Those looking into doing 3D printing on an industrial level can mostly disregard complexity since companies often provide trainers to help companies get the hang of machines. Industrial 3D printers also offer far greater precision than the artistic kind but at a much steeper price.

Rather than using the standard kinds of filament, industrial printers often have filaments that you can purchase from the producer, which helps eliminate the effects of different filament types on your prints.

Looking for a printer that also has its heating would be helpful. When doing large and precise print jobs, it can take time. It would be ideal for the piece to stay at the same temperature until it’s finished, so no structural weaknesses are introduced by uneven cooling.

Conclusion

Ceramic 3D printers come in many shapes and sizes with many specialties. However, some are better suited, even for their specialized tasks. Printers can be costly, so it’s best to look into them to ensure they meet your exact needs.

The Voxeljet VX1000 is one of the best printers for industrial use. It’s got good versatility that can make it fit many situations, alongside the capability to produce prototypes quickly. This speed can come in handy when a finished product can be released sooner.

In terms of artistic printing, I like the Cerambot Eazao. Its open design means you can easily make adjustments to your pieces. Its low price and ease of use are suitable for a first printer since they can help make sure ceramic 3D printing is for you.