- Last Updated: January 12, 2024

- Pat Nathaniel

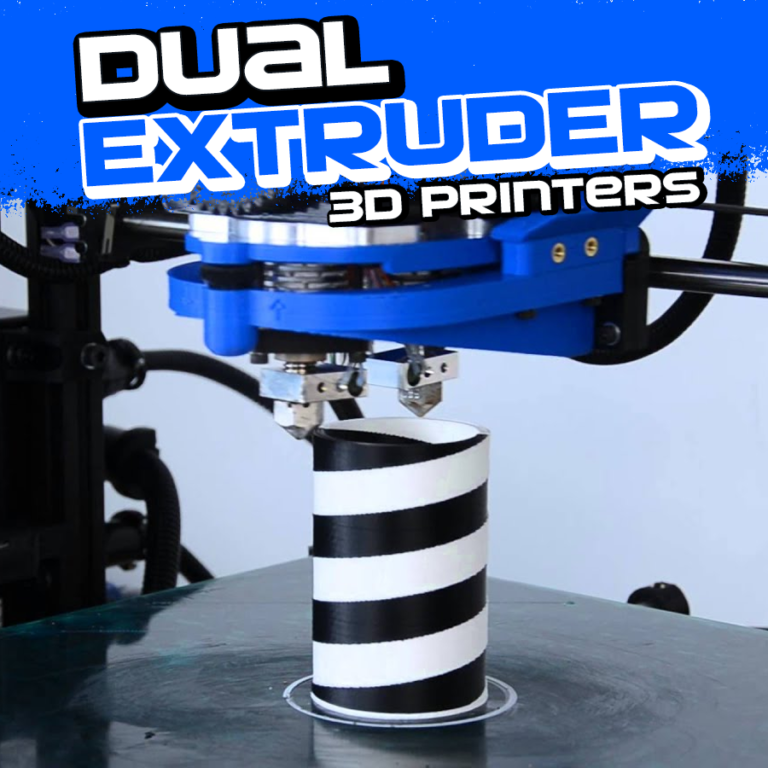

If you’re looking for the best dual extruder 3D printer, it’s not hard to get really overwhelmed.

You might want a dual extruder 3D printer so you can make prints with two colors, prints with water-soluble supports, or get an exceptional level of detail.

There are so many different features and specs to consider.

Be warned, though. A lot of companies say they can deliver a top-notch dual-extruder 3D printer – truth be told, most of them are not any good. To avoid wasting your money or time with a sub-par machine, we went ahead and screened each dual-extruder 3D printer in this category and picked the top 7.

Top Dual Extruder 3D Printers At A Glance

- Ultimaker S5 (Premium Choice)

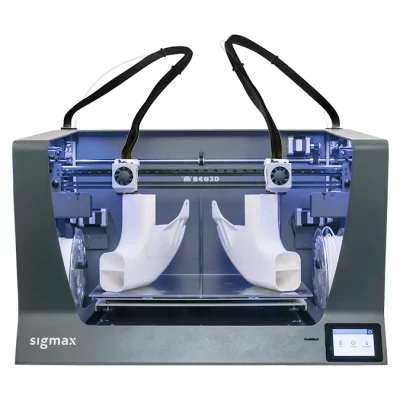

- BCN3D Sigma R19 (Best Value)

- Flashforge Creator Pro (Best Choice)

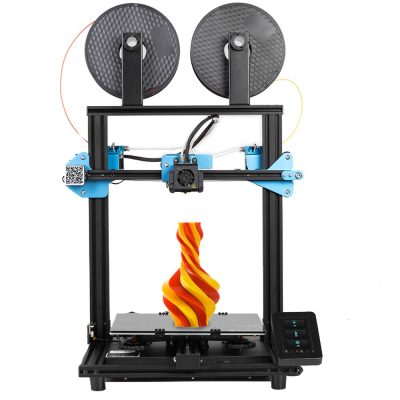

- Geeetech A10M (Best for Makers)

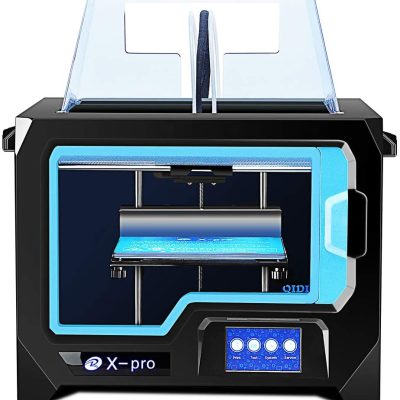

- Qidi Tech X-Pro (Simplest to Use)

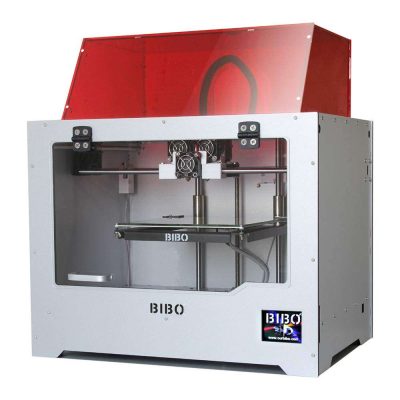

- Bibo 2 Touch

- Sovol SV02

Print Technology: Fused Deposition Modeling | Materials: Tough PLA, TPU 95A, ABS, Nylon, TPU | Filament Diameter: 2.85 mm | Build Area: 330 x 240 x 300mm | Max Extruder Temperature: 280 °C | Max Bed Temperature: 140 °C

The first and best 3D printer on this list is the mighty printer from Ultimaker. It also happens to be the best dual extruder 3D printer overall.

If a friend tells you not to get an Ultimaker product, they’re not your friend. Every one of their printers stands at the top of their respective categories. The S5 is no exception. It works from a free Slicer called Cura.

It takes a few minutes after plugging in the system for it to set up and you’re ready to run. A coworker and I plugged it in when we got to the office in the morning, and our first print was done by lunch – and believe me, at the time I was far from a professional.

This printer, in particular, has all the tech, precision, and versatility you’d expect from a professional-grade printer. You can expect to get the best 3D prints from this dual-extruder 3D printer.

Who is it for: Professionals, medium-sized businesses, aspiring professionals.

Pros

- Excellent Print Quality

- Great Bed Adhesion

- High Max Temp for its Two Extruders - Can Print a Ton of Different Materials

- Enormous Build Volume

- Quality Dual Extrusion, Especially for Support Material

- Comes Pre-Assembled

- UI is Really Friendly- Also Has a Touch Screen to Navigate

- Camera Installed to Keep Track of Progress

- Quiet Machine

- Includes Adjustable Light in the Cabin so You Can Keep an Eye on Your Print or Turn Off the Light Easily

Cons

- It’s a Little Pricey

- Print Time is Longer Than the Competitions

Print Technology: Fused Filament Fabrication | Materials: PLA, ABS, PVA, PETG, Nylon, TPU & HIPS | Filament Diameter: 2.85 mm | Build Area: 210 x 297 x 210 mm | Max Extruder Temperature: 290 °C | Max Bed Temperature: 100 °C

Next up is a dual extruder 3D printer from BCN3D.

If you’re familiar with the Sigma brand, you might recognize the mechanics of this printer. Though it looks familiar, this sucker got a massive upgrade under the hood. They added a new “IDEX system” which means a lot of new printing modes and design upgrades.

Additionally, there are a lot of UI overhauls with this new model.

Using this printer right from the box is as easy as connecting a few things together and plugging it into an outlet.

I will warn you though, you’re going to have some bed adhesion problems in the beginning since the bed temperature is a little lower than you’d like. There are new calibration and installation wizards that will quickly run through both processes.

You get a lot of bang for your buck with the Sigma R19. You can’t go wrong with this choice.

Who is it for: Professionals, prototyping shops, small companies.

Pros

- Dual Fans to Keep Independent Print Heads from Overheating

- Full-Color Touch Screen

- Rigid Metal Frame

- Calibration Wizard Makes Life Easy

- Enormous Build Volume

- Maintenance is Straightforward (Has a Ton of Literature Available)

- High-Quality Print Bed

- Price is Excellent for What You Get

Cons

- Expect A Lot Of Filament Purges – You Will Spend More Money On Material Over Time

- A Little Louder Than Other Printers

- It Takes A Short Time To Get Bed Adhesion Dialed In

Print Technology: Fused Deposition Modeling | Materials: PLA, ABS, PETG & TPU95A | Filament Diameter: 1.75 mm | Build Area: 227 x 148 x 150 mm | Max Extruder Temperature: 260 °C | Max Bed Temperature: 110 °C

If you have champagne taste but you’re on a beer budget, you should consider the Flashforge Creator Pro. The price tag is so reasonable on this machine it’s almost blinding. Even with the low price point, it’s still one of the best 3D printers.

The only cons to the Creator Pro are associated with how inexpensive the machine is. A few quality designs had to be overlooked to keep the price low, but it doesn’t hurt the overall performance.

What you’re getting is a stylish and totally enclosed dual-extruder 3D printer. The Creator Pro works quickly, comes with material to get you started, and sports a really sturdy frame. The LED screen has easy-to-use selection buttons next to it. The Creator Pro can easily print multiple materials, can work from an sd card, and is a top dual-extruder 3D printer.

Who is it for: Hobbyists, DIYers, small shops first starting with 3D printing

Pros

- Totally Enclosed System for Heat Retention and Better Prints

- Dual Fans to Keep the Extruders from Overheating

- Comes with 2 kg of Filament to Get You Started

- Metal Frame is Sturdy

- Price for the Value is Great

Cons

- 3 Knob Leveling is Unfavorable

- X, Y, and Z Rod Calibration is a Little Finicky

- Noisy Operation

- Build Volume is a Bit Small

Print Technology: Fused Deposition Modeling | Materials: PLA, ABS, Flexible PLA, Wood-Polymer, PVA, HIPS & PETG | Filament Diameter: 1.75 mm | Build Area: 220 x 220 x 260 mm | Max Extruder Temperature: 288 °C | Max Bed Temperature: 100 °C

If you’re a maker at heart, look no further than the Geeetech A10M. The reason this printer is great for makers is that it delivers an acceptable quality for a great price. Additionally, the nozzle gets so hot that you can 3D print just about any material type which is great for makers.

Since the intended audience isn’t professional or even semi-professional users, they can get away with a less desirable final quality. The dual extruder on this machine can compete with any other dual extruder 3D printers on the market.

The forums on Geeetech’s website is my favorite part about this printer, there’s such a strong sense of community for anyone who uses this printer. Also, the fact that the printer is pre-assembled despite its crazy-low sticker price still has me in shock all these years later.

Who is it for: Makers, DIYers, hobbyists

Pros

- Community of Geeeetech Makers to Help Field Questions and Give Suggestions

- Incredibly Cost-Conscious

- Heated Bed is Made of Silicon Carbide Glass, Followed by a Microporous Surface Cover

- Power Recovery Setting to Continue a Print if it Loses Power

- Top-Feed Filament Extruder Makes for Easy Changeovers and Troubleshooting

- Pre-Assembled

- Really High Extruder Temp to Print Different Materials

- Reliable Dual Extruders for Support Material

Cons

- Electronics Tend To Fail On This Machine

- Quality Leaes You Wanting More

Print technology: Fused Deposition Modeling | Materials: PLA, ABS & TPU | Filament Diameter: 1.75 mm | Build area: 230 x 150 x 150 mm | Max extruder temperature: 250 °C | Max bed temperature: 120 °C

If you’re new to 3D printing, you probably want an easy-to-use 3D printer. When a 3D printing expert thinks of a simple-to-use dual-extruder 3D printers, the Qidi Tech X-Pro comes to mind.

Having a print stick and removing it after is a piece of cake thanks to the removable and magnetic build plate.

Just another thing you don’t need to mess with.

Qidi has its own slicer software which is admittedly easier to use than Cura.

The printer comes with a flash drive with all of the instruction videos on it so there’s no feeling of helplessness during install. Even with all of the simplicity, you’ll wind up with a dual extrusion that has overall good consistency and no stringing. This is thanks largely to the print bed.

Who is it for: Tinkerers, starters, first-time 3D printers

Pros

- Great Sticker Price

- Super Easy to Use

- Enclosed Print Chamber

- Removable and Magnetic Build Plate

- Pre-Assembled

- Included Instruction Videos

- LCD Touch Screen is Really Responsive

Cons

- Small Build Volume

- Heavy Printer- Around 62 Lbs

Print Technology: Fused Deposition Modeling | Materials: PLA, ABS, HIPS, TPU, PETG, Nylon, Carbon Fiber & Polycarbonate | Filament Diameter: 1.75 mm | Build Area: 214 x 186 x 160 mm | Max Extruder Temperature: 270 °C | Max Bed Temperature: 100 °C

Bibo 2 Touch (also known as the Bibo 3D Printer) looks like a real blast from the past. Of course, appearances don’t matter, but this machine does look like it was made 20 years ago.

But don’t let the aged — or should I say retro — appearance fool you. Inside that clunky but sturdy aluminum shell sits a capable dual extruder 3D printer.

Bibo 2 Touch comes with all bells and whistles you’d expect, like copy printing, two-color printing, preinstalled Wi-Fi module, a filament runout sensor, and a print resume function. It’s a perfectly good printer that provides good value at its price.

As one of the bigger selling points, you can get a laser engraver module for the Bibo, transforming it into a 2-in-1 machine. Print your parts and then engrave logos, instructions, or other stuff on them — or on other materials for that matter.

Who is it for: Serious hobbyists, first-time SME 3D printers

Pros

- Great value for the price

- High extruder temperatures

- Good print quality

- Bibo has fixed a lot of the issues with previous 2 Touch versions

- Laser engraver module

Cons

- Acrylic cover needs assembly

- Laser engraver sold separately

- No automatic leveling

- Clunky and buggy user interface

Print Technology: Fused Deposition Modeling | Materials: PLA, TPU, HIPS, ABS, PETG & Wood | Filament Diameter: 1.75 mm | Build Area: 280 x 240 x 300 mm | Max Extruder Temperature: 260 °C | Max Bed Temperature: 110 °C

Sovol’s SV 3D printer range features a lot of machines. SV02 is the company’s dual extruder machine with a 2-in-1 hot end.

This means the SV02 only has one nozzle and can’t do things like copy or mirror printing. But it can mix two different materials into one print. Thanks to the high extruder and bed temperatures, you should be able to print with almost anything you want.

SV02 is a very affordable machine, but that low price doesn’t translate to poor performance. The prints it makes have good quality and stick to the print bed well without additives.

The printer also has a print resume function, which is a welcome surprise. You can also get some addons, like a BL-Touch sensor for automated bed leveling.

Speaking of that sensor, here’s a pro tip: buy it. Leveling SV02 is difficult and can easily lead to failed prints.

Note that Sovol also sells the SV04 — another dual extruder printer with independent nozzles and automatic bed leveling. There’s also the SV03, which isn’t a dual extruder printer, but has a much larger build volume than SV02.

Who is it for: Hobbyists, 3D printing beginners, DIYers

Pros

- Affordable

- Good print volume

- Nice print quality

- Quiet printing

- Easy to assemble

Cons

- Difficult bed leveling

- Prone to clogs

- Machine quality seems inconsistent

Twice the Extruders, Twice the Power

Do you want to print two parts at once? Or incorporate two different materials into one print?

Then you need a dual extruder 3D printer.

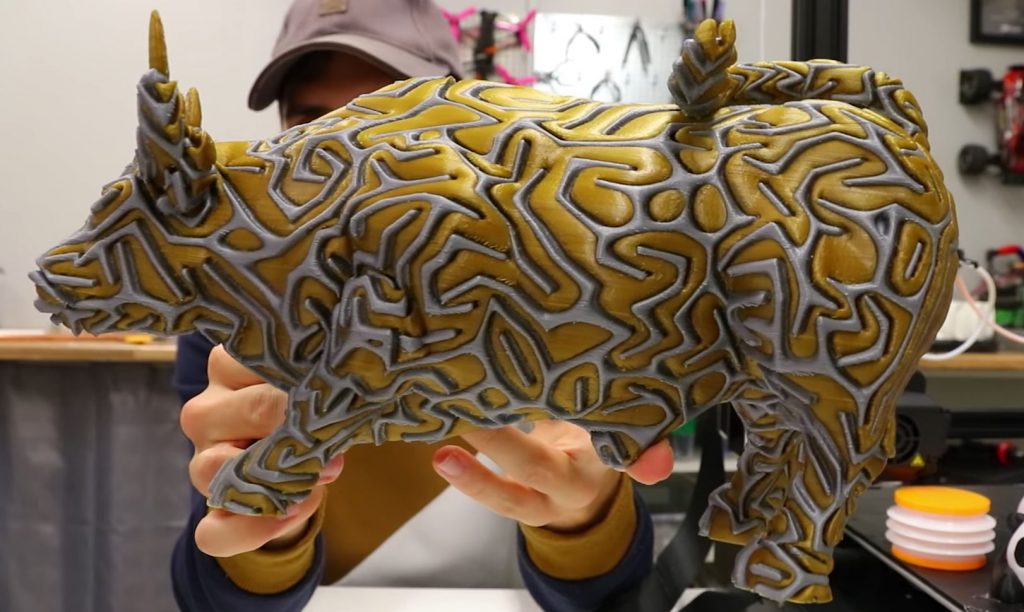

Dual extruder printers let you create beautiful prints in multiple colors, add several materials in one print to increase strength, or improve your productivity with multi-part printing. But you need to know how the tech works to get the most out of it.

Let’s take a closer look at dual extruder 3D printers and what makes them tick.

What is a Dual Extruder 3D Printer?

A dual extruder 3D printer is pretty much exactly what it sounds like — a 3D printer equipped with two extrusion nozzles. The printing process is the same as with single extruder machines, with one significant benefit.

Dual extruder printers can swap between active nozzles to print two different materials. You can use, for example, a water-soluble support material with a regular plastic filament to make your parts easier to post-process.

That’s the basic gist of it, but in reality, dual extruders are a bit more complex. There are three different types of dual extrusion printers, and each work differently.

The types of dual extruder printers include:

2-in-1-out Extruders

You could question whether 2-in-1-out extruders are really dual extruders. But they do print with two materials, so they often get pushed into this category. These extruders can take in two filaments at once. They then switch between them by retracting one filament and extruding the other, depending on the input parameters. During filament changes, the extruder purges the nozzle to clear it of the previous material.

Dependent Dual Extruders

Dependent dual extruders, or dual-nozzle systems, have two different nozzles that each extrude a different filament. These systems are called “dependent” because the nozzles move together.

Dependent dual extruders are faster than 2-in-1-out extruders since they don’t need to go through the whole filament swap process. You can also use a different nozzle size on each extruder for added versatility.

Independent Dual Extruders

Finally, independent dual extruders (IDEX) are the holy grail of dual extrusion. These systems have two nozzles that can each move independently.

As such, they’re incredibly versatile. They can print two materials at once on one print, print two copies of a part at a time, and print mirrored halves of one part (electronics cases, anybody?).

Pros and Cons of Dual Extruder 3D Printers

In general, dual extruder printing brings a lot of benefits with very few downsides. But it’s still not a completely bulletproof technology. Here are the pros and cons of dual extruder printing:

Pros

- Can print with two materials at once

- Ability to print soluble supports

- Mixing multiple colors in one print

- Ability to create stronger parts

- Potentially faster print speed

Cons

- More expensive 3D printers

- Two extruders need twice the maintenance

- 2-in-1-out extruders can clog or mix materials

- Dual extruders need a purging tower during printing

Considerations When Buying a Dual Extruder 3D Printer

So, you like what you’re reading and would like to dip into dual extrusion yourself? First of all, excellent choice.

But second, be cautious of which machine you buy.

Dual extruder 3D printers can be pricey, so you don’t want to waste your money on a printer that doesn’t satisfy your needs. When picking a printer, consider these factors:

- Type of Dual Extruder: As you learned, there are three common types of dual extrusion systems that don’t all serve the same needs. If you’re looking to make mirrored prints, for example, a dependent dual extruder won’t be enough for you.

- Build Volume: Build volume is always an important consideration with 3D printers, but it’s doubly that with dual extruder machines. For example, if you want to print two parts simultaneously, you’ll need a large chamber so you can fit both parts in at once.

- Calibration: Twice the extruders means twice the work. Dual extruders can be challenging to work with, and operating them manually can be difficult and time-consuming. It’s best to look for a printer with powerful automation features.

Do Dual Extruders Make Printing Faster?

Faster printing often gets touted as one of the big benefits of dual extruder systems. But is that really so?

It depends on what you’re printing.

Despite having two extruders, a dual extruder system probably won’t finish a single-filament print any faster than a single extruder system. Some IDEX systems might be able to lay down filament in two different places on the same print, but in general, these kinds of basic prints will be just as fast (or slow).

But even with single-filament prints, dual extruder systems can improve productivity. IDEX systems can print two copies of the same object at once. You’ll save time by making two prints in the time it could take to print one.

But where dual extruders really speed things up is in multi-material printing. Just think of trying to do that with a single extruder printer — you’d have to constantly swap filament spools and you’d have to do it fast.

Dual extruders make multi-material printing faster. That’s not necessarily because of a higher print speed, but because you won’t have to waste time swapping filaments.

In a nutshell, dual extruder 3D printers can make printing faster — under the right conditions.

Conclusion

If you want the overall best dual extruder 3D printer, you should go with the Ultimaker S5. It delivers professional-grade prints.

For the best possible value in your printer, you should look at the BCN3D Sigma R19.

If you’re looking for a dual extruder 3D printer on a budget, the Flashforge Creator Pro is going to be your best choice. It still delivers a great overall print quality, it just has a lot less sticker shock associated with it.

For all of the makers at heart, the Geeetech A10M was made for you.

DIYers and hobbyists who are looking for a nice dual-extruder 3D printer but don’t have all of the experience, the Qidi Tech X-Pro is the perfect pick. It’s so easy to use.

Anyone who’s on a tight budget but still wants to scratch their 3D printing itch, turn to the Sovol SV02. It’s a great printer that’s really affordable.

So there you have it, a great starting point for your search. By considering this list of the best dual extruder 3D printers, you’re sure to find exactly what you’re looking for. Whether you just started your search or you’re torn between a couple of printers, take a look at features you really love when you’re looking at these options.

You obviously want to make sure the printer is within your budget and has the appropriate build volume and nozzle temperature to print your preferred material. You should consider which additional features are attractive to you and if they’re worth the extra money.

You can’t go wrong with any printer on this list. There’s something for everybody. So what are you waiting for? Get to printing!

Related Articles: