- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

3D printers are a great way to get your part, but if you’re impatient, then you want the fastest on the market. At the same time, you don’t want to waste money or compromise on quality.

3D printers are a great way to get your part, but if you’re impatient, then you want the fastest on the market. At the same time, you don’t want to waste money or compromise on quality.

Don’t worry; this extensive list has you covered.

We will dive into the fastest FDM printers, then take a look at some resin options. Afterward, we’ll take a look at what print speed is good for a normal printer and why printers can’t go faster.

Let’s take a look at some of the fastest 3D printers available for you to buy today.

Table of Contents

- FDM 3D Printers

- 1. AnkerMake M5 (Best Choice)

- 2. FLSUN V400 (Best Value)

- 3. FLSUN Super Racer (SR)

- 4. Bambu Lab X1-Carbon

- 5. Prusa MK4

- 6. Qidi Tech iFast

- Resin 3D Printers

- 7. Original Prusa SL1S (Premium Choice)

- 8. Phrozen Sonic Mega 8K

- 9. Elegoo Mars 3 Pro

- 10. Anycubic Photon Mono 2

- What is a Good Print Speed for 3D Printers?

- Relationship Between Speed and Quality

- Limiting Factors for Speed

- How to Make a 3D Printer Faster

- What Happens If You 3D Print Too Fast?

- Conclusion

10 Fastest & Quickest 3D Printers At A Glance

FDM 3D Printers

1. AnkerMake M5 (Best Choice)

2. FLSUN V400 (Best Value)

3. FLSUN Super Racer (SR)

4. Bambu Lab X1-Carbon

5. Prusa MK4

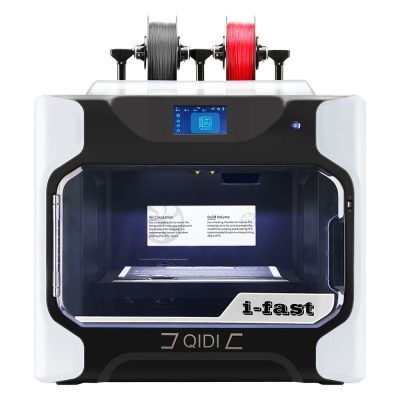

6. Qidi Tech iFast

Resin 3D Printers

7. Original Prusa SL1S (Premium Choice)

8. Phrozen Sonic Mega 8K

9. Elegoo Mars 3 Pro

10. Anycubic Photon Mono 2

FDM 3D Printers

3D Printer Type: FDM | Materials: PLA, TPETG, TPU, ABS | Build Volume: 235 x 235 x 235 mm | Max Print Speed: 500 mm/s

What the heck was that thing speeding by? Oh, it’s just AnkerMake M5’s print head. No reason for alert, carry on.

This is one of the fastest FDM printers we’ve seen. It can reach an absolutely ludicrous print speed of 500 mm/s. Any faster and this thing would go straight into plaid!

The printing isn’t the only thing that’s speedy about the M5 — it’s also quick to set up. With only four components to put together and automatic bed leveling, you can start printing within 30 minutes of opening the box if you take your time.

Controlling the printer is simple with the large touchscreen or your phone. That’s right, you can start and pause prints or receive printing status alerts through the AnkerMake App. If you’ve wanted to start your prints while traveling, this machine lets you do it.

Now, the high speed comes a bit at the expense of detail quality. Don’t get us wrong, the M5 creates solid prints at a minimum layer height of 0.1 mm, even if it doesn’t produce the sharpest details.

An AI-powered camera gives a welcome print quality boost by instantly alerting you of printing errors. The printer also has a resume function, so there’s no need to worry about power outages ruining your prints.

The 250 x 250 x 250 mm build volume isn’t the largest out there, but it’s sufficient for most prints.

Now, the M5 technically supports PLA, PETG, TPU, and ABS. However, the extruder can be temperamental and straight-up refuse to push some filaments through.

Overall, if you want fast prints, you can’t go wrong with the AnkerMake M5. It’s a solid machine in every way that will satisfy your need for speed.

Pros

- Super-fast speed

- Affordable

- Solid and sturdy machine

- Good print quality

- Plenty of advanced features

Cons

- Loud

- Temperamental extruder

- AnkerMake Slicer is only so-so

3D Printer Type: FDM | Materials: PLA, PETG, ABS, TPU, PC, Wood, Nylon | Build Volume: 300 x 300 x 410 mm | Max Print Speed: 400 mm/s

Right at the heels of the AnkerMake M5 is FLSUN V400. But this printer pulls something from its sleeve that might give it an edge — detail accuracy.

This delta 3D printer isn’t quite as fast as the AnkerMake, clocking in at 400 mm/s. Don’t take that the wrong way, though. It’s still an extremely fast printer.

Comparing these kinds of print speeds is pretty much like complaining your Ferrari only goes 200 mph instead of 220 mph. It’s still stupidly fast — what does that little bit of difference matter?

In terms of final print quality, though, the V400 inches ahead. With a minimum layer height of only 0.05mm (same as on the Super Racer) it can produce sharper details.

The V400’s hot end can heat up to 300°C, giving it the ability to melt a lot of different filaments. Although not all materials (looking at you, Nylon) are suitable for blistering print speeds, you have a lot of options for your prints.

What we really loved about this machine is the detachable, large touchpad. Our backs very much appreciated not having to hunch over the printer. Combined with automated leveling, a runout sensor, and Wi-Fi connectivity, this printer is simple to use.

There is a serious learning curve to assembly and efficient use, though. Also, the filament holder is a pretty sad L-shaped piece of metal.

But hey — just make a new filament holder as your first 3D printing project on this machine. You’ll get a great-looking component in no time!

Pros

- Really fast

- Great print quality

- Wide material options

- Good automation

- Detachable touchpad

Cons

- Steep learning curve

- Challenging to set up

- Sad filament holder

3D Printer Type: FDM | Materials: PLA, ABS, PETG & Flexibles | Build Volume: 260 x 260 x 330 mm | Max Print Speed: 150-200 mm/s

We’re in the Grand Prix of 3D printers, and our next contestant is the FLSUN Super Racer!

If you’re looking for a fast and accurate printer, this one’s for you.

With a print speed of 200mm/s, the FLSUN offers super precise detailing and accuracy. It’s a Delta-style printer that uses a sturdy linear rail to give the printer stability and keep your eardrums from exploding!

The Racer gives you a roomy 260 x 260 x 330 mm build volume for large vases, giant ducks, cosplay masks, and so on.

The FLSUN Super Racer comes with automatic bed leveling, which is a nice plus. It also has safety features built in place — which are really important for a printer.

You’ve got the resume print function so you don’t lose your print in a power outage (insert gif of Grandpa Simpson yelling at a power grid). Then you’ve got the filament detection feature so the Racer warns you when you’re soon to run out.

The FLSUN comes with a removable print bed — no need to struggle anymore with removing your prints. Here’s a neat trick: you can actually pop the print bed into the freezer for a few hours (with your printed part) for easier removal.

This printer has a 0.4mm nozzle that can support 1.75 mm filaments of PLA, ABS, and PETG. Sorry TPU folks, This Printer is not for U!

Layer thicknesses range from 5 microns to 30 microns — this printer really puts an emphasis on detail. Case in point, it’s got an accuracy of just 10 microns. Wow. You can achieve breathtakingly fine details!

Pros

- Fine detail and small layer thicknesses

- 200 mm/s

- Printing safety features

Cons

- Delta printer may have an initial learning curve due to different setup

3D Printer Type: FDM | Materials: PLA, PETG, TPU, ABS, ASA, PVA, PET, PA, PC, Carbon/Glass Fiber | Build Volume: 256 x 256 x 256 mm | Max Print Speed: 500 mm/s

Mere speed isn’t always everything — although it’s a lot. If you want a printer packed with advanced features, Bambu Lab X1-Carbon is here for you.

We could hardly believe that this machine is Bambu Lab’s first 3D printer. It’s simply loaded with all the bells and whistles you’d expect from veteran 3D printer makers.

Let’s start with the speed — there’s a lot of it. The X1-Carbon matches AnkerMake’s blindingly fast 500 mm/s.

The printing quality is also comparable between the two. The details aren’t the most intricate, but it’s overall perfectly good.

There are two things that set the X1-Carbon apart from its competition. The first is its AI-powered brain. Its lidar-equipped print monitoring system detects spaghetti and other non-pasta print errors with great accuracy.

Second, thanks to the 0.4 mm hardened steel nozzle, this machine can print with advanced carbon glass fiber filament. With Bambu Lab in your stable, you print strong, durable components — like spare parts for your car, for example.

You should be prepared to fiddle with the default settings after setup, though. They aren’t very accurate and waste material, so you need to put in some manual tweaks to get the most out of the machine.

You can also buy the Automatic Material System (AMS) addon that intelligently feeds filament into the printer at an ideal rate. That’s all well and good, but it doesn’t support reinforced filaments. With a carbon fiber-capable printer, what’s the point?

We’re pretty confident that these small flaws will be eliminated as Bambu Labs gets some more experience in the 3D printing scene. But even as it is, the X1-Carbon is an amazingly fast and advanced 3D printer.

Pros

- Super-fast printing

- Supports reinforced materials

- Good print quality

- Advanced AI-powered automation features

Cons

- Wastes material

- Inaccurate default settings

3D Printer Type: FDM | Materials: PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN | Build Volume: 250 x 210 x 220 mm | Max Print Speed: 200 mm/s

Ah, Prusa — the brand that launched a thousand clones. That’s really no surprise. The MK4 is a solid and fast 3D printer, particularly if you like to fiddle with your machine.

We appreciate that Prusa has made the MK4 suitable for both beginners and advanced users. You can get it as a fully assembled package you can set up in 10 minutes or as a DIY kit that you get to build yourself.

The machine is highly modular and it’s relatively easy to swap the components to suit your needs, as long as you know what you’re doing.

What about the speed, though?

Prusa MK4 can reach print speeds of 200 mm/s, rivaling the FLSUN Super Racer. It’s fast, although not as fast as the AnkerMake, FLSUN V400, or Bambu Labs. Still, pretty fast.

The MK4 produces high-quality prints with a minimum layer height of 0.05 mm, matching the V400. It also supports a wide range of materials like the Bambu Labs machine. With an all-metal, 300°C extruder, it should withstand even reinforced filament.

However, this machine doesn’t come with an enclosure. That limits your material options unless you’re willing to buy or build one. It also has the smallest print volume out of all the FDM machines we listed.

Despite its DIY nature, the MK4 comes with all the automation goodies you’d expect from a modern 3D printer, from bed leveling to filament runout detection and print resume functionality. Consequently, we found this machine to be very reliable. It just keeps going and going and going…

Prusa MK4 serves the same kind of solid Prusa quality we’ve come to expect. It’s a workhorse that offers reasonably high-speed printing that will satisfy both beginners and experienced makers.

Pros

- Great for DIY enthusiasts

- Good and reliable printing

- Suits both newbies and experts

- Wide third-party material support

Cons

- No enclosure

- Pretty noisy

- Mediocre build volume

3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, PVA, Carbon Fiber, Nylon & PC | Build Volume: 330 x 250 x 320 mm | Max Print Speed: 150 mm/s

Speed? Check. Dual extrusion? Check again!

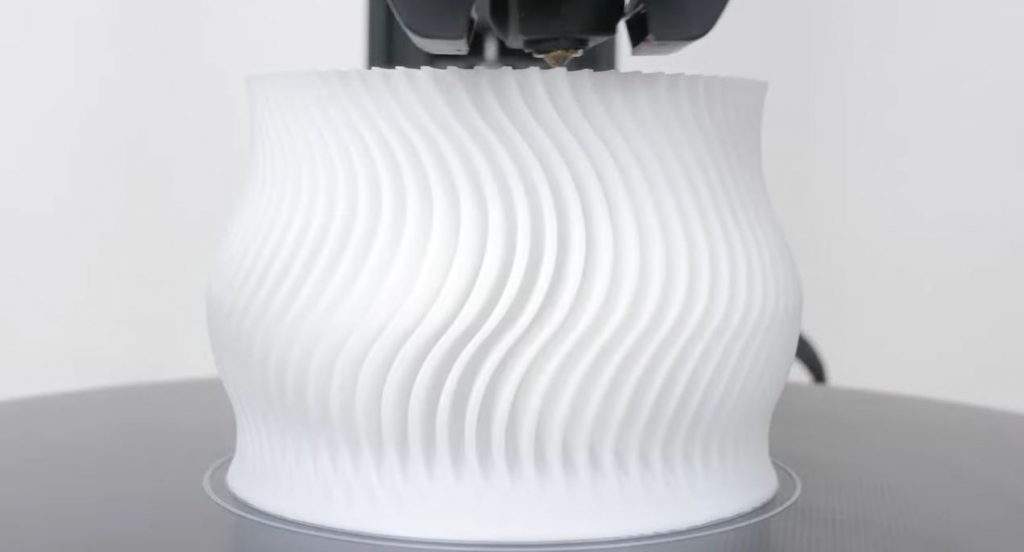

The Qidi Tech iFast is an FDM printer that gives you industrial-grade precision and speed at an affordable price tag. So if you want fast printing AND dual extrusion, this printer is perfect for you!

The iFast lives up to its name with a print speed of 150 mm/s. It also has a roomy build volume of 330 x 250 x 320 mm where you can cook up larger prints.

And with its multiple extruders, the iFast can print PLA, ABS, TPU, PETG, Nylon, carbon fiber, and water-soluble PVA.

It also has a heated enclosure for better printing of high-temp filaments — and built-in air filters to keep your printing space clean.

Removing our printed parts was a breeze with this printer — all we had to do was remove the flexible print bed, bend it a little, and the print popped right off in one piece!

The only thing we didn’t like was the noise coming from the stepper drivers when the iFast was in use. But if that isn’t a dealbreaker for you, this printer is perfect for speedy printing!

Pros

- High printing speed

- Dual extrusion

- Easy part removal

- Large build volume

Cons

- Noisy stepper motors

Resin 3D Printers

3D Printer Type: MSLA | Materials: 405 nm UV Resins | Build Volume: 127 x 80 x 150 mm | Max Print Speed: 1.4 s/layer

Highly detailed prints at a faster speed… The most coveted combination in 3D printing. Can anyone pull it off?

Well, Prusa has! With MSLA (masked stereolithography) technology and a high-res monochrome LCD panel, the SL1S provides amazingly detailed prints at 80 mm/hr.

Before you balk at this seemingly low speed (compared to FDM), the SL1S is markedly faster than the average resin printer speed of 30-60 mm/hr.

So if you want the sublime clarity and detail of resin prints at a comparatively faster speed, the SL1S is for you.

MSLA works by curing UV resin using an LCD to mask each layer’s cross-section. The SL1S comes with an 8 UV LED array to cure resin with amazingly sharp detail. It also uses a 2560 x 1620p monochrome LCD with a pixel size of just 49 microns.

This is an amazingly well-built printer (par for the course with Prusa), sporting a robust aluminum body with a 127 x 80 X 150 mm build volume. Perfect for smaller objects! And with a minimum layer thickness of 25 microns, you can easily capture fine details.

And, in typical Prusa fashion, it comes with a thorough manual to guide you through everything step-by-step, including potential printing problems. We loved the detailed and clear documentation — it truly sets a standard for other 3D printer companies.

This printer comes fully assembled — and as it’s a resin printer, you have the choice to buy it with a Cure & Wash station for post-processing of your prints.

The printer comes with a half kg of Prusament resin — though since it’s open-source, you can use virtually any resin you want.

Pros

- Amazing detail at relatively fast speed

- Sturdy and reliable aluminum build

- Very clear and helpful documentation

Cons

- Smaller build volume

3D Printer Type: MSLA | Materials: 405 nm UV Resin | Build Volume: 330 x 185 x 400 mm | Max Print Speed: 70 mm/hr

Resin printers generally have rather small build volumes… Generally. Phrozen Sonic Mega 8K shows resin machines can print big, and that they can do it fast.

This printer has a huge print volume of 330 x 185 x 400 mm. That’s enormous for a resin printer and quite big even when compared to FDM machines. In fact, the Sonic Mega 8K can make prints almost as massive as the FLSUN V400!

And let’s talk about the detail accuracy.

On paper, Sonic Mega 8K matches Prusa SL1S, with a 43-micron pixel size and 10-micron layer thickness. But the difference is that Phrozen has put an 8K resolution LCD screen into this printer. That translates into much finer and sharper details.

You can make huge and gorgeous prints with the Sonic Mega 8K. It’s ideal for printing an entire army of miniatures or big cosplay components, for example.

The speed of this printer is respectable as well, going up to 70 mm/hr. It’s not quite as speedy as Prusa SL1S, but still above the average resin printer, as we mentioned with the Prusa.

This printer has a solid, all-metal construction, which practically eliminates vibrations and results in more predictable print quality. Thanks to the pre-calibrated build plate, you’re ready to print pretty much out of the box.

One word of warning, though. We found that the big print volume is also this machine’s Achilles’ heel. With the biggest prints, gravity starts becoming your enemy so you’ll need to dial in your settings very carefully.

But if you want highly detailed massive prints fast, you can’t do much better than this behemoth.

Pros

- Huge print volume

- Ultra-high detail quality

- Reasonably fast

- Quick setup

Cons

- Very expensive

- Using the entire print volume is challenging

- Very messy printing process

3D Printer Type: MSLA | Materials: 405nm UV Resins | Build Volume: 143 x 90 x 175 mm | Max Print Speed: 30-50 mm/h

Are you looking for an affordable yet still fast and precise resin printer that can print big objects?

The Elegoo Mars 3 Pro is your answer.

It uses a light source of a whopping 36 UV LED lights and a Fresnel lens to produce a 405 nm wavelength. This combination yields high-quality prints with a smooth surface finish that you’ll love staring at and showing off to people.

As some other printers already mentioned, it uses a 4K monochrome LCD. It’s a 6.66″ screen that comes with anti-scratch glass of 9H hardness.

It’s like a screen protector for your printer’s LCD, which is very handy in the event of a resin spill. That way, if some resin does end up being where it shouldn’t, you’ll only have to replace the glass and not the whole LCD.

The light source and glass protector are both new features from the Elegoo Saturn S and Saturn 2, so this truly makes the Mars 3 a “Pro” machine.

It’s got a large build volume of 143 x 90 x 175 mm and, being a robustly built and reliable machine, is perfect for round-the-clock printing. It comes with a carbon filter for resin fumes and odor, as well as a powerful and efficient cooling fan. However, we could still feel the remnants of some odors when printing.

Let’s talk software — the Mars 3 Pro can be used with Chitubox or Lychee Slicer 3.0. Both are viable choices of software. You have to pay extra for a Chitubox Pro subscription, though.

It prints with a pixel size of an amazing 35 microns and takes about 2.2 seconds to print a layer.

Pros

- Large build volume

- Affordable

- High-quality printing

Cons

- Carbon filter not 100% functional

- Have to pay extra for Chitubox Pro

3D Printer Type: MSLA | Materials: 405nm UV Resins | Build Volume: 143 x 89 x 165 mm | Max Print Speed: 50 mm/hr

Talk about a strong newcomer! Anycubic Photon Mono 2 hit the market just last month (in April 2023), yet it’s already proving itself to be a capable and affordable entry-level resin 3D printer.

The Photon Mono 2 packs a lot of detail into the prints. It’s not quite on par with Phrozen Sonic Mega 8K — but few printers are.

With a 4K+ resolution, you’ll still get very detailed prints. Anycubic’s “LighTurbo” system gives the quality an additional boost by smoothing out details. In practice, you’ll need a magnifying glass to see the difference between this machine and the Phrozen.

We really liked the oversized screen protector on the Photon Mono 2. It does a great job at keeping the LCD screen scratch-free and also makes cleaning the machine a breeze.

The Photon Mono 2’s print volume is about the same as the Elegoo’s, being only marginally smaller. It’s not massive but serves its purpose.

This printer comes with Anycubic’s custom Photon Workshop V3 slicer. This program used to be a pain, but it’s improved a lot since its earlier versions and works well. That’s a good thing, too, since Photon Mono 2 doesn’t yet have Lychee or Chitubox support.

The machine is pretty affordable, but you can, unfortunately, see it in the build quality. We thought the plastic construction feels pretty flimsy and cheap. That didn’t cause any wobbling or other issues that would’ve affected prints, though.

All in all, this is a great, reasonably priced machine for dipping your toes into 3D printing.

Pros

- Good print quality and detail

- Reasonably priced

- Easy to clean

Cons

- Build quality feels cheap

- No Lychee or Chitubox support (yet)

- Limited print volume

What is a Good Print Speed for 3D Printers?

A good print speed really depends on what you’re using your printer for, and it’s all about personal preference.

For a recreational printer that you’re just using for fun, realistically nothing’s wrong with 1 mm/s – it’s just going to take a lot of patience.

3D printer manufacturers know that we aren’t patient, so they upped that number a lot.

As you look around the market, you’ll find that a lot of commercial printers can hit 40-60 mm/s comfortably.

For a little more money, you can hit 100 mm/s on a commercial printer. The higher-end units will run around 150 mm/s.

Manufacturers suggest running at 60% of the max speed so you get a higher quality.

But how is quality related to speed?

Relationship Between Speed and Quality

Speed and quality seem to be related in every industry – if your mechanic is the fastest in the world, you’re going to be sitting on the side of the road a lot.

3D printers are the same in this sense, but for a technical reason.

The actual speed of a printer moving in a straight line doesn’t affect the print a ton. It’s the change in speed that does.

When you’re in a car and you stomp on the gas or brake pedal hard, your body will lurch. When a 3D printer suddenly accelerates or slows down, the same thing happens.

When the 3D printer lurches, the print quality suffers. You’ll get stringers, wobbly sections, fuzzy exterior walls, and an inconsistent build.

A ton of effort has to go into ramping the printer up to speed and decelerating it without hurting the print.

There are other reasons why the speed can hurt the quality of print.

Limiting Factors for Speed

Don’t let this list fool you, a majority of printers on the market are painstakingly slow in comparison.

So what slows down 3D printers? Let’s look at the answer in terms of FDM printers.

If you recall, FDM printers work by laying down hot plastic from an extruder head that moves on a 3-axis setup, driven by tiny motors. Every step of this process limits how fast you can print

Cooling the Plastic

The first thing that limits how fast you print is how long it takes the hot plastic to cool.

Since you’re building on top of previous layers, the first layer has to be solidified enough before adding the second layer.

Imagine you’re painting a wall, but you don’t wait for the primer to dry before applying the first coat of paint. The result is similar to 3D printers.

The layers will drag, deform, and might get caught on the extruder nozzle. In other words, your final print will be unrecognizable.

Tiny Motors Driving the Motion

If you want a 3D printer to be small, quiet, and inexpensive, you need tiny motors to run the operation.

- Check out our review of the smallest 3D printers here

This is fine because the extruder isn’t heavy either, so you don’t need a lot of power.

If you want the printer to move faster, you need bigger, heavier, stronger motors. This would call for a complete redesign of how 3D printers look, and the added weight would be a huge problem.

The tiny motors are another limiting factor to the speed.

3-Axis Setup

The 3-axis setup (or gantry) is the final big hurdle.

It’s tough to understand how this limits speed without a deep explanation, but it works for the same reason that trains run on a single track.

Single-axis motion is really easy to speed up and predict the outcome. When you add the y- and z-axes, things become more unpredictable, and more vibration affects the process.

Your 3D printer relies on predictability and few vibrations. That’s the secret sauce to get good quality on your final print.

That’s why the printers have to take it slow on a 3-axis gantry, so the final prints turn out good.

Let’s see what can be done to make 3D printing faster.

How to Make a 3D Printer Faster

3D printers can be faster by getting rid of the limiting factors described above.

- Get rid of the jerk associated with quickly getting up to speed and slowing down.

- Use materials that cool a lot quicker or don’t require cooling.

- Step away from the tiny motors used to drive 3-axis printers.

- Lastly, get rid of the 3-axis setup altogether.

The way printing companies achieve this is by getting away from FDM altogether. They’ll opt for SLA, GDP, or MJF technologies which eliminate one or all of these limiting factors for speed.

Unfortunately, the way to make a 3D printer faster is to get away from FDM printers and move to another technology of printer.

What Happens If You 3D Print Too Fast?

Although the printers on this list focus on fast printing speeds, you can have too much of a good thing. 3D printing too fast can cause multiple different printing flaws and issues.

We’ve touched on some of them above, but these points are worth repeating. Here are the most common issues you’re likely to with a too-high 3D printing speed:

- Layer Separation: As we mentioned, an excessive printing speed may not give previous printed layers enough time to solidify or cure. As a result, you may see layer separation or layer shifts in the final print.

- Loss of Detail: The faster the print head moves, the less time it has to accurately recreate the STL model’s details. Printing too fast can result in missing or deformed details.

- Ghosting: No, we’re not talking about your printer not replying to your texts. Ghosting or ringing is a print defect where the outer surfaces of the print appear ripply or wavy. It’s usually caused by vibration stemming from excessive printing speed (or a poor-quality printer).

- Under-Extrusion: An under-extruding FDM 3D printer has its printing speed set higher than the filament flow rate. As a result, the machine doesn’t have time to deposit material properly. As a result, your prints may have gaps and holes, shifted or entirely missing layers, and other similar printing flaws.

- Clogging: Some materials (looking at you here, TPU) are very sensitive to high-speed printing. Printing these materials can deform the extruded filament at the nozzle and clog it. Always check the ideal printing speed for your materials so you won’t have to desperately try and scrape nozzles clean.

Conclusion

Every 3D printer owner eventually feels the need for speed. All machines on this list can offer fast printing speeds, but they’re not made equal.

Consider what and and how fast you want to print to find the ideal balance between part quality, printer price, and printing speed. If you need a few more pointers, here are our recommendations:

- AnkerMake M5 is the best speedy FDM printer, hitting a sweet spot between speed, price, and print quality.

- FLSUN V400 gives you a lot of fast value for your buck — as long as you don’t mind the learning curve of a delta printer.

- Original Prusa SL1S is offers excellent (if pricey) fast, premium-quality resin printing.

- Bambu Lab X1-Carbon offers you the latest tech features and an wide material range on top of speed.

Related Articles: