- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Wood you care to take a look at some of the best wood 3D printers available? Well, you’re barking up the right tree! (Oh no.)

Wood you care to take a look at some of the best wood 3D printers available? Well, you’re barking up the right tree! (Oh no.)

Whether you want to print wood figurines, make wooden jewelry, or you aspire to live in a real life Minecraft — yew can finally branch out into these new projects.

We’ve picked out the top 5 wood 3D printers to choose from that’ll leaf you amazed. (That was acorny intro. Our sincerest apolotrees.)

Okay, we’ll cut out the wood puns now. Let’s get right into the top 5 wood 3D printers!

Build volume: 250 x 210 x 210 mm

Table of Contents

- Wood 3D Printers At A Glance

- What is Wood 3D Printing? (+ Tips for Great Prints!)

- Temperature Settings for 3D Printing Wood

- Advantages and Disadvantages of Wood 3D Printer

- Is Wood PLA Actually Wood?

- Is 3D Printed Wood Filament Strong?

- What Can You Make With Wood Filament?

- So Which Is The Best Wood 3D Printer?

Wood 3D Printers At A Glance

1. Prusa i3 MK3S+ (Best Choice)

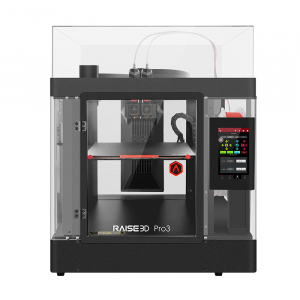

2. Raise3D Pro3 (Premium Choice)

3. MatterHackers Pulse XE (Best Value)

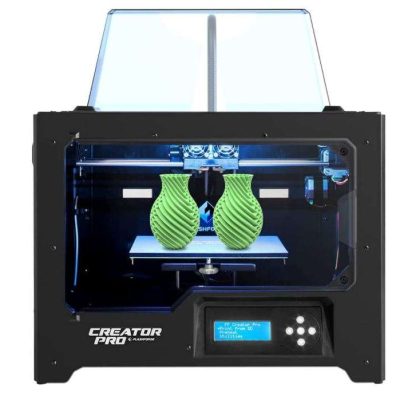

4. FlashForge Creator Pro (Best Wood 3D Printer for Beginners)

5. Creality Ender 3 S1 (Best Mid-Range Wood 3D Printer)

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon Filled & Woodfill | Build Volume: 250 x 210 x 210 mm

The Prusa i3 MK3S+ is, simply put, a top-notch 3D printer. Want to print something wooden? The Prusa’s got your bark. (I know I said I’d stop, but this was too good to resist.)

You can buy a pre-assembled version of the MK3S+, or you can buy a cheaper DIY version. If you’re new to 3D printing, don’t worry — Prusa is noted for its super thorough documentation that really guides new users through every step of the assembling and printing process.

With a 240W power supply, the print bed can consistently and evenly heat up to 100 degrees Celsius. This way, the filament will stick properly to the print bed, which is crucial to a successful print.

The MK3S+ comes with automatic bed leveling right out of the box. It also has a Stealth Mode setting for silent printing that enables you to become a 3D printing ninja.

And that’s not all.

Let’s talk software. The MK3S+ comes with PrusaSlicer, which is simply the best in its range. It has a mode for each skill level: beginner, advanced, and expert. It also comes with multi-material support if you plan on working with different filaments in the same print or printing with water-soluble supports.

If you want a great all-around printer for wood printing, and can either assemble it yourself or opt for the more expensive, assembled version, the Prusa i3 MKS3+ is your ideal choice and provides the best bang for your bark. (WHY????)

Pros

- Automatic bed leveling

- Powerful and intuitive software

- Evenly and properly heated print bed

- Amazing documentation

Cons

- Pricey assembled version

- No touchscreen

3D Printer Type: FDM | Materials: PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon, Glass Fiber Infused, Carbon Fiber Infused, Metal Fill & Wood Fill | Build Volume: 300 x 300 x 300 mm

Production. That’s the purpose of this printer summed up in one word. If you want to make rapid prototypes or have your own wood manufacturing factory at home — or just print really big builds — enter the Raise3D Pro3.

It’s a big 3D printer that comes with a dual extruder and a gigantic build plate at 300 x 300 x 300 mm. The most notable thing about this printer is the reliably amazing output. You can always count on a print turning out good with the Raise3D Pro 3.

Some printers you need to constantly tweak or adjust to make sure you’re getting the best settings — but the Raise3D Pro3 prints amazingly right out of the box. It can flawlessly handle overhangs and print at layer thicknesses of 25 down to 10 microns. It also can print at up to a crazy fast 150 mm/s — that’s what we mean when we say this printer’s purpose is production.

The Pro3 comes with an abrasion-resistant nozzle, which is GREAT for wood — as well as another nozzle suited for PLA. Abrasive filaments can often be a pain in the metaphorical 3D printing backside, so it was great that Raise3D addressed this issue.

Like its predecessor, the Pro 2, the Pro 3 has an HD camera for cool 3D printing time-lapses and monitoring the print — as well as a HEPA air filter to ensure a clean 3D printing process. It also comes with significant improvements from the Pro 2 such as a more stable bottom design.

So if you want a 3D printer for production or large prints, the Raise3D Pro3 is your printer.

Pros

- Robust and stable build

- Consistently high-quality prints

- 10 microns layer thickness

Cons

- Expensive

3D Printer Type: FDM | Materials: PVA, PLA, ABS, Nylon, Bronze PLA, Brass PLA, Wood PLA, Copper PLA, TPU, PETG, Carbon Fiber, Fiberglass, Aluminum PLA, Magnetic Iron PLA, ColorFabb XT CF20 (PET-G), CopperFill, BronzeFill, WoodFill, CorkFillr, Flexfill 98A TPU, PLA 3D870 (APLA) | Build Volume: 250 x 220 x 215 mm

Based on the Prusa i3 MKS3+, the MatterHackers Pulse XE is a solid, stable, and robustly built printer that was made for difficult filaments.

MatterHackers, being a company that resells 3D printers, had key insights into what customers wanted in their printers. So, the Pulse XE is their effort to put all that feedback into one printer.

Here’s the thing about the Pulse XE: Every component is really darn solid. It is as premium as you can get, using higher-end parts to ensure that it works super smoothly.

It comes with the Olsson Ruby which is literally a tiny ruby embedded in the tip of the Pulse XE’s nozzle. Wow. The ruby helps the nozzle resist abrasive and difficult materials i.e. wood

We’ve got a decent build volume of 250 x 220 x 215 mm, which is more than enough for hobbyists and people making smaller to medium-sized parts. And it can print at a resolution of 20 microns. Due to its lateral-bed design, its speed can only go up to 60 mm/s — pretty good, but lower than what some similar printers are offering.

The Pulse XE is ideal if you want a specialized printer to work not just with wood but other difficult filaments. If high quality — in your printer and your prints — is your priority, this printer is for you.

Pros

- Automatic bed leveling

- Solid printer build and high-quality parts

- Prints well right out of the box with no need for tweaking settings or upgrading the printer

- Comes with a magnetic removable build plate

Cons

- Expensive

- Not as fast as other printers in its range

3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU95A | Build Volume: 227 x 148 x 150 mm

New to 3D printing and want to print a bunch of wood stuff? Consider the FlashForge Creator Pro.

It’s an enclosed printer — points to Flashforge for safety and cleanliness. Enclosures are also really handy for keeping a nice ambient temperature inside the printer, which can help your print turn out better. It also protects your print from the outside air and random gusts of wind that might just blow your half-finished Groot figurine out of the window and right into your neighbor’s Thanksgiving dinner.

It comes fully assembled and has a dual extruder — maybe a bit ambitious for a beginner, but still, a handy feature to get into once you’re a bit more experienced with the ins and outs of 3D printing.

With a speed of up to 100 mm/s and a build volume of 225 x 145 x 150 mm, you can print objects relatively fast and you’ve got ample space to do it.

The Pro can print at resolutions from 100 up to 500 microns. Keep in mind that with this printer, smaller objects can sometimes have imperfections. The Pro is ideal for a beginner to print medium to larger-sized objects — if you want tiny objects with high-res detail, this probably isn’t the printer for you.

Pros

- Has an enclosure

- Comes fully assembled

- Dual extrusion

- Beginner-friendly

Cons

- Doesn’t have Wifi connectivity without an SD card

- Not ideal for super high-quality small objects

3D Printer Type: FDM | Materials: PLA, ABS, PVA, Wood, TPU, PETG, and PA | Build Volume: 220 x 220 x 270 mm

The newly released Creality Ender 3 S1 Pro is a mid-range, super capable printer with spectacular print quality similar to that of the Prusa i3 MK3S+ at almost half the price. It requires minimal assembly and is an upgrade of the Creality Ender 3 S1.

This printer is the one to get if you want top-quality and ease of use at an affordable price. It can print standard as well as engineering-grade filaments — so printing with wood filament is a piece of cake with this printer.

A big advantage of the Pro is its direct extruder arrangement — it makes loading filament easier, as well as allows you to print with more flexible filaments.

There’s also a fully metal hot-end that can reach up to 300 degrees Celsius, which, aside from being quite toasty, also enables you to print with just about any common filament out there. And this high-temperature hot end greatly decreases the risk of a clogged or jammed nozzle — which is a common problem with wood filament.

It also has a magnetic print bed which is resistant to higher temperatures, so that’s a pretty neat addition as well to extend the life of the print bed.

Now, the Pro supposedly offers silent printing but unfortunately, it is anything but and likes to do the printing version of singing which is a whole lot of fan noise. If that’s something you absolutely cannot accept, it probably will be a dealbreaker for you. All in all, this printer is great if you are on a budget and want the capabilities of a higher-end printer and don’t mind the printing noise.

Pros

- Automatic bed leveling

- Magnetic print bed resists higher temperatures

- Direct extruder arrangement for better extrusion

- PEI Spring Steel build plate

Cons

- Noisy

What is Wood 3D Printing? (+ Tips for Great Prints!)

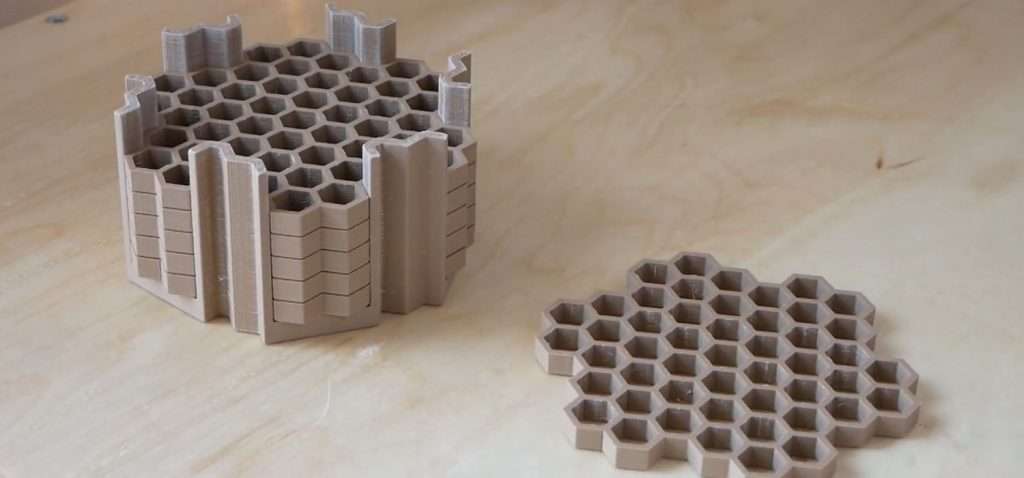

Wood 3D printing is when you use wood filament to print wood-like models. You can get wood filament for different types of trees, like birch, bamboo, and ebony, which is awesome.

When you’re printing wood, things are a bit different than with PLA. For starters, a nozzle of 0.5mm or more would be ideal to avoid jamming or clogging.

It’s generally a good idea to leave your print on fast speed, as well as use thicker layers — you don’t need super small layer thicknesses when it comes to 3D printing wood filament and can just go ahead and sand the layer lines out of your print when it’s done.

Printing fast with thicker layer thickness also makes sure your wood filament doesn’t stay too long in the hot end, which could be risky and burn the filament — and that’s a whole headache you don’t want to deal with, trust me.

Here’s a cool fact — when you are done printing, you can smooth the surface of your wood filament 3D print with sandpaper just like with real wood! Also, for an extra pretty look, you can apply lacquer to get that nice polished wooden surface finish.

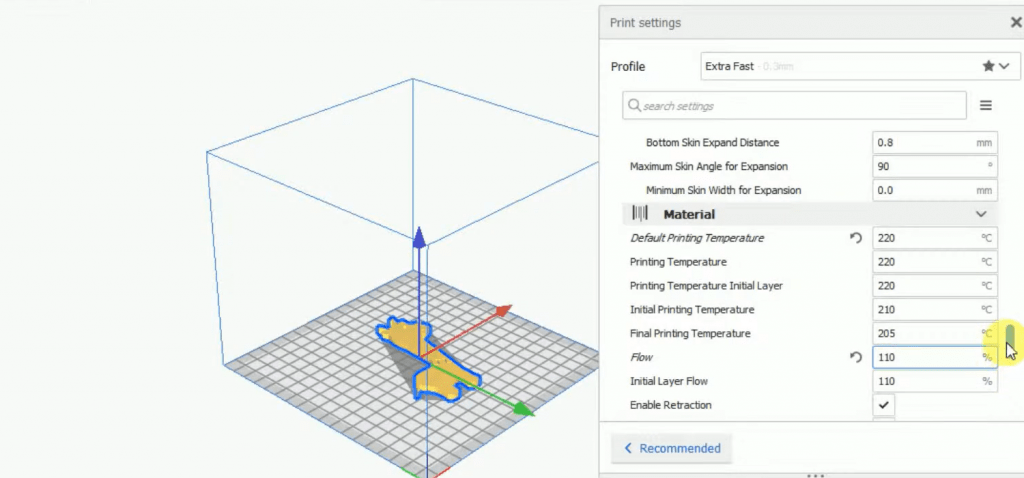

Temperature Settings for 3D Printing Wood

When it comes to temperature settings when printing wood, your printer’s hot end should be at about 170 up to 220°C depending on the filament. You can also set your print bed temperature to around 50 to 70°C. It is also recommended that your cooling fan should be on while printing wood filament.

A neat little fact about wood printing is that you can print at different temperatures for different shades of wood — the higher the temp, the darker your wood will go. So you can experiment with that if it’s something that strikes your fancy, but always be careful that the filament doesn’t burn in the nozzle or that your temperature goes higher than recommended.

Advantages and Disadvantages of Wood 3D Printer

Wood printing can be a, let’s just say, flaky process. (Get it? Like wood flakes? This is the last one, I promise.) Let’s go through the advantages and disadvantages of wood 3D printing.

First of all, it’s so much easier than woodworking and making things by hand — it’s like having a wood manufacturing plant right there on your desk.

Second, wood filament is highly resistant to rot, much unlike real wood. It smells and looks lovely — and after some post-processing, it can look just like the real thing.

However, wood filament does not have the same strength as wood — and because it’s a mix of wood fiber and PLA, its adhesion is much weaker than that of PLA and wood is notorious for not sticking to the build plate. So when you’re printing with wood it’s definitely a good idea to use an adhesive like glue or hairspray to make sure it’ll stick to the build plate.

It also can jam or clog smaller nozzles, so that’s something to keep in mind if you want to get started with this type of printing.

Is Wood PLA Actually Wood?

Yes and no. Here’s how the wood filament is made: wood actually gets ground down to a fine powder and then mixed with PLA to make a filament. Most wood filaments are about 70% PLA and 30% wood fiber.

Manufacturing wood PLA filament is a relatively more environmentally-friendly process than plastic filament as it uses natural wood fiber. You might ask why they don’t put more wood fiber, but there has to be a balance between the wood fiber and the PLA — otherwise it wouldn’t be an extrudable substance, which it needs to be when it comes to 3D printers.

We’ll go down a bit of a tangent here, but it’s one worth discussing. Those of you who are more environmentally conscious may point out that there’s a whole lot of wood waste out there. Instead of cutting down new trees, we could use that same wood waste and turn it into filament.

It’s like two birds with one stone.

That’s actually what happened at Michigan Technology University in 2018 where scientists got a whole bunch of furniture wood waste and then used it to make a wood filament for 3D printers. Pretty cool. We think it’s quite a commendable idea to use wood waste to basically regenerate trees and give them a new life with 3D printers, which can often not be the most environmentally-friendly process.

Is 3D Printed Wood Filament Strong?

No. 3D printed wood filament is typically more delicate and brittle than PLA and can often break if you’re not careful with it. It also has inferior layer adhesion than PLA because of the added wood fiber.

Point is, the main use of wood filament is for its aesthetics rather than functionality — it doesn’t have the same mechanical and tensile properties as real wood does, but does look like it on a surface level.

What Can You Make With Wood Filament?

If you’re feeling stumped, here are some great ideas for what you can print with wood filament.

If you play chess, a neat little project would be to 3D print your own chess pieces with wood filament for a really nice and polished-looking chess set.

You can also, at your own caution, experiment with higher temperatures (as long as they fall within the recommended range) to darken your wood filament to resemble darker woods.

Now the obvious options, you can print baby Groot from Guardians of the Galaxy or perhaps a Groot bust or statue if your printer is big enough.

If you’re so inclined, you can 3D print models of benches and tables and make your own cute little 3D printed wooden house!

There’s also the Elder Wand from Harry Potter, or perhaps you can design your own wand and print that. The possibilities are infinite with this filament.

So Which Is The Best Wood 3D Printer?

The Prusa i3 MKS3+ is a great all-around printer for printing wood if it works for your budget. It’s a solid printer that so many other printers are based on, and for good reason. It’s highly consistent in print quality, it’s got a really put-together design, and the price tag is definitely worth it.

If you’re looking for something more affordable, the Creality Ender 3 S1 Pro is a solid option that makes some amazing quality prints. Do consider that it can get noisy at times — otherwise, this is a great printer on a budget.

The Flashforge Creator Pro is a great little printer for beginners and it’s enclosed, which is great if you’ve got kids or pets. It’s also not the best on this list in terms of printing quality, but for a beginner, it should be great to learn the ropes with.

The MatterHackers Pulse XE is definitely our premium choice when it comes to wood printing. It’s fitted out with the best high-end parts to ensure flawless printing, and its main purpose is to tackle tricky filaments. It’s got parts to prevent any problems with wood printing, so if you can afford it and want something really high-end, the Pulse XE Is for you.

If you want a big printer and can afford the subsequently big price tag, the Raise3D Pro3 is what you need. It’s got a fast printing speed and consistently spectacular printing quality, and its robust design is built to not let you down.