- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Hey makers! We’re going to be taking a look at some of the best wood CNC machines out there.

Hey makers! We’re going to be taking a look at some of the best wood CNC machines out there.

Using the right router, you can create anything with wood beautifully and accurately. But if you use a low-quality CNC router, you’re better off throwing that thing in the trash and using an ordinary table saw instead.

No one wants subpar designs or the headache of figuring out what in the holy macaroni is wrong with your CNC router.

In this article, we’ll review 5 brands thoroughly tried and tested by our team of experts, so you’ll know exactly what the machine is like.

No need to spend your hard-earned money on a piece of junk that’ll never be worth it.

So, let’s get right into it!

Best Wood CNC Machines At A Glance

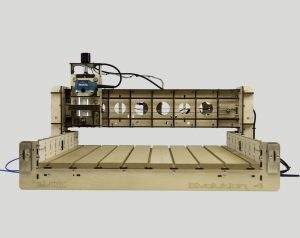

1. BobsCNC Evolution 4 (Best Choice)

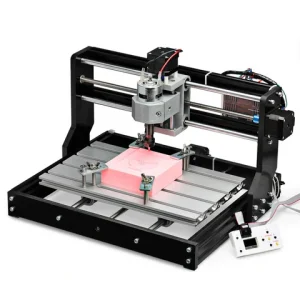

2. Genmitsu CNC 3018 Pro (Best Value)

3. Inventables X-Carve 1000mm (Premium Choice)

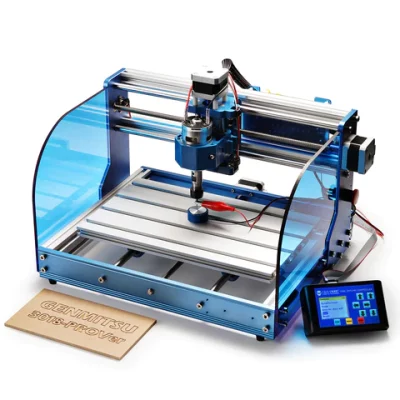

4. SainSmart Genmitsu 3018-PROVer Deskstop (Best Entry Level)

5. Genmitsu CNC Router Machine PROVerXL 4030 (The PROVer But Bigger)

Cutting Area: 610 x 610 x 85 mm | Materials: Wood, Plastics, Foam, Leather, PCB & Acrylic (Non-Metals)

Bob’s your uncle! Well, not exactly… he’s one of the founders of BobsCNC, and this router is one of THE BEST they have to offer. And if you’re already familiar with and don’t mind a bit of DIY, this router is perfect for your next wood-making project.

This machine offers impressive repeatability in the range of 0.1 to 0.05 mm — this means anything you build more than once will come out consistently near-identical.

This is essential if you’re looking for a machine, particularly for production.

The Evolution 4 can be configured with one of two spindle options. You can go for the DeWalt 611 with an RPM ranging from 16k to 27k. Alternatively, you have the Makita RT0701C from 10k to 30k.

It has a workspace of 610 x 610 x 85 mm — plenty of space for larger projects.

And here’s something reassuring to know in this age of abysmal Amazon reviews and horror stories: BobsCNC is well-known for its excellent customer service. And they’ve also set a standard for thorough and clear documentation — something greatly appreciated by their community of users.

Unfortunately, with this router, there is no offline control which means you can’t man the tool head yourself without a working computer.

Also, this machine comes fully unassembled, so if you’re new to CNC machines, it might be better to get a partially assembled router like the Genmitsu CNC PROVer 3018.

Pros

- Great repeatability

- Good documentation and customer service

- Ample workspace

Cons

- No offline control

Cutting Area: 300 x 180 x 45 mm | Materials: Plastic, Soft Aluminum, Wood, Acrylic, PVC & PCB

The Genmitsu CNC 3018 Pro is a consistent favorite amongst makers — and for a good reason. It’s a sturdy, well-built CNC router that you can make stuff out of wood with. And all at a super budget-friendly price tag.

Not just wood, though —it also supports acrylic, PVC, and even aluminum.

This router has a workspace of 300 x 180 x 45 mm — perfectly adequate for smaller applications.

Here’s an exciting thing: unlike many other CNC machines, the Genmitsu CNC 3018 Pro uses a 775 rather than a stepper motor. 775 motors can often reach higher speeds than the latter.

In fact, this particular motor can reach about 9000 RPM, which is pretty good for cutting into the materials mentioned above.

Now for those open-source nuts out there (we get it, you use Linux!), you’ll be pleased to know that the Genmitsu 3018 Pro comes with open-source hardware and software. This means you can add nearly any upgrades you want. You can even turn this machine into a laser engraver with the SainSmart laser engraving module!

This machine comes unassembled but takes around an hour to assemble.

Pros

- Great upgradability

- Fast motor

- Very affordable

Cons

- Smaller cutting area

Cutting Area: 750 x 750 x 65 mm | Materials: Hardwood, Softwood, MDF, Plywood, Plastics, PCB & Non-Ferrous Metals

Looking for a CNC router that you can always upgrade? Look no further than the Inventables X-Carve.

The X-Carve has a workspace of a whopping 750 x 750 x 65mm — and it’s unlikely that you’ll need much more than that.

The USP of this router is its flexibility. You can use it in its default state, or you can install any number of upgrades you want. This is because, like the Genmitsu PROVer routers, this router is open source. This is the perfect machine for DIYers and tinkerers.

Inventables offers a web app called Easel for basic controls, but if you’re a small business that requires more advanced features, you need to pay a monthly fee for the software.

The X-Carve features NEMA 23 stepper motors along the X, Y, and Z axes for very precise cutting.

This scalable router can work for individual hobbyists and businesses as they grow. When your operation gets bigger, there’s no need for a new machine! Just some upgrades if necessary, which Inventables sells in a different kit.

In its default configuration, it comes with a DeWalt 611 spindle which can use ⅛” and ¼” carving bits.

Under the workspace, a wasteboard is provided for additional protection and to prevent any damage from the spindle.

Pros

- Large working area for bigger projects

- Super upgradable and flexible

- Comes with a wasteboard for protection

Cons

- Need to pay monthly for more advanced software

Cutting Area: 260 x 155 x 35 mm | Materials: Wood, Acrylic, Bakelite, Plywoods, MDF, Polycarbonate & PCB-Making Boards

With a workspace of 260 x 155 x 35 mm, the Genmitsu 3018 PROVer is an excellent desktop CNC router for newcomers.

It comes semi-assembled, so this takes away from the challenge of having to assemble it yourself.

The 3018 PROVer sports an all-aluminum frame, as well as two acrylic panels for safety purposes. This keeps dust and wood bits from flying into your face. It also comes with a partial enclosure of sorts, which is great for a home environment.

This machine comes with quiet and powerful Toshiba TB6S109 drivers — making it doubly suitable for use at home. Hey, this router doesn’t just cut down on wood but noise too!

It also has a 1.8” touchscreen for offline control, which means you don’t always need to hook it up to a computer and can control the tool head yourself if need be (for example, in case of a power outage).

And just like the Genmitsu 3010 Pro, the PROVer can be upgraded with a laser engraver if you’d like to have that module available.

We weren’t super impressed with the documentation, as some essential details in setting up the carving machine were left out. Thankfully the Genmitsu user base has a lot of material and support to fill in the gaps.

Also, the workspace is a bit small, so if you want to carve bigger, go for the Genmitsu PROVerXL 4030.

Pros

- Affordable

- Great for home use

- Beginner friendly

Cons

- Workspace on the smaller side

- Documentation could be more thorough

Cutting Area: 400 x 400 x 110 mm | Materials: Wood, MDF, Plastics, Foams, Vinyl & Aluminum

“I’ll have a McPROVer, but make that a Large.”

This CNC router, also by Genmitsu, is a bigger version of the PROVer 3018, hence the XL. The “4030” is in reference to the size of its workspace, a decent-sized 400x300x110mm.

This bulky chap comes with a 300W spindle that’s resistant to overheating. And it can reach speeds of 12,000 RPM. Wow!

This yields a pretty impressive cutting speed of 2000 mm/min. So if you want to make larger stuff fast, this router can come in handy.

With an additional aluminum mount, this router is also compatible with the DeWalt 611 spindle, which is suitable for cutting harder materials.

It comes partially assembled, just like the PROVer.

One downside to this router is that offline control currently doesn’t come with the kit — however, it can be purchased separately.

Pros

- Upgraded workspace

- High-speed heat-resistant spindle

Cons

- No offline control included

What is a CNC Machine?

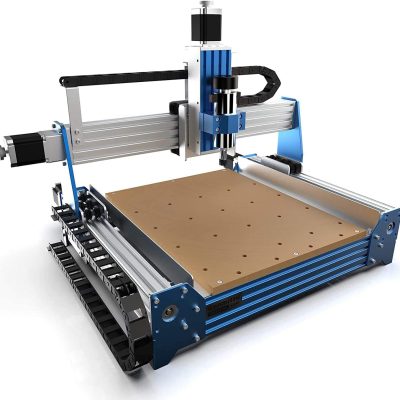

Computer numerical control (CNC) is a method of subtractive manufacturing that uses a spindle to cut or carve into the material to get the finished product. Here’s an ELI5: it’s an automated sculptor.

A CNC router uses pre-programmed computer code which controls and determines its movements to create an object, carving, engraving, etc.

How Does a Wood CNC Machine Work?

A wood CNC router works by using CNC controller electronics along with certain software to control a mechanical system.

Most wood CNC routers can move and cut in the X, Y, and Z axes — therefore, in three directions.

Parts of a Wood CNC System

The CNC controller works with the machine’s computer system to tell the motors how and where to move.

How does that work?

Well, the computer is fed some code — and that’s where you, the human, come in.

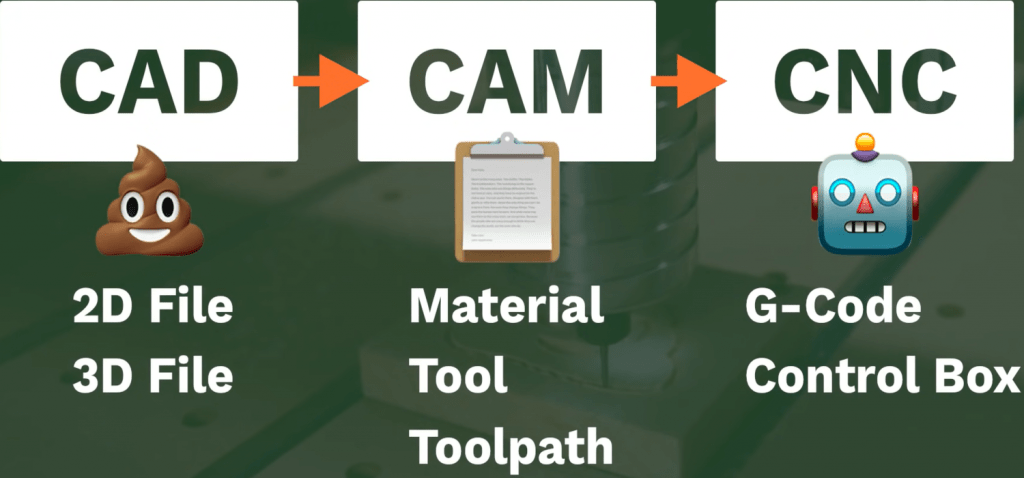

You see, this is where CNCs and 3D printers differ in feeding the design to the machine.

With 3D printers, your printer can generally print your design straight from the CAD file. But this is not the case when it comes to CNC routers. So before you try and force feed your machine some CAD it doesn’t want to compute, let’s look at how we can make our designs more palatable for CNC’s taste buds.

So, say you’ve designed a lovely wooden clock in your CAD program. Great! Now all you have to do is use the CAM and CNC controller software that have been provided to you.

These programs convert a 3D or 2D digital image into, most often, G-code — which the CNC understands and is more than willing to gobble up. And then, the parts of the CNC router will move by the code to create your desired design.

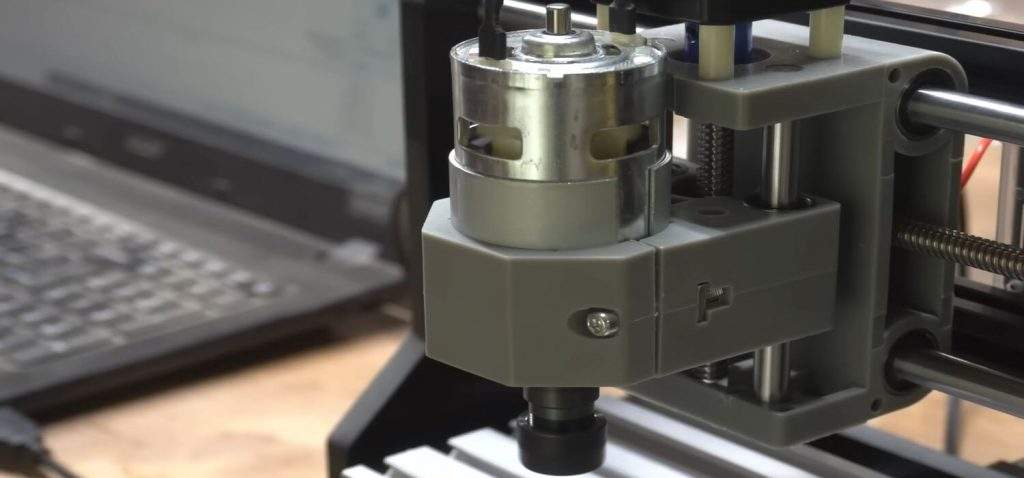

The Spindle

The spindle is what cuts and carves the material to make your design come to life.

How does the spindle work? It rotates a tool — often router bits (like a drill bit but for a router) — to cut the material.

The speed of the spindle depends on the material to be cut. Most spindles designed to cut wood fall in the range of 8k to 30k RPM.

Most CNC wood routers are capable of cutting aluminum as well!

The Cutting Bed

The cutting bed is where the cutting and carving take place. It is analogous to the build plate of a 3D printer — but where the printer builds the CNC router cuts.

The cutting bed is designed to support and secure the piece of material being cut. Some cutting beds use bolts and clamps to secure the material to the bed.

Other types are more suited to flat sheets of material that do not require clamping.

Motors

There are two main types of motors that CNC machines can use — stepper motors and servo motors.

Stepper motors are usually cheaper. They offer reliable and decent performance. However, what separates them from servo motors is the absence of a closed-loop system.

Servo motors can work in a closed-loop system. This means that once they receive directions from the CNC controller, they send a signal back to the controller that confirms they have finished the necessary action.

The motors turn the linear drive system, which moves the spindles to cut the material.

CNC Machine Advantages and Disadvantages

Advantages

Simply put, if you’re making stuff, CNC machines can be a blessing.

You can make super accurate and sturdy things, and there are endless possibilities of projects to take on.

Also, it’s much safer than traditional woodworking, which can be dangerous without proper equipment and precautions.

CNC routers can be used almost continuously unless they need to be repaired. And the repeatability they offer is perfect for manufacturing — everything you make on a CNC machine looks nearly identical.

Manually operated machines can be a pain in the backside, whereas you don’t need special training to use a CNC.

And usually, those machines are not capable of making elaborate designs, whereas a CNC, which is controlled by a computer, can pull those off pretty easily.

Disadvantages

However, there are a few disadvantages to CNC machines. Unlike 3D printing, CNC routers can create a lot of waste. Another disadvantage is that CNC routers can be expensive to maintain and repair, unlike traditional mills and lathes, which don’t cost as much.

So Which Is the Best Wood CNC Router?

If you’re looking for a budget-friendly CNC router that doesn’t sacrifice any quality or features, the Genmitsu 3018 Pro is the wood CNC machine for you.

Want a CNC router you always have the flexibility to upgrade if required? Look no further than the Inventables X-Carve.

If you’re a beginner, the Genmitsu 3018 PROVer is a great first wood CNC router that’s easy to assemble and start using at a low price tag.

If you want a bigger version of the PROVer, the PROVer XL 4030 is precisely that.

And if you want our best choice for a wood CNC router, it’s BobsCNC Evolution 4.