- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

Stringing on prints? Problems printing flexible filaments? It’s not you, it’s your extruder…probably!

Stringing on prints? Problems printing flexible filaments? It’s not you, it’s your extruder…probably!

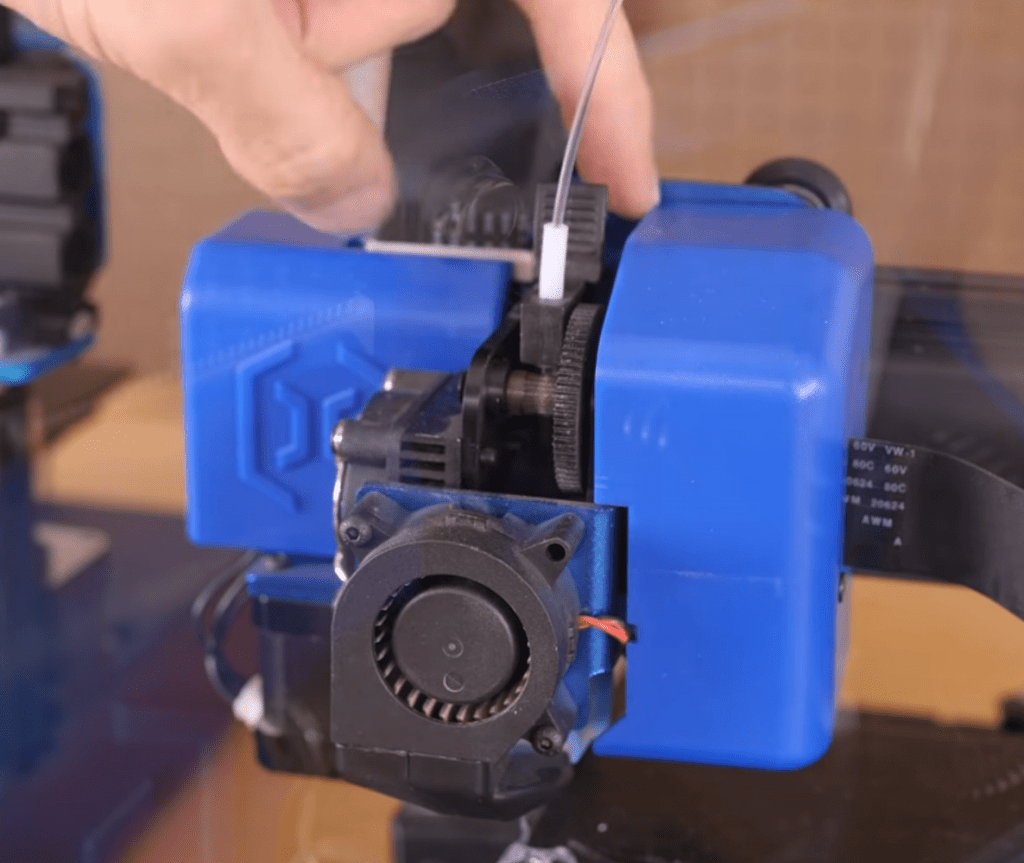

On 3D printers, there are two main types of extrusion systems that allow the printer to push filament through the melting sector (hot end): Bowden drive and direct drive. Most 3D printers have a Bowden drive extruder as this system is less expensive. However, direct drive extruders are a much better option.

The difference between the two extrusion systems is that a Bowden drive places the extruder motor separated from the hot end, where the filament melts. Filament is pushed from the extruder to the hot end through a PTFE tube, also known as a Bowden tube. On the other hand, a direct drive extruder puts the extruder directly (get it?) above the hot end, yielding less stringing, allowing you to print flexible filaments like TPU and other benefits.

Build Volume: 300 x 300 x 400 mm

Build Volume: 250 x 210 x 210 mm

Table of Contents

- Best Direct Drive 3D Printers At A Glance

- 1. Prusa i3 MK3S+ (best Overall)

- 2. Qidi Tech X-Max (Premium Choice)

- 3. Creality CR-10 V3 (Best Value)

- 4. Creality Ender 3 S1

- 5. Flashforge Creator Pro

- 6. Artillery Sidewinder X2

- Difference Between Direct Drive and Bowden Extruder

- What are the Benefits of a Direct Drive Extruder?

- Conclusion

So, if you’re looking for a new 3D printer that has a direct drive extruder, let us help you out in your hunt. Below, we’ve gone over a few of the top direct drive 3D printers on the market! Whether you’re on a budget, need to print high-temperature materials, or just want a good overall direct drive printer, we’ve got the printer for you!

Best Direct Drive 3D Printers At A Glance

1. Prusa i3 MK3S+ (Best Overall)

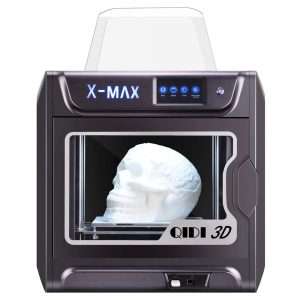

2. Qidi Tech X-Max (Premium Choice)

3. Creality CR-10 V3 (Best Value)

4. Creality Ender 3 S1

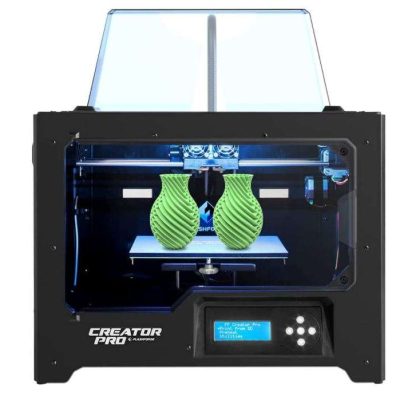

5. Flashforge Creator Pro

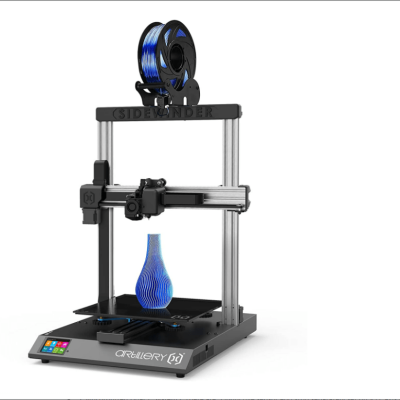

6. Artillery Sidewinder X2

3D Printer Type: FDM | Materials: PLA, PETG, ASA, ABS, PC, HIPS, Flex, Nylon, Carbon filled & Woodfill | Build Volume: 250 x 210 x 210 mm

There are many 3D printer manufacturers, but none are as revered or respected as Prusa Research, the developers of the Prusa i3 MK3S+. While its name doesn’t exactly roll off the tongue, the Prusa i3 MK3S+ is known for its reliability and premium print quality due to the use of high-quality components that almost never fail.

Most importantly, the MK3S+ features a BMG direct drive extruder manufactured by the 3D printing accessory company, Bondtech. Due to its 3:1 gear ratio, the BMG can push and pull filament through the hot end very forcefully, reducing stringing and under-extrusion in prints. Its dual-drive gears and direct drive placement make printing flexible filaments a breeze!

The extruder isn’t where the fun stops for the Prusa i3 MK3S+, though, as Prusa Research has poured a lot of effort into the electronics. The MK3S+ uses a 32-bit motherboard equipped with an ultra-fast processor chip to provide a smooth operating experience for the graphical user interface on the printer’s full-color LCD. The board also has a port for a filament runout sensor located by the printer’s extruder and ensures that the extruder is always receiving filament, allowing you to finish off almost-empty spools without worrying.

The firmware on the printer runs on the motherboard and is a fork of the popular Marlin firmware program, optimized for the MK3S+ by Prusa Research. The firmware supports Prusa’s silent printing mode, which uses the motherboard’s Trinamic stepper motor drivers to quiet the motors, so the printer isn’t a distraction. The firmware also has a power loss recovery feature, so, in the event of an electricity outage mid-print, your printer will resume printing once power is restored.

On a similar note, the MK3S+ has a spring-steel build plate that provides excellent first-layer adhesion due to its PEI coating. And once a print is complete, you can remove the magnetic and flexible bed, bend it, and pop your model will pop off!

With a powerful extruder and a lot of thought put into the other features, like electronics and build plate, the Prusa i3 MK3S+ is a no-brainer choice for the best overall direct drive printer!

Pros

- Powerful direct drive extruder

- Automatic bed leveling sensor

- High-quality parts used for all features

- Excellent motherboard with a fast processor

- Filament runout sensor

- Great PEI build plate

- Smooth axis motion

- Large and active community (e.g. Reddit, PrusaPrinters Forum)

Cons

- Slightly more expensive than some lower-quality options

- Assembly required for the kit version

- No built-in enclosure for printing ABS

3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 300 x 250 x 300 mm

If you have a little bit more dough to spare and are looking to print large models, then you should consider the Qidi Tech X-Max. From the labs at Qidi Technology, the X-Max boasts a large build volume of 300 x 250 x 300 mm. With this much space, you can print all your favorite Thingiverse models, from a full set of T-Rex bones to cosplay accessories.

The X-Max is more than just a printer with a large print space, and it can also print with a wide range of filaments. Moreover, the printer has an enclosed frame that traps heat around the build space, creating the optimal environment for printing temperature-sensitive materials like ABS and ASA. Of course, you’ll need a powerful hot end to support these materials too, and the Qidi Tech X-Max’s nozzle can reach temperatures as high as 260°C, more than enough for most filaments.

Of course, the printer has a direct drive extruder printhead, but Qidi Tech did things a bit differently than other 3D printing companies. The X-Max has a swappable printhead system that you can use to switch from the printhead best for PLA, ABS, and TPU to the additional printhead included that’s best for printing Nylon, carbon fiber, and polycarbonate filaments. Of course, both printhead assemblies have a replicated direct drive extruder configuration with a quick-release lever for fast filament swaps.

The X-Max comes fully assembled and also has a removable build plate, very similar to a spring-steel bed. The X-Max’s bed attaches to the frame magnetically, and you can bend it without any permanent damage to remove prints quickly.

The Qidi Tech X-Max’s substantial build volume, integrated enclosure, and swappable extruder system make the perfect printer for creating prototypes and large models in basically any material you want.

Pros

- Swappable printheads for printing different materials

- Large print volume for printing huge models and prototypes

- Magnetic and flexible print bed for removing models easily

- Enclosed print space for printing high-temperature materials like ABS

Cons

- Expensive compared to lower-quality printers

- Swappable printheads expose the messy wiring of the hot end

- Nozzle may not be able to reach optimal printing temperature for PC

3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU95A | Build Volume: 300 x 300 x 400 mm

Creality is not a name to ignore in the 3D printing industry, and they have some of the best consumer-grade 3D printers under their belt. Like the X-Max we talked about above, the CR-10 V3 also has an ample build space, with a volume of 300 x 300 x 400 mm. With such a large build volume, you might expect the printer’s frame to be a bit unstable, but Creality solved this issue by including support rods that hold the printer’s frame firmly in its position.

Unlike Creality’s other printers, which typically have Bowden extruders, the CR-10 V3 uses a Creality-made direct drive titan extruder. The extruder was designed after E3D’s original Titan extruder and has a beefy stepper motor geared 3:1 against the drive gear for powerful extrusion. With the direct extruder configuration, you’ll experience less stringing than with Bowden extruders, and you’ll also be able to print flexibles more easily.

As indicated by the name, the CR-10 V3 is Creality’s third version of their original CR-10 printer, and there have been a few upgrades, such as the enhanced motherboard. The V3’s motherboard is considered Creality’s silent board, and it has TMC2208 stepper motor drivers that will quiet the motors on the printer for noise suppression.

The motherboard also has a few more ports than the first-version motherboards, which is how the BLTouch sensor onboard the CR-10 V3’s printhead is connected. This popular choice for a bed leveling sensor takes super accurate measurements from the nozzle to the printing surface to achieve a consistently high-quality first layer. Also available on this board are extra fan ports, which Creality makes use of with the dual cooling fans on the V3 that cool filament as it flows out of the nozzle, so prints don’t droop.

Of course, as with any printer, the build plate is also important, and the CR-10 V3 comes with a standard Creality tempered glass bed. While it might not be flexible, its smooth but slightly-textured surface is absolutely spectacular when it comes to first layer adhesion. And, as soon as the heated bed cools down after a print, parts just pop off due to the miniscule highs and lows on the glass, making part removal nothing to worry about.

When it comes to printing large, the Creality CR-10 V3 does a good job. However, the printer offers more than that, and its Titan direct drive extruder, auto bed leveling sensor, cooling fans, and glass build plate make the machine capable of high-quality prints with a lot of detail.

Pros

- Powerful Titan extruder with 3:1 gear ratio and dual-drive gears

- Multiple cooling fans for proper part cooling

- Textured glass bed for easy first layer adhesion

- Silent mainboard for quiet printing

- Large build volume for printing large models

- Stable frame design for safety

- Filament runout sensor for detecting filament outages

Cons

- Large and heavy printhead assembly

- No automatic bed leveling sensor

3D Printer Type: FDM | Materials: PLA, TPU, PETG & ABS | Build Volume: 220 x 220 x 270 mm

If you’re into 3D printing in the slightest, we’ll bet you’ve heard of the Creality Ender 3, one of the pioneers in the consumer 3D printing industry. Now, imagine if all of the Ender 3’s minor issues, like loose gantry belts, manual bed leveling, and Bowden drive extruder, were solved. Well, you’re looking at the Creality Ender 3 S1, where the “S” probably stands for suped-up because the S1 has got it all.

On this version of the Ender 3, Creality strayed from their typical approach of manual leveling and added an automatic bed leveling sensor, known as the CR-Touch. The CR-Touch is really just a copy of the BLTouch, with a similar low-profile frame that doesn’t take up much space and fantastic accuracy and repeatability that will yield a great first layer of every print. The printer also has a filament runout sensor right below the filament spool, so you can rest easy knowing that if your filament were to run out or break, the printer will pause until a new filament is inserted.

The direct drive extruder is another new feature to the Ender 3 series, and the S1 has Creality’s newly developed Sprite extruder. The Sprite is a direct drive extruder that uses a dual-drive mechanism to better push filament through the hot end, and there’s a release arm for quick filament changes. Despite its powerful extrusion capabilities that allow you to print traditional (e.g. PLA) and advanced (e.g. flexibles) filaments with high print quality, the extruder assembly is pretty small, so the build space isn’t affected.

Creality also did a great job managing the cables on the printhead, using a single ribbon cable to power and send data for the hot end, thermistor, extruder, and CR-Touch. While cable management might not seem like a big issue, loose or hanging wires can cause the printer to accidentally damage itself, so this ribbon cable reduces this risk. Lastly, the Creality Ender 3 S1 also has a spring-steel PEI build plate, which provides great print adherence but is flexible and magnetic so removing models is still super easy.

Given the Ender 3 S1’s fairly low price and all of the features it comes with, it’s safe to say that this direct drive 3D printer is a bargain and an excellent choice for anyone looking for a mid-size 3D printer that’s basically maxed out in every way.

Pros

- Compact and powerful direct drive extruder

- Low price compared to other options

- Onboard CR-Touch automatic bed leveling sensor for good first layer

- Filament sensor for ensuring filament is flowing properly

- Spring-steel bed for good adhesion and easy part removal

- Multiple other mini-features, like belt tensioners, tool drawer, good cable management, and filament spool

Cons

- Low maximum bed temperature could prevent printing with ABS

- Awkward filament runout sensor placement

3D Printer Type: FDM | Materials: PLA, TPU, PETG & ABS | Build Volume: 220 x 220 x 270 mm

And in a flash, this printer stole our hearts…and will hopefully steal yours too! The Flashforge Creator Pro is another mid-size 3D printer that has not one but two direct drive extruders! That’s right, you can print models in multiple colors with this machine, and its large build volume of 227 × 148 × 150 mm should be enough to satisfy most 3D printing projects.

The Creator Pro is a dual extrusion FDM printer with hotend nozzles located on a single printhead and a direct drive extruder for each one. Having dual extruders allows you to print with different color filaments or even different materials, which can be helpful in some scenarios, like building a particular prototype.

However, unlike other dual extrusion 3D printers on the market, the Creator Pro has a highly sturdy frame with multiple gantries supporting each axis to ensure a high level of precision during printing. The well-built structure also allows for faster printing as the dual extruder printhead assembly can move more smoothly across the conduit rail gantries.

When it comes to materials, the Creator Pro handles different filaments like a champ! Its enclosed design with a maximum heated bed temperature of 120 °C and a maximum nozzle temperature of 240 °C allow for printing ABS, ASA, and other high-temperature materials. Also, the direct drive extruders make printing flexibles like TPU much easier.

You can start printing to the printer using an SD card or USB stick, and the printer has a direct interface with multiple buttons that should make operating the Creator Pro very simple.

So, if you’re just getting into 3D printing but still want top-of-the-line printing features like dual-extrusion and direct drive, the Flashforge Creator Pro is no printer to overlook.

Pros

- Dual extrusion system, each with a direct drive extruder for printing multi-color or multi-material models

- Decent build volume

- Smooth printhead motion for enhancing print quality

- Easy operation through SD card and USB stick and buttons for the interface

Cons

- No touchscreen interface for more straightforward operation

- Somewhat low nozzle temperature could prevent you from printing with higher-temperature filaments

3D Printer Type: FDM | Materials: PLA, ABS, Flexible PLA, Wood, PVA & HIPS | Build Volume: 300 x 300 x 400 mm

Another large format printer with a superb direct drive extruder is the Artillery Sidewinder X2. With a print volume of 300 x 300 x 400 mm, what you can print is unlimited! Artillery, the manufacturer of the Sidewinder X2, also didn’t cheap out on the frame and used dual Z-axis stepper motors to prevent the X-axis gantry from sagging.

Kind of like the Creality CR-10 V3, the Sidewinder X2 has an extruder based on the E3D Titan design, with a 3:1 gear ratio with two drive gears. This should help prevent filament slipping and offer increased extrusion power over a Bowden extruder. As the extruder is in a direct drive configuration, you can also print flexible filaments much easier because it won’t be able to stretch as much as it would on a Bowden extruder.

The printer is pretty easy to operate, and it has a full-color touchscreen LCD running an excellent graphical user interface. The printer also uses a 32-bit mainboard with a fast processor chip, so the interface should run smoothly. The board, like many 32-bit options nowadays, has extra ports for specific purposes, such as a filament sensor which comes with the Sidewinder X2 and will pause your printer if the filament breaks or runs out, so you don’t have to constantly check your machine.

The Artillery Sidewinder X2 is like a large-format version of a typical i3 printer, but its easy-to-use touchscreen control interface, 32-bit mainboard, filament sensor, and powerful Titan extruder make the X2 stand out from the competition.

Pros

- Large build volume

- Powerful Titan extruder with 3:1 gear ratio in a direct drive configuration for printing flexible filaments

- 32-bit mainboard with touchscreen full-color interface for easy printer operation

- Well-built frame for safety and smooth printhead motion

Cons

- No automatic bed leveling sensor for a consistent first layer

- Somewhat large printhead assembly

Difference Between Direct Drive and Bowden Extruder

As we’ve explained, direct drive is one of two types of extrusion systems found on 3D printers. Bowden-drive, the alternative approach, places the extruder motor separate from the hot end on the printhead with a PTFE tube connecting the two. Direct drive eliminates this separation, placing the extruder on the printhead and directly above the hot end.

What are the Benefits of a Direct Drive Extruder?

The result is that filament has to travel a lot less between the extruder and hot end, and, in turn, the extrusion is more precise because there’s less room for errors. With this precision comes better print quality because extruder-related issues like stringing and under-extrusion are less likely to occur. You can also print flexible filaments, like TPU and TPE, because the filament has less room to stretch and bend like it would on a Bowden extruder.

Another benefit of a direct drive configuration is the reduced retraction length (slicer setting) associated with the system. Larger retractions can lead to a nozzle or hot end jam, so using a smaller retraction distance is a benefit of this configuration. It also can reduce print time because the extruder has to do less work while still achieving the same effect on the printer’s extrusion.

Overall, direct drive is the superior extrusion system, with only a few criticisms, such as a smaller area to work with (fix) the extruder mechanism. If you have a 3D printer that runs a Bowden-drive extruder system, it might be a good idea to upgrade to a direct drive extruder. This is especially the case if you want to print flexible filaments or have problems with nozzle jams, stringing, or under-extrusion.

There are a handful of standalone direct drive extruders that you can buy and add to your printer to replace its Bowden drive configuration. The Bondtech BMG, E3D Titan, and MicroSwiss direct drive extruder are a few examples of extruder systems. If you’re looking for a complete printhead, which contains both a direct drive extruder and a hot end, the E3D Hemera and E3D Titan Aero are both excellent choices.

Conclusion

Now that you’ve seen the best direct drive 3D printers, you may be wondering, “how do I choose the right one”? Well, of course, there’s no one right option, but some printers are better suited towards certain users with specific needs.

If you’re looking for a good deal, a printer that has a lot of features per dollar, then the Ender 3 S1 might be your best bet. However, if you’ve got a little extra to spend, the Prusa i3 MK3S+ is an excellent choice due to how much effort and detail Prusa Research put into the machine with all of its small features. And, if you have no budget, the Qidi Tech X-Max might be the one for you, given that it’s the most expensive option on the list and is equipped with more expensive features like an enclosure and swappable printheads.

However, remember that what printer you decide on depends entirely on your specific needs (and budget). All of the printers on this list are excellent choices, and all have top-quality direct drive extruders, so every printer is “the best” to someone out there.