- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

Sick of printing normal, rigid 3D models? Why not give flexible filament a try?

Sick of printing normal, rigid 3D models? Why not give flexible filament a try?

Flexible 3D printing filament materials, like TPU, TPE, and TPC, allow you to print models that are truly flexible. Parts made in this filament are super elastic and can be bent, stretched, and folded without breaking. Say goodbye to brittle PLA parts!!!

I’ve scoured Amazon and other 3D printing marketplaces, testing tens of different TPU and flexible filaments. After a ton of testing, I’ve found the best TPU filament is Overture’s TPU filament as it’s decently easy to print while still very elastic.

Sunlu TPU filament is a close second, and it’s a great option for any 3D printing enthusiast on a budget. And, if you want the most flexible parts, you can check out NinjaTek NinjaFlex filament, as it offers the most elasticity.

Want to hear about more of the best TPU filament options? Just keep reading!

Table of Contents

- Best Flexible / TPU Filaments At A Glance

- What is TPU Filament?

- Different Types of TPU

- When to Use TPU Filament?

- TPU VS TPE VS TPC

- How to Print with TPU Filament

- Does TPU Filament Need to be Dried?

- How to Dry TPU Filament

- How to Store TPU Filament

- How to Identify if the TPU Filament is Wet?

- Advantages and Disadvantages of TPU Filament

- Conclusion

Best Flexible / TPU Filaments At A Glance

First up, we have Overture’s TPU filament. Highly rated with numerous reviews, this flexible printing filament has top-notch print quality. It cleans up very nicely and is absurdly strong.

Overture features its flexible filament in 12 colors: from black, purple, and green to various shades of blue, you have so much to choose from! The filament has a shore hardness of 95A and can stretch to 3x more than its original length.

Based on the product’s reviews, compared to past TPU filaments they have used, Overture’s TPU is extremely stretchy yet very stable. This makes the filament perfect for a range of DIY projects.

The filament is easy to print, given its excellent bed adhesion, low warp, and low odor. It’s also clog-free, guaranteeing a smoother, more stable printing experience. However, it can take a while to get your printer settings to work as the filament is really soft and flimsy.

Once you get past the first layer, prints should be smooth sailing. To get the first layer to stick well, a glue stick can come in handy. Also, make sure to print this filament slowly to give it time to melt and extrude.

Lower temperatures result in more stringy prints, but starting too high in temperature is a bad idea. It’s recommended to start your prints around 200°F and work your way up depending on how stringy the prints are. Stringing problems can also arise if your filament is wet, so make sure it’s dry before using!

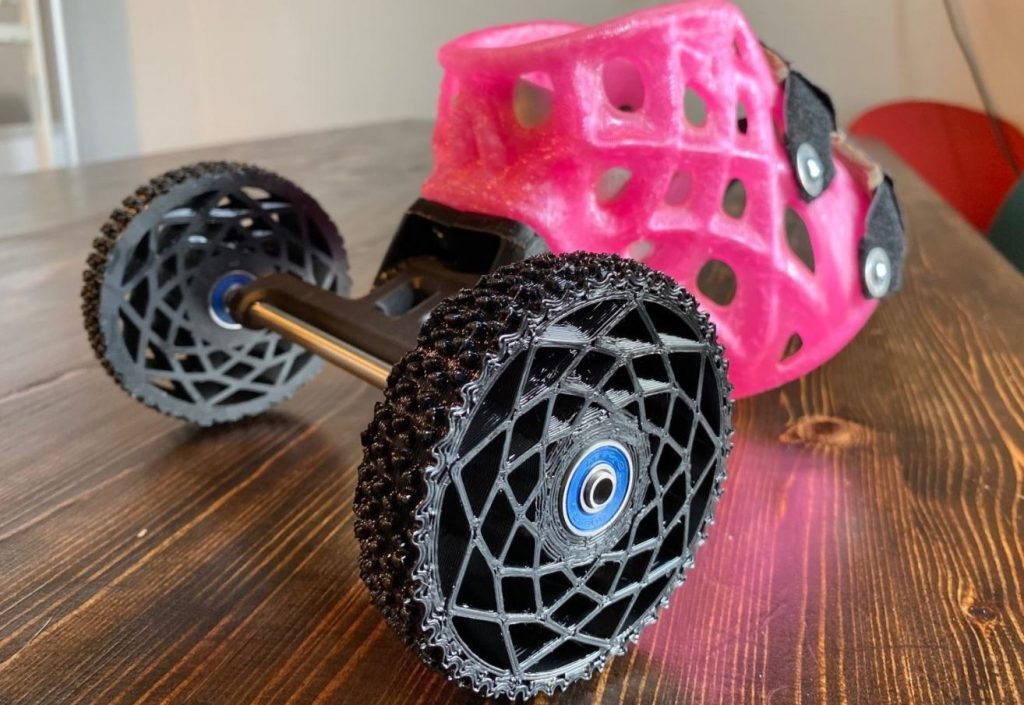

There are many fun projects to test with Overture’s flexible filament. You can make things like belts, bottle holders, tires for mini car models, phone cases, and even table feet for your printer table to help with vibrations.

This option is perfect if you’re looking for something more stretchy/rubbery for a reasonable price.

Sunlu has made a name for itself when it comes to normal and flexible filaments and is very familiar in the market. Sunlu flexible filament is a great option if you are looking for something that is the best value for your money. It won’t disappoint!

Sunlu’s TPU has a handful of available colors, depending on their stock. Currently, there are 4 different color options on Amazon, including black and blue. Some people find that the filament colors are bright in comparison to other filament colors.

The shore hardness of this filament is 95A, making it pretty flexible. Sunlu TPU provides great-quality prints, given that you have the printer settings just right. You can print numerous things with this filament. Examples of past prints include washers, wheels, mini figurines, and phone cases.

It’s extremely important to give this filament adequate time to dry out. A filament dryer is also highly recommended considering Sunlu’s filament is extremely hygroscopic, like most TPU filaments.

As mentioned before, finding the right settings to print with Sunlu TPU is important, as the filament is prone to clogging. Although you may end up with clogged nozzles in your initial stages of testing, the final prints with this filament are definitely worth the work and patience. Using a higher temperature than what’s recommended may work better with your prints.

There is also a tendency for prints to stick to the bottom of your print bed. So, instead of pulling off your print, it’s recommended to use a scrape underneath to avoid pulling the print apart.

The Sunlu TPU filament is affordable in comparison to other filaments, but it’s important to remember that Sunlu sells its flexible Filament in 0.5kg. Regardless, the filament has great flexibility, and prints come out really strong with nice layer bonding. This is a great, well-rounded filament in terms of quality, strength, and price.

Next up, we have Ultimaker’s TPU flexible filament. Ultimaker is established for its open-source 3D slicer for FDM printers, the Ultimaker Cura, on top of its printers and a wide range of filaments. Its TPU filament is offered in 4 different colors: black, white, blue, and red.

The TPU has a shore hardness of 95A with a tested elongation factor of 580%. The filament is essentially rubberlike and is great for durability and flexibility purposes. The material has great resistance to corrosion from oils and chemicals.

Some reviews say that the filament tends to string a lot, leading to clogged nozzles and over-extrusion. Considering that stringing is common with any flexible filament, this problem can be fixed by adjusting and experimenting with printer settings. Getting printer settings right can be difficult, but afterward, printing is quite simple.

Once you find the right settings, prints with the Ultimaker TPU are no less than excellent. Although on the pricier side of TPU filaments, the Ultimaker TPU is well worth it. You can make several prints of your liking, such as miniature figures, everyday objects you need, and even headgear.

NinjaTek’s NinjaFlex TPU is by far the brand’s most popular flexible filament. NinjaTek has many colors in its TPU collection that are unique and different from that of other TPU brands. Colors include grass, lava, snow, and neon, among many others.

NinjaFlex has an 85A shore hardness level. It can stretch up to 660% of its original length before breaking! This is significant when comparing NinjaFlex to other TPUs with 95A shore hardness levels. 85A is about twice as stretchy.

A concern with NinjaFlex TPU from customers is that it can be difficult to print. One factor is that fluctuations in temperatures affect the print significantly. Slicer settings also play an important role. Just like with any other TPU filaments, experimenting with printer settings until you find what is good for your printing is necessary for the best quality prints.

This filament also tends to be on the pricier side of filaments, but prints are consistently flawless once you find the best printer settings for you! Ninjaflex is a great application for prints like vibration dampers and other personal/industrial projects.

The Flexfill Series by Fillamentum offers a wide range of variety in terms of flexibility and visual appearance. You can choose from many different color options, from pistachio green and carrot orange to vertigo gray. Filaments come in shore hardness levels of 98A or 92A, depending on the spool. 92A is softer and more flexible than the 98A filaments.

Filamentum’s TPU is great for both personal projects and practical uses. You can make children’s toys and figurines, can holders, edge protectors, and even seals to fix leaks in your own home! The finishing of the filament is really nice and glossy.

There are some important tips to follow when printing with Flexfill to avoid problems other customers have encountered. Print speed is extremely important, and taking it slow is definitely worth the wait for the amazing end results.

When it comes to tension, make sure not to press the flexible filament too much, or it will run out of the extruder. And finally, for softer filaments, turn off your retraction. (Customers recommend turning off retraction for 92A but not 98A).

All around, the Fillamentum Flexfill series puts forward great TPU filament options for a reasonable price. The TPU filament has great chemical resistance as well. Just remember to store your filament in an airtight bag to avoid moisture!

Next on our list is PolyFlex TPU by Polymaker. With color options of black, white, red, blue, yellow, and orange, customers have a lot to choose from. Polyflex is both durable and stretchy!

The shore hardness of Polymaker PolyFlex is 95A.

This is flexible but stiffer than NinjaFlex. Think about it as the “halfway” point between Ninjaflex flexible filament and regular (PLA) filament. This is great for projects and prints like wallets, belts, etc.

Among the other TPUs, PolyFlex is definitely one of the easiest TPU filaments to print. While it does have a stringing issue, it is minimal and can be easily cleaned up with little post-processing. Customers say that stringing usually occurs when printed in multiple small parts closer to each other. Turning up the temperature for the first layer is suggested since it provides better adhesion as the filament cools fast and then shrinks.

There are under-extrusion issues to watch out for, as the extruded will not push the same amount of filament as solid plastic. Increasing the flow rate can easily fix this issue. Changing retraction settings is also extremely important with this TPU. After the configuration is figured out, prints come out really well.

SainsSmart TPU is another one of my favs. For this filament, you can choose from 11 different colors, including some basic ones like blue and black, as well as some sexier shades, like emerald, mango mojito, and galaxy blue.

Reviews say that a few colors aren’t completely true to what they look like in their pictures, so keep that in mind when ordering.

SainSmart TPU is popular with numerous reviews as a stringing-resistant and reliable flexible filament. It has a shore hardness of 95A. SainSmart sells this TPU in 0.25-kg spools, making the price very affordable for those who don’t want to print a lot of filament.

Compared to other filaments, SainSmart TPU is on the more beginner-friendly side. Several customers mention how it was their first TPU to print with and that they encountered little to no problems.

The filament has very little stringing, great adhesion, and only a few little blobs that can be cleared up by turning the print settings. You may not even have to post-process your prints!

One thing to watch out for is that the filament does not come dry! Make sure to thoroughly dry the filament before using it for the best quality prints. Once you get printing, this filament is great for amputee purposes (e.g. joints, fingertips), figurines, drone parts, and whatever you desire!

Priline TPU is a great option for TPU filament that is extremely affordable for amazing prints. This TPU sells in 1kg spools and has about 10 color options for customers to choose from.

With a shore hardness of 98A, prints have a nice rubbery feel and are more firm in comparison to SainSmart TPU. You can play around with the infill percentage to change the flexibility of your prints.

This filament is also great for beginners. Customer reviews compliment the consistency of strong and beautiful prints with this TPU. Priline TPU proves to be significantly better than the brand’s PLA filaments.

Prints stick to the bed really well, so be sure to use a glue stick on the bed beforehand to help with getting prints off. Also, make sure to upgrade your extruder to a direct drive to avoid any clogging problems.

One problem with this filament is the consistency of its diameter. According to some user’s reviews, this filament’s diameter can go as low as 1.6 mm, causing tons of problems with the extruder.

Still, most of the time, Priline TPU can put out some amazing prints.

If you’re looking for a filament that is more like hard rubber than flexible, Priline TPU is perfect for you!

ColorFabb’s varioShore TPU is one of a kind and unlike the other filaments on this list. What makes this filament so special is that ColorFabb adds baking soda, a foaming agent, to its TPU plastic blend.

For reference, foaming agents remove air bubbles from the mixture, and for TPU filaments, foaming typically makes the plastic less flexible but more consistent. As such, it’s super easy to achieve high-quality prints with ColorFabb varioShore TPU once you’ve got the right slicer settings. Tune once, and you’re set for the whole roll!

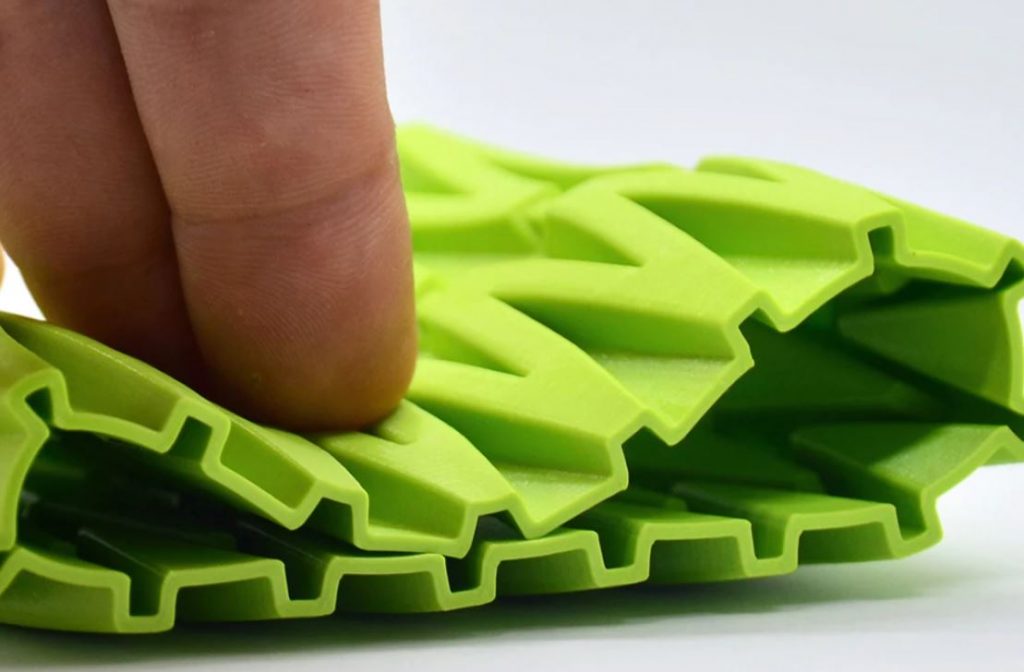

With the filament’s foaming agent, the filament’s shore hardness ranges from 55A (maximum foamed) to 92A (unfoamed). Shore hardness changes based on how you print the TPU based on temperature and infill. For example, shore hardness decreases with lower infill values.

This filament works surprisingly well with both Bowden and direct drive extruders, but printing at a low speed is important. Stringing is inevitable with this TPU due to the core properties of the polymer, but prints can still look amazing if you properly tune your slicer profile.

Overall, this filament is a great option if you are looking for a smooth and easy printing experience.

ColorFabb TPU comes in 2 colors: black and natural. You can print things like shoe soles and bike grips, to list a few examples. Given the softness, toughness, and low density of this material, it is perfect for buoyant prints and makes it great for floating parts.

The MatterHackers Pro Series TPU comes in 7 colors: black, grey, white, clear, red, green, and blue. It has a shore hardness of 95 with an elongation factor of over 600%.

This TPU creates prints with great flexibility and is super durable with high resistance to abrasion. MatterHackers TPU is flexible like NinjaFlex but more rigid.

The printing process isn’t too difficult as the filament is quite simple to work with. The TPU does not need adhesive to stick to anything. It also has great dimensional accuracy making your job easier as the filament gives you great quality control and fewer problems to run into.

The filament is designed with stiffness to make sure it goes through the extruder with no problems. This feature can save you a lot of time when printing with TPUs. Finished prints have great layer adhesion and bonding between each layer, making them great for printing anything from small items to bigger projects.

What is TPU Filament?

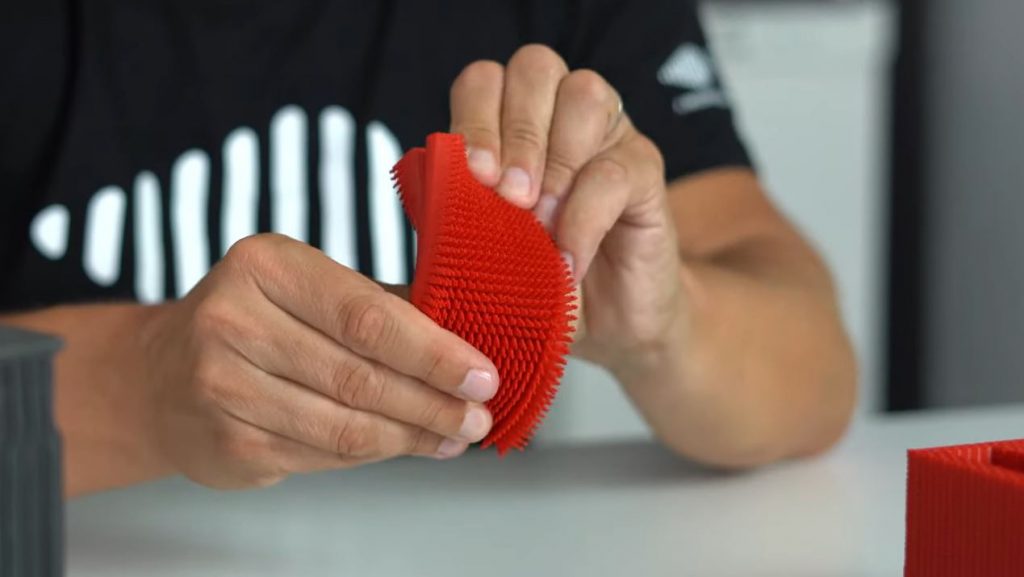

Thermoplastic Polyurethane (TPU) is a flexible 3D printing filament composed of thermoplastic elastomers. Characteristics such as its thermoplastic elastomers make the material as elastic as rubber but as durable as plastic.

TPU is an extremely versatile material as it improves production and enriches the performance of various things. Many fields use TPU filament, from the sporting goods industry for footwear all the way to the aerospace and automotive industries for panels and sensors.

Different Types of TPU

There are 3 main classes of TPU: Polyester, Polyether, and Polycaprolactone.

Polyester

Polyester TPU is the most popular of the 3 types of TPU. Polyester itself is a synthetic fabric that is derived from petroleum and is one of the world’s most popular textiles.

Polyester TPU holds many great qualities. It has amazing mechanical properties like high tensile strength, puncture resistance, and durability in abrasive environments. For example, polyester TPU is unaffected by oils and chemicals and is excellent in applications requiring resistance to fuels, oils, water, and other chemicals. (Overall outstanding performance when in contact with fuel and solvents.)

This type of TPU also withstands elevated temperatures and is more resistant to heat aging in comparison to other polymers. On Top of these qualities, polyester is compatible with PVS, and other types of plastics are great for transparency purposes in prints and offer a good balance of physical properties.

Polyether

Polyethers are considered elastomeric materials, which are classified as materials exhibiting elastic or rubber-like properties. The material is commonly used for making precision impressions. Polyester TPU is made from polyols containing ether groups creating hydrolysis- and microbe-resistance grades. While polyether TPU is slightly lower in its measure of density (specific gravity) than polyester and polycaprolactone TPU, polyether offers low-temperature flexibility.

Polyether offers good abrasion/tear resilience, provides excellent impingement resistance, and features greater resistance to moisture, all while performing better in low temperatures. Another plus is its durability against microbial attraction, meaning it does not attract bacteria.

An important feature of polyester TPU is its hydrolysis resistance. This allows the material to be suitable for application where water is in consideration. For example, Polyether TPU would be great if the product is expected to be submerged or exposed to humid or wet conditions.

Polycaprolactone

Polycaprolactone TPU is a considerably smaller class compared to polyester and polyether TPUs. Polycaprolactone is a biodegradable polyester. This TPU has low-temperature performance due to its lower melting point.

Regardless of being biodegradable, Polycaprolactone still holds the inherent toughness and resistance of polyester-based TPUs. It has a relatively high resistance to hydrolysis and is the ideal raw material for hydraulic/pneumatic seals.

When to Use TPU Filament?

You should use TPU filament whenever part flexibility is required or you want to make a very impact-resistant 3D print.

For example, a few weeks ago, my camera mount for my Eachine racing drone snapped in half. I used TPU filament to 3D print a replacement and the part’s impact-resistance has made it last many more crashes!

Other examples of when you might want to 3D print parts in TPU or another flexible filament include plastic jewelry, fidget toys, shoe insoles, phone cases, an art piece, or even a mouse bungee.

TPU VS TPE VS TPC

When exploring flexible filaments, you’ll probably discover TPE and TPC filaments on top of TPU. What exactly is the difference between these three?

TPE stands for thermoplastic elastomers. This categorizes any plastics with rubber-like qualities that are extremely flexible and durable. TPE can withstand things that regular filaments like ABS or PLA cannot handle.

TPU stands for thermoplastic polyurethane and is actually a variety of TPE. It is easier to print as it is more rigid compared to TPE. TPU is also more durable and better when it comes to retaining elasticity in cold temperatures.

TPC stands for thermoplastic copolyester. It’s not as common or popular as TPU, but similar for the most part to TPE. TPC has higher resistance when it comes to chemicals and UV exposure.

How to Print with TPU Filament

While TPU is more difficult to print compared to other filament materials simply due to its flexibility, any 3D printer can print TPU. However, it is important to remember that every TPU brand and printer is different, meaning printing with TPU filament is not the same every time.

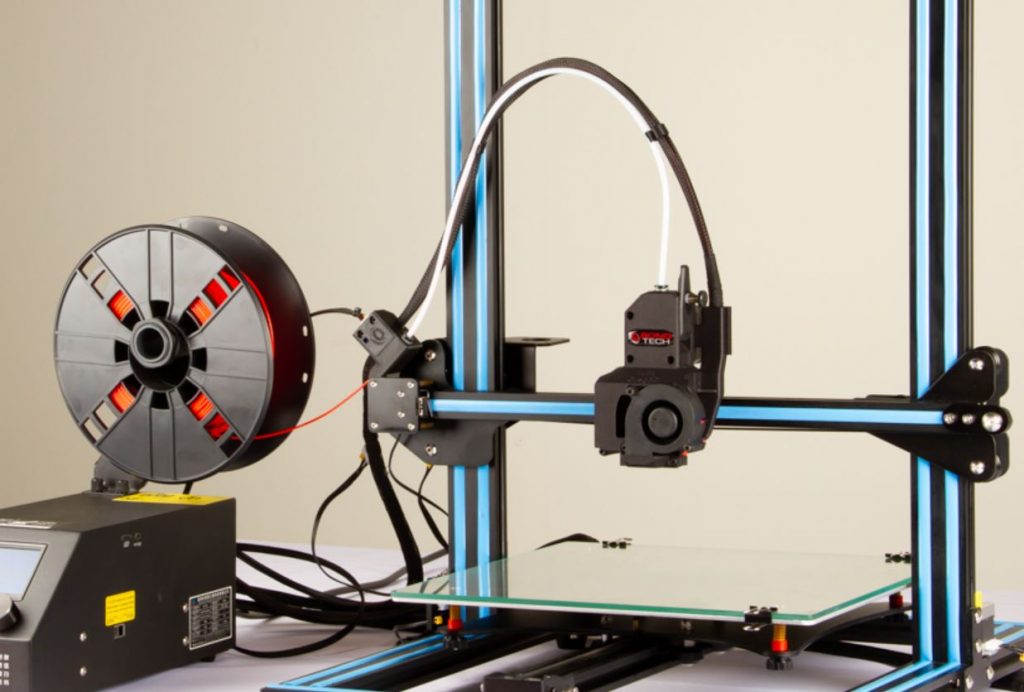

First off, you’ll want a 3D printer with a direct drive extruder to print TPU or flexible filaments. That’s because these filaments stretch, which affects their diameter, leading to printing issues like increased stringing or even a hot end clog. Having a direct drive extruder configuration will allow you to use lower (or even 0) retraction, so the diameter of the filament doesn’t change.

While you need a direct drive extruder to achieve high-quality prints, you don’t need an enclosure to print TPU, like you would with ABS or PC. I also advise using a hardened steel or stainless steel nozzle as brass nozzles might degrade too quickly when printing TPU or another flexible material.

After you’ve got the hardware down, you’ll need to tune a slicing profile. This means checking your nozzle temperature settings, which should be around 220-230 °C, a little higher than the temps for PLA (around 200 °C).

Also, you need to optimize the printer’s feed rate and retraction settings to prevent clogging. The printing speed for TPU should be lower than your print speed for other materials (e.g. PLA), as this flexible material requires patience for high-quality models.

But, after that, you’re golden!

Does TPU Filament Need to be Dried?

Yes!

TPU is a hygroscopic material, meaning the plastic absorbs moisture from the air easily. And, if moisture seeps into your flexible filament or any 3D printing material for that matter, then printing it will be much more difficult. Moreover, wet filaments yield low-quality prints and can even lead to hot end clogs on your 3D printer.

How to Dry TPU Filament

To dry flexible filament (or any filament), you need to remove the moisture from the plastic to restore the material to its original, dry state. You can do this using either a filament dryer or a conventional cooking oven.

Filament Dryer

The first method to dry your filament is using a proprietary filament dryer device. This is my personal favorite method as I find it yields the driest filaments compared to using a conventional cooking oven.

If you’ve never heard of them before, filament dryers are devices that hold a filament spool (or a few) and are equipped with a heating element. Filament dryers actively heat the contained spools and the air around them to relieve the plastic of any moisture trapped inside. Typically, silicone gel packets are also present in filament dryers to further assist in removing water from the filament material.

As for what temperature to use, I like to dry TPU and other flexible filaments at 70-80 °C for 3-5 hours. But if the manufacturer of your filament provided a recommended temperature and time, go with that!

My favorite filament dryer is the Sunlu FilaDryer S1, as it’s pretty budget-friendly and has both a powerful heating element and an accurate humidity sensor. Feel free to check out our article all about the best filament dryers to learn more about these devices and your options!

Also, try not to leave the heating element turned on for more than 6 hours. That’s because filament, especially flexible filament, has been known to degrade when over-heated or heated for too long a time.

Cooking Oven

If you don’t have a filament dryer device, though, and need to dry your flexible filament, you can also use a conventional cooking oven.

A cooking oven obviously doesn’t offer the neat features of a proprietary filament dryer, like low-temperature heating capabilities and a humidity sensor, but it gets the job done.

To dry your filament using an oven, simply place your wet filament spool (or a few spools) on a baking pan and place it in your oven. I suggest using a temperature between 60-90 °C and leaving the spools inside the oven for 3-5 hours.

Make sure not to use too high a temperature or to leave the filament inside the oven for too long. That’s because overbaking your filament, whether it’s a flexible filament or a normal filament, can cause its diameter to change, which will lead to printing issues.

How to Store TPU Filament

Once you’ve dried your filament, you need to store it in a container that won’t let moisture come in, as TPU is a hygroscopic material and will absorb any moisture from the air. Remember: keeping your filament dry increases the overall quality of your prints!

The best way to store flexible filament is using a filament dry box, such as the PrintDry container. These proprietary boxes have been designed specifically for keeping filament dry!

However, you can also DIY your own filament dry box using some air-tight Tupperware, like those you might find in your kitchen. Or you can even use your filament dryer device, just as long as you turn off the heat because over-cooking your flexible filament could make it even more difficult to print.

How to Identify if the TPU Filament is Wet?

There are various things to look for to identify if your TPU filament is wet before using it.

Common signs of a wet spool can easily be seen or heard.

Observe the extrusion. If the filament is wet, you will see and/or hear it. Look for bubbles forming in the extruded material. Steam may even come from the filament. You should also listen for hissing, popping, or cracking sounds, as these usually indicate wet filament as well.

Above, you can see that the print on the left side was made with dry filament, while the model on the right was made with wet filament. The difference is very obvious!

Advantages and Disadvantages of TPU Filament

Below, you’ll find a list of advantages and disadvantages of TPU Filament. See what TPU offers you!

Advantages

- Stretchy/Flexible but Durable

- Good impact resistance

- Vibration damping and shock absorption

- Low shrinkage and warping

- Plenty of color options

- Chemical-resistant

Disadvantages

- Hygroscopic

- Pos-processing can be difficult

- Must be printed at low temperature

- Can string and clog

Conclusion

Overall, TPU and flexible filament is a must-have filament material for any makers or 3D printing enthusiasts. If you can get over the printing difficulties, such as using a direct drive extruder and drying your filament, then you’ll love the flexibility of TPU, TPE, and TPC filament.

Flexible models are super fun, and you can make some amazing bracelets and necklaces with a flexible filament. Plus, parts made with flexible filament are also super impact-resistant, which is perfect for printing models like phone cases and camera mounts.

The best TPU filament is easily Overture’s TPU filament. This flexible filament is very easy to print, provides terrific impact resistance, and is also pretty budget-friendly.

On this note, if you’re looking for the best value flexible filament, then you’ll love Sunlu TPU filament. This filament is a great bang for your buck, and while it’s not the most flexible on the list, it’s easy to print and is also pretty strong.

Lastly, if you want the more bendy, flexy, and elastic models, then definitely check out NinjaTek NinjaFlex TPU filament. This is easily the most flexible filament on the list, with a low Shore Hardness rating that makes printing flexible models a breeze!

Enjoy!