- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Want to bring science fiction to your crafts and manufacturing projects? Then you should cut your materials with lasers!

Want to bring science fiction to your crafts and manufacturing projects? Then you should cut your materials with lasers!

Laser cutters have become exponentially more accessible in the past few years, thanks to falling prices and advanced technology. With a laser cutter, you can quickly cut precise patterns and designs out of many different materials.

A laser cutter is a must-have for any home workshop or small manufacturing business.

But the machines aren’t cheap and their capabilities vary wildly. You must make your choice carefully or you might blow a lot of cash on a cutter that won’t even slice soft butter.

Read on to find out which is the best laser cutter for you in 2024.

Table of Contents

- Best Laser Cutters At A Glance

- Cut Designs at Laser Accuracy

- What is Laser Cutting?

- Laser Cutters VS Laser Engravers — What’s the Difference?

- 7 Things to Consider When Choosing the Best Laser Cutter

- Types of Laser Cutters

- Materials You Can Laser Cut

- Laser Cutter VS CNC Router

- Get a Machine that Makes the Cut

Best Laser Cutters At A Glance

1. FLUX Beamo 30W (Best Choice)

2. OMTech 40W (Best Value)

3. Glowforge Plus (Premium Choice)

4. xTool D1 Pro 20W (Most Accurate)

5. Triumph Fiber Laser Cutting Machine (Metal Cutting)

6. Full Spectrum Laser Muse Core 45W (Most Customizable)

7. SFX Reci W8 (Industrial Performance)

Laser Type: CO2 | Laser Power: 30W | Cutting Area: 300 x 210 mm | Max. Cutting Speed: 300 mm/s | Feature Highlights: HD camera, Dedicated App, Wireless Connectivity

There are few one-size-fits-all solutions. But then there’s FLUX Beamo.

The Beamo is one of, if not the best laser cutter you can buy.

This little box is a great laser cutter for beginners, hobbyists, teachers, or even small-scale crafts businesses. Its 30W CO2 laser has enough power to slice through a good range of materials.

Beamo can also engrave an even wider material range. It’s a versatile and flexible work partner for any use case.

The machine is simple to use, thanks to its dedicated control app that works on any computer and even on mobile devices. It combines with an internal HD camera that helps you position your cutting pattern in real-time.

Beamo also has Wi-Fi connectivity, so you won’t have to mess around with USB drives or cables. If any laser cutter can offer drag-and-drop functionality, it’s Beamo.

With a stylish and lightweight design, Beamo will fit in any garage, workshop, or classroom. Of course, the compact form factor comes with the downside of a limited cutting area.

As a cherry on top, FLUX sells Beamo at an affordable price. But if you have some cash burning a hole in your pocket, you have plenty of options to upgrade the Beamo with a rotary add-on, diode laser, or autofocus.

FLUX Beamo is a fantastic choice for both newbies and veterans alike.

Pros

- User-friendly

- In-built HD camera

- Sleek and lightweight

- Material support

Cons

- Mediocre cutting area

Laser Type: CO2 | Laser Power: 40W | Cutting Area: 203 x 304 mm | Max. Cutting Speed: 255 mm/s | Feature Highlights: External Controls, Removable Work Bed, Red Dot Guidance Laser

You get what you pay for, goes the famous saying. Unless you’re buying the OMTech 40W. Then you’ll get more than the cost would imply.

This incredibly budget-friendly laser cutter packs a 40W CO2 laser, which beats even the FLUX Beamo. Although it’s marketed as a “laser engraver” (and can do that job perfectly well) it has enough strength to cut a lot of different materials.

OMTech has also included a nice bundle of advanced features that make the cutter punch above its price tag.

First and foremost, it has external controls and a clear LCD display for monitoring machine status. An ammeter shows the current going through the laser tube in real-time so you can easily set the power to the right level.

There’s also a red dot guidance laser that shows exactly where the machine will cut. The dot makes misaligning your cuts a real challenge. You can also remove the work bed to get an extra two inches of working area.

As a downside, some users say that build quality can vary between individual machines. The work area on this laser cutter is also pretty limited, so it won’t work for large designs.

All in all, though, OMTech 40W is the best laser cutter you can get at this price.

Pros

- Amazing value

- Laser power

- Advanced features

- Easy setup

Cons

- Limited work area

- Variable build quality

Laser Type: CO2 | Laser Power: 40W | Cutting Area: 279 x 495 mm | Max. Cutting Speed: N/A | Feature Highlights: Autofocus, Material Detection, HD Camera, Wi-Fi Connectivity

Glowforge’s products have a reputation as the go-to laser cutters for hobbyists and small businesses. The Glowforge Plus laser cutter is a premium machine that shows its fame is well-earned.

As you’d expect from a premium machine, Glowforge Plus has good cutting power that rivals the OMTech 40W. Combine that with the large work area and you can supersize your cutting patterns.

The machine can slice a lot of different materials and also work as a laser engraver with even more material options. Thanks to the precise laser, you can make accurate cuts and etch intricate designs.

Like FLUX, Glowforge includes an HD camera that combines with the operating software for easy pattern placement. To make the machine even simpler to use, it has a powerful laser autofocus and can identify the material to pick the right settings on its own.

Quick and productive, as a pro should be.

Glowforge Plus is an internet-connected machine that offers wireless connectivity. Unfortunately, it’s a real internet addict — you can’t use the web-based operating app without an active connection.

Then there’s the price. This is a premium machine, so you have to pay a premium for it.

It’s money well-spent, though. If you’re a serious hobbyist or even a business owner, investing in Glowforge Plus might be worth it.

Pros

- Good cutting power

- Simple usability

- Highly automated

- Large cutting area

Cons

- Slow cutting speed

- Expensive

- Needs internet connection

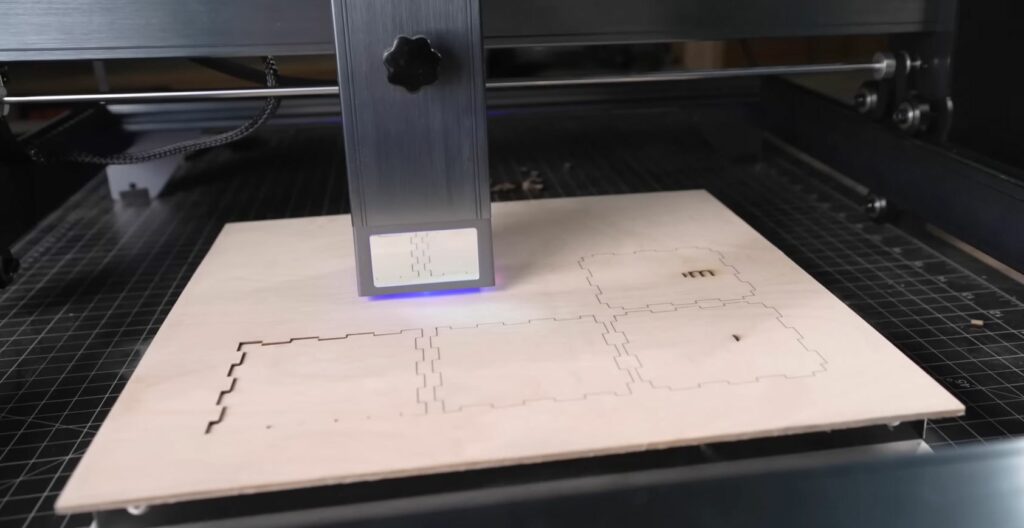

Laser Type: Diode | Laser Power: 20W | Cutting Area: 430 x 390 mm | Max. Cutting Speed: 400 mm/s | Materials: Acrylic, Cardboard | Feature Highlights: Focus Adjustment Lever, Flame Detection, Detachable Risers

Do you want to make accurate laser cuts? Do you want them fast? Then xTool D1 Pro 20W is the laser cutter for you.

You might think that 20W of laser power isn’t very much compared to other laser cutters on this list. But in practice, the diode laser has enough power to cut a 1cm thick wood panel in one pass.

Trust us, you won’t be asking for more power with the D1 Pro.

This laser cutter also works fast. Working as a laser engraver, it can reach a blistering 400mm/s. Cutting will naturally slow things down some, but it’s still one of the fastest machines on this list.

But the real kicker is the accuracy.

D1 Pro’s diode laser makes very thin cuts and its focus adjustment slider helps you improve the accuracy even further. The belts moving the laser cutter unit are also reliable and accurate.

You can also tailor D1 Pro to your needs with a wide range of upgrades. Add a rotary, expand the already huge work area, or install an air assist feature if the flame detection sensor isn’t enough.

The hardware on the machine is great, but it lags behind in software. The xTool app bundled with D1 Pro is pretty awkward to use, so just go ahead and buy Lightburn instead.

As soon as you resolve your software woes, xTool D1 Pro 20W offers plenty of laser cutting accuracy.

Pros

- Cutting power and speed

- Large work area

- Very accurate

- Upgradability

Cons

- Pricey

- Poor software

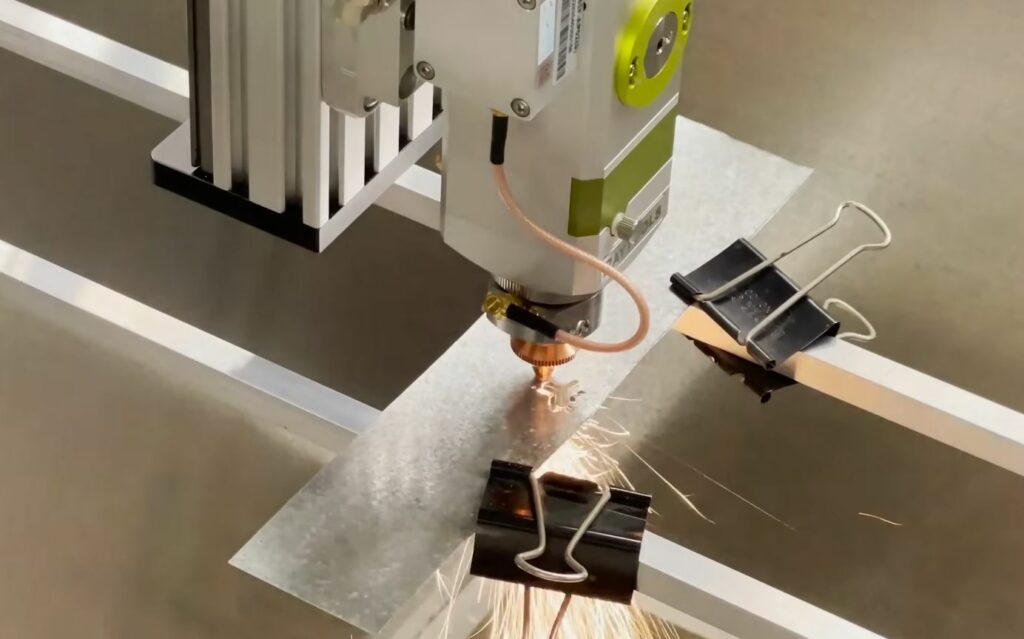

Laser Type: Fiber | Laser Power: 50W | Cutting Area: 100 x 100 mm | Max. Cutting Speed: 7000 mm/s | Feature Highlights: Integrated Computer and Software, Metal Cutting

Serious needs require serious tools. Triumph Fiber Laser is a professional-to-the-bone laser-cutting machine that can even slice metal.

You’ll notice this is a professional-grade machine as soon as you look at it. The laser cutter comes with an industrial computer integrated into its large stand.

You won’t have to try and get the system connected to your own laptop. And since the software is tailor-made for it, this machine is very simple to use.

Triumph’s laser cutter provides industrial-level power with its 50W fiber laser unit. Case in point, this machine can even cut some thin metals, like brass or aluminum.

Simply put, material choice becomes a non-issue with this laser cutter.

On top of power, Triumph serves up speed in spades. This device cuts and engraves at lightning-fast speed, so your projects will be done in no time. It’s also extremely precise and cuts even the most detailed designs accurately.

Reliability is an important part of professional performance since time wasted on maintenance is time you’re not producing anything. That’s not a concern with the Triumph — with a 100,000-hour laser life, you can focus on running a business.

But there’s one significant drawback — the smallest cutting area on this list. Even with the optional expansion lens, the huge Triumph can only cut within a 200 x 200mm square.

Triumph Fiber Laser performs as an industrial-grade cutter should, if only within a limited area.

Pros

- High power

- Lightning-fast speed

- Low maintenance

- High accuracy

Cons

- Very expensive

- Large machine

- Small work area

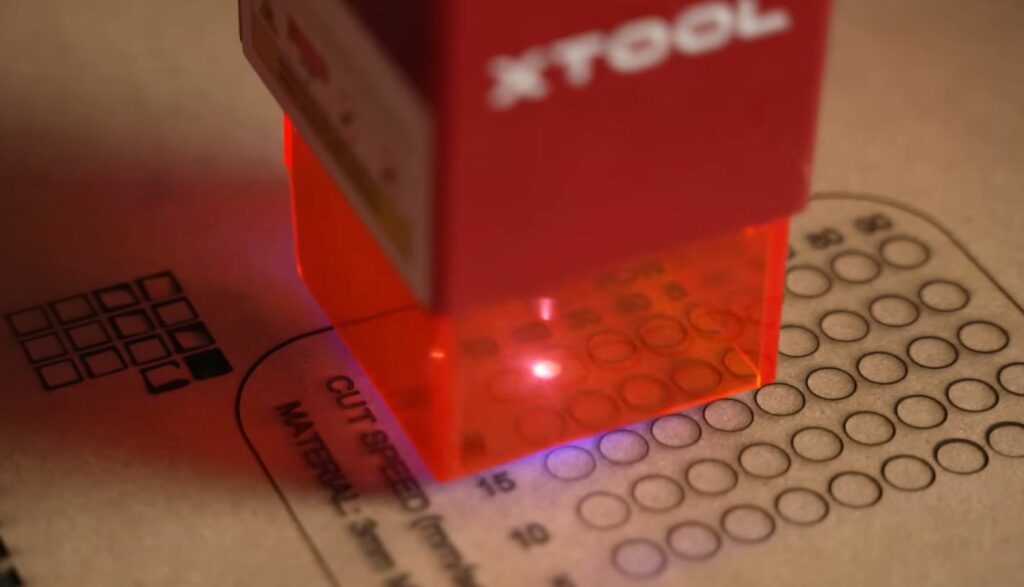

Laser Type: CO2 | Laser Power: 45W | Cutting Area: 508 x 305 mm | Max. Cutting Speed: N/A | Feature Highlights: LCD Touchscreen, Removable Floor

Do you like to customize everything you own to fit your wants and needs? Full Spectrum Laser (FSL) Muse Core 45W offers you plenty of options for modifying your laser cutter.

Even without any modification, Muse Core is a capable laser cutter. Just its default 40W CO2 laser beats FLUX Beamo in power and can cut acrylic, fabric, wood, and more.

You can also cut very large pieces, thanks to Muse Core’s very well-sized work area. And if that’s not enough for you, just pop off the removable floor.

Just like that, you can cut and engrave objects larger than the machine itself.

Muse Core really starts to shine when you begin to swap its parts around, though. Changing the laser to the 45W option lifts the machine out of the gray mass of mid-range laser cutters.

But wait, there’s more! You can get the FSL Coolbow, an air/water cooler that keeps the laser temperature optimal and clears fumes from the cutting chamber.

Are those fumes getting to you? You can buy the Fume Extractor add-on. There are also rotary and focus lens options.

That said, you kind of need to spend money on the add-ons. Without them, Muse Core is “just” a decent mid-range laser cutter.

If you’re ready to make the investment, though, FSL Muse Core is a tinkerer’s dream.

Pros

- Large cutting area

- Excellent customizability

- User-friendly

Cons

- Costly

- Mid-range machine as standard

Laser Type: CO2 | Laser Power: 180W | Cutting Area: 1300 x 900 mm | Max. Cutting Speed: 50,000 mm/s | Feature Highlights: Autofocus, External Controls, Water Cooling, Air Assist

Say what you will, sheer overwhelming power has its own advantages. If it’s power you want, SFX Reci W8 provides enough performance to be at home in a small factory.

Reci W8’s specs are in a completely different league when compared to other machines. Its 180W CO2 laser loses in power only to Triumph’s fiber laser.

Reci W8 won’t quite cut metal, but it’ll engrave it. Besides that, it’ll slice practically any softer materials.

This machine boasts the largest cutting area on this list. You can fit almost anything you might need to cut in its huge chamber. And it’s also fast to boot.

The performance doesn’t stop there, though. An autofocus feature and red-dot indicator make prepping this laser cutter a breeze, so you can start cutting quickly.

An air assist keeps your cuts sharp and accurate. You can also say goodbye to a learning curve with the included easy-to-use software.

Users looking for industrial-grade performance can’t do much better.

But as an industrial machine, this is a very, very expensive laser cutter. It’s also an enormous beast with a weight approaching a ton. You’ll need a big dedicated workshop to house this behemoth.

Then again, that’s to be expected from a professionally oriented laser cutter like SFX Reci W8.

Pros

- Powerful

- Fast cutting

- Huge work area

- Standard autofocus

Cons

- Very expensive

- Huge machine

Cut Designs at Laser Accuracy

Whether you’re a hobbyist who loves crafts, an Etsy seller, or the owner of a manufacturing SME, a laser cutter can be a real boon to your work. Laser cutters can slice intricate shapes out of material quickly, accurately, and affordably.

But if you’ve never owned a laser cutter or laser engraver before, you may be scratching your head about what these things actually are.

How does a laser cutter work? And what can you actually do with one?

Read on to learn the basics of laser cutting, from the machine’s working principles to what you can cut with them.

What is Laser Cutting?

A laser cutter is a manufacturing machine that cuts patterns or shapes out of a sheet of material. To cut the design, they use — you guessed it — a high-power laser beam.

A laser cutter focuses intense light into one small spot — like a kid playing with a magnifying glass, only with much more power.

The laser burns through the material, creating the cut. Since the beam is highly concentrated, laser cutters can slice through material very precisely.

Laser cutting isn’t a new invention and it’s been used in industrial-scale manufacturing for ages. But in the past 10 years or so, the machines’ sizes and prices have fallen enough that even consumers can afford them.

So, there’s never been a better time to get into laser cutting!

Laser Cutters VS Laser Engravers — What’s the Difference?

You often see laser cutting machines listed as laser engravers in online stores and vice versa. It can get confusing when you see one machine sold as both a laser cutter and a laser engraver.

What’s the difference?

It all comes down to power. Often, the only difference between a laser engraver and a cutter is how much laser power it has.

Laser engraving machines are less powerful than laser cutters. They can etch and engrave designs onto a material, but don’t have enough power to cut through it.

Laser cutters, on the other hand, have more powerful lasers. This means a laser cutter can practically always also function as a laser engraver — you just have to tone down the power output.

It’s also good to know how this variance in power shows in practical terms. Let’s take a brief look at what happens during laser cutting and laser engraving.

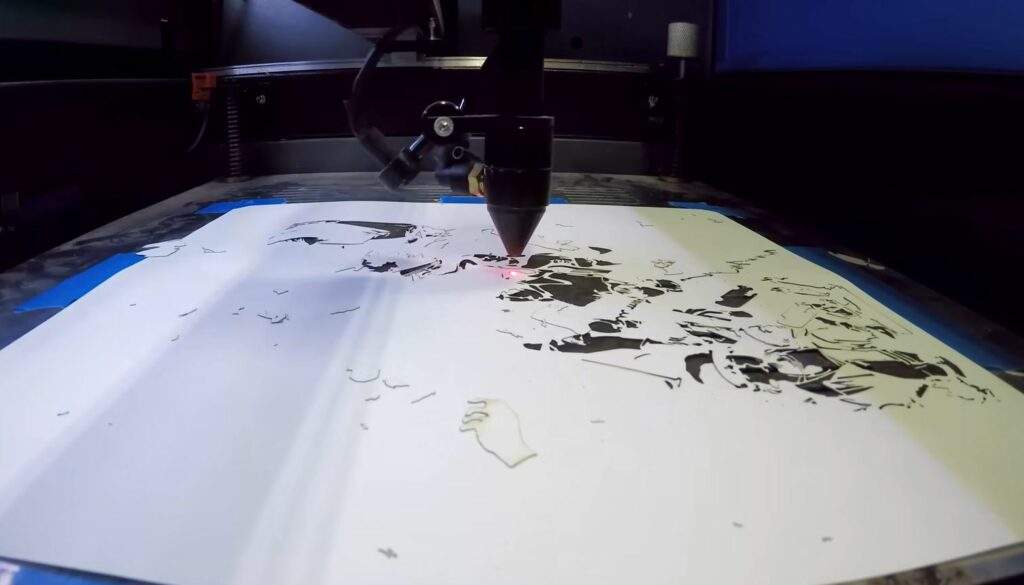

Laser Cutting — Thermal Separation

A laser cutting machine uses its high-power laser to project a huge amount of thermal energy — in other words, heat — onto the material surface. As the laser contacts the material, it begins to burn, melt, or vaporize it.

Once the machine has cut through the first spot, it starts moving the laser along the pattern the user has input to the machine. You’ll generally upload these patterns as vector image files.

Due to the high heat, there’s always a chance the material could catch fire and/or produce combustion fumes. That’s why laser cutters generally have an air assist function to blow out flames and ventilation to clear the chamber of smoke and fumes.

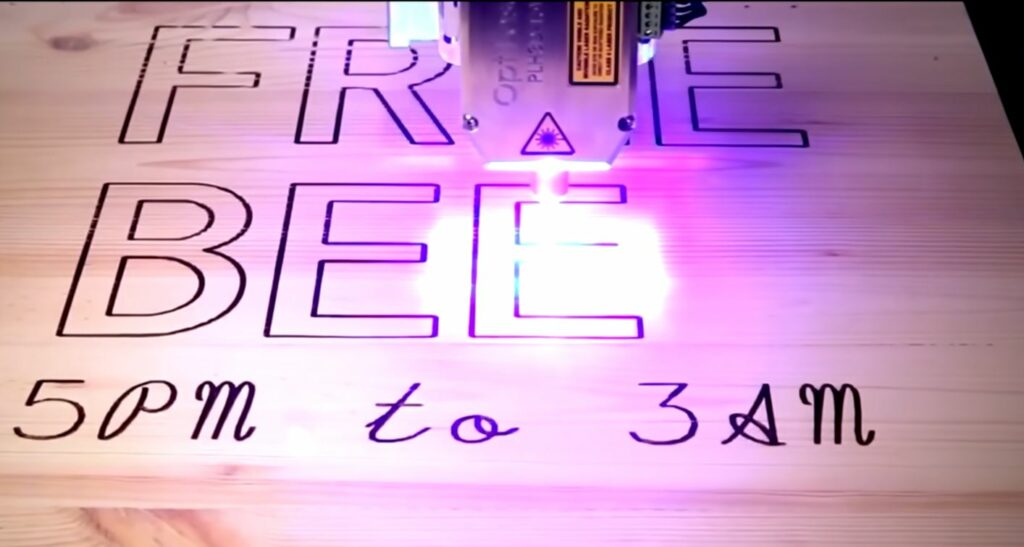

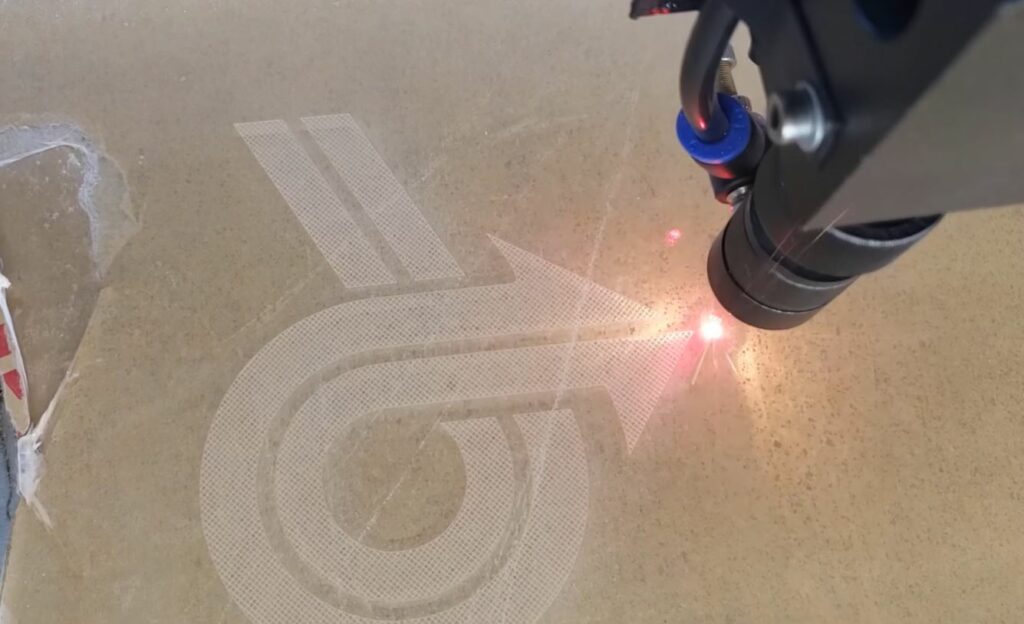

Laser Engraving — Precision to the Design

Laser engraving machines begin the work process just like laser cutters. The difference is that the beam doesn’t cut through the material.

Instead, it carves the uploaded image or text into the object by burning away only a part of its surface. Laser engraving supports a wider variety of file formats, including JPG, PNG, and vector images.

Since a laser engraver doesn’t burn that deeply into the object surface, they often support more material options than desktop-sized laser cutters. You could theoretically use a laser engraver to cut materials as well, but that would need many passes over the same path, which isn’t time- or cost-effective.

7 Things to Consider When Choosing the Best Laser Cutter

So, you’re ready to purchase a laser cutting machine. But there are so many laser cutters out there — just look at this list!

How do you pick the best laser cutter for your purposes?

Like with most things, considering what you actually need makes choosing the right laser cutter much easier. Here are seven things to consider before you buy your machine.

1. Laser Power

As you learned, the power of the laser cutting machine’s laser unit largely determines what it can cut. Ask yourself whether you need to cut thick, hard materials — like acrylic.

If you’re planning to produce thick cut-outs, you should look for a machine with as much power as possible. However, if you know you only want to etch logos or text into your products, choosing a less powerful laser engraver helps you avoid wasting money on power you just don’t need.

2. Cutting Speed

Time is money. If you run a home manufacturing business with tight turnaround times, look for a machine that can cut patterns as quickly as possible.

There’s a but, though. The faster the laser cutter moves its beam, the less time it has to burn through the material.

Move too fast and the beam won’t cut the material properly.

However, practically every laser cutter allows you to adjust the cutting speed for different projects and materials. The bottom line is — choose a machine with fast cutting speeds if you intend to do a lot of cutting.

3. Cutting Area

Do you want to cut big patterns out of large sheets of material? Then you need to find the laser cutters with the biggest possible cutting area.

However, don’t look only at the size of the work platform itself. Many laser cutters allow you to work on objects or materials sheets larger than the machine itself.

They may have removable side panels or floors that allow you to insert very wide or deep objects into the work area. Keep an eye out for features like this if you plan to cut large patterns.

4. Cost

Naturally, you need a budget when shopping for laser cutters. Deciding the highest price you’re ready to pay in advance helps you avoid wasting time by browsing machines you can’t afford.

Also, note that laser cutters can eat up a lot of energy during the cutting process. If you’re worried about your electricity bill, check the machines’ power requirements and pick one with energy-saving features.

5. Accuracy

The beams of laser cutters are generally small, but even they vary between machines. If you aim to cut very precise patterns or engrave intricate designs, try to choose a machine with the smallest laser spot size.

In addition, make note of the laser cutter’s motion control system. The more precisely it can move the laser, the more accurate your cuts will be.

Finally, you should be aware of laser power’s effect on cutting accuracy. A powerful laser can cause excess heat damage around the edges of the cut and result in poor quality. Choose a laser with the right amount of power and learn how to adjust the laser intensity during cutting preparation.

6. Machine Size

Laser machines have become very compact, but they can still take up quite a bit of space. After all, a large work area necessarily makes the cutter larger as well.

Keep the size of your work desk or workshop in mind when picking a machine. You can always reorganize the space to make room for a laser cutter, but it’s an extra hassle you can easily avoid.

7. Laser Lifespan

Nothing lasts forever, and neither will your cutter’s laser unit. Having to constantly replace the laser unit can quickly rack up the laser cutter’s operating costs.

In general, it’s always best to choose a machine with a long-lasting laser unit. Some companies don’t list the estimated laser lifespans for their cutters, so check online for reviews or pop an email over to the manufacturer before making a purchase.

Types of Laser Cutters

Not every laser cutter is built the same. Different machines use different technologies to generate the laser beam.

The laser type can have a big impact on the machine’s performance. Think about what kind of laser you need before buying a laser cutter.

The three most common laser technologies used in desktop-sized laser cutters are CO2, diode, and fiber lasers.

CO2

CO2 lasers are the most common type of laser unit found on desktop-sized laser cutters. They provide a good balance between affordability and power, making them well-suited for machines of this scale.

As you can probably guess from the name, CO2 lasers generate their laser beam by directing an electric current through a carbon dioxide-filled glass tube.

The electricity reacts with the gases, emitting light. A series of mirrors direct the light through a lens, resulting in the slicing laser beam.

A CO2 laser offers fast straight-line cutting with enough power to make a cheap and versatile choice for many materials. The mirrors are fragile, though, so you might burn the initial cost savings by having to replace the laser unit.

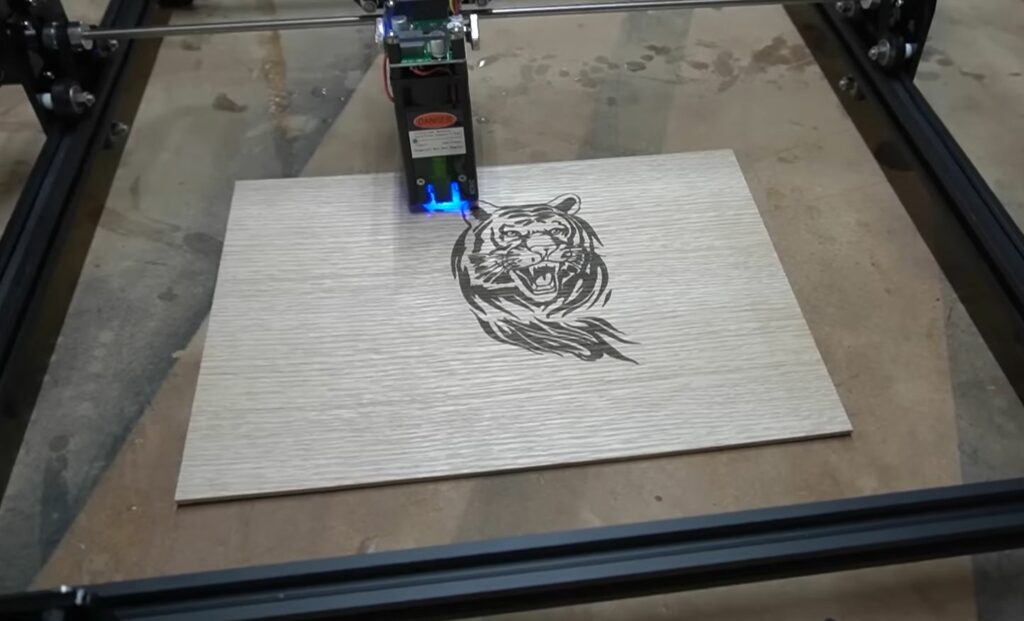

Diode

Diode lasers are relative newcomers to the laser cutting scene. They’re by far the cheapest laser unit option — even cheaper than CO2 lasers.

Diode units use a light-emitting diode (in other words, a powerful LED) to create light that it projects through a two-layer lens. The lens bounces the light beam back and forth until it builds up to a laser.

Although diode lasers are the cheapest laser unit option, they’re also the weakest. Even the most powerful ones can reach only about 20W of power.

This is why you’re more likely to find a diode unit on a laser engraver rather than on actual laser cutters. But, if you know you’ll be working with thin and soft materials, they can be a good and very affordable option.

Fiber

Fiber lasers are power players in laser cutting. As you saw with the Triumph Fiber Laser cutter, they have enough kick to even cut metal.

That power stems from the technology in the laser unit. Optical fibers infused with rare earth elements emit light that goes through a lens.

Lasers produced in this manner are extremely stable and simple to focus. Hence, they can pack a lot of punch.

Unfortunately, that power comes at a sky-high cost. Although fiber lasers have low maintenance costs, the machines themselves are very expensive.

Materials You Can Laser Cut

You now know what laser cutters do and how they work. But what can you actually cut with them?

As simple logic states, the more power your laser cutter has, the wider the variety of materials it can cut. A laser engraver may only be able to cut paper (if even that) while strong fiber lasers can slice even metal with relative ease.

That said, practically all laser cutters on this list can cut the following materials:

- Acrylic

- Cardboard

- Cork

- Fabric

- Leather

- Paper

- Rubber

- Wood

Note that even though your laser cutter can cut a certain material, there’s always a limit on how thick of a cut it can make. You can cut thicker sheets by making multiple passes along the same cutting route, but that can negatively affect the quality of the cut.

Finally, not all materials are suitable for laser cutters. Some can even be lethal. Laser-cutting vinyl, for example, will produce toxic chlorine gas and hydrochloric acid that can harm both your laser cutter and you.

Always check whether a material is safe for laser cutters before trying to cut it.

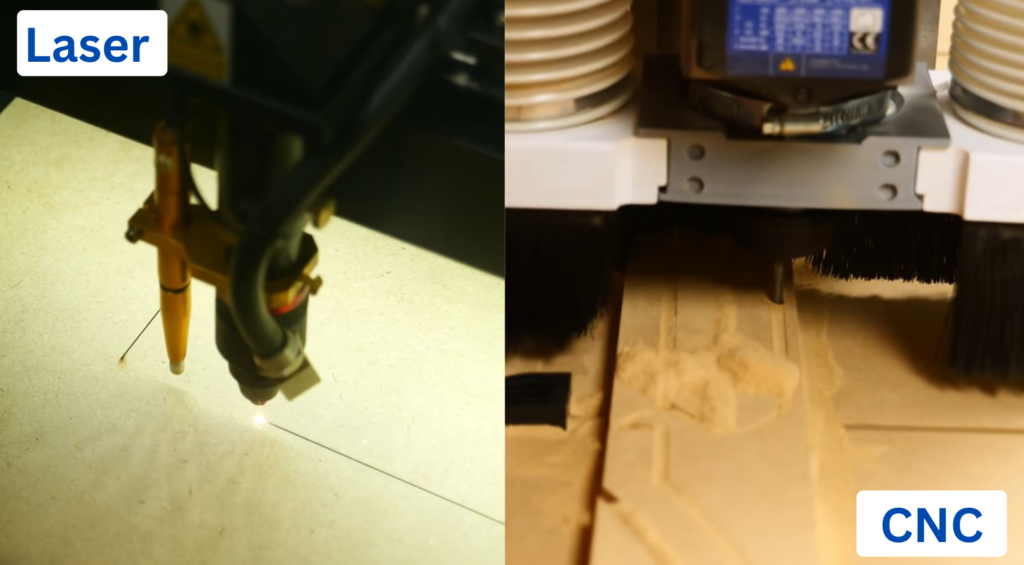

Laser Cutter VS CNC Router

If you’re a more professional manufacturer, you might wonder whether you need a laser cutter or a CNC router.

Generally speaking, the choice comes down to the power and accuracy you need.

Laser cutters can cut materials very quickly and accurately, producing precise cuts for high-quality results. On the other hand, the laser’s power is limited and will not work with thick or highly reflective materials.

CNC routers, on the other hand, can chew through even thick or hard materials, like metal, with ease. But that sheer brawn comes at the cost of detail accuracy. A CNC router can’t produce as precise details as a laser cutter or laser engraver.

If you need precision and speed while working with soft materials, choose a laser cutter — for power to shape hard stuff, pick a CNC router. Or, for maximum versatility, have both in your workshop.

Get a Machine that Makes the Cut

A laser cutter is a great addition to the arsenal of any hobbyist or professional creator of high-detail crafts. With the right machine, you can cut quick and precise patterns out of many different materials.

This list details the best laser cutters on the market in 2024. But if you’re still not sure what to get, here are our recommendations:

- FLUX Beamo 30W offers you the best balance of power and value.

- OMTech 40W is a capable budget option.

- Triumph Fiber Laser is what you need to cut metal.

- FSL Muse Core 45W is a capable cutter that you can fine-tune to your needs.