- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

3D printers have come a long way from their beginnings. In fact, conveyor belt technology is a recent addition to the field of 3D printing. The first generation of conveyor belt printers only came out in 2017, so don’t worry if you’re not familiar with them!

3D printers have come a long way from their beginnings. In fact, conveyor belt technology is a recent addition to the field of 3D printing. The first generation of conveyor belt printers only came out in 2017, so don’t worry if you’re not familiar with them!

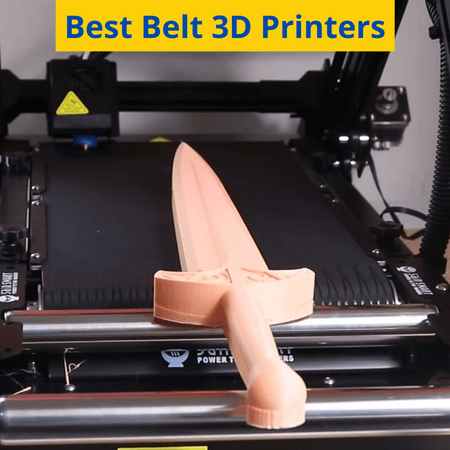

What exactly are belt 3D printers? The main difference from regular 3D printers is that belt 3D printers have a belt embedded into the build platform creating an infinite Z-axis. Basically, you can print continuously, whether you’re printing multiple prints or one very long print (cosplay swords anyone?).

Things to consider before purchasing a belt 3D printer include print speed, build quality, the printer’s motherboard, the different electronic features, and the extruder.

We’ll go more into our favorite belt printers, exploring these various features. Keep reading to understand how the printer works and explore the versatile uses of belt printers.

Best Belt 3D Printers At A Glance

1. Creality CR-30: 3DPrintMill (Best Choice)

2. SainSmart Infi-20 (Best Value)

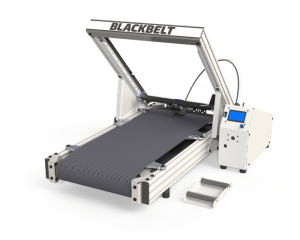

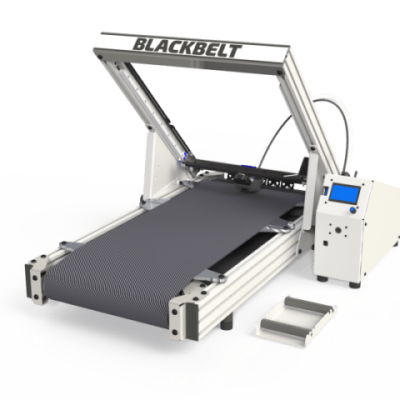

3. Blackbelt 3D (Premium Choice)

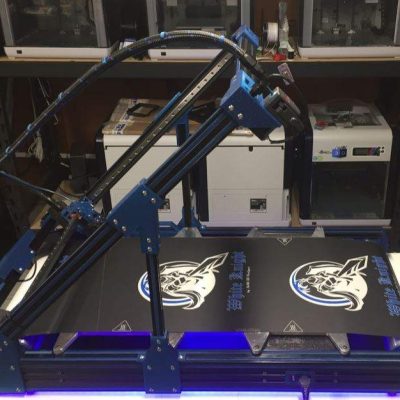

4. The White Knight (Best for DIY Enthusiasts)

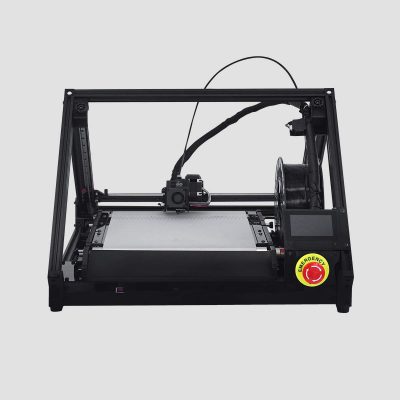

5. iFactory3D One Pro

3D Printer Type: FDM | Materials: PLA, PLA+, TPU & PETG | Build Volume: 200 x 170 x ∞ mm

First up we have the Creality CR-30, also known as the 3DPrintMill. This belt 3D printer is one of the most well-known belt 3D printers out there.

It can be a little tricky to get the printer working, but once you get over the initial learning curve, the printer is amazing. It’s packed with numerous features. From a 32-bit motherboard to a filament runout sensor and an all-metal dual drive extruder, Creality makes sure that the CR-30 is one of a kind.

The 3DPrintMill also holds features like a full-size SD card slot and a fast heating hot end. The printer’s solid frame is large enough for you to print relatively wider prints. The printer also comes mostly assembled and ready to print, making your job easier.

The Stable Core-XY structure ensures that you have a great printing experience. This motion system allows for faster motion and greater accuracy. Because the CoreXY system moves the X and Y plane together, overall mass is reduced, increasing the print speed of the printer.

The Creality CR-30 stands out for its low price point among other belt printers. Even with its lower price, the printer is known for its great build quality, sturdiness, and overall strength. The printer is also compatible with many materials, including PLA, PETG, and TPU.

Overall, the capabilities of CR-30 are well worth the investment. If you don’t mind spending time making the machine work for you and getting the best results, this printer is perfect for you. You will be able to play around with it, making adjustments to the hardware as you like!

Pros

- Super stable Core-XY structure

- Relatively affordable

- Stable frame

- All-metal extruder

- Filament runout sensor

- Durable nylon belt

Cons

- Takes time to get it working

- User Interface feels outdated (chunky)

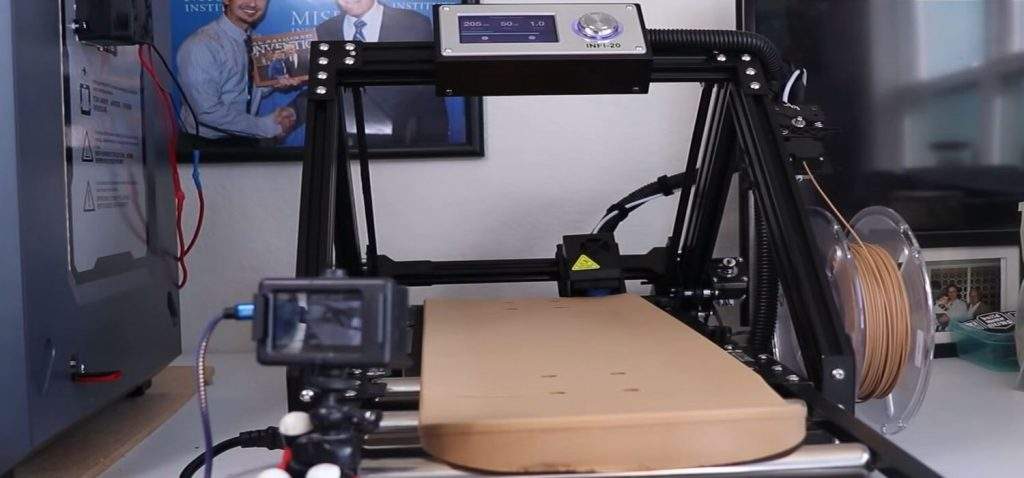

3D Printer Type: FDM | Materials: PLA & PETG | Build Volume: 200 x 180 x ∞ mm

The Sainsmart Infi-20 is similar to the Creality 3DPrintMill as Sainsmart is actually partnered with Creallity. While this belt 3D printer is slightly bulkier than other printers, it’s extremely affordable and a great option.

The user interface on this printer is really nice and has a modern look to it. It comes with a straightforward interface that allows you to keep track of the printer’s status easily. The SainSmart Slicer software that comes with this printer gives you a boost in your infinite 3D printing journey.

The Infi-20 is also really easy to set up. Even though the printer isn’t fully assembled, the simple design of the printer on top of the built-in layers provides an easy start for you with the belt printer.

Another feature of this printer includes the stable CoreXY structure. This feature ensures great print adhesion and smooth print quality. With this belt 3D printer, you print a model that is as long as you want or as many times as you want. Your only true limit is how much filament you have.

Pros

- Large print area

- Modern user interface

- Filament runout sensor

- Stable frame

- Affordable

Cons

- Bulky design

- Not a very visually-appealing look

3D Printer Type: FDM | Materials: ABS, PLA, TPU, Co-Polyester & PETG | Build Volume: 340 x 340 x ∞ mm

Although a bit pricier in comparison to other belt 3D printers, the Blackbelt 3D is extremely versatile. This printer provides customers with three versions of the conveyor belt: a desktop version, a frame version, and a frame version with a roller table.

The Blackbelt 3D is also not compromised to a single degree. Its E3D V6 hot end can print at an angle of 15°, 25°, 35°, or 45° on the heated conveyor belt. The printer supports various filaments, including PLA, PETG, ABS, TPU, and XT, among many others.

The printer also comes assembled and mostly ready. There are some accessories and features that are sold separately, such as the Blackbelt Server and the Filament Runout Sensor. Still, the printer boasts many other features.

The Blackbelt has a large XY build area which allows for larger-sized prints. For 3D prints 1300mm or longer, it’s recommended to use a roller table to provide additional support during the 3D printing process. Additionally, this belt 3D printer is able to print overhangs without using any support material.

The motherboard and power supply unit are located together in a separate box, saving space and making the machine frame larger. The printer also comes with many fans and linear rails to create a smooth printhead motion for large prints.

With so many features, the Blackbelt proves to be an exceptionally high-quality machine. But, it’s not cheap. Considering the price, the machine is great for the industry and business environment. If you are looking for a belt 3D printer for hobbyist reasons, the Blackbelt may not be the best option for you.

Pros

- Large build volume

- Adjustable print angles

- Super reliable

- High-quality prints

- Well-developed and looks great

Cons

- Pricey

- Bulky/Heavy

- Outdated User Interface

3D Printer Type: FDM | Materials: PLA, ABS, PETG & TPU | Build Volume: 400 x 430 x ∞ mm

The White Knight is different from the printers we’ve touched on so far. This 3D belt printer is an open-source DIY project in which you can build the printer yourself!

The quality is not as great as a Creality or a Blackbelt 3D belt printer, but there’s no doubt regarding the exciting challenge the White Knight comes with. Considering you can build the printer yourself, the printer consists of many 3D printed parts and hardware pieces which reduces the overall costs. Still, you will have a large but sturdy frame.

As a DIY 3D belt printer, the White Knight is an open-source design, downloadable at no charge from Thingiverse. The community surrounding the White Knight is a huge part of this printer’s success. There’s a large community behind this project that can assist you through the build process.

Even though you can probably add any feature you would like to the White Knight, the printer holds many features by itself. There are linear rails for smooth printhead motion, a high-temperature hot end, and an extruder for consistent filament flow.

Still, there are some things to watch out for. The White Knight is known to be difficult to level the bed, which is definitely not ideal for many users. The bed also isn’t heated, meaning you’ll probably only be able to print PLA filament.

Pros

- Huge build volume (bigger than Blackbelt)

- Allows for customization

- Customizable with features

- Very helpful community

Cons

- No heated bed

- Can be tricky getting the printer assembled

3D Printer Type: FFF | Materials: PLA, PETG, TPU, With Additional Enclosure: PC, ASA, Nylon & ABS | Build Volume: 290 x 180 x ∞ mm

Finally, we have the iFactory3D One Pro. This 3D belt printer is the upgraded version of the original iFactory One. The printer is loaded with numerous features and is priced great for all that it comes with.

While it isn’t a DIY printer like the White Knight, the iFactory3D does require a good bit of assembly to get it running. This belt 3D printer is known for its variety of unique features.

The printer comes with an onboard camera that monitors your prints and makes sure everything is running smoothly. There’s even an AI-enabled failure detection software built into this system to prevent mistakes.

Other features include the dual-gears, direct extrusion E3D Hemera print head, and a high-temperature heated bed. The printhead provides reliable and precise extrusion. The printer also has linear rails, a Duet 3D motherboard, a touchscreen LCD, and a Wi-Fi-enabled Raspberry Pi4.

Pros

- Large build area

- AI failure detection software

- Linear rails

- E3D Hemera direct drive hot end

- Built-in Raspberry Pi 4 (OctoPrint)

- Easy-to-use LCD

Cons

- More assembly required

- Does not look as well constructed as printers by larger companies

What Is a Belt 3D Printer?

To recap, a belt 3D printer is a 3D printer with unique features allowing it to print continuously or in a series (part-after-part production). There are many advantages to this type of technology.

Automatic 3D print removal allows for the 3D printer to immediately start the next job, increasing overall productivity. Infinite 3D printing allows belt 3D printers to print objects beyond what fits on the printer’s build platform. This type of printer can print an infinitely long object in the Z direction.

As an FDM/FFF 3D printer, a belt 3D printer can print at an overhand up to about 45°. Depending on what is being printed, a conveyor belt 3D printer can minimize the overall support material needed making impossible overhangs possible.

How Does a Belt 3D Printer Work?

As mentioned before, belt 3D printers have a belt embedded in their build platform. But the belt alone doesn’t make infinite Z-axis printing possible. That goes to the 45-degree printing angle of belt printers, which enables infinite printing along one axis.

Conveyor belt 3D printers used FDM technology (Fused Deposition Modeling). Materials are fused together and layered on top of each other to create an object.

While printing, the belt pulls prints away from the nozzle. Prints do eventually fall off the belt, but this could be avoided easily by having a support structure. Support structures can be anything from a table to a set of rollers in front of the bed that meet the printer’s height.

Touching on bed adhesion, as of right now, you can’t have a fully heated conveyor belt bed, but painter’s tape does the job.

For a belt 3D printer to function appropriately, the x and y axes are rotated at an angle instead of being parallel to the build plate. The z-axis conversely is replaced with a conveyor belt. The conveyor belt allows prints to not be limited by the size of the build platforms, unlike regular 3D printers.

Advantages and Disadvantages of a Belt 3D Printer

Belt 3D printers hold numerous advantages over other 3D printers, but there are also some disadvantages to consider.

Advantages

Considering that belt 3D printers can be used for continuous printing, these printers are great for automated or even semi-automated production. They make mass-production and printing really large models simple.

Even with the belt printer’s large print volume capacity, there is no loss in average speed. Additionally, print removal is automatic and hassle-free. It’s also possible to have a partially heated bed with these printers.

Considering these features, belt 3D printers are great for professionals working in the business industry as it is suited great for large, expensive projects. It’s also a great option for hobbyists.

Disadvantages

There are some limitations to keep in mind if you are considering buying a belt 3D printer. Belt 3D printers are relatively more expensive than other 3D printers. Belt 3D printers can also require additional support structures, which adds to the overall costs.

On top of costs, belt 3D printers can’t print certain types of materials depending on the printer. You also can’t use a glass print bed. The print speeds are noticeably slower compared to other 3D printers.

Another factor to consider is that belt printers can take up a lot of space. Especially since you may need additional structures to support prints that are longer than the print bed. Additionally, belt 3D printers are still in development (new tech) and may result in lower print quality.

Uses of a Belt 3D Printer

Belt 3D printers are extremely versatile when it comes to their uses. Keep reading to find out the different ways you can use your own belt 3D printer.

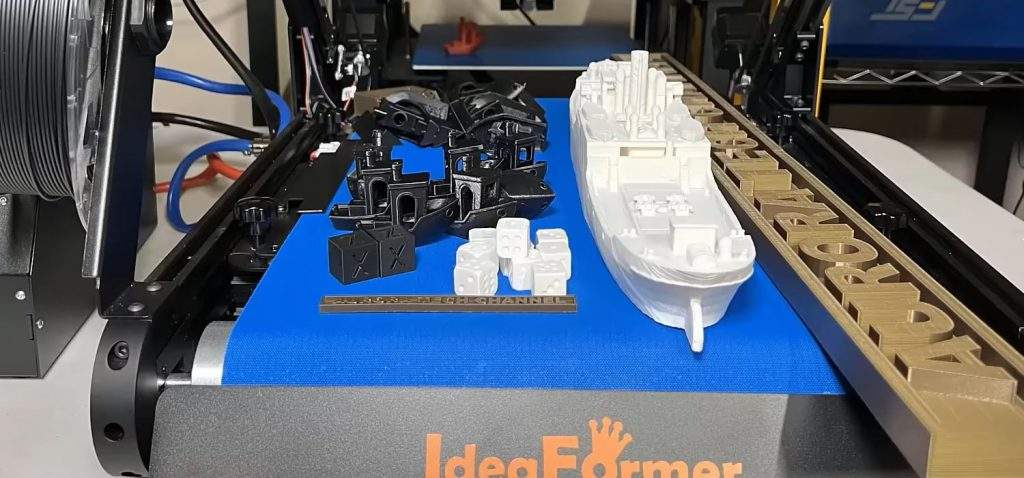

Print Farm

Print farms are groups of 3D printers that run together continuously to increase overall production rates.

Given the endless Z-axis, which allows for mass production and the printing of very large parts, it’s clear to see that a print farm made completely out of belt 3D printers is a game changer.

Unlike a print farm with regular 3D printers, a print farm with belt 3D printers completely addresses the single-volume problem that comes with 3D printing, as belt 3D printers can print multiple prints continuously.

Cosplay (Long Prints)

Belt 3D printers also work for cosplay purposes. With a belt printer, you can create any 3D printed prop you want.

By printing your own cosplay props, there’s no doubt that you will enjoy faster printing times, better quality products, and the flexibility to make it your own!

There is no limit to what you can make with a belt 3D printer.

Regular Printer

At the end of the day, a belt 3D printer can still do everything a regular 3D printer can do. You can print regular-sized models. Think of a belt 3D printer as a 2-in-1! You’re not limited to the dimensions of a standard 3D printer.

Conclusion

It’s no doubt that belt printers offer some super incredible benefits, like infinite printing capabilities and part-after-part production. But what belt printer to get is the question?

My personal favorite and #1 rec is the Creality 3DPrintMill, AKA the CR-30. This printer has a large following, with many optional upgrades available. Additionally, the machine is loaded with many cool features, like a durable nylon belt, sturdy frame design, filament runout sensor, and all-metal extruder; this makes the print quality spectacular.

And, if you want an even more professional belt printer, then definitely check out either the iFactory3D One Pro or the Blackbelt 3D. The One Pro is loaded with many advanced consumer features, like linear rails for smooth motion, an E3D Hemera direct drive hot end, and even a built-in Raspberry Pi 4 for OctoPrint control. And the Blackbelt 3D, while very expensive, is super reliable due to its frame design and many sensors.

If you’re shopping on a budget, though, and are trying to get the most bang for your buck, then I’d point to the Sainsmart Infi-20 as it’s reasonably priced and has a few cool features like a filament sensor and sturdy frame.

Lastly, if you’d rather DIY your printer, then check out The White Knight. While this printer is definitely a pretty complicated build, it gives you the opportunity to fully customize the features on your printer. Plus, many of the parts are common hardware that can be picked up at your local hardware store.