- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

Polycarbonate is THE STRONGEST filament material out there for FDM 3D printers. It’s not even close when you compare it to PLA or ABS.

Polycarbonate is THE STRONGEST filament material out there for FDM 3D printers. It’s not even close when you compare it to PLA or ABS.

So if you’re printing something that needs true strength, whether it’s a monitor stand or a bike part, then you should definitely try out PC filament.

But which one to go with?

While there are many polycarbonate filaments available online that all call themselves “strong”, I’ve found that the best polycarbonate filament is Polymaker’s PolyMax PC. This filament isn’t too expensive but provides insane strength while still being relatively easy to print.

But if you’re looking for pure strength, then I’d suggest 3DXTech 3DXMAX PC filament. This filament is about as strong as it gets for consumer-grade 3D printing, and I promise you that any part you print in this filament won’t fail you.

Want to hear about more of the best polycarbonate filament options? Keep reading!

Table of Contents

Best Polycarbonate Filaments At A Glance

1. Polymaker PolyMax PC (Best Choice)

2. Gizmo Dorks (Best Value)

3. Ultimaker PC Filament (Premium Choice)

4. 3DXTech 3DXMAX PC (Best Strength)

5. Raise3D PC (Best Print Quality)

6. 3DXTech ezPC Polycarbonate Filament (Easy to Print)

7. Proto-Pasta PC-ABS Alloy

Polymaker is one of the most popular manufacturers of consumer 3D printing filaments, making everything from PLA to PC. The Polymaker PolyMax PC filament, also called Polymaker Tough PC filament, is my personal favorite polycarbonate filament.

The first thing you’ll notice about PolyMax PC is that it’s available in a pretty wide assortment of color options, including black, white, natural (cream), gray, and even red and blue. This is unique for a polycarbonate filament as most filaments of this material only come in either clear or black.

But what I love most about PolyMax PC is that it’s exceptionally easy to print. Despite being PC, notoriously one of the most difficult materials to 3D print, Polymaker’s Tough polycarbonate filament is surprisingly easy-going. Moreover, I barely had to tune any of my slicer settings (e.g. temps) to achieve decent-quality 3D prints.

Sadly, as some reviewers have pointed out, this is because PolyMax isn’t actually true, pure polycarbonate. Instead, it’s a similar material called Polycaprolactone with additives that enhance its strength so that it’s close to that of PC. As such, the strength isn’t top-tier.

But don’t be fooled. When I say the strength of PolyMax isn’t as good as normal PC, I’m not saying it’s weak by any standards. In fact, PolyMax easily ranks in the top five ten strongest filaments I’ve ever used, offering significantly more strength than PLA, ABS, and PETG.

So if you’re just starting out with polycarbonate filament and want a strong option that’s still easy to print, then definitely give Polymaker PolyMax PC a shot. I guarantee you that you won’t regret it!

Pros

- Good value

- Very strong

- Decently easy to achieve high-quality prints

- Lower hardware requirements (lower temps needed)

- Many color options

Cons

- Not as strong as other polycarbonate filaments

Gizmo Dorks is a manufacturer of 3D printing filament, and while they’re not the most popular company in the space, they certainly make a good value polycarbonate filament.

This filament has a diameter tolerance of +/- 0.03 mm, meaning this filament was very precisely manufactured and shouldn’t cause any issues with your extruder. It’s also a very impressive tolerance for a filament at this price point.

Gizmo Dorks suggests printing this filament with a nozzle and bed temperature of 255-300 °C and 100-120 °C, respectively. These are pretty high temps for a polycarbonate filament, but they indicate that this material is very pure and strong.

Additionally, a higher printing temperature will provide better layer-to-layer adhesion for prints, making them less brittle. So maybe the relatively high temp requirements aren’t entirely a bad thing?

But my favorite part of this filament is that Gizmo Dorks sells it in 200-gram spools. As such, the price is super low, making it a budget-friendly option for anyone who wants to try out polycarbonate filament but doesn’t want to drop $50+ at once.

Pros

- Very budget-friendly pricing (200g spools)

- A great bang for your buck

- Very strong and great layer-to-layer adhesion (not brittle)

- Low diameter tolerance

Cons

- Relatively high-temperature requirements

- High print quality can be difficult to achieve

We’ve all heard about Ultimaker, the developer behind Cura (the most popular 3D slicer) and the manufacturer of some popular high-end 3D printers like the Ultimaker 3. Ultimaker also makes filaments, including a polycarbonate option.

Ultimaker’s polycarbonate filament is pretty reasonably priced (even if their printers aren’t), but it’s objectively a pretty high-end filament. With a temperature resistance of up to 110 °C, this filament can survive in even the hottest environments. Additionally, the filament is known to be insanely strong, making it perfect for printing any industrial-grade parts or models that will face a lot of physical stress (e.g. bike part).

Sadly, there are some pretty big downsides to this filament. For one, Ultimaker PC only comes in three colors: black, white, and clear. But the worst part is that this filament only comes in a 2.85 mm (AKA 3.0 mm) version, meaning it won’t work on 1.75-mm filament printers, which are most machines nowadays, like the Creality Ender 3 or Prusa i3 MK3S+.

But if you’re okay with the limited color options and have a compatible 3D printer, like the Ultimaker 3 or LulzBot TAZ Pro, then it’s perfect!

Pros

- Very strong

- Decent print quality

- High-temperature resistance

Cons

- Not available in a 1.75-mm version; limited printer compatibility

- Limited color options

If you’re looking for THE filament for strength, then you won’t find one better than 3DXTech’s 3DXMAX PC. As you probably could tell from the all-caps name of the filament, 3DXMAX PC is a filament material designed with part strength as the #1 goal.

The filament is heat resistant up to 147 °C, which is absolutely bonkers, making it an exceptional temperature-resistant material. Moreover, you’ll be able to print parts that can survive in very high temperatures, like under the hood of a car.

Additionally, strength is out of this world. According to the Technical Data Sheet for 3DXMAX PC, this filament has a tensile strength (at break) of 62 MPa, which is almost double the tensile strength of PLA (~37 MPa). You won’t have to worry at all about a 3D print in this filament breaking!

But, with high strength comes intensive printing requirements. The suggested nozzle temperature for 3DXMAX PC is 280-310 °C, higher than any polycarbonate filament on this list. You’ll also need a heated enclosure, a bed capable of reaching at least 110 °C, and a powerful adhesive (e.g. Magigoo) for the print bed.

But if strength is your main concern, then go for it! Just be prepared for the difficult printing process and limited color options!

Pros

- Insanely strong

- High-temperature resistance

- Very impact-resistance and durable

Cons

- Limited color options

- Heated enclosure is recommended

- High nozzle and bed temperature requirements

- Difficult to achieve prints with a high print quality

Raise3D is a company that’s very similar to Ultimaker, with a 3D slicer (IdeaMaker) and many 3D printers, such as the Raise3D E2, under their belt. Raise3D also sells one hell of a polycarbonate filament.

Out of all of the polycarbonate filaments I’ve tried, I achieved probably the best print quality with this one. I can’t explain it, but Raise3D polycarbonate filament just prints very nicely.

Maybe it’s the long list of printing suggestions, from the nozzle temperature and printing speed to retraction and fan speed, that Raise3D provides for their PC filament. Or maybe it’s the inherent quality of the raw materials used for the filament.

Whatever the case, achieving detail on prints is much easier with this filament than the other options, making it perfect if you want to print detailed cosplay parts that need to be strong or small mechanical assemblies.

The temperatures required for this filament are a bit on the lower end of the spectrum for PC filament, so strength won’t be as high. But, honestly, it’s definitely worth it for the print quality of the filament, especially if you need to print parts that are small but need to be very detailed and decently strong.

Pros

- Great print quality

- Many recommended print settings from Raise3D

- Very strong

Cons

- Not super popular with the community

- Not as strong as other polycarbonate filaments

- Limited color options

Another polycarbonate filament option from 3DXTech is ezPC, a filament that…you guessed it…is easy to print. Well, relatively easy, at least.

Moreover, 3DXTech ezPC filament is still polycarbonate, so it won’t be as easy to print as PLA. But, it also will make achieving high-quality prints much easier compared to regular polycarbonate filaments.

The suggested nozzle and bed temps for ezPC are 255-275 °C and 90-110 °C, respectively. These temperatures are relatively low for PC filament and are actually very similar to the recommended temps for ABS. This means you’ll be able to print ezPC on more printers because the heaters don’t have to be able to go up as high as they would for other PC filaments.

The sacrifice you make for the easier printing experience, though, is the strength of the material. While ezPC filament is still insanely strong, especially when compared to PLA and ABS, it’s not as strong as 3DXTech’s 3DXMAX PC filament. But I assure you that this filament is still more than strong enough to be used for basically any print, whether it’s a phone stand or drone frame.

So, if you need a filament that’s very easy to print, works on lower-end 3D printers, but still has a good bit of strength, check out 3DXTech’s ezPC filament!

Pros

- Lower nozzle and bed temperature requirements

- No heated enclosure requirement

- Easy to achieve good print quality

- Very strong

- Four color options (white, black, clear, and red)

Cons

- Not as strong as 3DXMAX and other polycarbonate filaments

- Expensive

Finally, we have ProtoPasta’s PC-ABS Alloy filament. Unlike the other options on this list, ProtoPasta PC-ABS isn’t solely based on PC polymers but also ABS plastic. This was done to make the printing experience for the part-polycarbonate filament a bit easier than a typical PC filament.

And it worked!

ProtoPasta PC-ABS Alloy requires noticeably lower temps than a typical polycarbonate filament. Additionally, not too much strength is lost as ABS isn’t too weak a plastic to begin with. Moreover, ProtoPasta found that their PC-ABS alloy was stronger than plain ABS, but less strong than just plain PC filament.

Sadly, this filament is pretty expensive, which makes sense as ProtoPasta is a pretty well-regarded filament company. But, if you want a filament that eases your transition from ABS to PC, then the PC-ABS Alloy filament is perfect!

Pros

- Easier to print than normal polycarbonate filament

- Very strong

- Easier to tune the slicer profile

Cons

- Expensive

- Not as strong as plain PC filament

- Not very popular (limited community support)

What is Polycarbonate?

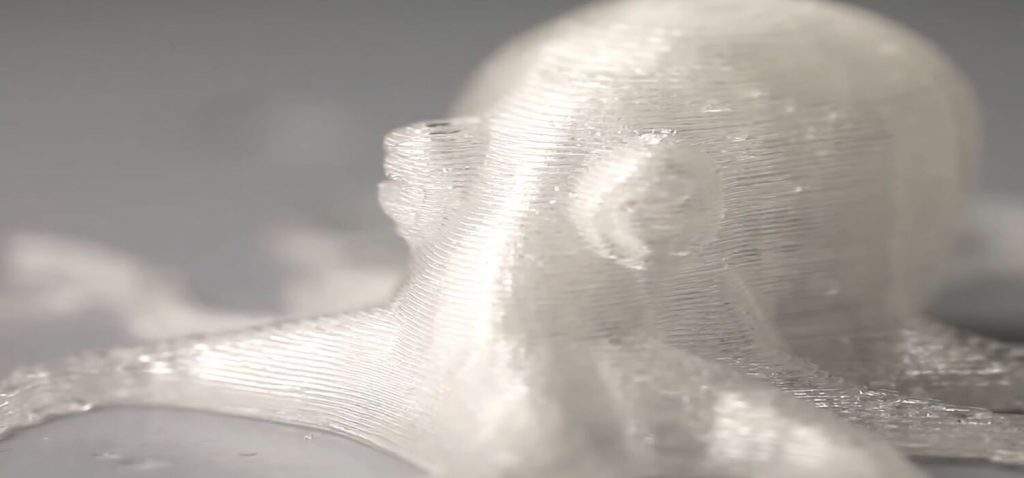

Polycarbonate is a high-end thermoplastic material with insane strength and durability properties. Commonly abbreviated as PC, polycarbonate is usually clear in color. As such, it’s usually the material used whenever visibility and strength are both needed, like for eyeglass lenses, lamp shades, and dashboard covers.

Polycarbonate is also used for medical devices, automatic parts, and protective gear, where overall strength is needed, but metal doesn’t make sense.

Of course, PC has also been made into a 3D printing filament. PC filament is considered the strongest 3D printing filament, offering significantly more strength than traditional printing materials like PLA, ABS, and PETG.

When to Use PC Filament?

You should use PC filament whenever strength is your main concern. Additionally, if you need both strength and transparency for a part, polycarbonate filament is perfect!

Of course, a part 3D printed in polycarbonate filament isn’t unbreakable, but it’s certainly extremely durable and strong. So, if you’re printing a lock, part for your bike, robot/machine attachment, or any other part that will face a lot of physical stresses, PC filament is the one for you.

How to Print PC Filament?

Although it’s super strong, polycarbonate filament is often criticized for its printing difficulty. On top of very high hardware requirements, achieving high-quality prints on PC is very hard.

The first thing you’ll need is a 3D printer with both a high-temperature hot end and a high-temperature heated bed. That’s because PC filament requires nozzle and bed temps of around 280 °C and 100 °C, respectively. Of course, different polycarbonate filament brands require different temps, but these maximum temps work for most PC filaments.

But, on top of high-temperature equipment, you’ll need to enclose your 3D printer. If you don’t have a 3D printer yet, you can check our article about the best enclosed 3D printers. But, if you’ve already got a printer, you can check out our piece on the best 3D printer enclosures, such as the Creality enclosure or a DIY one.

An enclosure is necessary to ensure that the ambient temperature around your PC part is high enough to prevent the layers from separating and cracking.

And, even with all of this hardware, you’ll need to fine-tune your 3D slicer settings to get good print quality for your prints. This means printing many temperature towers, stringing tests and other test prints and evaluating each, and changing the settings accordingly.

But once all of that is done, you’ll be set! Personally, I think PC filament’s strength is worth the price!

Check out our article on the best 3D printers for polycarbonate to find a 3D printer that’s PC-ready out of the box.

How to Store PC Filament?

3D printing filament needs to be stored dry because if there’s moisture in the air, the plastic will absorb it, and then your prints will turn out a lot worse.

While moisture absorption (hygroscopic) for filaments is universal, some materials are more hygroscopic than others. Sadly, polycarbonate filament, in particular, is very hygroscopic, meaning it absorbs moisture very fast from the air. As such, you need to store it in a very dry environment.

I strongly suggest getting a 3D printer dry box as these containers are super effective at keeping filaments dry. Some even have built-in heaters, which can remove moisture from wet filament! You can check out my article about the best filament dryers and dry boxes to see some options.

Advantages and Disadvantages of Using PC Filament

If you want a brief run-down of all the pros and cons of polycarbonate filament, check out the list I’ve compiled for you below:

Pros

- Super strong

- Yields very impact-resistant prints

- Resistant to high temperatures

- Slightly flexible (makes it less brittle)

- Can be transparent

- Non-conductive

Cons

- Requires an enclosure and other hardware (e.g. steel nozzle, high-temp hot end, high-temp bed)

- More expensive than other filament materials

- Very hygroscopic; it needs to be kept in a dry and warm environment

- Not many color options usually

- Sensitive to slicer settings (requires a lot of tuning to get good prints)

Do You Need An Enclosure for 3D Printing PC Filament?

Yes!

As I mentioned, an enclosure is necessary for 3D printing PC filament because this thermoplastic needs to be warm and away from winds in order to print well.

An enclosure helps with this by trapping the heat produced by the printer. As such, it raises the ambient temperature around the machine, improving printing performance for PC and other high-temperature filament materials (e.g. ABS, ASA).

Additionally, an enclosure keeps out unwanted air drafts or winds, such as air blowing from an AC unit. These air drafts can hurt the print quality because it affects the ambient temperature.

Is Polycarbonate Stronger than PLA, PETG, & Nylon?

Yes! Yes! And yes!

Polycarbonate is stronger than every other 3D printing filament. While some composite options, such as carbon fiber-infused nylon, come close, PC filament still takes the crown by all metrics, whether its shear strength, weight-holding abilities, or heat resistance.

If we had to rank these four materials in terms of strength, from weakest to strongest, it would go as follows: PLA, PETG, Nylon, and PC.

It’s been tested that PC filament is over 1.5 times stronger than PLA, which is insane!

Conclusion

Overall, polycarbonate is the perfect filament material when strength for your 3D prints is your top concern.

Polycarbonate offers the most strength out of any 3D printing filament, lightyears ahead of PLA, ABS, and PETG.

I’ve found that the best polycarbonate filament is Polymaker PolyMax PC as it’s a great mix of value, strength, and printability.

But if you want the strongest PC filament, then 3DXTech 3DXMAX is the one for you, offering more strength than any other product. Just be prepared for a more difficult printing experience.

And, on this note, if you want to print PC but are worried about the printability of the material, then I suggest going with 3DXTech’s exPC filament. This filament has lower temperature requirements and is less sensitive to the slicer settings, making it easier to achieve high-quality prints.

Enjoy!