- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Do you like heavy metal? Then you’ll love carbon fiber.

Carbon fiber 3D printers can create parts as strong as metal out of lightweight reinforced plastic. And they do it at a fraction of the cost.

But you need the right kind of 3D printer to print with carbon fiber filaments. Using an inadequate printer with these advanced materials will only result in broken components and expensive maintenance.

Read on to learn what the best carbon fiber 3D printers are in 2024.

Table of Contents

- Top 10 Carbon Fiber 3D Printers in 2024

- 1. MakerBot METHOD X Carbon Fiber Edition (Best Choice)

- 2. Qidi Tech X-Plus (Best Budget Option)

- 3. Ultimaker S5 (Premium Choice)

- 4. Raise3D Pro3 (Most Reliable)

- 5. Pulse XE (High Performance)

- 6. Markforged Mark Two (Best For Strongest Parts)

- 7. Bambu Lab X1 Carbon (Most Advanced)

- 8. Raise3D E2CF (Best Value)

- 9. Qidi Tech X-CF Pro (Best Second Printer)

- 10. Flashforge Creator 4S (Best for Large Parts)

- Printing with Carbon Fiber-Reinforced Filament

- Chopped Carbon Fiber VS Continuous Carbon Fiber

- Is 3D Printed Carbon Fiber Strong?

- Ideal Designs for Carbon Fiber 3D Printers

- Tips for Successful Carbon Fiber Printing

- Pros and Cons of Carbon Fiber 3D Printers

- Go Strong, Go Carbon Fiber

Top 10 Carbon Fiber 3D Printers in 2024

1. MakerBot METHOD X Carbon Fiber Edition (Best Choice)

2. Qidi Tech X-Plus (Best Budget Option)

3. Ultimaker S5 (Premium Choice)

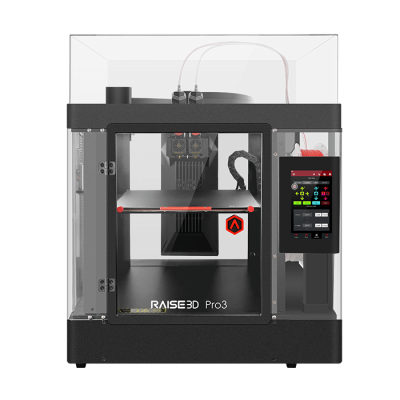

4. Raise3D Pro3 (Most Reliable)

5. Pulse XE (High Performance)

6. Markforged Mark Two (Best For Strongest Parts)

7. Bambu Lab X1 Carbon (Most Advanced)

8. Raise3D E2CF (Best Value)

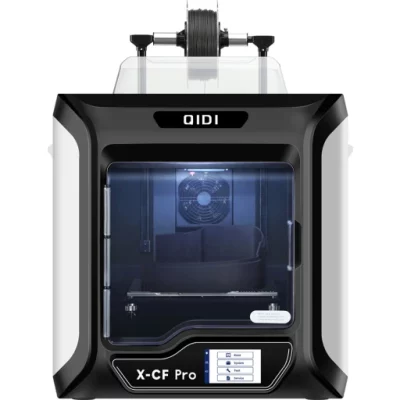

9. Qidi Tech X-CF Pro (Best Second Printer)

10. Flashforge Creator 4S (Best for Large Parts)

3D Printer Type: FDM | Materials: Tough, PLA, PVA, PETG, Nylon, Nylon Carbon Fiber | Build Volume: 152 x 190 x 196 mm | Layer Resolution: 20 microns | Max Print Speed: 500 mm/s

If you’re only ever going to buy one carbon fiber 3D printer, make it the MakerBot METHOD X Carbon Fiber Edition (CFE). This machine brings you everything you could need.

With a minimum layer resolution of 20 microns, this printer creates surface details few FDM printers can match. That quality is due to the enclosed chamber that guarantees uniform heating.

METHOD X CFE also features dual extruder printing and can print water-soluble supports. It ships with three different extruders, each optimized for different filaments. You can print with practically any filament you want.

This fully production-ready printer supports everything from basic PLA to high-performance materials, even from third parties. It can even print parts good enough to replace metal. If you can dream it, METHOD X CFE can print it.

But wait, we haven’t gotten to the best part yet.

METHOD X CFE is automated to a mind-blowing degree. Material loading, bed leveling, Z-axis, and nozzle calibration… The printer takes care of it all on its own and saves you hours in print preparation. Just hit Start and move on with your day.

If we have to nitpick to find downsides, you have to wait a bit for parts to cool down due to the heated chamber. As a professional quality (pro-quality) printer, METHOD X CFE is also pricey.

Note that MakerBot recently announced its merger with Ultimaker. The companies say they will keep manufacturing their respective printers, but we’ll have to wait and see what future support will be like.

But if you want to print carbon fiber filaments, get the MakerBot METHOD X CFE. It’s simply the best carbon fiber 3D printer available.

Pros

- Extreme dimensional accuracy and detail

- Supports plenty of materials

- Almost everything is automated

Cons

- Expensive

- Small build volume

- Uncertain future support

3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU, Nylon, Carbon Fiber & Polycarbonate | Build Volume: 270 x 200 x 200 mm | Layer Resolution: 50 microns | Max Print Speed: 100 mm/s

Whoever said there’s no such thing as affordable quality hasn’t seen Qidi Tech’s X-Plus. This printer serves up incredible flexibility at a price point well below $1,000. The machine achieves that versatility by essentially having two sides to it.

What exactly does that mean?

X-Plus ships with two swappable extruders — A and B. Similarly, it has a double-sided flexible printing bed and two filament holders.

Extruder A, combined with the A-side of the print platform and the external filament holder, makes printing regular filaments a breeze. The outside filament holder smoothly feeds PLA, ABS, or TPU filament into the machine.

But it’s the B-side where things get advanced. Extruder B is specifically designed for harsher advanced materials, like nylon or carbon fiber filament. You place carbon fiber materials into the internal filament holder within the ventilated enclosed chamber, which keeps their temperature steady for excellent print quality.

With X-Plus, you also get a very generously sized print chamber — well beyond what you’d expect at this price. You can easily print either large-scale parts or a whole bunch of small components from carbon fiber-reinforced filaments right at home. If you’re dreaming of an advanced 3D printing station in your garage, X-Plus makes your dreams come true.

But the low price shows in some things. The user manual and online resources are pretty poorly translated and occasionally devolve into non-English. Luckily, the company’s excellent customer service will quickly answer any questions.

Qidi Tech X-Plus is your printer of choice for reliable carbon fiber printing that won’t break the bank.

Pros

- Affordable price

- Large print volume

- Great customer service

- Supports a wide range of materials

Cons

- Poorly translated documentation

- Overtly sticky print platform

3D Printer Type: FDM | Materials: Tough PLA, TPU 95A, ABS, Nylon, TPU | Build Volume: 330 x 240 x 300 mm | Layer Resolution: 20 microns | Max Print Speed: 24 mm/s

Are you serious about carbon fiber 3D printing? Do you want to make pro-quality parts with a pro-quality machine at your home? Ultimaker S5 will keep you in business — with a capital B.

S5 is a popular machine among such huge companies as Volkswagen and Ford, and for a good reason. Its impressive collection of features makes it an “always-on” production powerhouse.

The S5 has swappable print cores and ships with three different ones. You can change them as needed to print with more than 200 filaments of different thicknesses and properties. Simply pop in the hardened print core and you’re ready to print carbon fibers.

But S5 goes much further in productivity.

With its dual extruders, S5 can print two different filaments at once. It can also automatically swap between the extruders on the fly to deliver accurate and multi-color parts. You can easily fill the S5’s massive print chamber with huge carbon fiber components.

If you’re looking for more dual extruder 3D printers check out our article here.

But one of the best things about the S5 is how easy it is to use. You can quickly set up the machine with the large touchscreen and it comes with advanced automated features, like bed leveling. Ultimaker’s Cura software unlocks further control options.

Of course, all this comes at a price, which is very high. S5 is also a big machine, so it can’t fit in just any living room corner.

Anybody looking to run a professional carbon fiber printing business from home can’t go wrong with Ultimaker S5. After all, it’s built for professionals.

Pros

- Massive filament range

- Dual extruders

- Easy to use

- Huge print volume

Cons

- Industrial-level price tag

- Occasional software issues

- Mediocre print speed

3D Printer Type: FFF | Materials: PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, Nylon, Glass Fiber Infused, Carbon Fiber Infused, Metal Fill & Wood Fill | Build Volume: 300 x 300 x 300 mm | Layer Resolution: 10 microns | Max Print Speed: 150 mm/s

Raise3D Pro3 looks like it could take an atomic blast with just a shrug. The sturdy appearance is a great indicator of what you can expect. If it’s reliability you’re after, here you go.

Pro3 is a workhorse in every sense of the word. It will keep printing for hours with steadily excellent print quality.

How does the printer achieve that?

The automatic bed leveling and calibration certainly help. So do the dual extruders that heat up to 300°C, which is enough to process a wide selection of filaments, including harsh carbon fiber-reinforced materials, without jams or clogs.

Those extruders give Pro3 an impressive 10-micron minimum layer height. Contributing to the predictable print quality is also the HEPA-filtered enclosed chamber with air circulation management. It keeps the temperature stable while filtering out excess noise and printing fumes.

Imagine safely running a printer in the same room and still hearing your thoughts. That’s not something many carbon fiber printers can achieve. Trust me, a quiet 3D printer is like a bidet. It’s something you didn’t know you needed in your life.

Maintenance is also a cinch. You can swap the printer hot ends literally within seconds. The printer automatically pauses prints if you open the chamber door and has power loss recovery features. Pro3 also includes the smart EVE assistant system that helps you troubleshoot problems for a quick fix.

True to its tank-like nature, the printer is bulky and kind of slow, though. And that’s a great way to wrap things up. Raise3D Pro3 is like a stubborn turtle — it prints steadily and reliably, come what may.

Pros

- As reliable as they come

- Consistently good print quality

- Dual extrusion

- Quiet and filtered enclosure

Cons

- Bulky

- Print speed is slow-ish

3D Printer Type: FDM | Materials: PVA, PLA, ABS, Nylon, Bronze PLA, Brass PLA, Wood PLA, Copper PLA, TPU, PETG , Carbon Fiber, Fiberglass, Aluminum PLA, Magnetic Iron PLA, ColorFabb XT CF20 (PET-G), CopperFill, BronzeFill, WoodFill, CorkFillr, Flexfill 98A TPU, PLA 3D870 (APLA) | Build Volume: 250 x 220 x 215 mm | Layer Resolution: 20 microns | Max Print Speed: 60 mm/s

Those looking for a high-performance machine to produce carbon fiber prints shouldn’t miss Pulse XE. It’s a real gem of a carbon fiber 3D printer — literally.

Pulse XE has an optional nozzle that’s tipped with an Olsson Ruby. This jewel-tipped nozzle is built to withstand abrasive materials, like nylon and carbon fiber filaments. Another thing contributing to Pulse XE’s high performance is how easy it is to start printing. The machine comes with every component pre-installed and it’s ready to print right out of the box.

Not only are the prints high quality, so are the printer’s parts. Pulse XE is built from well-crafted, high-quality materials and needs little maintenance.

Just plug it in and after a short automatic calibration, you’re good to go for years.

As an interesting quirk, Pulse XE is designed to work specifically with MatterHackers’ MatterControl software. The features the application unlocks give the printer incredible versatility — if you have a dedicated computer.

Unfortunately, Pulse XE does have a couple of downsides.

First, it moves the print bed horizontally during printing. This method gives it a sluggish print speed since fast movements could cause layer misalignment. The detail quality can make up for the lack of speed, though.

Second, Pulse XE doesn’t come with an enclosed chamber. Exposure to room temperature air could lead to layer separation and there’s nothing to filter out printing fumes.

But at less than $1,500, Pulse XE is an affordable high-performance carbon fiber printer. With an added enclosure, it can only get better.

Pros

- Affordable price

- Easy and quick setup

- Low maintenance

- Detailed prints

Cons

- Slow print speed

- Needs a computer

- No closed enclosure

- Small build volume

3D Printer Type: CFF | Materials: Onyx, Carbon Fibre, Fibreglass, Nylon, Kevlar, High Temp. Fibreglass | Build Volume: 320 × 132 × 154 mm | Layer Resolution: 100 microns | Max Print Speed: N/A

Markforged Mark Two is here to show you what heavy-duty means. When you need the roughest and toughest parts, this machine will deliver in spades.

Unlike most carbon fiber 3D printers that use chopped carbon fiber filament, Mark Two uses continuous carbon fiber printing. Using a second extruder, it feeds a steady strand of carbon fiber between material layers, giving parts uniform strength. Not only that, but Mark Two can also reinforce parts with kevlar or fiberglass.

And the result?

Parts that are more than twice as tough as aluminum.

The heavy-duty theme carries over to Mark Two’s general habitus. It’s a professionally-built, sturdy machine with an enclosed heated print chamber. This gives the parts a high print quality and contributes to their incredible strength.

So, if you’ve ever wanted to run a home factory to make spare engine parts for cars or motorcycles, this is your machine.

But do note that Mark Two is an industrial machine to boot. It doesn’t have automatic calibration, so you’ll have to dial in all the settings manually. Fortunately, the large and responsive touchscreen makes setup easier.

Mark Two works only with Markforged’s proprietary Onyx nylon material, which is expensive. That only adds to the printer’s staggering retail price, so you better be serious about continuous carbon fiber printing.

But if you are and you have the money, go right ahead. Anyone looking for an industrial-level carbon fiber printer to make incredibly strong parts won’t find a better machine.

Pros

- Professional print quality

- High part strength

- Continuous carbon fiber technology

- Intuitive controls

Cons

- Not affordable on a hobbyist budget

- Proprietary materials

- Manual calibration

3D Printer Type: FDM | Materials: PLA, ABS, PETG, Flexibles | Build Volume: 256 × 256 × 256 mm | Layer Resolution: 100 microns | Max Print Speed: 500 mm/s

No one’s born a master of their craft — unless your name is Bambu Lab. It’s hard to believe the X1 Carbon is Bambu Lab’s first 3D printer because it’s one of the most advanced carbon printers.

The X1 Carbon has brains. It features an AI-powered, lidar-equipped print monitoring system that keeps a close eye on the first layer’s quality and any possible spaghetti.

Forget about babysitting your printer — the X1 Carbon is its own nanny.

The X1 Carbon uses CoreXY kinematics, which makes it seriously fast. This printer rivals the Makerbot in speed, reaching a blazing 500mm/s.

You might expect the high speed to result in mediocre print quality, but that’s not the case. Although X1 Carbon can’t reproduce the smallest details, it reliably makes high-quality prints.

Printing great parts at a fast speed — what more do you want?

How about a wide material selection? Thanks to the 300°C hot end and 120°C print bed, the X1 Carbon prints with carbon-fiber-reinforced filaments and anything else you might ever want.

And if that’s not enough, the printer is available bundled with Bambu Lab’s Automatic Material System (AMS). This little box sits on top of the printer and intelligently feeds filament into it at an ideal rate.

Yet, the X1 Carbon has its downsides. It wastes a lot of material during multi-material printing. Additionally, although the printer itself supports them, the AMS doesn’t work with reinforced filaments. So… What’s the point?

Despite its flaws, the X1 Carbon is an incredible first effort from Bambu Labs. Suitable for both beginners and veterans, it’s a game changer that genuinely advances 3D printer tech.

Pros

- Super fast

- Simple usability

- High print quality

- Solidly built

- Advanced AI features

- Relatively affordable

Cons

- High material waste

- Default settings aren’t very accurate

3D Printer Type: IDEX | Materials: Carbon Fiber Reinforced Filaments | Build Volume: 330 x 238 x 238 mm (294 x 238 x 238 mm with dual extruders) | Layer Resolution: 100 microns | Max Print Speed: 150 mm/s

Raise3D E2CF isn’t the cheapest carbon fiber printer. But for every penny you pay, you get awesome value in usability and performance.

This carbon fiber printer makes printing these advanced materials a breeze. It’s so reliable and easy to use that you can leave it running alone for hours. Just come back in the evening for perfectly printed parts.

The E2CF achieves this level of reliability by being specifically tailored for reinforced materials. The robust dual-gear extruder grips filament firmly and feeds it to the high-strength nozzles at a steady pace.

You won’t have to worry about clogs or constant maintenance.

The print quality is also very good. The detail isn’t the sharpest, but that’s not the point of carbon fiber printing anyway.

The user interface is as straightforward as that of the Raise3D Pro3. The E2CF has the same automatic calibration and bed leveling. The setup process is quick and you can get to printing in no time.

Reinforced filaments can be sensitive to moisture, but that’s not an issue with the E2CD. It comes with two Dry Boxes to house your material. The cases keep the filament dry to maintain high print quality, although they’re a bit tricky to fill.

As a cherry on top of it all, the E2CF shares the Pro3’s IDEX printing technology. The independently moving dual extruders can mirror or duplicate parts to boost the (admittedly slow-ish) print speed.

There’s one clear downside, though. This printer’s so heavily oriented toward reinforced filaments that it can’t print regular ones.

The Raise3D E2CD strikes a happy value balance between professionalism and consumer-friendliness. It’s a great machine if you’re after reliable, small-batch production — or if you want a carbon printer that just works.

Pros

- Good value for money

- Reliable and simple to use

- Good print quality

- Low-maintenance

- Dual extruders

Cons

- Only works with reinforced materials

- Difficult filament loading

- Slow-ish

3D Printer Type: FDM | Materials: PLA, ABS, PETG, TPU | Build Volume: 300 x 250 x 300mm | Layer Resolution: 50 microns | Max Print Speed: 120 mm/s

You bought your first cheap 3D printer — like Qidi Tech X-Plus — but now you feel like you’re starting to outgrow the budget model. Sound familiar? Then let me save you from wasting time looking for your second printer.

Get the Qidi Tech X-CF Pro. With an affordable price and great performance, it’s a perfect step up from your first printer.

But what makes it so good?

The X-CF Pro makes parts with great print quality. It’s accurate and the detail level beats much more expensive printers, like the Markforged or Raise3D E2CF.

You can reliably get that quality, too. Despite the affordable price, the X-CF Pro is solidly built. The steel frame doesn’t wobble, the enclosed chamber keeps temperatures steady, and the leveling is quick and easy. A handy runout sensor can save your prints if you run low on filament during a run.

Overall, this printer is simple to use with a clear, responsive touchpad. It does have “automatic” leveling, but it’s pretty temperamental. Not that it matters — as I said, manual leveling is so easy you won’t miss the auto feature. As a bonus, it’s a valuable learning experience!

Like the X-Plus, X-CF Pro comes with two swappable extruders. The high-temp extruder for carbon fiber and other abrasives heats all the way up to 350°C. It will melt your material, no matter what it is.

As to the downsides… The X-CF Pro is kind of slow, I guess. The documentation also has Qidi’s trademark incomprehensible translation.

Qidi Tech X-CF Pro punches way above its price tag. It doesn’t bristle with bells and whistles but has every feature you need to make great prints — just like an ideal second printer should.

Pros

- Affordable price

- Reliably good prints

- Great build quality

- Well-sized print volume

Cons

- Slow printing

- Poor documentation

- Unreliable automatic leveling

3D Printer Type: FFF | Materials: Nylon (PA6), PLA, PETG, PC-ABS, PAHT, ABS, ASA, PP, PA, and PC | Build Volume: 310 × 240 × 270 mm | Layer Resolution: 50 microns | Max Print Speed: 120 mm/s

Remember that hippo from the cartoon Madagascar who sang about liking ‘em big? No, it’s just me? Anyway, if that hippo bought a 3D printer, he’d go for Flashforge Creator 4S.

Flashforge Creator 4S builds huge carbon-fiber prints. With the giant 400 x 350 x 500mm print chamber, you can make the largest, chunkiest parts you’ve seen.

But it’s not all about the size.

Creator 4S uses the same kind of IDEX technology as the Raise3D printers. The independently moving print heads are great for a machine this big. You could print supports from a water-soluble filament to make post-processing large prints faster or print two medium-sized parts at once to speed up the process.

This printer doesn’t skimp with print quality, either. Thanks to the 50-micron layer height, you can print big parts with accurate details and complex shapes.

The sturdy construction and simple controls make printing with the Creator 4S easy. Just dial in your settings and let the machine do its magic without worrying about print errors.

And finally, there’s a whole bunch of advanced features. There’s no AI (like on the Bambu Lab printer) but you get all the other goodies, like automatic leveling, a runout sensor, print recovery, and a built-in HD camera for print monitoring. All of that makes getting successful prints that much easier.

There are two big buts, though. First, Creator 4S is huge — a big print chamber needs space, after all. Second, the price tag is even bigger. This is not a printer for regular home users.

But if you run an engineering business and need big carbon-fiber prints, stop reading and go buy Flashforge Creator 4S. You won’t be disappointed.

Pros

- Massive build volume

- High print detail and quality

- Dual extruders

- Advanced sensors and features

Cons

- Massive machine

- Very expensive

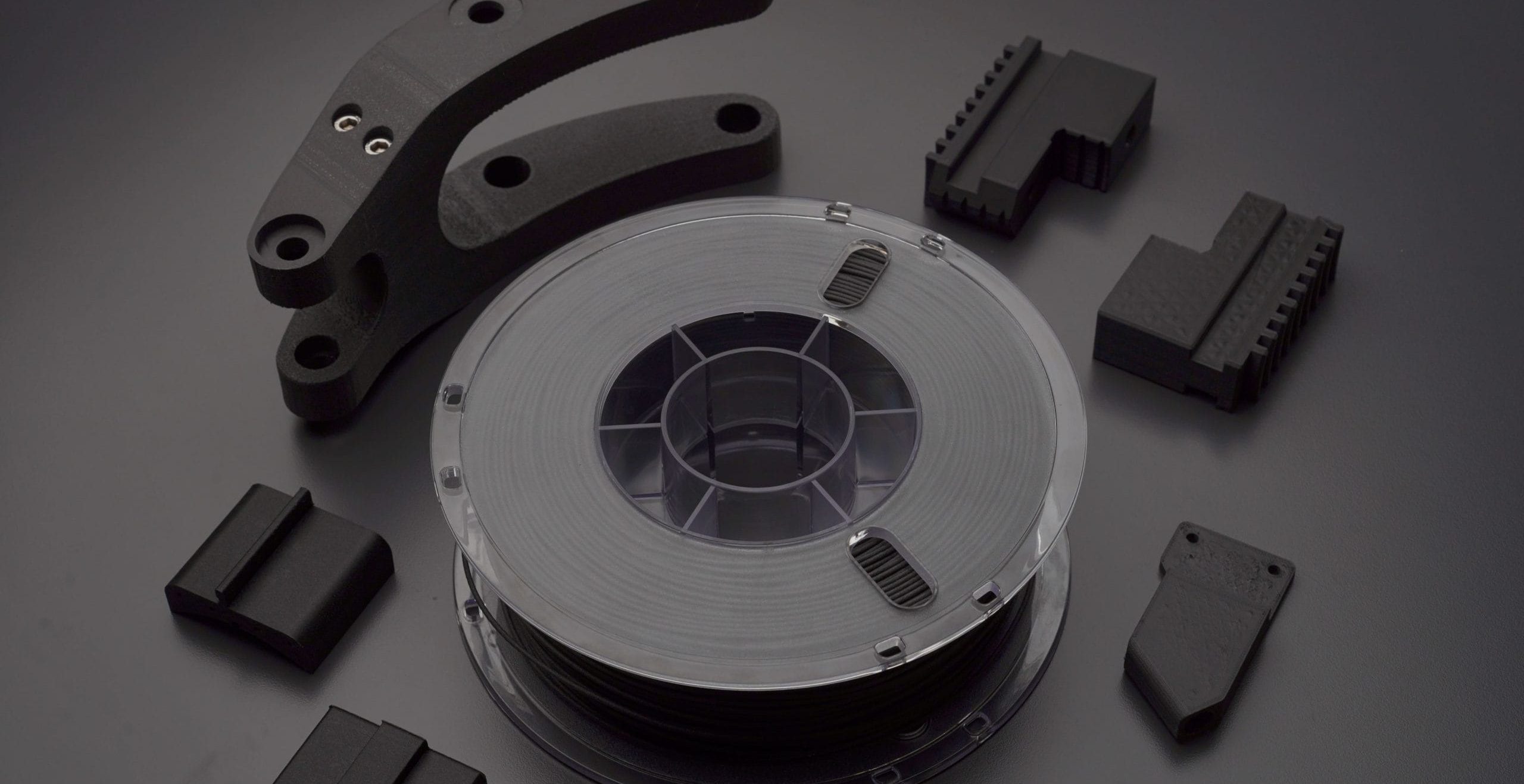

Printing with Carbon Fiber-Reinforced Filament

Carbon fiber can make for incredibly tough but lightweight parts. But you can’t get successful results even with the best carbon fiber 3D printer if you don’t understand the material you’re working with.

So, what exactly is carbon fiber?

We often think of sleek and shiny carbon fiber as modern, but carbon fiber was first made all the way back in 1860. The material consists of carbon atoms bonded together into thin but long chains. But when you print with “carbon fiber” filaments, you’re not actually printing with just carbon fiber.

Instead, 3D printers use either carbon fiber composites or reinforcement. But how do these two technologies differ from each other?

Chopped Carbon Fiber VS Continuous Carbon Fiber

When most people talk about “carbon fiber filaments,” they generally mean chopped carbon fiber filament. As it says on the label, manufacturers mix short carbon fibers into the base material to make these materials

The most common base for chopped carbon filament is PLA. This thermoplastic creates accurate surface details but isn’t very sturdy — unless you mix it with carbon fibers. The presence of carbon fiber material gives the filament enhanced mechanical characteristics.

Not every carbon fiber filament is PLA, though. For example, Onyx — the proprietary material Markforged Mark Two relies on — is based on nylon. Nylon is naturally strong, so you can imagine how strong it gets with carbon fibers. The downside is nylon’s high melting temperature and abrasiveness, but then again you need a reinforced nozzle to print carbon fiber in the first place.

The second carbon fiber technology is continuous carbon fiber reinforcement. If your 3D printer uses this technology, it will feed a continuous strand of carbon fiber into the part you’re printing alongside the thermoplastic filament. The web of continuous carbon fiber makes for extremely sturdy prints, but you need a specialized (and typically expensive) printer with dual extruders.

So, what’s the bottom line?

Continuous carbon fiber reinforcement generally gives you stronger parts, since the carbon fiber filament hasn’t been broken into a billion tiny bits. On the other hand, chopped carbon fiber filament is usually much cheaper. It can still be very strong, but the strength will ultimately depend on how much carbon fiber is mixed into the filament.

Is 3D Printed Carbon Fiber Strong?

Carbon fiber’s main selling point is that it produces strong and durable parts. But is that really true?

When people talk about the “strength” of carbon fiber, they often actually mean “rigidity.” In this sense, yes — carbon fiber-reinforced filaments can create extremely rigid parts. With the right material and carbon fiber 3D printer, you can make parts that are more rigid than metal.

That said, carbon fiber-reinforced 3D printed parts are not flexible. It will take a lot to get them to bend, but once they do, the parts will easily snap and break.

The bottom line about carbon fiber parts’ strength is this — they will not bend. We mean that in both a positive and negative sense.

Ideal Designs for Carbon Fiber 3D Printers

Although carbon fiber parts can snap, you shouldn’t take it as a downside. In fact, carbon fiber is one of the best materials to use for parts that you don’t want to bend.

Let’s put it this way. Big-name aerospace and automotive manufacturers — like Ford and Boeing — use carbon fiber 3D printers. They wouldn’t do that unless the technology delivered first-class parts.

But carbon fiber has much to offer you even at home. You can print carbon fiber parts that will perform fantastically as:

- Supports

- Cases or shells

- Tools

- Propellers

- Gears

Carbon fiber 3D printers are particularly popular with drone and RC car enthusiasts. The lightweight and high toughness of the material are tailor-made for these kinds of uses.

Tips for Successful Carbon Fiber Printing

Printing technical materials like carbon fiber isn’t quite as straightforward as with plain plastics. The properties of carbon filament make the printing process more involved and demand more from your printer.

Here are some tips that help you get high-quality carbon fiber parts:

- Use a Hardened Nozzle: Chopped carbon fiber is very abrasive and can quickly wear down low-end printer nozzles. Make sure whichever printer you use has a hardened steel nozzle or another kind of high-performance nozzle.

- Tweak Retraction Settings: The carbon fibers within the filament won’t melt during printing and they can clog your nozzle. It’s a good idea to use low or no retraction to avoid material oozing and clogging your printer.

- Lower the Print Speed: Some of the listed printers can reach very high speeds, but you can’t print carbon fiber in a rush. A lower print speed can give you better detail quality and prevent nozzle clogs.

- Up the Nozzle Size: Nozzles with bigger diameters (0.5 mm or more) are better for carbon fiber printing. They let the fibers pass through more easily and further prevent clogging issues.

- Increase Temperature: Hardened steel nozzles are less thermally conductive than brass ones. Set your hot-end temperature a bit higher than the filament’s recommended setting to keep the material flowing smoothly.

Pros and Cons of Carbon Fiber 3D Printers

Pros

- High part strength and rigidity

- Low part weight

- Very little shrinking

- High heat and abrasion resistance

Cons

- Expensive printers and materials

- Prone to clogging and oozing

- Potentially brittle parts

- Abrasive filaments need a hardened steel nozzle

Go Strong, Go Carbon Fiber

So, there you have it. Carbon fiber 3D printing lets you make industrial-strength parts with relative ease. Carbon printers aren’t the cheapest machines on the market, but they’re a great investment for any printer user who likes and wants their parts as tough as they come.

I’ve covered many printers, though. If that’s a bit too much to take in, here are my recommendations for the best 3D printers for carbon fiber in different categories.

- If you just want to get to printing with the best machine, go for MakerBot METHOD X Carbon Fiber Edition.

- For a budget option, I recommend Qidi Tech X-Plus or Pulse XE.

- Those looking for the most bang for their buck can’t beat the value of Qidi Tech X-CF Pro.

- Bambu Lab X1 Carbon boasts advanced features that show you the future of 3D printing today.

- Home engineers looking for a professional machine will love either the Ultimaker S5 or Flashforge Creator 4S.

Armed with any of these printers, you’re ready to start producing parts that stand out from the rest with their toughness and durability.