One of the biggest weaknesses within the 3D printing industry currently is that people don’t think parts are strong. And, unfortunately, they’re usually right because most prints are made out of PLA, a relatively weak plastic that’s easy to print.

If you’re looking for the strongest 3D printer filament, you’ll want to check out materials like polycarbonate, nylon, ABS, PEEK, and carbon fiber (composite).

“Oh, but I can’t print that on my shitty consumer-grade 3D printer”.

YES, YOU CAN! You just might have to modify the machine a little bit, like adding an enclosure or stepping up the hot end temp.

Want to learn more about the strongest 3D printer filaments out there, well keep reading soldier because we’ve got a boatload of options for you!

Table of Contents

Types of Filament Strength

Before we get into the strongest 3D printer filaments, you should know that there are different ways to measure the strength of materials. Moreover, the term “strength” is actually pretty broad and doesn’t specify in what way the filament material is strong.

Is it strong when you compress it? Is it strong when you stretch it? Is it strong when you throw it in a fire?

These are all questions you might be having, and there’s a different strength measure for each of them. We’ve explained some of the most popular strength tests below:

Tensile Strength

Our first measure of strength is tensile strength, which is the most commonly-used strength measurement for 3D printer filaments.

Tensile strength refers to how much you can pull a material apart before it breaks. In other words, it’s the strength of elongation (at the breaking point).

A filament’s tensile strength is usually measured in pounds or pounds per square inch (PSI). The higher the tensile strength PSI of filament material, the less likely it is to break when being pulled apart.

Impact Resistance

Second, we have impact resistance (AKA impact strength), which is how much impact force a material can handle before it breaks. Measured in kJ/m2, the impact strength is important because if you’re printing a part that will be smashed into a wall or something of the like, you wouldn’t want it to shatter on impact.

Temperature Resistance

Third, temperature resistance, scientifically known as glass transition temperature, is also super important for 3D printer filaments. Temperature resistance is usually measured in degrees (in °C) and refers to how much heat a material can handle before the part starts to soften and deform (melt).

As FDM 3D printers have to melt a filament to print it, the temperature resistance is directly correlated to the recommended bed temperature for printing the filament. For example, PLA has a temperature resistance of about 60 °C, and this is the same temperature most manufacturers recommend using for the print bed.

UV Resistance

Next, we have UV resistance, which is a little bit similar to temperature resistance, but less correlated with the actual temperature and more about the level of UV rays (e.g. sunlight) a material can handle.

If you want to 3D print a part for outdoor use, you’ll want to use a filament material that has a high UV resistance (otherwise your part will be half-melting when exposed to sunlight for a few hours). UV resistance doesn’t have a good measurement system, but we’ll use relative comparisons to other materials (as well as examples) when we can.

Chemical Resistance

Lastly, we’ve got chemical resistance, which, as you guessed, is how able a material is to withstand different chemicals. For 3D printer filaments, this is useful to know which solvents a material reacts to. For example, ABS isn’t chemically resistant to acetone, so exposure to this material (e.g. nail polish remover) will soften your 3D print if it’s made of this material.

Basically, all 3D printing plastics are chemically sensitive to at least a few materials, but not all of these materials are common. For example, polycarbonate plastic is soluble (softens in) dichloromethane, but you won’t be finding this way-too-long-of-a-name chemical unless you work on the floor of a pharmaceutical plant.

I’ll let you know, though, if any of the materials we go over are chemically sensitive to more common chemicals.

Strongest Filament Materials

Now that you know some different measures of strength, it’s time to get into our discussion of the strongest 3D printer filament materials.

I’ve personally scoured the market, purchasing and testing different 3D printer filament materials to determine which ones are the strongest. In the sections below, I’ve detailed my findings for the top five strongest 3D printer filaments that you can print on a consumer-grade machine.

Of course, results will vary depending on which brand you choose for a given filament material because each manufacturer likes to blend their materials with their own special set of additives. Because of this, I’ve provided a few specific examples (brands) for each material that I know to be strong.

1. Polycarbonate

By far, the strongest 3D printer filament that you can get for consumer use is polycarbonate. Polycarbonate, known as PC for short, is an insanely strong plastic material that’s commonly used for parts that require high durability, like medical components, robot frames, and so much more.

But don’t take my word for PC’s strength, just check the test results. Moreover, one test study found that parts made in PC had a tensile strength of 9800 PSI. For comparison, the same part printed in ABS had a tensile strength of only 4700 PSI, which is still strong, but shows just how resistant to stretching PC really is.

On this note, PC is a super rigid material, and parts printed in plastic don’t like to go outside of their original shape. For example, if you print a cube in PC filament and step on it a hundred times, it will still be in the shape of a cube. This is an excellent property to have for making industrial-grade parts that can be used in places where they face a lot of physical forces.

Unfortunately, polycarbonate filament is extremely hard to print. On top of needing a high-temperature hot end, a powerful heated bed, and an enclosure for your printer, you’ll also need to fine-tune a slicer profile and repeatedly print test models until you can achieve high-quality prints in this material. It’s definitely worth it for the strength, though, I promise!

To save you time, we’ve reviewed the best 3D printers for polycarbonate here.

Honestly, I’ve tried a few PC filaments from a few different manufacturers, and they all come out super strong, so the brand doesn’t matter too much here. But I’ve still listed three of my favorite PC filament options below:

- Good Value: PolyMaker PolyMax PC Filament

- Strongest: 3DXMAX PC Filament

- Premium Quality: Raise3D PC Filament

Pros

- Insanely strong (high tensile strength)

- Chemically resistant

- UV resistant

- Not all-too expensive

Cons

- Abrasive; requires a steel nozzle

- Requires an enclosure

- A high-temperature hot end and bed are necessary

- Difficult to achieve high print quality

2. Nylon

The second strongest 3D printer filament I could find was nylon, a plastic that offers strength not in rigidity but in its flexibility. While nylon isn’t considered a flexible material, it’s certainly semi-flexible, which lends the material a hand when it comes to impact strength. You can run a part printed in nylon into a wall thousand times or try to stretch it, and it simply won’t break.

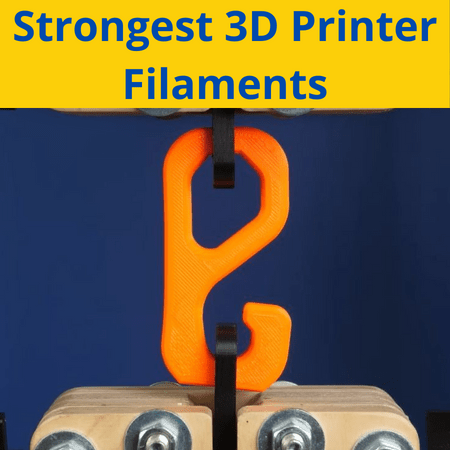

In a test conducted by MatterHackers, a hook printed in their nylon filament was able to hold a maximum of 404 pounds. For reference, the maximum tensile strength of the PLA part was a mere 185 pounds.

But what I love most about nylon filament is that while it’s noticeably flexible, it’s just rigid enough to be easy to print. As such, you don’t need a direct drive extruder to make high-quality parts in nylon, as you would for flexible materials like TPU or TPE.

On this note, nylon is also very easy to print, and I actually thought it was about just as simple to use as PLA. The only difference was that I needed to use decently higher hot end and bed temperatures (you can see a list of the best nylon-compatible 3D printers here). But this also means nylon has a high-temperature resistance, which is nice to hear.

Overall, if you want a super-strong 3D printer filament but without any printing difficulties, nylon filament is the one for you. There are also a lot of options when it comes to this material of filament, and below, I’ve provided a few of my favorites:

- Good Value: Overture Nylon Filament

- Easiest to Print: Polymaker PolyMide CoPA

- High Print Quality: MatterHackers PRO Series Nylon Filament

- Strongest: MatterHackers NylonX (carbon fiber composite)

Pros

- Semi-flexible

- Very high impact resistance and tensile strength

- Relatively easy to print

- Decently high-temperature resistance

- Composite options available

Cons

- Can get expensive

- Not rigid (can’t be used for certain types of parts)

3. ABS

ABS is considered one of the most difficult materials to print, but this doesn’t stop it from being one of the strongest materials too. Moreover, ABS is known for its rigidity and also high print quality, once you get your printed tuned-in.

The material performed very well in MatterHackers’ test of tensile strengths, with a hook made in the material being able to withstand up to 284 pounds of downward force. As we mentioned in our discussion of nylon filament, PLA was only able to hold 184 pounds.

It’s important to mention that ABS is not super chemically resistant, and it’s soluble in acetone, the same chemical that most nail polish removers are made of. But I don’t find this to be a bad thing because it’s not everyday someone is just throwing nail polish remover around rampantly until it breaks a print made of ABS. In fact, I like that ABS is soluble in this chemical because it makes layer smoothing ABS models super convenient, and you can make some very smooth prints.

To print ABS, you’ll need a heated bed capable of reaching at least 90 °C and a hot end that can get up to 245 °C. You’ll also need an enclosure as ABS plastic is very sensitive to temperature changes and air drafts during the printing process. You can read our list of best 3D printers for ABS for more info.

Once you’ve got the settings down, printing is a breeze with parts coming out with a very high level of detail. Supports also snap off of ABS models super easily!

If you want an ABS filament, check out one of the reputable brand options below that I’ve personally tested and loved:

- Good Value: Sunlu ABS Filament

- Easiest to Print: Hatchbox ABS Filament

- Highest Print Quality: Polymaker ABS Filament

Pros

- Easy to achieve a high print quality once printing requirements are met

- Inexpensive

- Pretty strong and rigid

- Can be layer smoother with acetone

- High-temperature resistance

Cons

- Requires an enclosure

- Requires a high-temperature heated bed

4. PEEK

Next, we’ve got PEEK filament, which is at the peak of consumer-grade filament strength (get it?). Seriously.

This filament is actually stronger in terms of tensile strength than every other filament material on this list, with an average tensile strength of over 13000 PSI.

So why did we rank it lower? Well, that’s because it’s very hard to print and it’s very expensive. Moreover, I wasn’t sure if PEEK is actually consumer-grade because it’s kind of in between the industry and consumer levels.

Your typical PEEK filament spool costs over $200 and usually is only 500 or 750 grams (not 1 kg). But it’s hard to ignore the sheer strength of this material. On top of the insane tensile strength of PEEK, the material also is very chemically resistant, which is why it’s commonly used for parts in the oil and gas industry.

But, to print PEEK, you’ll need a machine that can safely and consistently run a hot end temperature of 400 °C and a heated bed temperature of 120 °C. Of course, an enclosure is also required too, as with basically all high-temp materials. Even after you have that, achieving a high level of print quality is very difficult.

But if maximum strength is what you’re looking for, then PEEK might be an option to consider. Below are my favorite options for this type of filament:

Pros

- Insanely strong

- Very durable

- Very rigid

- High-temperature resistance

Cons

- Requires a high-temperature hot end and bed to print

- Requires an enclosure

- Sensitive to slicer settings (difficult to achieve good print quality)

- Very expensive

- Not very consumer friendly

5. Carbon Fiber Composite

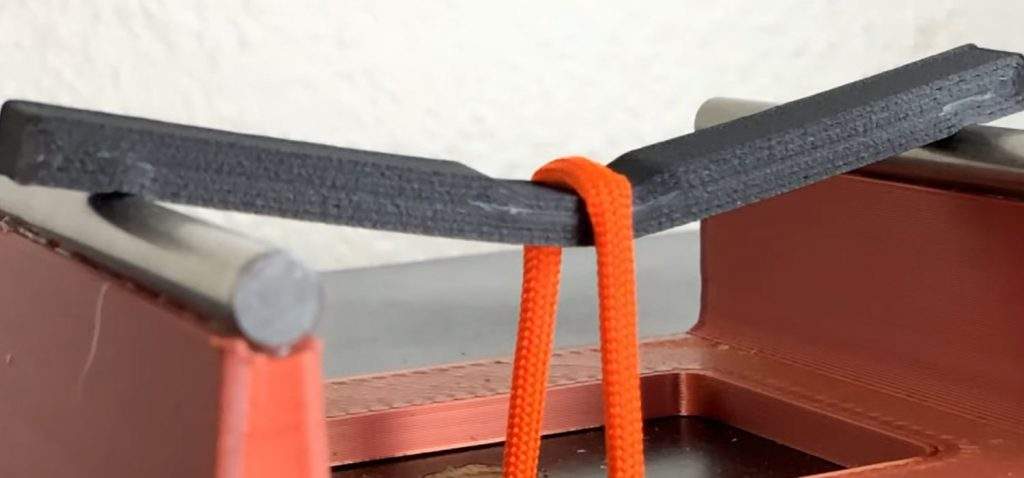

Lastly, we’ve got carbon fiber composite. While straight carbon fiber (CF) would’ve been a stronger choice, it’s not an option for consumer-level printers because it can’t be melted easily.

Carbon fiber composites are filaments based on traditional printing materials, like nylon or even PLA, but infused with small bits of CF that enhance the filament’s strength.

There isn’t one single option for CF composite, so the strength varies. But the strongest I’ve found are nylon-based CF filaments. For example, MatterHackers’ NylonX carbon-fiber-infused filament was able to hold 408 pounds, just 7 pounds less than the same part printed in a polycarbonate filament. So not bad at all!

Additionally, CF composite filaments are not even that difficult to print. That’s because these filaments preserve many of the properties of their base materials, so PLA-based and nylon-based composites print as easily as their base material.

Sadly, this also means that CF composite filaments are chemically sensitive to both chemicals that dissolve the base material as well as those that dissolve carbon fiber. But, unless the base material is ABS (not many are), it shouldn’t be that big of an issue.

If you want to check out some CF composite filaments, check the list below of my favorite options. I’ve also provided the base material for each one and ranked them by strength (strongest at the top).

- MatterHacker’s NylonX (based on nylon)

- Fillamentum Carbon Fiber Nylon CF15 (based on nylon)

- 3DXTECH CarbonX PP (based on polypropylene)

- 3DXTECH CarbonX PETG (based on PETG)

- 3DXTECH CarbonX PLA (based on PLA)

Pros

- Usually easy to print

- Many options

- Not super expensive (most of the time)

- Very strong

Cons

- More chemically sensitive than straight carbon fiber

- It can be difficult to compare different CF-infused filaments

Why Do You Want Strong Filament?

You want a strong filament because you don’t want your 3D prints to break whenever the going gets tough, and they’re faced with some physical forces.

For example, if you printed a little desk toy and you dropped it once, it would be a waste if it broke. I mean, you only dropped it once! But sadly, that’s what happens when you print things in PLA, the most popular filament material for 3D printing.

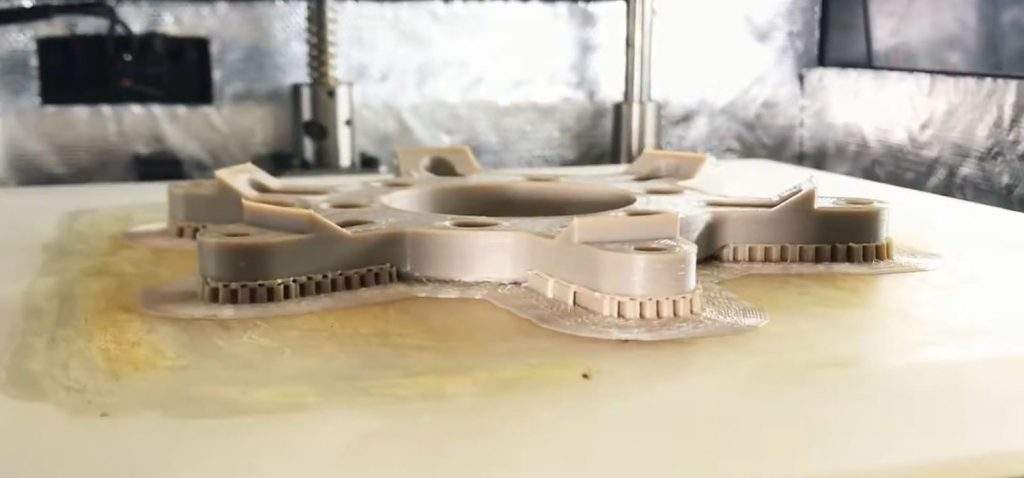

Printing a model in an actually strong filament will ensure it doesn’t break on the first drop… the second…or the third, and so on. On top of that, you need to be using a strong filament if you’re printing anything that will face physical pressures on a day-to-day basis, such as a part that goes on a robot or on a CNC machine.

So either print with a strong filament or be okay with having to re-print the same model over and over again every time it faces any physical force.

Conclusion

Strength is something everyone should look for in a 3D printing filament. While you won’t get much of it in PLA, there are many other filament material options out there that are much stronger.

If you want the strongest 3D printer filament, then you’ll want polycarbonate. Of course, if you can, get PEEK filament, but note that it’s also super difficult to print, even more so than PC.

For an easier printing experience, I’d definitely recommend looking at a nylon filament or a carbon fiber composite option, as these are pretty straightforward when it comes to printing and provide ample strength for all your engineering needs.