- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

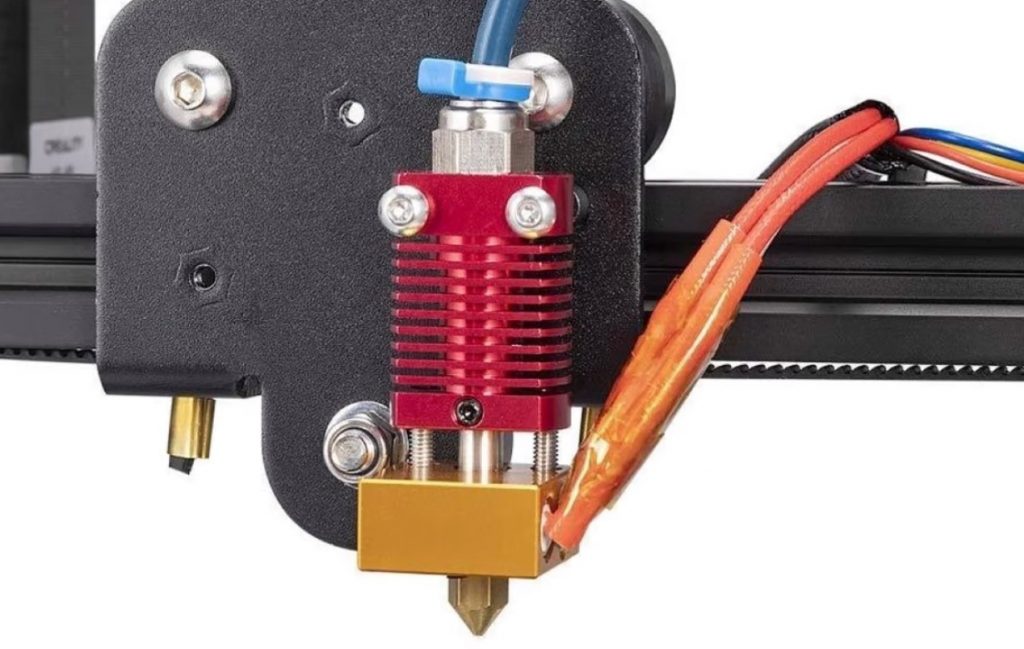

The hot end is where all the action on a 3D printer happens. Inside, the filament is melted at super high temperatures and flows out the nozzle, where it’s shaped into your 3D model.

The hot end is where all the action on a 3D printer happens. Inside, the filament is melted at super high temperatures and flows out the nozzle, where it’s shaped into your 3D model.

The Creality Ender 3 (Pro/V2) is one of the most beloved machines in the 3D printing community, known for being a great bang for your buck and super upgradeable.

However, the stock hot end assembly is nothing special, and many users (including myself about a thousand times) have had issues, like under extrusion and hot end clogs, with it.

Luckily, because the Ender 3 (Pro/V2) is open-source and has such a large following, there are many hot end upgrade options for the machine. My favorite Ender 3 hot end upgrade is the E3D V6, an all-metal hot end that’s super reliable and can go up to 300 °C.

Want to hear about more of the best Ender 3 hot end upgrades?

Just keep reading!

Best Ender 3 (Pro/V2) Hot End Upgrades At A Glance

1. E3D V6 All-Metal Hot End (Best Choice)

2. Creality Spider (Best Value)

3. Micro Swiss All-Metal Hot End (Premium Choice)

4. Creality Sprite Extruder Pro (Built-In Extruder)

5. E3D RapidChage Revo Six (Easiest to Use)

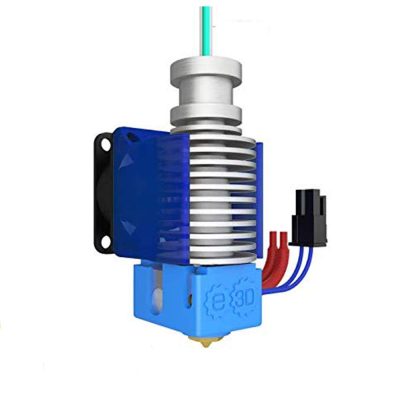

If you’re a 3D printing enthusiast, then you’ve probably heard of E3D, the leading manufacturer of high-quality 3D printer hot ends. The E3D V6 is easily the company’s most popular product and it’s been out since 2014. But, just because it’s old doesn’t mean it’s not as good as the newer hot ends in the market.

The E3D V6 is an all-metal hot end, meaning it doesn’t have a PTFE liner on the heat break. Because of this, the V6 can reach very high temperatures, up to 300 °C, because you don’t have to worry about the PTFE liner burning as you do with the Ender 3’s original hot end.

Moreover, the 300 °C limit means you can print a wide variety of filament materials, from PLA to polycarbonate and everything in between.

Additionally, the E3D V6 has an intuitively-designed cylindrical heat sink. Compared to the rectangular heat sinks seen on most hot ends, this cylindrical heat sink is much more effective at dissipating the heat from the heat block. This means overheating problems like heat creep, which can cause hot end clogs, aren’t likely to happen on the V6.

Sadly, though, the E3D V6 isn’t a super easy installation on the Creality Ender 3 (Pro/V2). That’s because the hot end has different mounting screws and uses a different thermistor cable.

But don’t worry because you can easily overcome these challenges by 3D printing a compatible Ender 3 E3D V6 hot end mount and also changing your printer’s firmware to account for the different thermistor cables.

So, if you want a solid hot end that’s reliable and can print many different filament materials, the E3D V6 is the perfect option!

Pros

- Widely compatible

- High maximum temperature

- Cylindrical heat sink for good heat dissipation

- Very reliable

- Stainless steel heat break

Cons

- The included hot end fan is pretty weak

- Requires new mount and firmware changes for installation

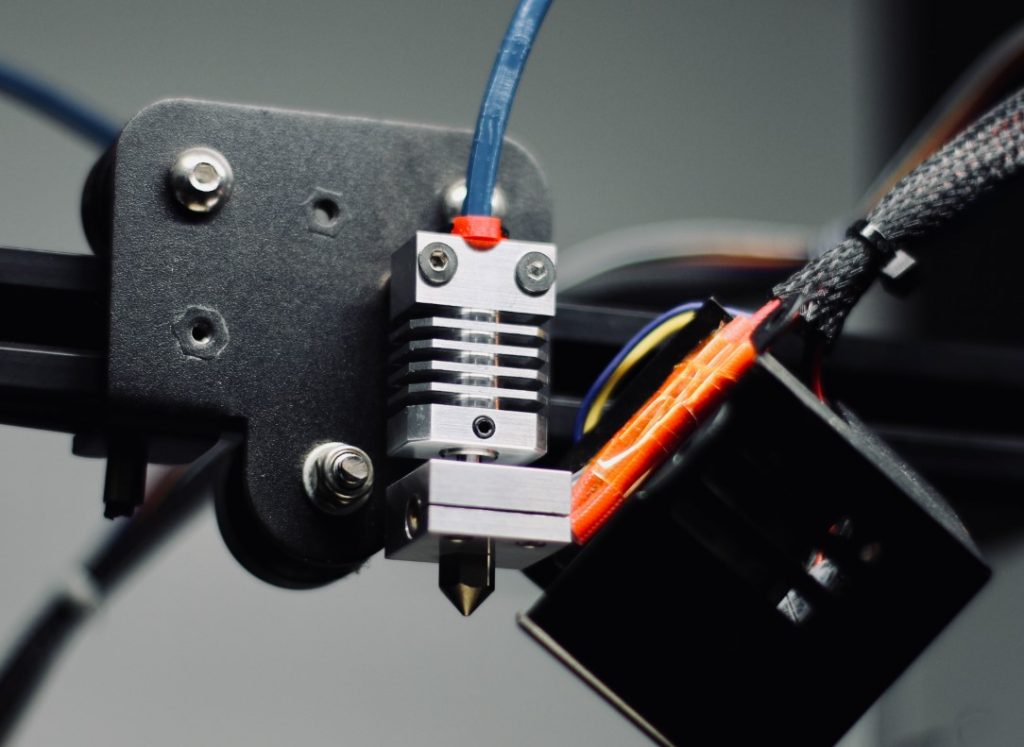

Creality seems to always be making new products, and the Creality Spider is one of their latest inventions. The Spider is a super high-temperature hot end that’s a great bang for your buck.

The Spider, like the E3D V6, is all-metal, which means it can reach high nozzle temperatures safely. How high, though? Well, according to Creality, the Spider can reach up to 500 °C, which is absolutely insane and easily one of the highest-temperature hot ends on the market.

With this heating capability, you can use the Spider to print literally any filament material, whether it’s PLA, nylon, carbon fiber, polycarbonate, or acrylic!

But even if you don’t plan on printing super high-temperature filaments like polycarbonate, the Creality Spider hot end is still a great option for fast printing. That’s because Creality specifically designed the Spider for printing fast, and the hot end can sustain print speeds up to 250 mm/s!

Additionally, installing the Spider hot end on your Ender 3 (Pro/V2) as Creality used the same mounting holes as the original hot end. You’ll also need to change the firmware, so it’s compatible with the new heater cartridge and thermistor wires.

Overall, the Creality Spider is a terrific hot end upgrade for the Ender 3 if you want to print high-temp filaments or use insane print speeds. And, with a price tag under $50, the Spider is very reasonably priced and has a great bang for your buck.

November 2023 Update: If you want the latest and greatest, there’s a newly released upgraded version of the Spider called the Spider 3.0.

Pros

- Insanely high-temperature capabilities

- Great value

- Enable super fast printing

- Easy mounting installation

Cons

- Requires firmware changes for installation

- Not a large community backing

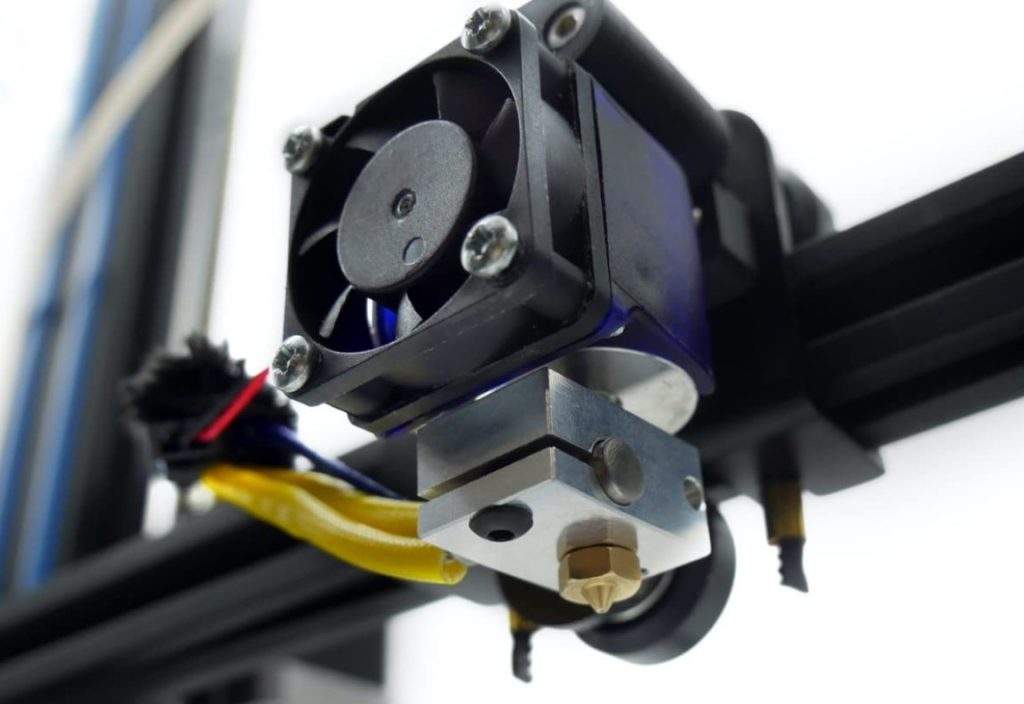

Micro Swiss is another manufacturer of 3D printer hot ends and accessories, and their All-Metal hot end is a popular upgrade option for the Ender 3.

The Micro Swiss All-Metal hot end doesn’t have a PTFE liner, as indicated in its name, and this enables you to use temperatures as high as 300 °C without an issue. With this improvement in temperature range, you’ll be able to print materials like PC and nylon with the Micro Swiss hot end.

But what I love most about the Micro Swiss All-Metal hot end is its high durability. The hot end has a titanium heat break, so it won’t be breaking or degrading anytime soon. And, because all of the components on this hot end are metal and precisely manufactured, the Micro Swiss hot end is super reliable when it comes to extrusion.

I’ve used this hot end before, actually, and I’ve literally never had a problem with extrusion with it. Just make sure to run the hot end fan to eliminate heat creep for this hot end, as it’s prone to this issue.

It’s also worth pointing out that this hot end features the same mounting screws as the original Ender 3’s hot end, so installation is super light.

So, if you want a hot end that’s durable, reliable, and capable of getting super hot, definitely give the Micro Swiss All-Metal hot end a look!

Pros

- Same mounting screws as stock hot end

- High maximum temperature

- Reliable

- Included steel nozzle

Cons

- Somewhat expensive

- Prone to heat creep (needs powerful hot end fan)

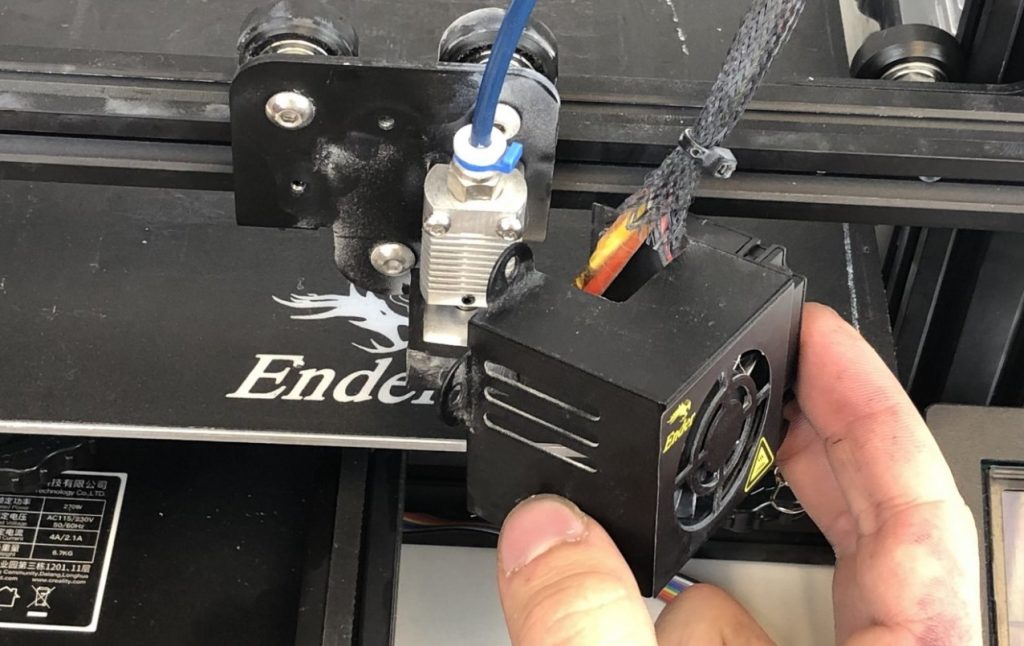

Another product from the manufacturer of the Ender 3 is the Creality Sprite Extruder Pro. As you probably noticed from the image above, the Sprite Extruder Pro isn’t your typical hot end. Instead, it functions as a direct drive printhead, meaning it contains both an extruder motor and a hot end.

The Creality Sprite Extruder Pro is the stock printhead on the new Ender 3 S1, and it’s a terrific upgrade option for the older version of the Ender 3, including the Original, Pro, and V2.

As for the hot end part of the Creality Sprite Extruder Pro, it’s all-metal with a maximum temperature of 300 °C. So say hello to previously out-of-reach materials like PC, nylon, or carbon fiber composite.

The hot end also contains a titanium heat break, which improves the reliability and accuracy of the extrusion process on the Sprite Extruder Pro. That’s because this type of heat break won’t degrade as fast as other heat breaks.

![]()

Besides the hot end, though, the Creality Sprite Extruder Pro also kills it when it comes to the built-in extruder. As I mentioned, the Sprite Extruder Pro is a direct drive printhead, meaning it’s much better at printing flexibles, like TPU filament, compared to Bowden extruder configurations.

Additionally, Creality took a hint from E3D and used a 3:1 gear ratio for the extruder assembly. This ratio provides a lot of torque for pushing filament, so under extrusion shouldn’t be an issue!

There are also a few other noteworthy features on the Sprite’s extruder, such as an adjustable tension screw, a quick release lever for fast filament swaps, and a well-placed part cooling fan.

Sadly, installing the Creality Sprite Extruder Pro on the Ender 3 (Pro/V2) isn’t super easy because the entire assembly is meant for the Ender 3 S1’s hardware. However, it is possible if you use the included adapter from the Creality Sprite Extruder Pro kit and follow the wiring guide on their website.

So, if you want to print flexibles, high-temp materials, or just really want a direct drive extruder, I strongly recommend the Creality Sprite Extruder Pro!

Pros

- Direct drive extruder

- 3:1 gear ratio for powerful extrusion

- Small and compact

- Included printhead carriage adapter

- Cooling fan and hot end included

- High-temperature capabilities

- Reliable

- Quick release lever for filament

Cons

- Requires firmware changes

- Relatively difficult mounting process

- Wiring is a challenge

- CR-Touch not included (like on Ender 3 S1)

Lastly, we’ve got the E3D RapidChange Revo Six. The Revo Six is one of E3D’s latest products, and it’s meant to eventually replace the original E3D V6 hot end.

The Revo Six is equipped with E3D’s new RapidChange technology. This means the nozzles for the Revo Six have a built-in heat break. You can see what I mean in the image below of a standard E3D Revo RapidChange nozzle:

The integrated heat break means that you can easily fix a hot end clog on a Revo hot end by simply swapping the nozzles. And because of E3D’s intuitive, quick-release system on their RapidChange Revo hot ends, you can actually change the nozzle without heating it up. No burnt fingers anymore!

But, besides the RapidChange mechanism, the Revo Six hot end is an overall amazing product. It can reach 300 °C without an issue, and the heater block was made with safety in mind. Moreover, the heater block has a positive temperature coefficient, which means it won’t melt, even at extreme (500+ °C) temperatures.

As for installing this hot end, the process is a little difficult. You’ll need to 3D print a compatible Ender 3 mount (options on Thingiverse) and also change your firmware, so it supports the new thermistor and heating wires.

But if you want a hot end that makes nozzle changes easy and also provides super reliable extrusion, then give the E3D RapidChange Revo Six a shot!

Pros

- Special nozzle

- RapidChange enables quick and easy nozzle swaps (even when cold)

- Provides reliable extrusion

- Safe heater block

- Exceptional print quality

Cons

- Proprietary nozzle (limited options)

- Requires new mount and firmware changes for installation

Why Upgrade the Hot End?

You should upgrade the hot end on your Creality Ender 3 (Pro/V2) to make your 3D printer more reliable and versatile.

Moreover, it’s a well-known fact that the stock hot end on the Ender 3 is far from perfect. As I mentioned previously, many users have extrusion problems with this hot end, likely due to the cheap parts used for the assembly.

Upgrading to a higher-quality hot end will make the extrusion on your 3D printer both more accurate and more reliable. No more frequent mid-print failures!

Additionally, the stock Creality hot end on the Ender 3 has a maximum temperature of only 260 °C. While this is enough for printing PLA, ABS, PETG, and TPU, you’ll want something a little more powerful to print stronger materials like PC, nylon, or carbon fiber composites. Upgrading the hot end gives you the ability to print these higher-temp filament materials, so you can print stronger models.

Considerations for Hot Ends

When looking for a hot end, whether for your Ender 3 (Pro/V2) or another 3D printer, there are a few important factors to look at. Below, I’ve gone over the points I considered when picking which hot ends were included in this article:

Compatibility

The first thing I looked at for an Ender 3 hot end upgrade was its compatibility. Because while the Creality Ender 3 is super popular, not all hot end products work with it.

For a hot end to be considered compatible with the Ender 3, it first needs to have the same voltage as the printer, which is 24V. Additionally, there must be a way to mount the hot end to the Ender 3’s printhead carriage, whether through the original mounting screws or a 3D printable bracket.

All of the options I reviewed in this article are fully compatible with the Ender 3 (Pro/V2).

Maximum Temperature

The maximum temperature of a hot end is also super important as it controls the range of filament materials that the hot end can print.

The Creality stock hot end on the Ender 3 (Pro/V2) can only reach up to 260 °C, so I suggest looking for a hot end that can go higher than this. All of the options I reviewed in this article do!

But what specific maximum temperature you should look for is dependent on what filament materials you plan on printing. If you want to print a lot of PC and nylon, you should look for a hot end with a max temp of at least 300 °C.

But if you just want to stick with PLA and maybe some ABS, a hot end with a high temperature of around 26-285 °C will be fine.

User Experience

The user experience of a hot end is also extremely important. By “user experience”, I’m talking about the overall extrusion performance and reliability of the hot end. You won’t like a product that fails 50% of the time and provides inconsistent extrusion, as your prints will always fail.

While there’s no one metric for determining the user experience of a 3D printer hot end, you can check the reviews. Moreover, if many users didn’t like using a certain hot end, then, chances are, you won’t either.

Value

Lastly, we have the value of a hot end, which I like to think about as the cost per performance of features.

Furthermore, while performance for a hot end is very important, it’s not worth a million bucks.

I like to determine the value of a hot end in relative terms. For example, I think, for the price, the Creality Spider is a better bang for your buck compared to a more pricey hot end like the Slice Engineering Mosquito, even if it’s a better product (performance-wise).

Conclusion

It’s vital that you get a hot end that provides consistent, precise, and reliable extrusion for your Ender 3 (Pro/V2).

There are many factors that go into a good, high-performance 3D printer hot end, and I’ve found that the best option is the E3D V6. Its all-metal construction and precisely-engineered components provide a super-accurate extrusion system that never fails. Additionally, it’s compatible with a wide range of printers, including all versions of the Creality Ender 3.

If you’re looking for an easy replacement, though, then I’d have to recommend the MicroSwiss All-Metal hot end, as it’s a super quick installation on the Ender 3. That’s because the mounting screws on this high-temp hot end match the ones on the stock Ender 3 hot end.

And lastly, if you want a hot end that doubles as a direct drive extruder, give the Creality Sprite Extruder Pro a shot. Its integrated extruder motor and assembly provide a lot of pushing force for inserted filament, making it much easier to print flexibles like TPU filament.

Enjoy!