- Last Updated: January 12, 2024

-

Pat Nathaniel

Pat Nathaniel

Want to buy a metal 3D printer but are confused by all the options? SLS, SLM, DED… HUH?

Not to worry. In this article, we’ll discuss different types of metal 3D printers and what you can do with them. We’ve thoroughly tested each printer to help you figure out which one suits you best.

Whether you’re on a budget or looking for an elephant-sized printer to amp up your production, we’ve got you covered (no trunk included). Whatever your specific needs, there’s a printer on this list that is bound to suit you. Unless you want to 3D print metal clowns — in which case, no.

Let’s get right into it!

Table of Contents

- Best Metal 3D Printers At A Glance

- 1. Markforged Metal X (Best Value)

- 2. Desktop Metal Studio System 2 (Best Choice)

- 3. XJet Carmel 700 (Best Accurate Metal 3D Printer)

- 4. SLM Solutions SLM 125 (Best for Small to Medium-Sized Components)

- 5. Rapidia Metal 3D Printer (Most Affordable Metal 3D Printer)

- 6. EOS M 100 (Best For Medical Use)

- 7. Trumpf TruPrint 1000 (Best Dental 3D Printer)

- 8. HP Metal Jet S100 (Best Speedy Printer)

- 9. Sharebot MetalONE (Best For Research And Testing)

- 10. Sciaky EBAM 300 (Best Printer for Large-Scale Production)

- What Is Metal 3D Printing?

- Who Uses Metal 3D Printing?

- What Are the Types of 3D Metal Printing Technologies?

- Factors to Consider when Buying a Metal 3D Printer

- Advantages of Metal 3D Printing

- Disadvantages of Metal 3D Printing

- What are the Metals that can be 3D Printed?

- So Which Is the Best Metal Printer?

Best Metal 3D Printers At A Glance

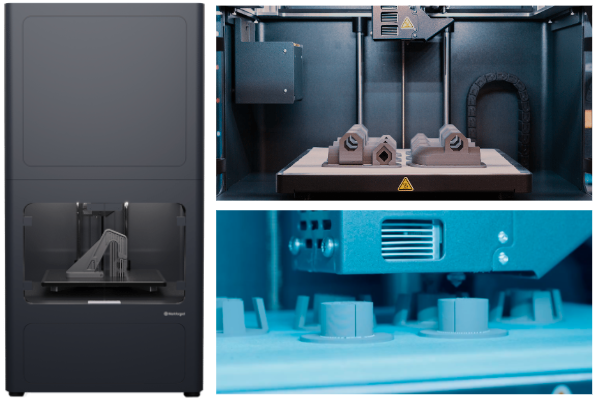

1. Markforged Metal X (Best Value)

2. Desktop Metal Studio System 2 (Best Choice)

3. XJet Carmel 700 (Best Accurate)

4. SLM Solutions SLM 125 (Best For Small To Medium-Sized Components)

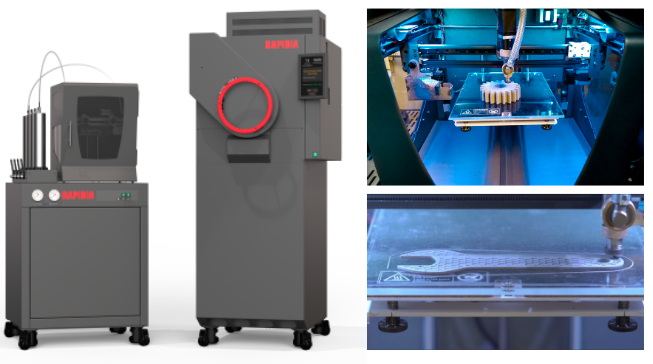

5. Rapidia Metal 3D Printer (Most Affordable)

6. EOS M 100 (Best For Medical Use)

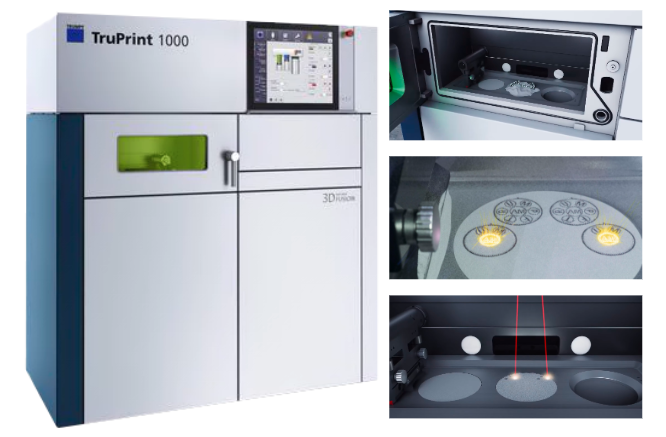

7. Trumpf TruPrint 1000 (Best Dental 3D Printer)

8. HP Metal Jet S100 (Best Speedy Printer)

9. Sharebot metalONE (Best For Research And Testing)

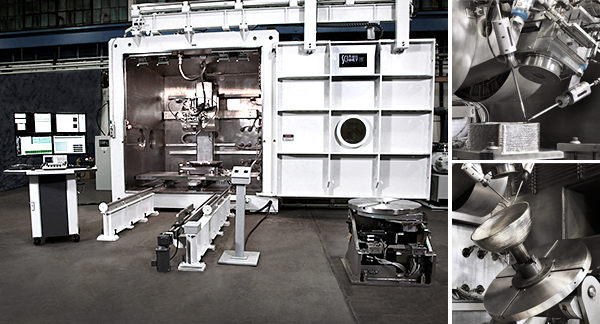

10. Sciaky EBAM 300 (Best Printer For Large-Scale Production)

3D Printer Type: ADAM | Materials: 17-4PH Stainless Steel, Copper, h13 Tool Steel, Inconel 625, A2 and D2 Tool Steel| Build Volume: 300 x 220 x 180 mm

Are 3D printing costs making your wallet scream and melt into oblivion? You might want to look at the Markforged Metal X.

It’s an affordable yet capable machine with a minimum layer thickness of 50 microns. This printer comes at a fraction of the cost of typical metal printers — so if you’re a small business, this printer is perfect for you.

It uses ADAM (Atomic Diffusion Additive Manufacturing) technology. It’s generally much safer than other metal 3D printing processes because it uses metal powder rods bound in a plastic filament.

This means no direct contact with metal powder, which is harmful if inhaled. This also means you’ll need little PPE and don’t need to invest in a metal powder management system. Nice!

The printer prints the bound powder filament layer by layer into a solid object.

After that, you put the object in a debinder, where it’s washed in a debinding solution. The final step is sintering — the plastic binder is burned off, and the metal powder fuses together. Phew. There’s your finished product!

This is a reasonably decent-sized printer with a build volume of 300 x 220 x 180 mm. It’s not gigantic, but as long as you’re not printing spare rocket parts, it’s enough space.

The Metal X can print using proprietary filaments by Markforged in stainless steel, copper, Inconel, and tool steel.

Pros

- Affordable

- Strong, complex structures

- Safer than traditional metal 3D printing technologies

Cons

- A lot post-processing

3D Printer Type: BMD | Materials: 17-4 Stainless Steel, 316L Stainless Steel, H13 Tool Steel, 4140 Chromoly Steel, Copper, Titanium Alloy| Build Volume: 300 x 200 x 200 mm

Like the Markforged Metal X, Desktop Metal’s Studio System 2 extrudes bound powder filament to create a 3D object. (And no, there’s no metal music playing in this particular studio!) If you’re looking for an all-around excellent metal 3D printer that’s easy to use, this one is it.

With a sizable build volume of 300 x 200 x 200 mm, you can easily print larger objects at a decent speed of 16 cm3/hr.

What sets Studio System 2 apart from others is its convenience. Objects printed with Studio System 2 don’t need debinding. You only put your finished part in the furnace, where the binder will be melted and the metal powder sintered into a solid object. Time-saving much?

As this printing process uses bound powder filament, it’s safe to use in an office environment.

Also, with the Desktop Metal Studio System 2, you can easily print high-quality metal parts with complex geometries. We recommend it as our go-to office metal 3D printer.

Pros

- Easy and quick two-step process

- Safe

- Affordable

Cons

- Could be faster

3D Printer Type: Material Jetting | Materials: Metal, Ceramic | Build Volume: 501 x 140 x 200 mm

Want a metal 3D printer with outstanding accuracy? With a minimum layer thickness of 8 microns, it’s a lightweight and versatile printer that can print objects five times faster than conventional printers while maintaining high surface quality and finish.

This speedy yet accurate printing is thanks to material jetting technology. How does it work? Well, the printheads are equipped with lots of nozzles — which shoot millions of ink drops quickly.

And over 98% part density means you’re guaranteed strong parts. This makes this printer ideal for usage in aerospace, automotive, and industries where you need sturdy parts.

The Carmel uses soluble supports, which need to be dissolved and sintered to achieve the final result, similar to the Markforged.

Sadly there isn’t much material versatility here — this printer only comes with a cartridge for stainless steel and soluble supports. But if you want to work exclusively with steel, this printer is perfect for you.

Pros

- High accurate

- Very speedy printing process

Cons

- Only comes with stainless steel

3D Printer Type: SLM/DMLS | Materials: Stainless Steel, Cobalt-chrome, Nickel Alloy, Aluminum, Titanium | Build Volume: 125 x 125 x 75 mm

Looking to print smaller objects? The SLM 125 is a sturdy, reliable metal 3D printer that delivers consistently precise builds. With a build volume of 125 x 125 x 125 mm, this machine is best for printing small to medium-sized parts.

How detailed are the prints, you may ask? Well, the SLM 125 prints parts with a layer resolution of 20 microns — meaning it captures details with high clarity and resolution. This is ideal for smaller objects that require precise detailing.

Fun fact! Despite the name SLM 125, this is actually an SLS printer. Way to add to the confusion, SLM Solutions! Since this is an SLS printer, it works by sintering metal powder into the desired shape.

The SLS 125 supports a wide range of metals: stainless steel, aluminum, nickel alloy, titanium, cobalt chrome, and tool steel.

The SLM 125, like many other SLM Solutions printers, features bidirectional coating. This speeds up the build rate, which is a relatively fast 25 cm³/h.

Another benefit of this printer is its low gas consumption which considerably saves money, gas, and energy.

Unfortunately, this printer is not office-friendly as you need to handle metal powders directly. It’s also on the pricey side — so if you’re on a budget, consider the more affordable options.

Pros

- Fast build rate

- High-quality prints

- Minimal gas consumption

- 20 microns layer resolution

- Supports lots of materials

Cons

- Costly

- Not office-friendly

3D Printer Type: FDM | Materials: Stainless Steel, Inconel, Ceramic, Zirconia | Build Volume: 200 x 280 x 200 mm

Looking for an environmentally-friendly 3D printer that’s also friendly on the budget?

Unlike many other metal 3D printers, the Rapidia features a two-step process: print and sinter. No debinding process is necessary, and you can quickly get next-day prints.

How does it work?

It extrudes a safe water-based and solvent-free metal paste onto a mildly heated glass bed, one layer at a time, to create a metal part.

The Rapidia features two extrusion heads, one for metal paste and the other for polymer-based supports. You have the option of 0.4mm or 0.6mm nozzles.

The water-based metal paste is water soluble, which means you can fuse unsintered parts using only water.

After sintering, the fused pieces have the strength of a single part. You can choose an infill percentage of your part with 100% for strong builds with fully solid sections and 20% for lightweight builds.

This printer is very affordable compared to other systems. It has a build volume of 200 x 280 x 200 mm and a fast build rate of 40 cm3/hr, which is faster than expensive printers.

The Rapidia currently supports type 316L Stainless Steel, and 17-4PH Stainless Steel, with other materials in development.

Pros

- Environmentally-friendly water-soluble metal paste

- No powder handling required

- No debinding

Cons

- Only supports stainless steel at the moment

3D Printer Type: SLM/DMLS | Materials: Cobalt-chrome, 316L Stainless Steel, Ti64 Titamiun, Tungsen W1 | Build Volume: 100 x 100 x 95 mm

Want a small, sharply accurate metal 3D printer for medical applications? The EOS M 100‘s your guy!

With a scan speed of up to 7 m/s, the EOS M 100 prints objects in precise 30-micron layers.

This printer is a more compact version of the EOS M 290 and comes with a build volume of 100 x 95 mm — perfect for manufacturing small medical devices.

It uses a 200W fiber laser with a laser spot diameter of just 40 microns for consistent part quality in complex, detailed, and delicate parts.

Here’s the cool thing — the EOS M 100 enables you to monitor printing progress.

How?

Well, it has a large color screen that displays the printer’s process flow overview. It shows what the machine is doing and how much material is left, as well as any faults, shortages, or issues.

The M 100 is designed to build things from start to finish without interruption or assistance. It has a 1.3-megapixel camera which enables remote monitoring.

Also, if you want to change materials quickly, it has a material drawer that easily slides out. Neat!

Its software includes EOSPRINT and EOS RP Tools. EOS supplies its materials, including CobaltChrome, Tungsten W1, Titanium To64, and Stainless Steel 316L.

This machine costs a pretty penny, but for clinics, hospitals, and medical practitioners, it’s worth it.

Pros

- Perfect for medical applications

- Variety of materials

Cons

- Expensive

3D Printer Type: SLM/DMLS | Materials: Stainless Steel, Tool Steels, Aluminum, Nickel, Cobalt-chrome, Titanium, Copper | Build Volume: 100 x 100 x 100 mm

Want an even more specialized metal 3D printer than the EOS M 100? Enter the Trumpf TruPrint 1000. This printer was MADE for dentistry with a suitably compact build volume of 100 x 100 x 100 mm.

The TruPrint 1000 features a built-in system for producing dental implants with layer thicknesses of 10 microns for a precise fit and smooth surface quality. With the Preform feature, you can make 64 crown bases in one go. Nice!

This printer comes with touchscreen control with a dedicated app, as well as a built-in camera for real-time monitoring.

It comes with a multiplate option that allows you to insert as many as four plates at a time in the build cylinder. This keeps the printing process running smoothly without any interruptions.

The TruPrint 1000 uses a 200W laser with a 55-micron spot beam, but you have the option to use a 30-micron laser for higher accuracy. The printer has layer resolutions of 10 to 50 microns.

This printer has a rather turtle-y speed of 2 to 18 cm3/hr — not the fastest, but it’s expected with small and precise builds that they should take time to print.

Nearly any geometry can be produced with this printer — and easily printed into an excellent metal part.

It also has a fantastic multi-laser option, which enables you to work with 80% more productivity than with a single laser.

The TruPrint 1000 supports stainless and tool steels, aluminum, nickel, cobalt chrome, copper, and titanium, as well as some precious metals.

Pros

- Highly accurate builds

- Multi-laser option for more productivity

- Supports many materials

Cons

- Slow build rate

3D Printer Type: MJF | Materials: Stainless Steels | Build Volume: 430 x 309 x 200 mm

The newly-released HP Metal Jet S100 uses Metal Injection Molding (MIM) technology to print parts at whizzing speeds. And if you want one of the fastest metal 3D printers out there, this one’s for you.

The S100 is the Roadrunner of metal 3D printers — with a build speed of 1990 cm3/hr, you can almost hear it say, “Beep beep!”

It has a large build volume of 430 x 309 x 200 mm.

How does it work?

The S100 is equipped with six printheads that jet millions of droplets of material to create a 3D-printed part.

These six printheads are fitted with a total of 63,360 nozzles. We’re not joking! And with this, you’ll get a fine resolution of 1,200dpi (dots per inch).

Using this printer reduces the cost per part compared to regular SLM machines by 20 to 33%. There’s also no need for supports — which in itself saves costs.

It currently supports 316L and 17-4PH Stainless Steels, with the possibility of more supported materials in the future.

The S100 requires a lot of post-processing: heat treatment, depowdering, and sintering.

As for durability, you can print 96% dense parts for maximum strength and robustness. You can also print a nearly infinite number of geometries and control the density of the finished product.

Pros

- Super fast printing

- No supports

- Density control

Cons

- A lot of post-processing required

3D Printer Type: SLM/DLMS | Materials: 316L Steel, Cobalt-chrome| Build Volume: 65 x 65 x 100 mm

The first metal 3D printer by the Italian 3D manufacturer Sharebot, this DMLS printer has a build volume of 65 x 65 x 100 mm. It may be small, but since this printer is targeted at R&D, it’s good enough for the job. If you want to test materials for 3D printing on a small scale, this printer is perfect for you.

The metalONE comes with a 200W laser featuring a 1070 micron spot resolution, as well as a nitrogen generator to keep the print environment inert.

It comes with an integrated webcam and supports Ethernet for remote printing. It also has a 14-inch touchscreen, not for playing Baby Shark at full volume (thank goodness), but for easy control of the printer.

It features a 5 microns minimum layer thickness as well as an XY resolution of 20 microns — with these features, this printer yields high-quality builds.

The metalONE is easy to use. You can start a new print in 10 minutes — and it takes under half an hour to clean the printer and change the powder.

This printer is affordable, and here’s the part that will interest researchers — it has completely open parameters. It also provides photos of each layer.

For safety, the metalONE uses a three-filter filtration system to prevent any metal powder particles from reaching outside the enclosed build area.

Pros

- Perfect for academic settings

- Super precise, detailed, high-res builds

- Three-filter system

Cons

- Smaller build volume

3D Printer Type: DED | Materials: Titanium Alloys, Inconel 718, Inconel 625, Tantalum, Tungsten, Niobium, Stainless Steels, 2319 Aluminum, 4043 Aluminum, 4340 Steels | Build Volume: 5791 x 1219 x 1219 mm

Want a colossal metal 3D printer? It gets no bigger than this. Literally.

This printer uses EBAM (Electron Beam Additive Manufacturing). This process uses an electron beam gun (sounds pretty cool, eh?) It deposits metal wire layer by layer until it becomes the final object.

This printer gives you a lot of metals to choose from — niobium, aluminum, Inconel, titanium and titanium alloys, and zircaloy, among many others.

If you want to make big metal things, we can recommend no better printer. It’s got an INSANE build volume of 5791 x 1219 x 1219 mm. We promise those aren’t just random numbers.

And with that, it has a comically fast build rate of 7 to 20 lbs per hour. It can print parts up to 19 feet in length.

In the vein of the famous quote by Spiderman’s Uncle Ben, with a giant printer comes a giant price tag. Boeing and the U.S. Department of Defense use this printer — so this gives you an idea of the cost. Unless you make as much money as a small country, forget about buying it.

Also, using this printer saves about 80% of the material cost. For this price, it had better!

Pros

- Mind-blowingly gigantic

Cons

- Mind-blowingly expensive

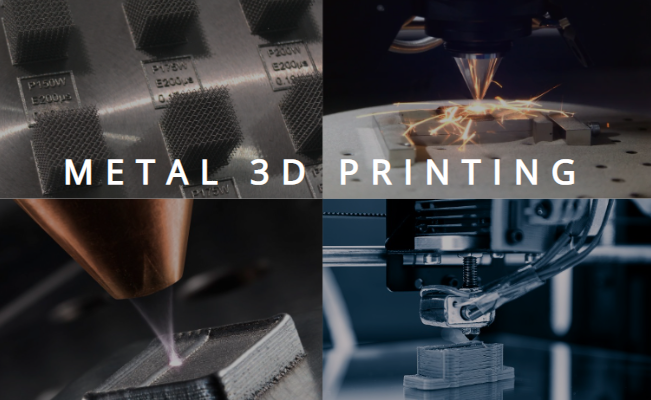

What Is Metal 3D Printing?

Metal 3D printing is the process of printing objects with metal powder, bound metal filament, or wire. It encompasses various technologies that vary in affordability, efficiency, and quality.

Who Uses Metal 3D Printing?

Metal 3D printing is used in virtually every industry that traditionally manufactures parts with metal.

From medical applications (such as spinal and dental implants) to aerospace, automotive, and military, there are loads of companies that are using 3D printing to speed things up and cut costs.

What Are the Types of 3D Metal Printing Technologies?

Laser Powder Bed Fusion 3D printing (SLS, SLM, DMP)

Laser Powder Bed Fusion (LPBF) is an umbrella term that encompasses multiple technologies. But they all have two things in common: metal powder and lasers.

Selective Laser Melting (SLM) is a metal 3D printing process that melts metal powder with lasers to create an object.

You have most likely noticed the similar-sounding SLS, which stands for Selective Laser Sintering. First of all, how are these two different? And what the heck is sintering!?

Well, SLS printers fuse metals with a laser, but by sintering rather than melting. Sintering is a process in which metal powder is heated with lasers, but it doesn’t allow metals to reach their melting point. This procedure is more suited to alloys, while SLM is suited to pure metals.

DMP (Direct Metal Printing), also known as DMLS (Direct Metal Laser Sintering), is just another name for SLS… We wish the 3D printing community would agree on one freakin’ name!

Directed Energy Deposition (DED)

Directed Energy Deposition (DED) is a metal 3D printing method that uses lasers and energy beams to melt a material deposited by a nozzle.

Metal Filament Extrusion (FFF, FDM)

FDM (Fused Deposition Manufacturing) is a printing technology that creates robust, sturdy builds with decent accuracy.

It works by extruding filament through a heated nozzle. This technology is used primarily to develop strong and durable, rather than aesthetic, parts.

FFF works through the same process as FDM, but it doesn’t have a heated print environment. This can cause its prints to be less accurate and likely to warp. FFF printers are often much cheaper and more accessible than FDM ones.

Material Jetting and Binder Jetting

Binder jetting is an additive manufacturing process in which a printhead jets a liquid binding agent onto a powder bed. This is one of the fastest metal 3D printing processes available.

Material jetting uses the same technology as binder jetting — but while binder jetting deposits a liquid binding agent, material jetting directly deposits the 3D printing material itself.

Factors to Consider when Buying a Metal 3D Printer

Printing Technology

As you can see, there are a whole lot of technologies available.

To choose between them, you have to consider 1. Do you want an office-friendly printer? Or are you prepared to handle powder directly (with the necessary protection, of course)?

SLS and SLM printers are costlier, and you must invest in powder circulation systems. If you prefer an office-friendly system, go for an FDM printer.

Accuracy

How accurate do your builds need to be? For reasonable accuracy, you’ll want an XY (horizontal) resolution of at least 20 microns.

The accuracy of a printer indicates its repeatability — this feature is crucial with most applications.

Print Quality

Print quality is determined by layer thickness/resolution. A smaller layer thickness equals better print quality.

The difference between print quality and accuracy — accuracy is how true the print is to the 3D model and copies of the print, while the print quality is the surface resolution.

If you’re building large metal parts for aerospace or automotive applications, the surface finish might not be as crucial as its sturdiness.

However, this feature is essential for medical applications and jewelry-making. For decent print quality, you need a layer thickness of at least 30 microns and below.

Ease of Use

Metal 3D printers look intimidating, but manufacturers take great pains to make them accessible and easy to use without much training.

With touchscreens, cameras, automation, and intuitive software, the ideal metal printer doesn’t require a dedicated operator — and can be left to print by itself until the part is ready.

Build Volume

If you are primarily printing small objects, opt for a smaller build volume. For large objects, you will need a large build volume. (Duh. I know!)

Material Compatibility

An important aspect to help you decide on a printer is material compatibility. Which metals are you looking to use?

Most metal 3D printers are compatible with stainless steel and tool steel. Many others are also compatible with cobalt chrome, aluminum, and titanium. Some printers can also print precious metals.

Always ensure this beforehand, as it’s critical that your chosen printer can print with your desired material.

Price

Metal 3D printers are some of the most expensive 3D printers available. Luckily, there are some affordable options. Some technologies are more costly than others.

Binder and material jetting are the most expensive, with SLM/SLS printers close behind. FDM and FFF printers are much more affordable.

Advantages of Metal 3D Printing

Freedom of Design

With metal 3D printing, you can reduce the overall weight of your parts by designing complex lattices and internal channels.

You can also print multiple parts at once, as well as complex assemblies. Also, you can do the impossible with 3D printing and take on designs and geometries that simply cannot be done with traditional methods.

Easy and Quick Prototyping

With metal 3D printing, you can easily and quickly create functional prototypes from metals. This saves time and money, especially in the aerospace and defense industries, where one small design mistake can be super costly.

Minimal Material Waste

Metal 3D manufacturing is much less wasteful than traditional methods, which are usually subtractive — such methods result in a lot of waste. When it comes to 3D printers, what you need is what you use — no more, no less.

Affordability and Fast ROI

3D printing/additive manufacturing is much more affordable than its subtractive counterpart. With lower material cost and cost per part, you can make some serious savings over time and a good ROI.

Though printers can be initially expensive, manufacturers are rolling out more accessible and affordable printers than ever.

Another benefit — not only is it cheaper than outsourcing, but it allows you to be self-reliable rather than depending on a third party. And there’s no need to keep a standing inventory of parts.

The costs of CNC manufacturing can quickly stack up — from casting and tooling to molding — which can be a hard blow to budgets.

Convenience and Speed

Unlike traditional manufacturing, you can print parts immediately and on demand.

There’s no need to wait weeks to receive a part, and if you ever need to adjust, you can amend your design in CAD and print it straight away.

Disadvantages of Metal 3D Printing

High Initial Cost

Though printers can save money, time, and labor, they’re initially an expensive investment. Especially LPBF metal 3D printers, which have a lot of costly lasers… Those often require additional post-processing stations, including debinders and sintering furnaces.

Strength of Parts

3D printers can create complex geometries — but in terms of tensile strength and density, they are yet to reach the level of traditionally-manufactured parts. That isn’t to say they’re brittle or weak.

On the contrary, printers can create substantial and sturdy objects. However, traditionally manufactured things are usually more structurally solid — since they’re carved out in one piece, not layers like 3D printing.

As 3D printing goes more and more into the mainstream, we can expect more progress and development in this field.

What are the Metals that can be 3D Printed?

Nearly any metal that can be traditionally manufactured can be 3D printed.

From stainless steel and tool steel to alloys and pure metals, many printers support several types of a single material. For example, printers often offer support for 316L Stainless Steel and 17-4PH Stainless Steel.

There’s also aluminum, titanium, cobalt chrome, and Inconel — which most printers are commonly compatible with.

Metals suitable for medical applications include titanium and aluminum, which are biocompatible and feature ideal strength-to-weight ratios that make them very useful in the medical field.

Metals suitable for aerospace and automotive include (again) aluminum and titanium alloys like Scalmalloy and Ti64.

A few printers also offer compatibility with precious metals for the jewelry industry.

So Which Is the Best Metal Printer?

If you want the biggest metal 3D printer, the Sciaky EBAM 300 is just that. With its massive build volume, it’s perfect for manufacturing metal objects up to 19 feet tall.

If you’re looking for an eco-friendly printer that’s safe to handle, you have the option of the Rapidia 3D printer — as well as Desktop Metal’s Studio System 2, which we recommend as our go-to metal 3D printer. It’s a reliable and efficient printer that yields excellent results — and best of all, it’s office-friendly!

If you want a printer for medical applications, the EOS M 100 is particularly suited to the job — and if you’re looking for a specialized dentistry printer, the Trumpf TruPrint 1000 is perfect.

Want an excellent printer for the price? The Markforged Metal X is another reliable and office-friendly machine that gets you consistently accurate and sturdy builds.

If it’s the speed you’re after, the XJet Carmel 700 and the HP Metal Jet S100 are suitable candidates.

If you want a good ol’ reliable LPBF printer for small to medium-sized prints, look no further than the SLM 125.

Printing 3D parts for research and development? The Sharebot metalONE, with its completely open parameters and high-resolution printing, is exactly what you need.