When choosing a filament for 3D printing, many people consider using nylon and PETG. Both are high-performance filaments, and while they’re both excellent in many ways, they each come with their own challenges.

Nylon is an excellent option if you need something durable yet flexible and aren’t worried about your budget. PETG is more affordable but less durable, so the one that will be best for you will depend on your project and budget.

To help you decide between nylon and PETG, we’ve broken down both materials’ differences, advantages, and disadvantages.

Table of Contents

What is Nylon?

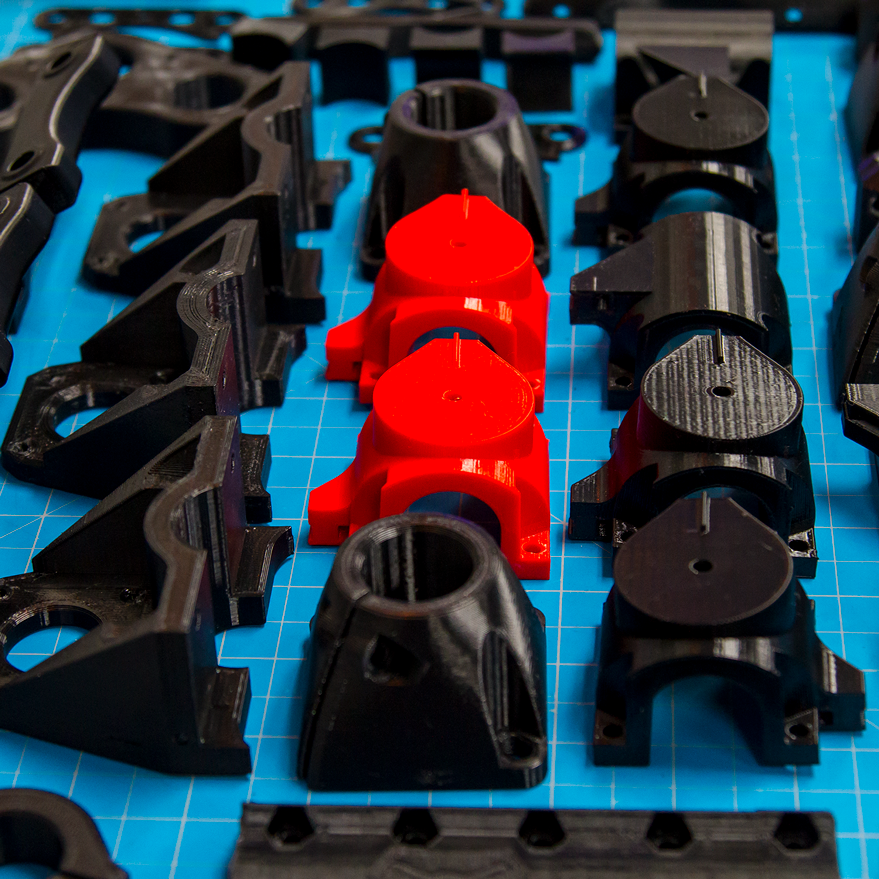

NYLON FILAMENT

Nylon is a popular filament choice because it’s suitable for almost all applications when you need something that has durability and strength. There are a lot of nylon options, but generally, they all have the same characteristics:

- Highly durable

- Strong

- Fairly flexible

The ideal projects to use nylon for are ones that go through a lot of wear and tear once they’re made. You want to use something other than nylon for objects that will get wet because it can absorb moisture and degrade the item.

The best things to print with nylon include engineering components, zip ties, and hardware. Projects that could benefit from nylon could be plastic gears, cable ties, etc.

What is it Made Of?

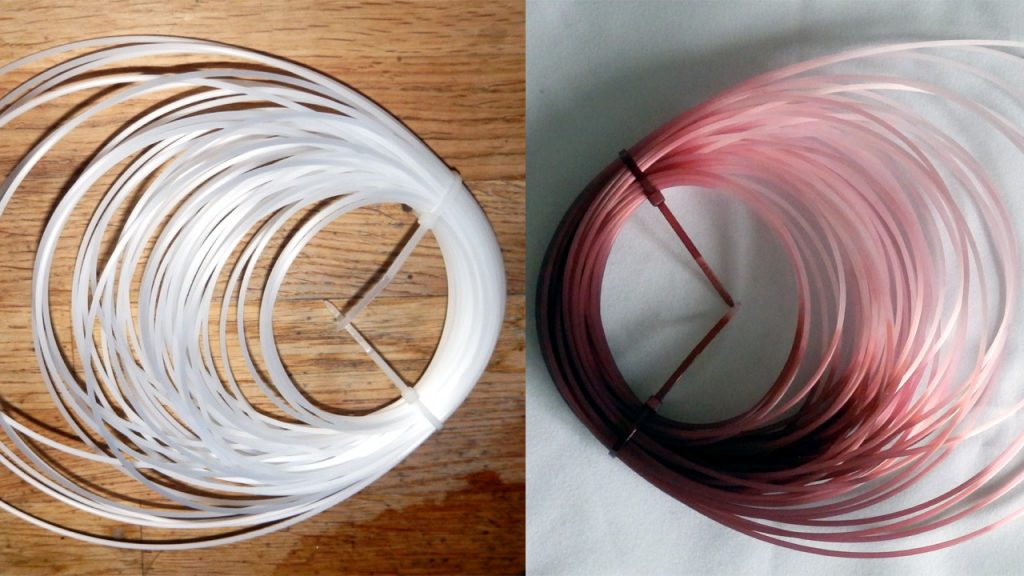

WHAT IS NYLON MADE OF?

Nylon is made up of different polyamides, making it a synthetic copolymer. There are a lot of types or configurations of nylon to choose from. It has a thermoplastic property that makes it one of the most popular choices for 3D printing.

Advantages and Disadvantages of Using Nylon

There are several reasons why nylon is one of the top choices for 3D printing filaments. Many of the advantages of using this material greatly outweigh the disadvantages.

1. Abrasion Resistance and Low Friction

One of the main advantages of using nylon for your 3D printing needs is its abrasion resistance and low friction. Being abrasion resistant is beneficial if you’re printing objects that are likely to be dropped, fall, or endure wear and tear.

Using nylon will ensure that whatever you’re printing won’t have scratches or break easily.

2. Can Be Colored Before Printing

CAN BE COLORED BEFORE PRINTING

With other filament materials, you have to wait to color the object once it’s printed, which can be time-consuming. With nylon, you can change the color to whatever you want before you print the item to save yourself some time.

3. No Odor

Additionally, if you’ve ever printed with a 3D printer before, you know that some filaments emit an odor that can be off-putting. Printing with nylon won’t leave your workspace smelling like plastic. The lack of odor makes nylon an ideal material for those who are sensitive to scents.

4. Can Warp During Printing Process

Even though nylon is one of the top 3D printing filament choices, there are still disadvantages to choosing this material. One of the main disadvantages of printing with nylon is that the material tends to warp easily during the printing process.

You have to be extra careful to mind the temperature requirements for the material, or you’ll end up wasting it.

5. Expensive

EXPENSIVE

Another downside to nylon is the price tag. Nylon is much more expensive than other filaments, especially PETG. If you have a higher budget, this might not be a disadvantage for you, but if you are on a strict budget and have never printed with it before, you might want to avoid using the material.

6. Increased Hygroscopic Properties

When comparing nylon and PETG, they both are relatively moisture-resistant, but nylon has more hygroscopic properties. If you’re making something that has a risk of being exposed to moisture, you should avoid using nylon.

7. Releases Caprolactam When Heated

Lastly, a huge disadvantage to using nylon is that Caprolactam is released when you heat it. Caprolactam is a potential carcinogen.

The good news is that it only releases when you heat nylon, and unless you’re using nylon to print often, your risk is minimal. If you’re often printing, you’ll want to take the necessary precautions when using this material.

Some precautions you should take include printing in a ventilated area and using a mask to prevent inhaling the Caprolactam. As long as you’re not inhaling the fumes from printing with nylon every day or over a long period of time, you shouldn’t have an issue.

What is PETG?

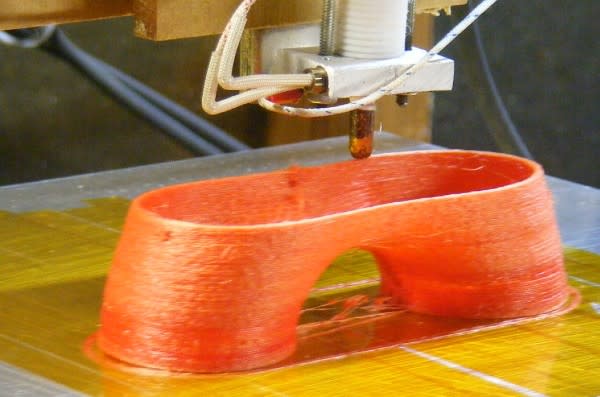

PETG FILAMENT

PETG (Polyethylene terephthalate glycol) is another common 3D printing filament. It’s an ideal material to use when you’re making items that are going to be getting wet, near water, or close to chemicals.

It doesn’t have nearly as many printing requirements as nylon does, which is why many people, beginners, and experienced printers, like the material. It’s a stiff plastic that’s easy to print on, has durability, and minimal flexibility. The main things to know about PETG are that it is water- and chemical-resistant.

What is it Made Of?

WHAT IS PETG MADE OF?

Manufacturers make PETG from the same material that plastic water bottles are made from, Polyethylene Terephthalate (PET). The letter G in PETG comes from the ethylene glycol that many use to let the purchaser know that the PET filament is glycol-modified. The glycol makes the filament less brittle and produces a clearer appearance.

Advantages and Disadvantages of Using PETG

There’s a lot to like about using PETG for your 3D printing. Many people like both nylon and PETG for printing, but there are a few advantages that make PETG stand out as a better printing material.

1. Easy to Print and Doesn’t Warp Easily

PETG is known for being very stiff. While this can be a downside for some projects, it’s ideal when you’re printing something that doesn’t need any flexibility. This stiffness also makes it easy to print with.

Its stiffness also means it’s not as prone to warping as nylon, which is an admirable advantage.

2. Moisture-Resistant and Chemical-Resistant

If you ask people who’ve printed with PETG, they mainly prefer this material because it’s resistant to various elements. Not only is PETG more moisture-resistant than nylon, but it’s chemical-resistant too.

Objects that will be near water or get wet accidentally won’t get damaged when you print with PETG. You can create fish tank decorations or anything else and easily wipe the water away from the item without worrying about it warping, discoloring, or deteriorating.

You can also use this filament to make items you’ll clean with standard household cleaners without worrying about ruining your 3D printing work.

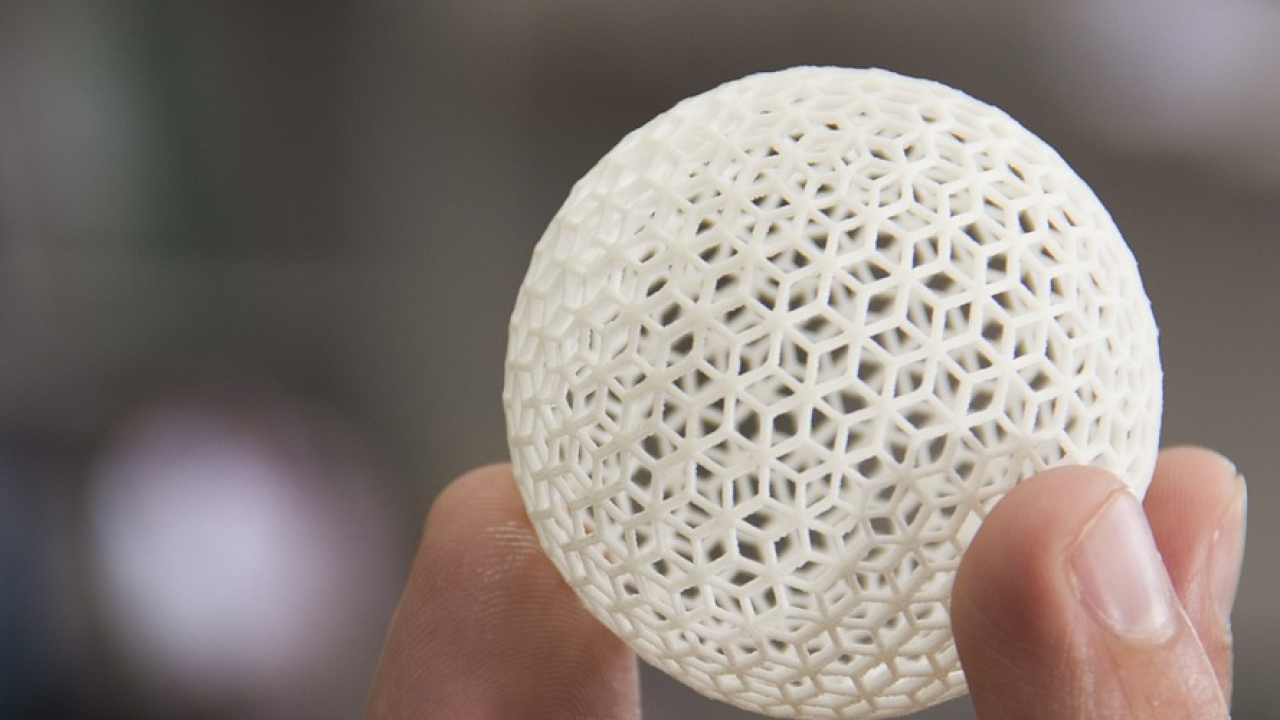

3. Smooth Finish

SMOOTH FINISH

An area where PETG excels is its smooth finish. There are hardly any rough spots when you’re finished printing with PETG, and it provides a beautifully smooth surface that other filaments don’t always offer.

4. Affordable

For those newer to 3D printing, PETG is much more affordable and easier to work with than nylon.

5. Not Much Odor

An advantage PETG shares with nylon is the lack of odor. You shouldn’t smell a strong or chemical odor when printing items with this filament. Some people report smelling something when using this filament to print, but generally, it doesn’t have a scent like ABS.

6. Prone to Scratch

Despite some excellent advantages, there are some considerable disadvantages to working with PETG. Even though it’s a solid and durable material, it is prone to scratches. You’ll want to be careful when handling your final project to avoid scratches and other dings to it.

7. Not UV-Resistant

NOT UV-RESISTANT

PETG might be moisture and chemical-resistant, but it’s not UV-resistant. You can place it where UV rays from the sun will hit it, but be aware that over time it will change color and potentially deteriorate, ruining your work.

8. Requires a Special Nozzle

To 3D print with PETG, you’ll need a special nozzle. While this isn’t a significant disadvantage to some, it’s worth noting because you’ll need to purchase the nozzle in addition to the PETG filament.

Some people find that when using the nozzle, the PETG can get stuck or get stringy, which can be frustrating and waste the filament.

Differences Between Nylon and PETG

Several key differences between nylon and PETG can help you determine which material you should be using.

The first main difference between the two materials is that PETG is chemical-resistant, whereas nylon isn’t. If you’re making something that you want to be more resistant to corrosion and chemical exposure, then you will want to go with PETG rather than nylon.

Impact resistance is another factor that sets nylon and PETG apart. Impact resistance means how much shock an item can absorb when someone drops it or it falls. Nylon is more impact resistant than PETG, so nylon is a better material for items that are more prone to falling.

PETG is known for being water resistant, which makes it an excellent choice for outdoor items. Nylon tends to absorb water which can contribute to warping and the item deteriorating quicker than something made with PETG.

Strength is another difference between the two materials. While the difference is minimal, nylon is technically a little stronger than PETG. So, if you’re choosing a material solely based on strength, you’ll want to opt for nylon over PETG.

How you’ll use both materials for printing is a significant difference. As discussed below, there are differences in temperatures, printing bed adhesion, and more.

The Proper Way to Print Nylon VS PETG

Knowing how to print nylon and PETG properly can be another deciding factor when it comes to choosing the right filament for your project. Below you’ll find information on correctly printing things with nylon and PETG.

There are some similarities in the printing process, but the differences are essential to know. You’ll be able to see the main differences printing-wise and then determine if one is better for you or not.

Printing Nylon

PRINTING NYLON

When printing nylon with your 3D printer, you’ll want to make sure that the extruder temperature stays between 428°F and 518°F (220°C and 270°C). As for the printing bed temperature, you can keep it between 170°F and 194°F (70°C and 90°C).

The absolute maximum operating temperature of nylon is 194°F (90°C). You’ll need to adhere your nylon to the printing bed before beginning. The best way to adhere the nylon is to use a glue stick or PEI (Polyetherimide) sheet.

When printing with nylon, you’ll want to adjust the temperature in five-degree increments to get the ideal temperature for your project. It will vary depending on the size and shape of your item but be sure to stay within the specified temperature range, or your 3D project won’t come out correctly.

Check out our related article on the best nylon 3D printers here.

Printing PETG

PRINTING PETG

If you’re using PETG to print your items, the extruder temperature needs to be lower than when you’re working with nylon. The extruder temperatures should stay between 445°F and 482°F (230°C and 250°C). The printing bed temperature for PETG is similar to nylon, and it only differs by five degrees.

The printing bed temperature should stay between 167°F and 194°F (75°C and 90°C). As for what you can use to adhere the PETG to the printing bed, a glue stick is a great option and is similar to when working with nylon. The main difference is you cannot use PEI sheets, but blue tape works wonders when using PETG.

You’ll need a special nozzle when printing with PETG that you don’t need when using nylon. When you’re ready to print with PETG, you’ll need to watch your project to ensure that the filament isn’t getting stuck in the nozzle or getting too stringy.

Proper Storage of Nylon VS PETG

The best storage for both nylon and PETG is to keep them in dry, cool places. While PETG can tolerate more moisture than nylon, to keep it in the best condition possible, looking for a dry and cool place is ideal.

When you store either material in a warm or damp place, the material can deteriorate and warp, making printing with the filament much more challenging or even impossible in some cases.

Which is Stronger: Nylon or PETG?

Nylon and PETG are both considered to be strong filament materials. The difference strength-wise is minimal, but technically, nylon is slightly stronger than PETG.

Even though nylon and PETG’s strength is very similar, the durability difference is substantial, with nylon ranking higher in strength and durability than PETG.

Nylon VS PETG: Which Filament is Friendlier to Use for Beginners?

If you’re new to 3D printing, PETG filaments will be the most beginner-friendly material out of nylon and PETG. Not only is PETG more affordable than nylon, but it’s easy to print and doesn’t warp as easily as nylon filaments. It can also tolerate a little more moisture than nylon if it comes in contact with water.

Related Articles: