- Last Updated: January 12, 2024

-

Jackson O'Connell

Jackson O'Connell

If you have a 3D printer, you’ve probably heard of a few different filament materials, like PLA, PETG, and ABS. But what if I told you there was a material that’s much stronger than PLA, less challenging to print than ABS, and easier to layer smooth than PETG?

If you have a 3D printer, you’ve probably heard of a few different filament materials, like PLA, PETG, and ABS. But what if I told you there was a material that’s much stronger than PLA, less challenging to print than ABS, and easier to layer smooth than PETG?

Well, that, my friend, is ASA.

ASA, short-hand for acrylonitrile styrene acrylate, isn’t as popular as PLA, PETG, or ABS, but it’s got some superior properties that make the plastic worth using. While I won’t bore you with the details about the plastic’s origin and all (that comes later), it’s worth noting that ASA was developed as an alternative to ABS, so many of its properties are somewhat similar.

And, just like ABS, you can 3D print with ASA.

I’ve printed with many different filaments, and perhaps the best ASA filament I’ve found is Prusament ASA. Developed by Prusa themselves, this material prints like a charm, and parts printed in the filament respond very well to post-processing.

But if you’re looking for value, I’d recommend going with Sunlu’s ASA filament. It’s not the most popular out there, but it’s a great bang for your buck, and it prints decently well.

Want to learn more about ASA and the best ASA filaments? Just keep reading!

Best 3D Scanners At A Glance

- Prusament ASA (Best Choice)

- Sunlu ASAFilament (Best Value)

- 3DXTech 3DXMax ASA (Premium Choice)

- Fillamentum ASA Extrafill (Most Durable)

- Polymaker PolyLite ASA (Easiest to Print)

- Overture ASA Filament

- FormFutura ApolloX ASA

Prusament is a very high-quality filament line developed by Prusa Research, the company behind the Prusa i3 MK3S+ and Prusa Mini+. Prusament sells a handful of different filament materials, including PETG, PLA, and, of course, ASA. Prusament ASA is easily my favorite ASA filament overall; let me tell you why!

First off, Prusament ASA comes in seven different colors, including Saphhire Blue, Galaxy Black, Lipstick Red, and, most popularly, Prusa Orange. Having this many color options is pretty uncommon for an ASA filament, so I have to give credit to Prusament!

Besides the colors, though, Prusament ASA also responds super well to layer smoothing treatment. After a quick acetone vapor bath, the layer lines on my Prusament ASA prints had basically disappeared. The smooth surface also made it easy to paint over the original filament color as well as bond different ASA parts together.

Printing Prusament ASA may seem a little daunting at first, considering the higher-than-normal temperature recommendations. But, once you’ve got the settings tuned properly, achieving high-quality prints is super easy.

Next, Sunlu is a Chinese 3D printer manufacturer that sells a handful of 3D printers, accessories, and filaments. Sunlu’s ASA filament isn’t the best out there, but its low price makes it a great bang for your buck!

For under $30, you can get a 1 kg spool of Sunlu ASA filament, which is a total steal for this material! And, it’s not a garbage product either, with many terrific properties that make it well worth the low price.

For one, Sunlu reports that their ASA filament has a diameter tolerance of just +/- 0.02 mm. This is well below the industry average of +/- 0.05 mm and indicates that this filament will cause very few issues regarding your printer’s extrusion process.

Additionally, the suggested temperature ranges for printing Sunlu ASA filament are under the typical ranges for an ASA filament. As such, you can print Sunlu ASA on a wider range of printers!

Unfortunately, lower temperature requirements also suggest less strength and durability for the filament. But Sunlu ASA is still ASA, so while parts made in this filament might be weaker than those made in another ASA filament, they’ll still be significantly stronger than any model printed in PLA.

So, if you want to save a few bucks on filament this month and are looking to try out ASA, definitely give Sunlu ASA filament a shot!

Next, 3DXTech is a company that specializes in making top-notch 3D printing materials, especially those with a lot of strength. The company’s 3DXMax ASA filament is no different, offering an enormous amount of strength and durability compared to other ASA filaments.

While 3DXMax is a good bit more expensive than other ASA filaments, it’s got the numbers to back it up. Its tensile strength is reported to be 45 MPa, so prints should be pretty strong.

But what’s more impressive is its flexural strength of 78 MPa. For reference, PLA and PETG have flexural strengths of about 50 and 40 MPa, respectively. As such, parts printed in the 3DXMax ASA filament can be flexed and bent a lot before breaking; this makes the filament perfect for printing impact-resistant parts, like a drone camera mount.

But if you’re looking for an ASA filament that can bring the power, then 3DXTech 3DXMax ASA filament is for you!

Fillamentum is a high-quality European manufacturer of filament, and their Extrafill line of filament includes an amazing ASA material.

Filmmanetum Extrafill ASA comes in a wide assortment of colors, as you can see below. Examples include Traffic Black, White Aluminum, Natural, Sky Blue, Traffic Yellow, and more!

But besides the color options, Extrafill ASA has a lot going for it, especially its mechanical properties. Moreover, the filament has a reported tensile strength of 42 MPa, which is very good, and 8 MPa than Fillamentum’s ABS filaments. And Extrafill ASA has a 35% elongation at break, meaning it’s flexible enough to withstand a lot of impact collisions and bending.

But besides the color options, Extrafill ASA has a lot going for it, especially its mechanical properties. Moreover, the filament has a reported tensile strength of 42 MPa, which is very good, and 8 MPa than Fillamentum’s ABS filaments. And Extrafill ASA has a 35% elongation at break, meaning it’s flexible enough to withstand a lot of impact collisions and bending.

So, if you want to print durable parts, I strongly suggest Fillamentum ASA Extrafill filaments! It’s also not very expensive, so your wallet will like it too!

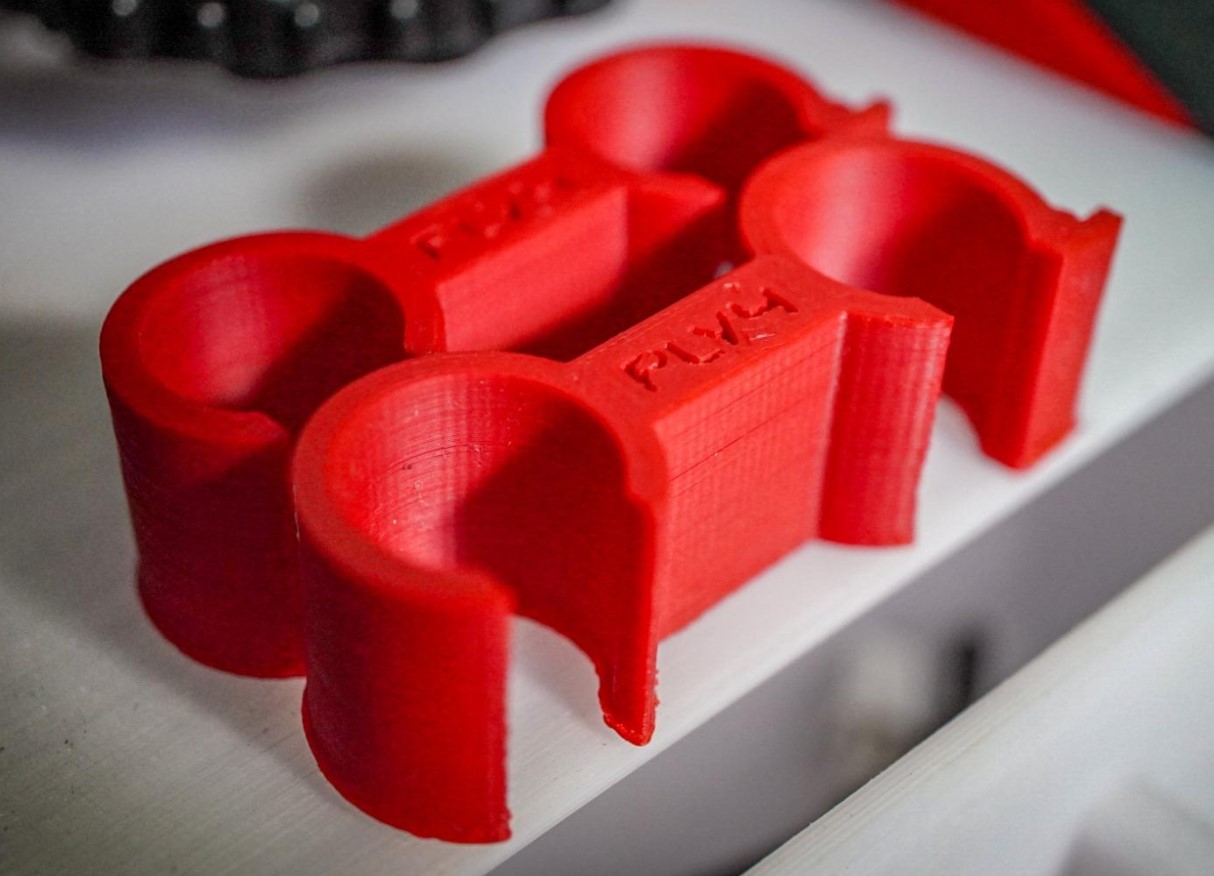

Polymaker is one of the most popular filament brands out there, and they make tens and tens of different filaments. PolyLite ASA is one of my favorite products from Polymaker as I’ve found that it’s super easy to print, even for being an ASA filament.

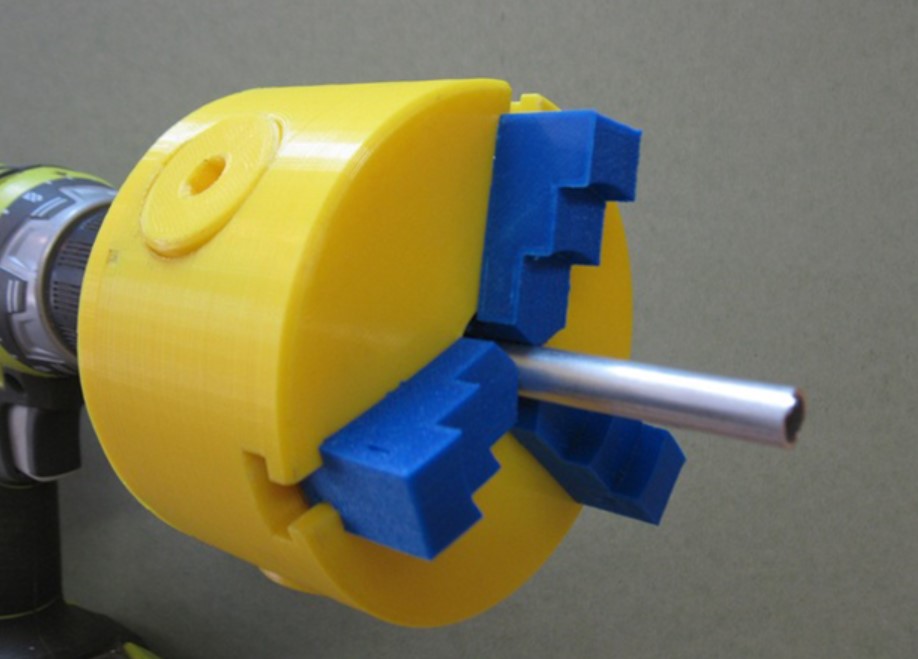

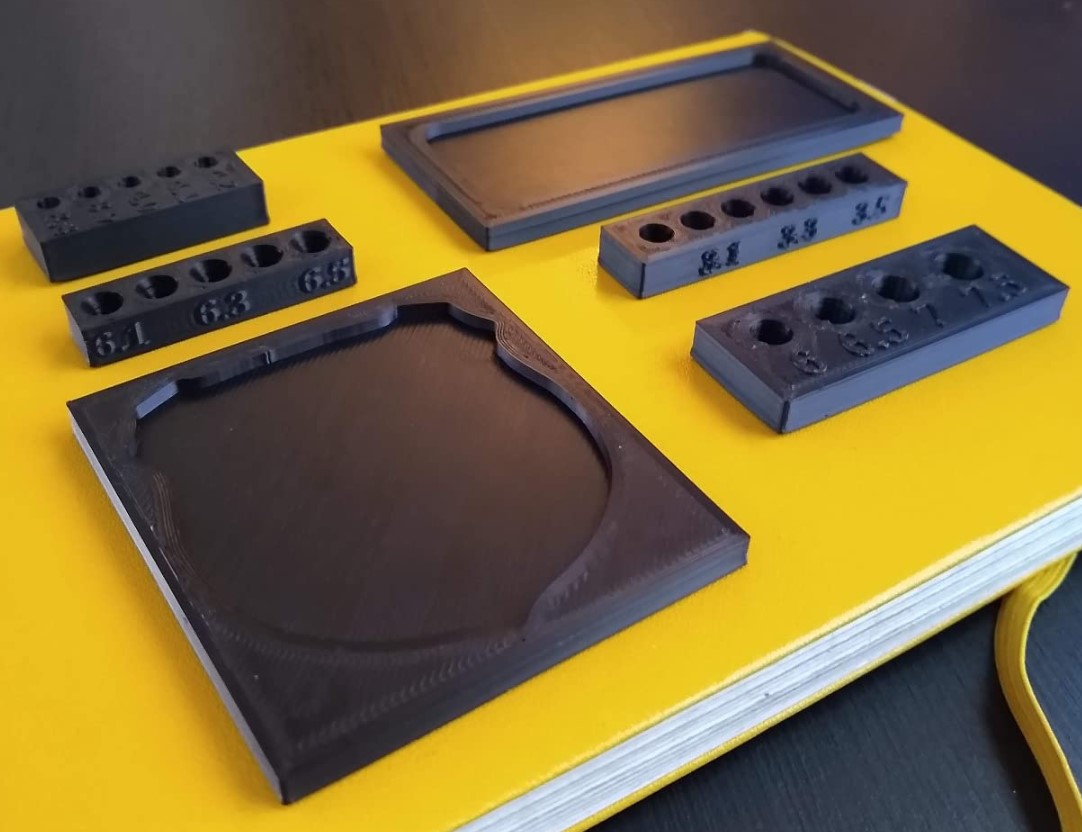

Just check out these high-quality prints made with PolyLite ASA!

According to the manufacturer, you should print PolyLite ASA with a nozzle and bed temperature of 250 °C and 85 °C, respectively. This is slightly lower than the norm for ASA plastic, making the filament more widely compatible with different 3D printers.

And I’ve found that you don’t need to spend too much time tuning your slicer profile to achieve decent prints with PolyLite ASA filament. Moreover, many positive user reviews state that you can print PolyLite ASA right out of the box and gets prints with an exceptional level of print quality.

So, if you hate dealing with slicer settings, I advise you to try out ASA filament with Polymaker’s PolyLite ASA filament. I promise you won’t regret it!

Overture is another super popular manufacturer of consumer-grade filaments, and their ASA filament is very worthy of being included on this list.

You can get Overture ASA in six different colors, including red, blue, gray, white, black, and orange! Plus, all Overture ASA filaments come on eco-friendly cardboard spools!

According to the manufacturer, Overture ASA filament has a diameter tolerance of just +/- 0.03 mm. Though it’s not as low as Sunlu’s ASA filament (+/- 0.02 mm), it’s still much lower than the typical +/- 0.05 mm, so you shouldn’t have to worry about your extruder clogging while printing this filament.

And, on this note, Overture ASA filament should print like a normal ASA filament, with no special requirements or above-average temperatures. In fact, you can actually use a slightly-lower bed temperature, which means the bed adhesion for this filament is naturally pretty good!

Unfortunately, low bed temperature recommendations indicate that Overture ASA filament might not have high-temperature resistance. But, let’s be honest, your prints probably won’t be facing an 80+ °C environment, so it’s not that big of a deal.

Lastly, FormFutura ApolloX filament is one of my favorite filaments for printing parts that need to be durable. I’ve actually printed a handful of models for my bike in this filament, and all of them are still standing strong.

ApolloX is a special ASA material blend developed by FormFutura, and the filament is meant to be used for printing long-lasting outdoor parts. Whether it’s a bike part, a part of a car bumper, or a mount for your Christmas lights, you can trust that FormFutura’s ApolloX ASA filament will yield parts that can handle even the harshest environments.

The filament is known for being super UV and temperature resistant, so it will take a lot of sunlight and heat to ever deform a part printed in ApolloX filament. And you also don’t need to worry about part strength as ApolloX has that in the bag, with a tensile strength of 47.5 MPa.

What is ASA Filament?

Acrylonitrile styrene acrylate, or ASA, is a thermoplastic material developed as an alternative to ABS. Discovered way back in the 60s, ASA offers a host of terrific mechanical properties, including high impact resistance, toughness, UV resistance, and more.

ASA plastic, while not as widely used as ABS, is still very popular. Parts made in this material can be found in home appliances, car interiors, outdoor furniture sets, and more.

Of course, perhaps the largest application of ASA plastic is for 3D printing. Today, there are many different ASA filaments on the market today. And, though PLA, ABS, and PETG are still vastly more popular filament materials, the market for ASA filament is growing quickly.

When to Use ASA?

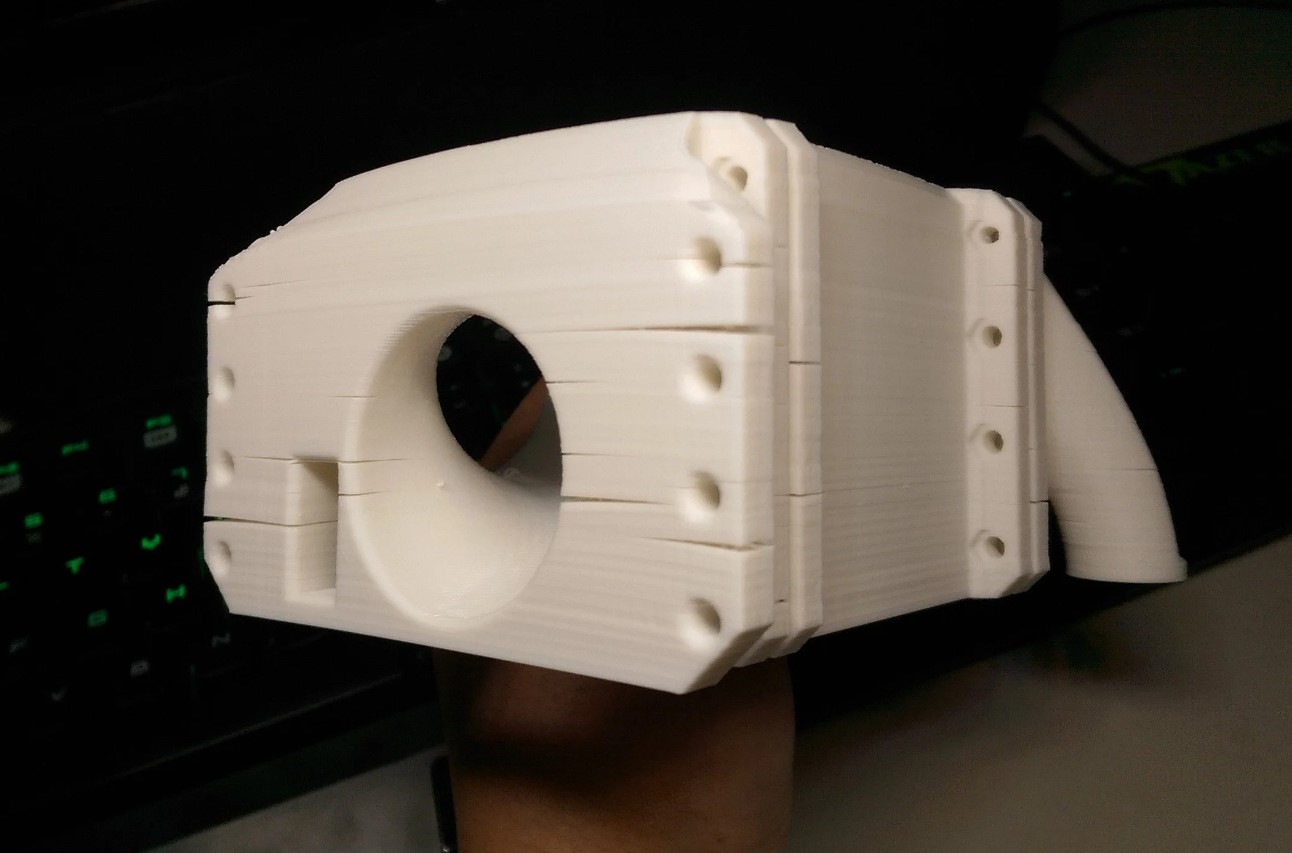

ASA filament is best suited for printing parts that require strength and durability, as that’s what the plastic’s properties are centered around. Examples of parts where ASA is useful might include 3D-printed outdoor light mounts, fence gate locks, tent stakes, and even parts for your own 3D printer.

But strength isn’t ASA’s only advantage. Because ASA is soluble in acetone, it’s a good material to use for any 3D printed models that you want to layer smooth, such as display pieces. So, if you want to print a Batman bust or a sexy phone case, you might want to try printing them in ASA and layer smoothing the part to make it look nicer.

Of course, you can also just use ASA to print general models, too, like a phone stand or something that doesn’t need to look nice or have a lot of strength. While other materials, like PLA, might be better for these types of models because they’re easier to print, if you like working with ASA, then there’s no reason to stop!

ASA VS ABS

As I’ve mentioned, ASA was derived from ABS, and many of the plastic’s properties are very similar. But, there are still many noticeable differences between ASA and ABS.

First off, ABS, in a 3D printing context, is the more difficult material to print. Moreover, ABS has a higher melting point than ASA, so you’ll need to use a higher nozzle and bed temperature to print ABS filament. This means fewer machines are compatible with ABS filament.

On top of that, ABS is a more sensitive material than ASA, and small changes in the slicer settings will have a more significant impact on the print quality of a part made with ABS filament than one made with ASA filament.

While this doesn’t seem like a big issue, it’s really annoying and makes print quality issues, such as cracking and layer separation (seen below), more common when printing ABS filament.

Besides ease-of-printing, though, ASA also offers slightly better mechanical properties than ABS. Although the strength and durability of the two materials are approximately the same, ASA exhibits much better UV resistance than ABS. As such, parts made in ASA filament will fair much better under the sun (or another UV source) than those made with ABS.

ASA VS PLA

PLA is often considered the king of 3D printing filaments as it’s the most popular printing material. But, when you compare it to ASA, PLA doesn’t seem like much of a king.

Most notably, ASA is significantly stronger than PLA, with a tensile strength of about 50 MPa, compared to PLA’s rather-wimpy 30-ish MPa. This difference means that parts made in ASA filament will be noticeably stronger and more durable than PLA. Additionally, because ASA is slightly flexible, parts printed in this material will be a lot more impact-resistant than those made in PLA.

And, just like with ABS, ASA is a lot more UV-resistant than PLA. A 3D print made of PLA is literally so weak to UV light that it will significantly deform after just a few hours under the sun.

It’s also worth mentioning that ASA is easier to layer smooth than PLA. While you need to use super special equipment and chemicals to smooth the layers of a PLA model, you can layer smooth an ABS part with just some nail polish remover (acetone). Couldn’t be simpler!

Sadly, though, what ASA doesn’t beat PLA in is ease of printing.

PLA has a lower melting point than ASA, meaning PLA filaments require lower nozzle and bed temperatures. Plus, you don’t need an enclosure to achieve high-quality parts, like you do with ASA. And PLA is also not as sensitive to slicer settings, so getting a good print quality is much easier with this material.

But nonetheless, ASA is still a great filament material, especially if you’re printing a part that requires strength or durability.

How to Print ASA Filament

Printing ASA filament is a little bit more difficult than printing PLA or PETG. But don’t worry, because, in this section, you’ll learn everything you need to know to achieve high-quality prints right from the get-go.

The first thing you should note is that ASA filament prints with a nozzle temperature between 24-265 °C and a bed temperature in the 100-110 °C range. While this is much higher than the temperatures for printing PLA, don’t worry; just try not to touch either the hot end or bed!

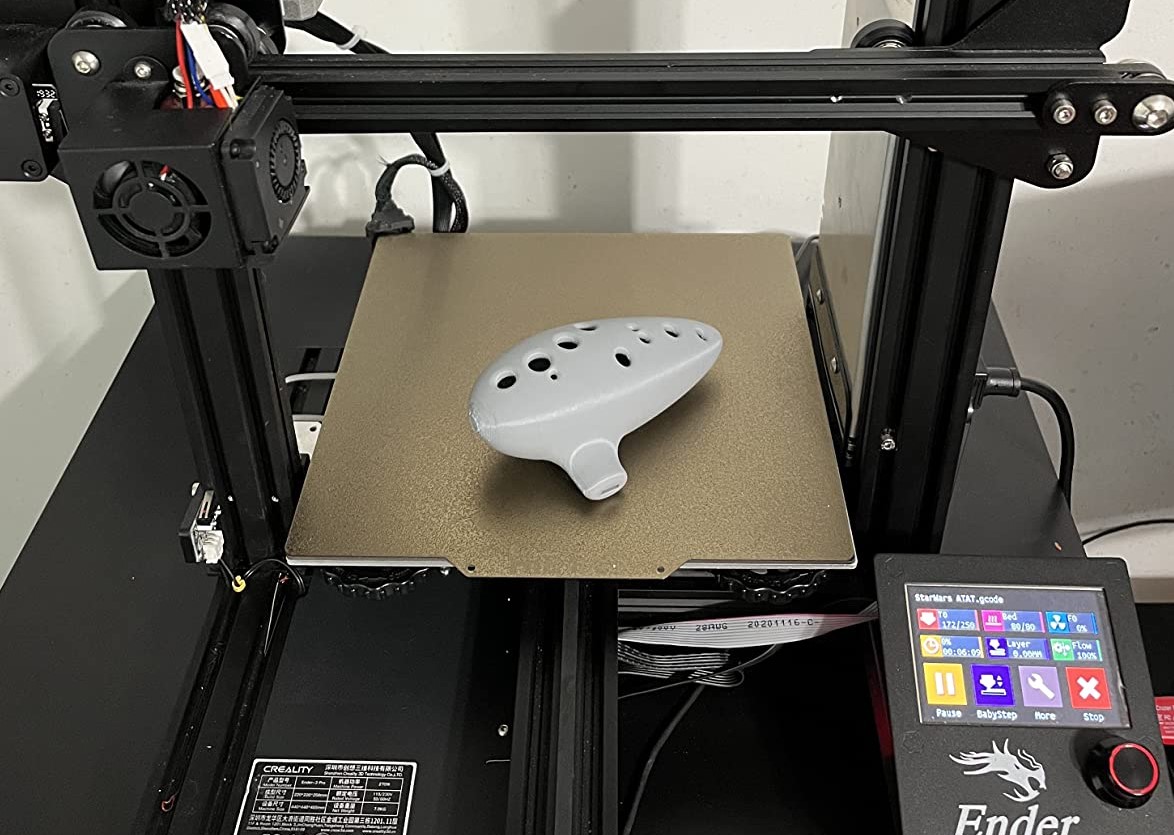

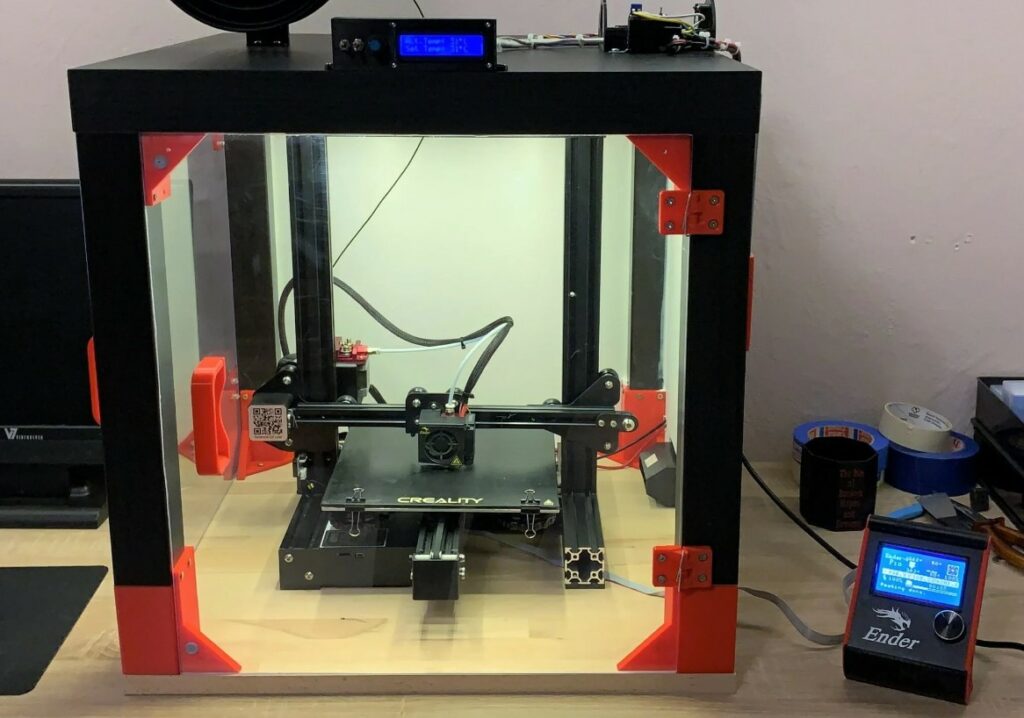

Luckily, you don’t need a direct drive extruder to print ASA, like you do with flexible materials (e.g. TPU), so either a Bowden or direct drive configuration will work. However, what you will need is an enclosure.

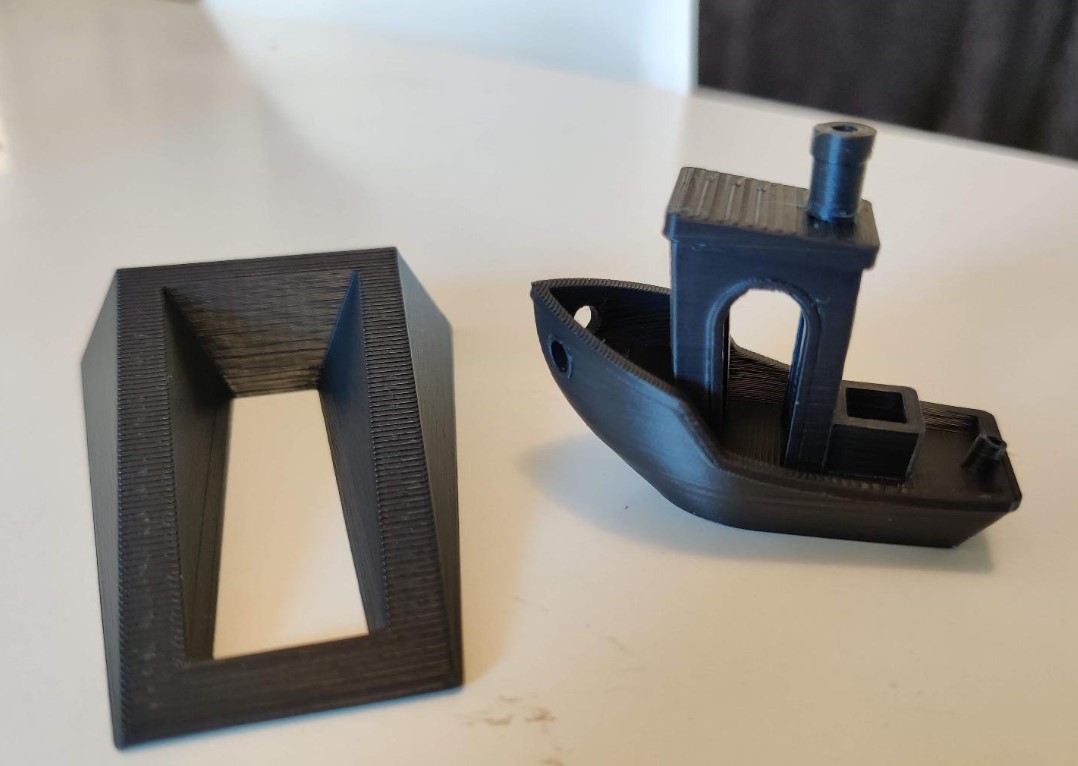

An enclosure, like the one seen below, traps the heat the 3D printer produces around the print space. This provides the optimal environment for ASA plastic to bond because ASA loves heat! Printing without an enclosure might still work, but you’re much more at risk of experiencing problems like warping and layer separation in your prints.

Finally, while ASA is less sensitive when it comes to slicer settings than ABS, it’s still pretty sensitive. As such, start with the default ASA print settings in your 3D slicer (e.g. Cura, PrusaSlicer) and tune the settings as you print different models.

I suggest starting with a calibration print, like a 20 x 20 x 20 mm CHEP cube or a 3DBenchy, evaluating the model, and making changes to the default settings to optimize the slicer profile for your printer.

Advantages and Disadvantages of ASA Filament

Below you’ll find a list of advantages and disadvantages of ASA filament.

Advantages

- High UV resistance

- Terrific strength and toughness

- Great impact-resistance

- Easier to print than ABS

- Can be easily layer smoothed

- Parts can be bonded together (with solutes)

- Once your slicer settings are tuned, printing is easy

Disadvantages

- Slightly hygroscopic

- Fewer filament options compared to other materials

- Requires an enclosure

- Still more sensitive to slicer settings than PLA

Conclusion

At the end of the day, ASA is one of the best and most efficient 3D printing filament materials out there. It’s easier to print than ABS, offers more convenient layer smoothing than PETG, and is so much stronger than PLA! What’s not to love about ASA!!!

While options for this type of filament are somewhat limited, you still have many to choose from.

Prusament ASA is probably the best ASA filament, as it’s made by one of the best filament manufacturers out there, and the material is super high-quality. Prusament ASA prints super well, especially with Prusa’s provided slicer settings, and parts are strong and respond well to layer smoothing. Plus, the filament’s very reasonably priced.

On this note about price, if you’re looking to save a few bucks, I suggest checking out Sunlu’s ASA filament. It’s a total bargain, and the filament is still very high-quality, with prints coming out decently strong.

And finally, if you want the highest-end ASA 3D prints, I suggest getting 3DXTech’s 3DXMax ASA filament. This filament offers the highest strength metrics of any ASA filament I’ve seen, and it’s also decently easy to print.

Enjoy!